Oven

An oven and liner technology, applied in the field of ovens, can solve the problems of oven sealing, heat energy dissipation, and long time required, and achieve the effects of avoiding heat energy dissipation, safe and reliable use, and ensuring longevity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

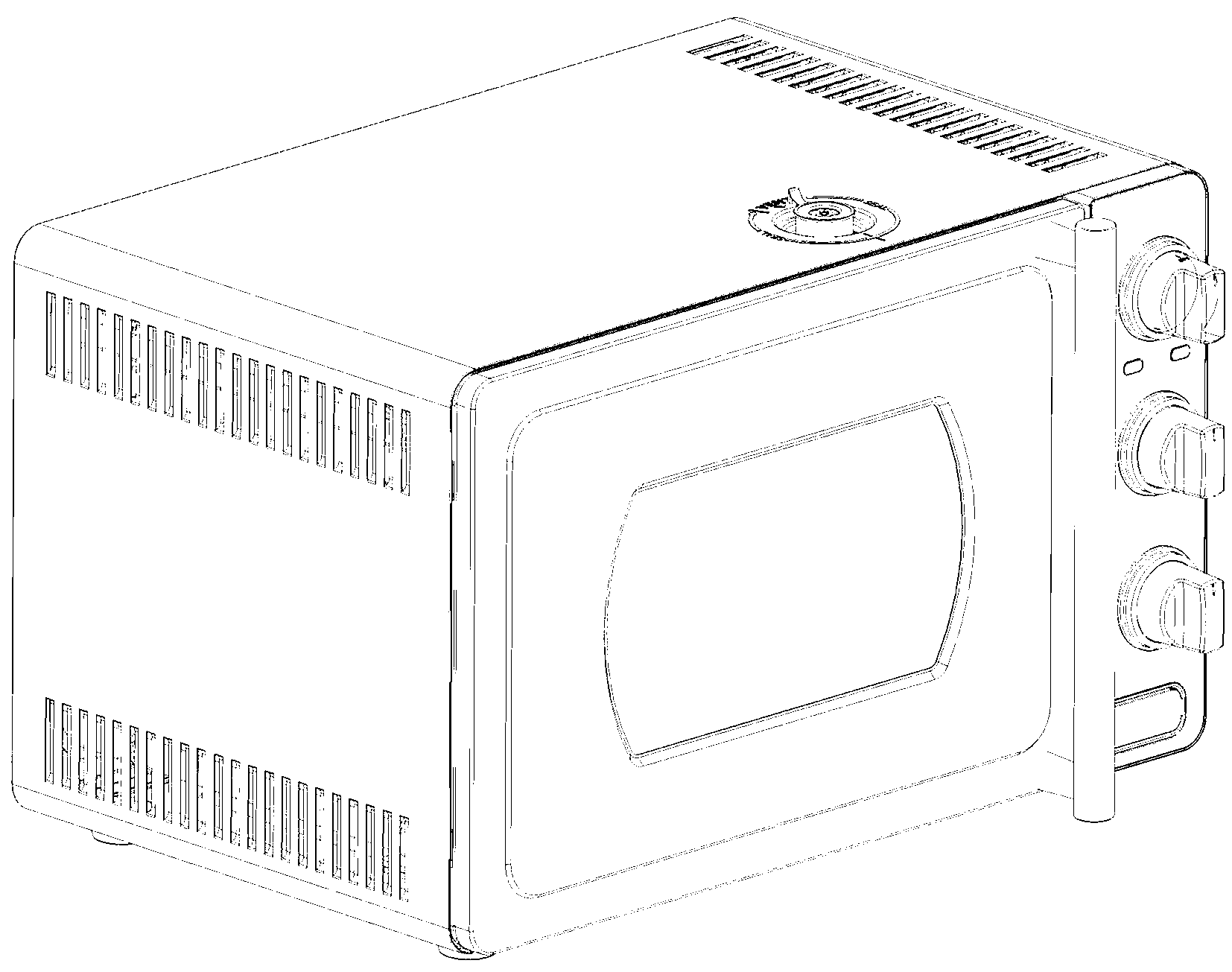

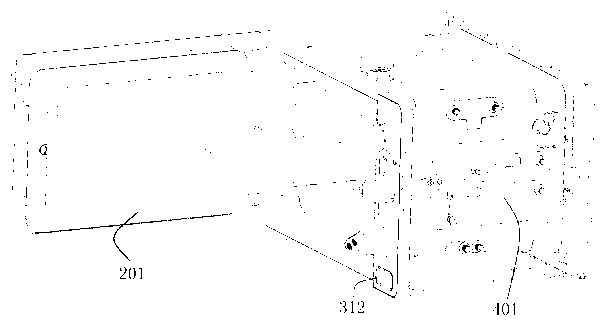

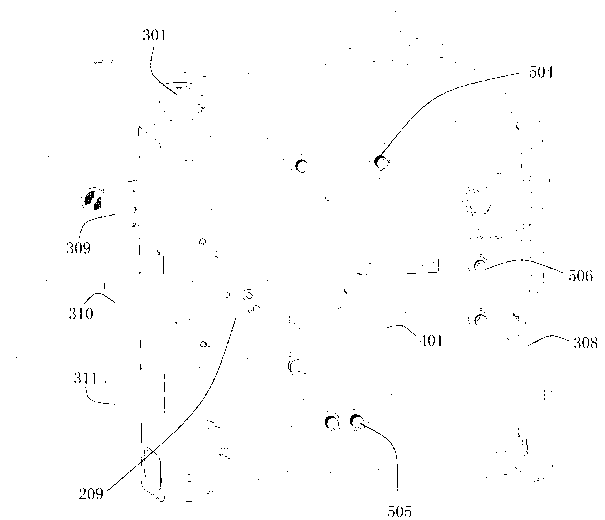

[0035] Such as Figure 1 to Figure 3 As shown, an oven of the present invention includes an inner container assembly, a door assembly, a heating assembly and a control assembly, and the door assembly, the heating assembly and the control assembly are all arranged on the inner container assembly. The inner container assembly is used to place the food that needs to be baked, the door assembly is used to open and close the door, the heating assembly bakes the food in the inner container assembly by heating, and the control assembly controls the working process of the entire oven. In order to make the appearance of the oven more beautiful and the structure more integral, the present invention also has a shell on the periphery of the liner assembly.

[0036] Such as Figure 4 , Figure 5 As shown, the inner container assembly includes an inner container 101 , a front panel 102 and a rear panel 103 . The liner 101 is made of a flat plate (such as an iron plate) by stamping and we...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that in this embodiment, the oven does not have the rotary assembly in Embodiment 1, but only includes an inner container assembly, a door assembly, a heating assembly and a control assembly, and the structure is relatively simpler.

[0050] Other structures are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com