Patents

Literature

91 results about "Methane clathrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

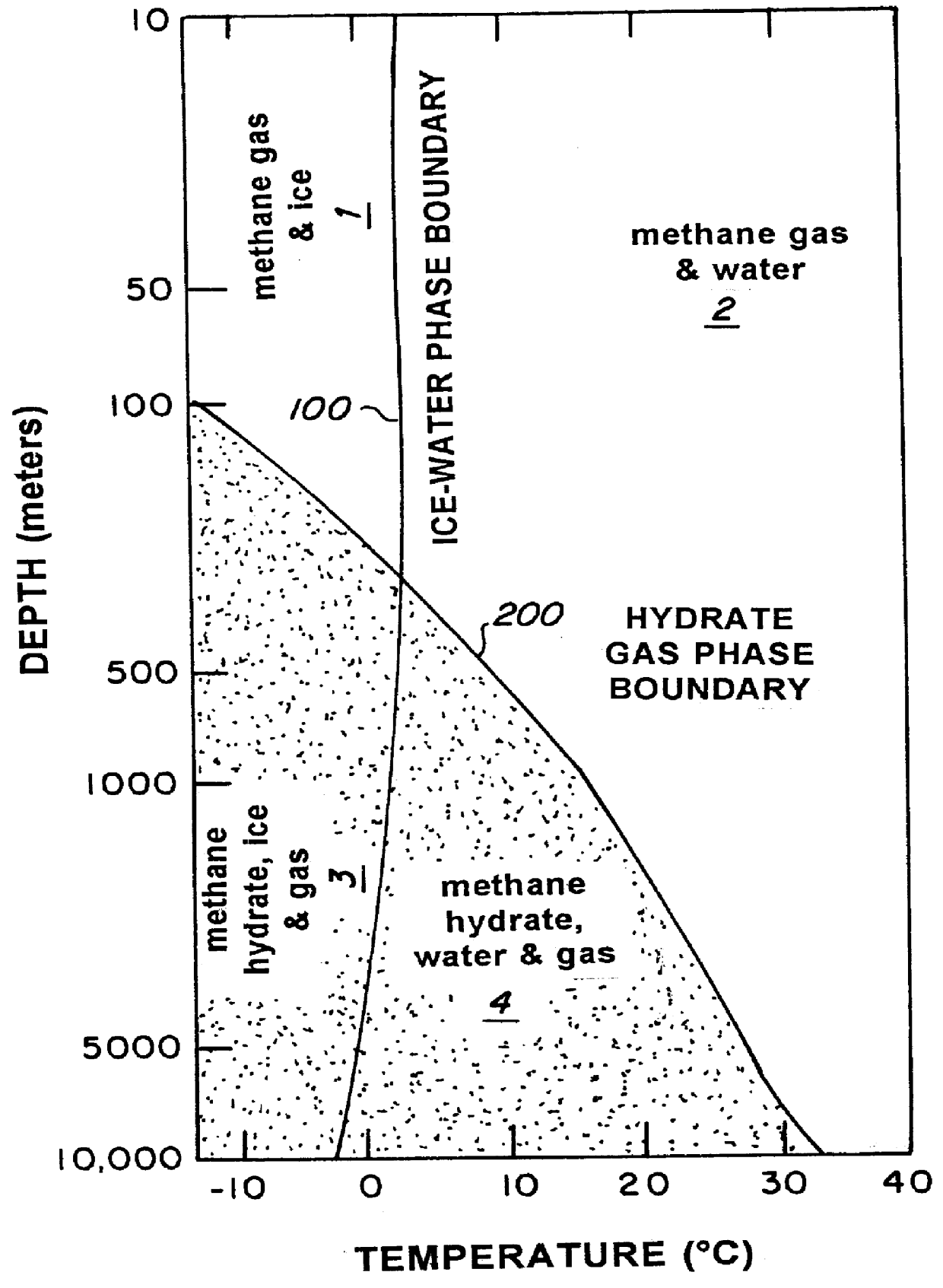

Methane clathrate (CH₄·5.75H₂O) or (4CH₄·23H₂O), also called methane hydrate, hydromethane, methane ice, fire ice, natural gas hydrate, or gas hydrate, is a solid clathrate compound (more specifically, a clathrate hydrate) in which a large amount of methane is trapped within a crystal structure of water, forming a solid similar to ice. Originally thought to occur only in the outer regions of the Solar System, where temperatures are low and water ice is common, significant deposits of methane clathrate have been found under sediments on the ocean floors of the Earth.

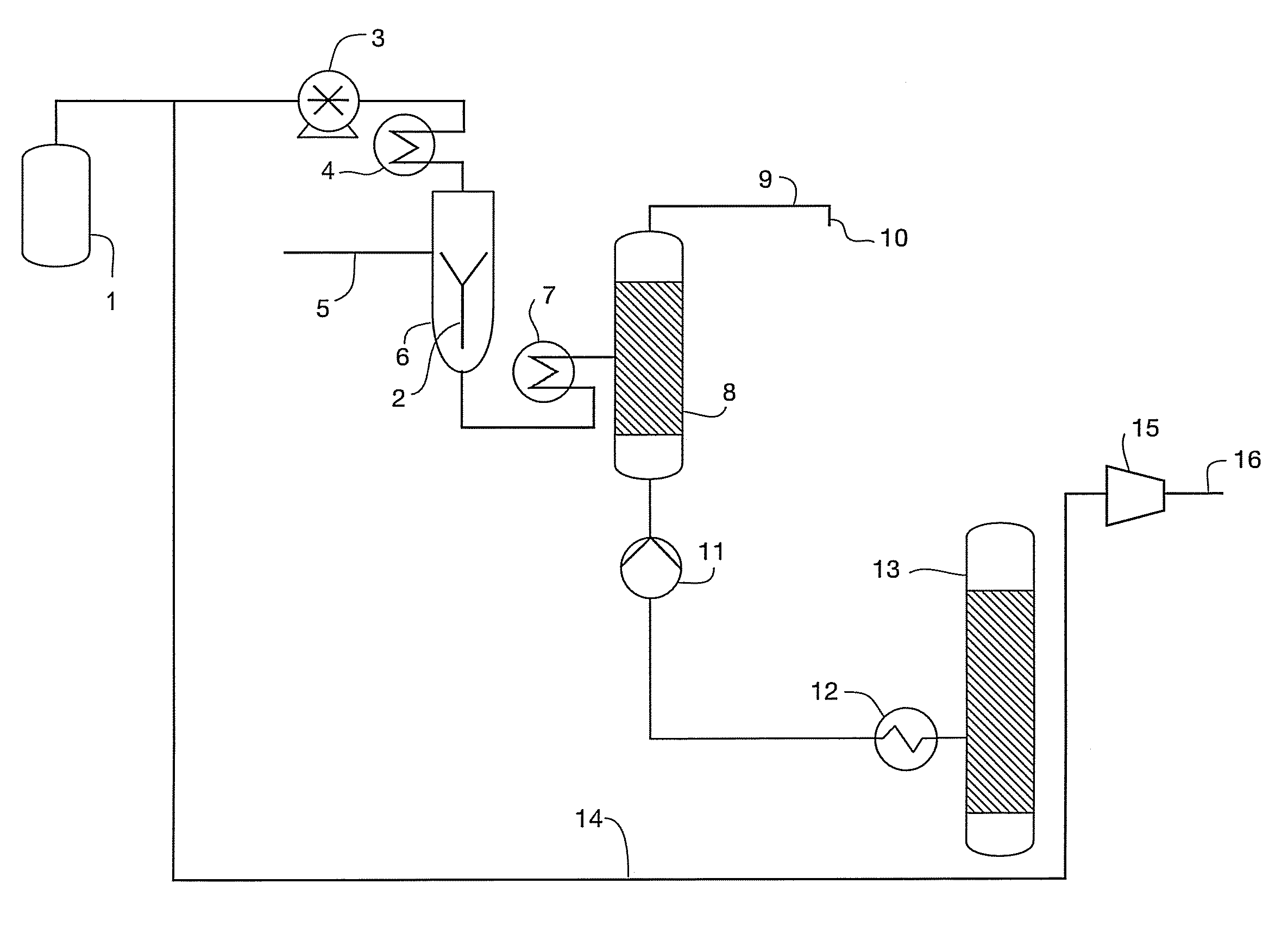

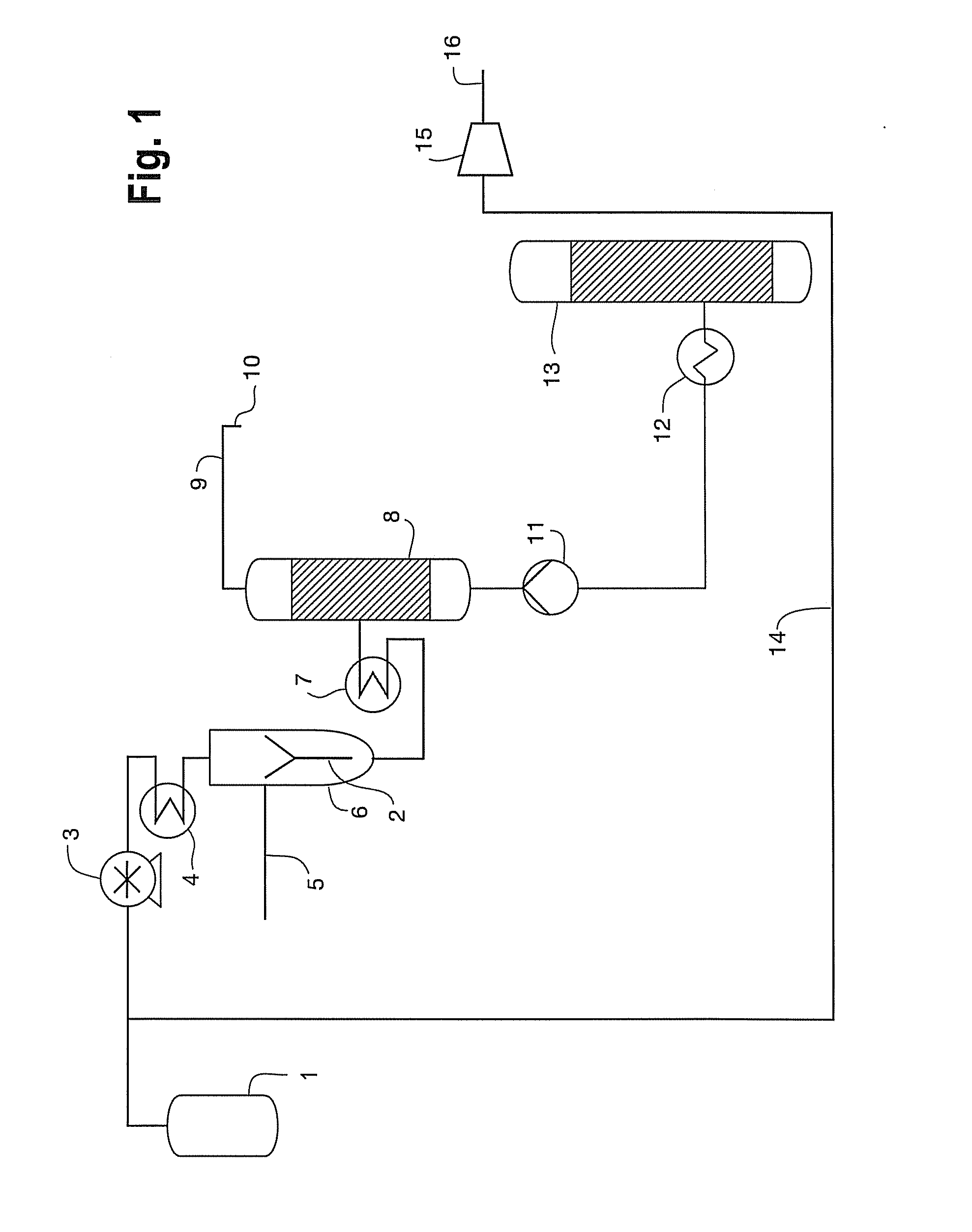

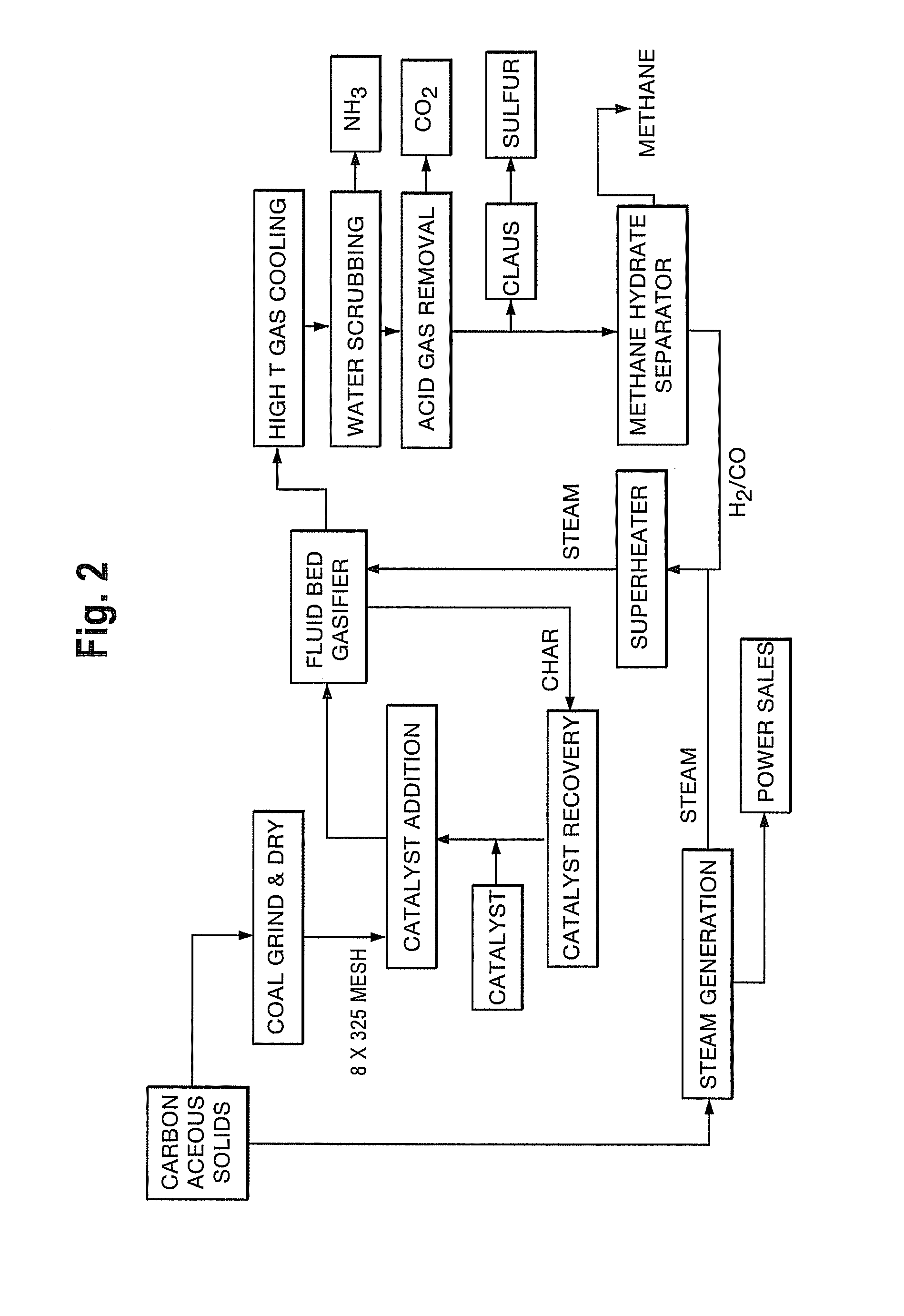

Process and Apparatus for the Separation of Methane from a Gas Stream

InactiveUS20090260287A1Combustible gas chemical modificationHydrogen separation using liquid contactHydrogenWater vapor

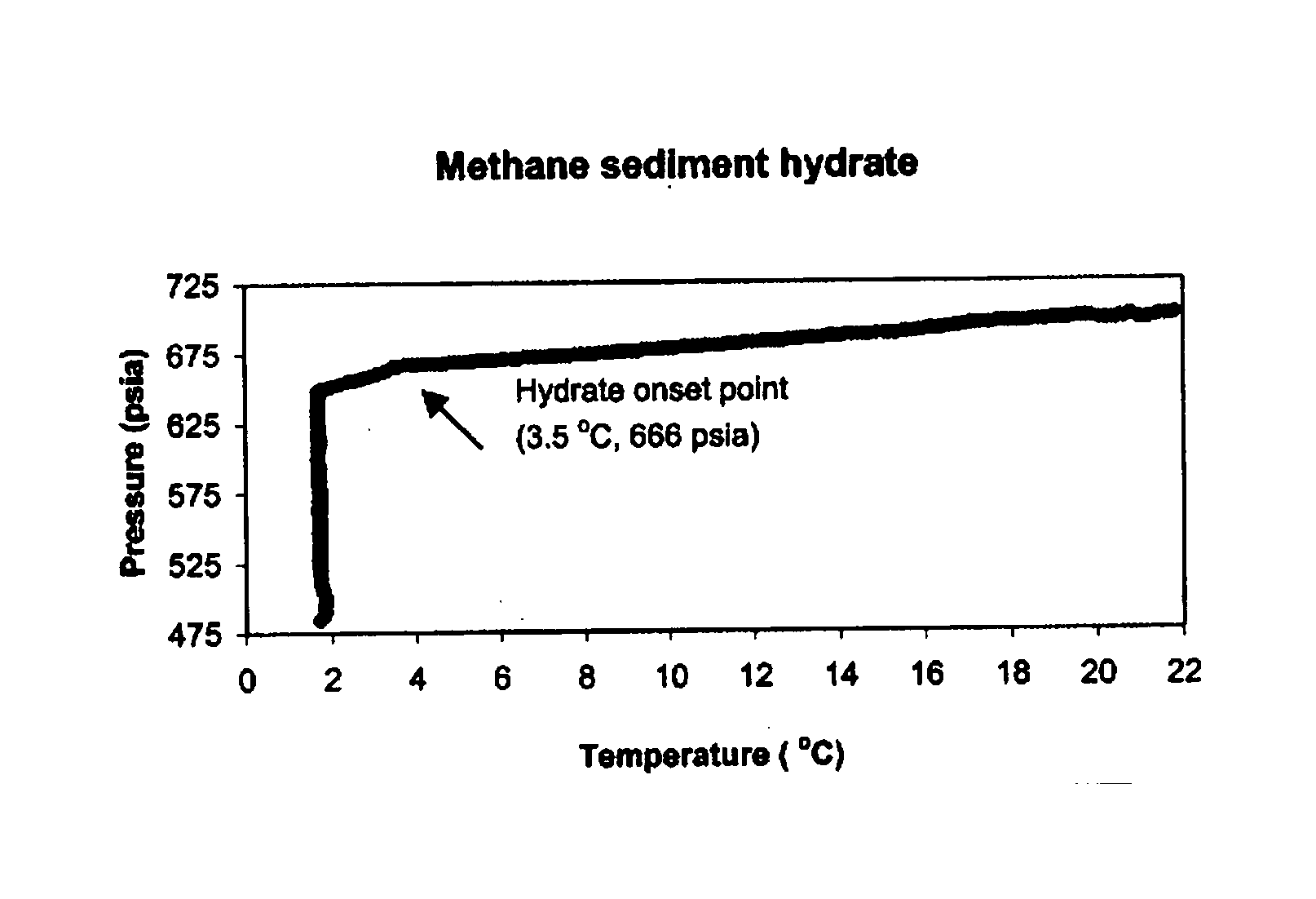

Processes for conversion of a carbonaceous composition into a gas stream comprising methane are provided, where an energy-efficient process and / or apparatus is used to separate methane out of a gas stream comprising methane, carbon monoxide, and hydrogen. Particularly, methane can be separated from hydrogen and carbon monoxide using novel processes and / or apparatuses that generate methane hydrates. Because hydrogen and carbon monoxide do not readily form hydrates, the methane is separated from a gas stream. The methane can be captured as a substantially pure stream of methane gas by dissociating the methane from the hydrate and separating out any residual water vapor.

Owner:SURE CHAMPION INVESTMENT LTD

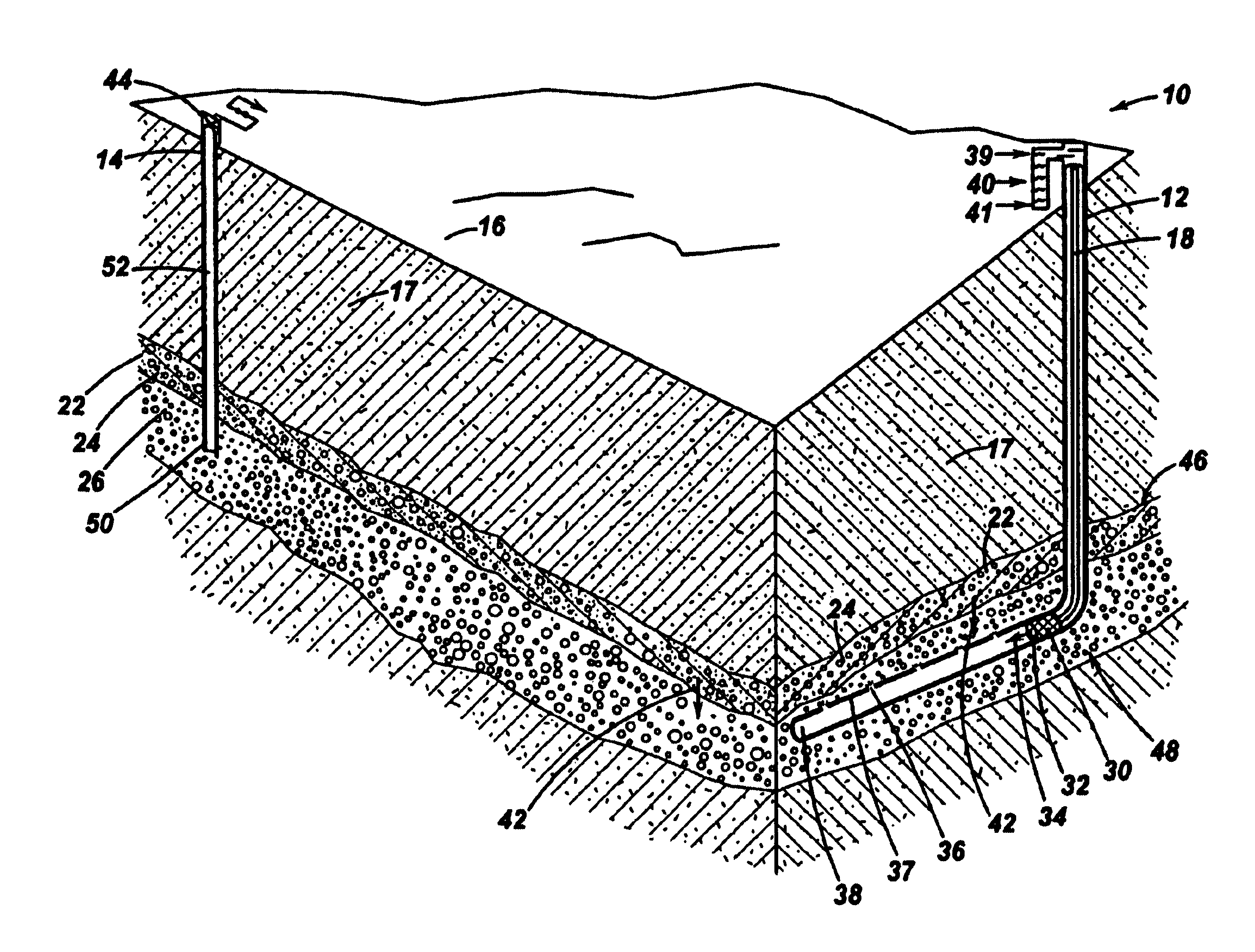

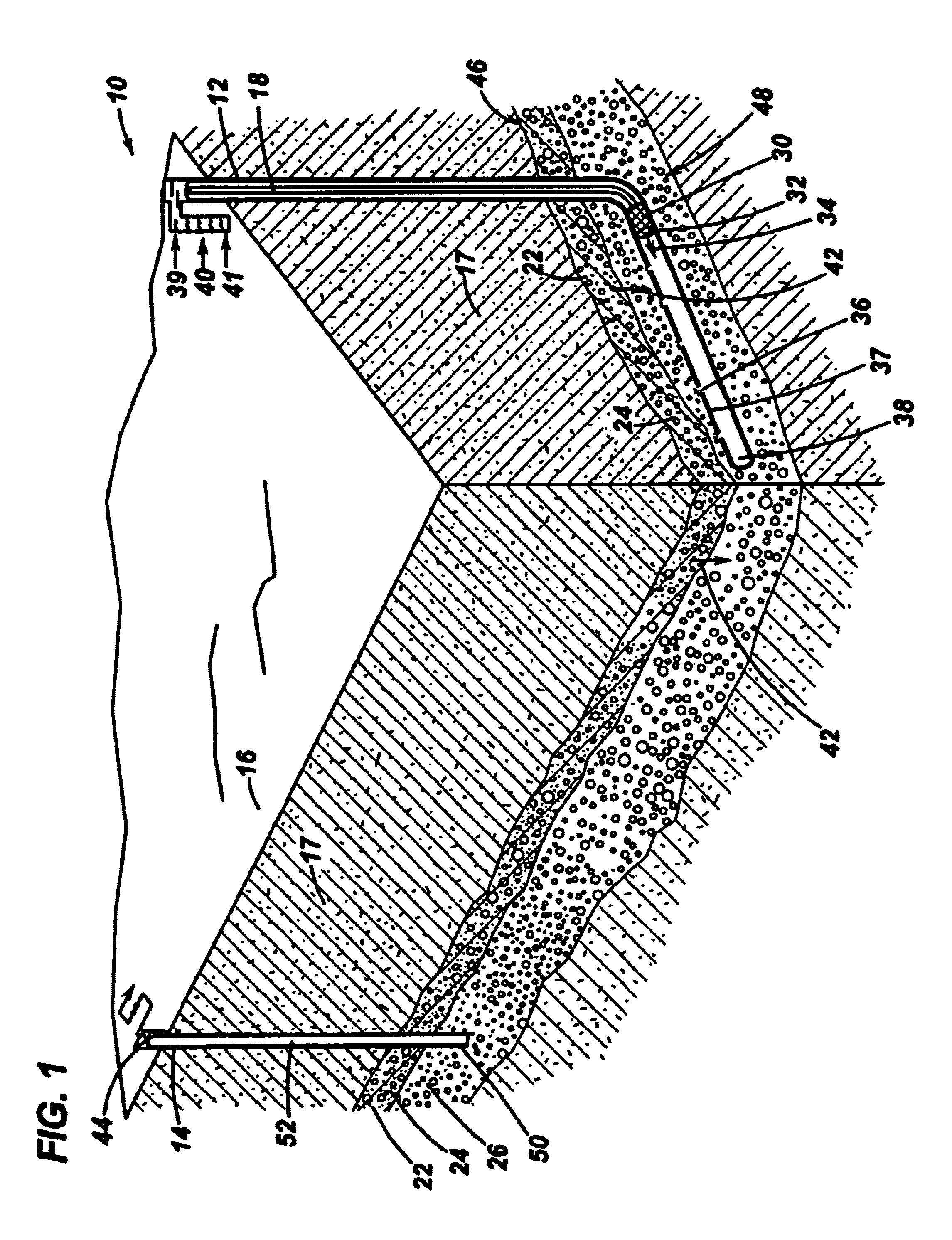

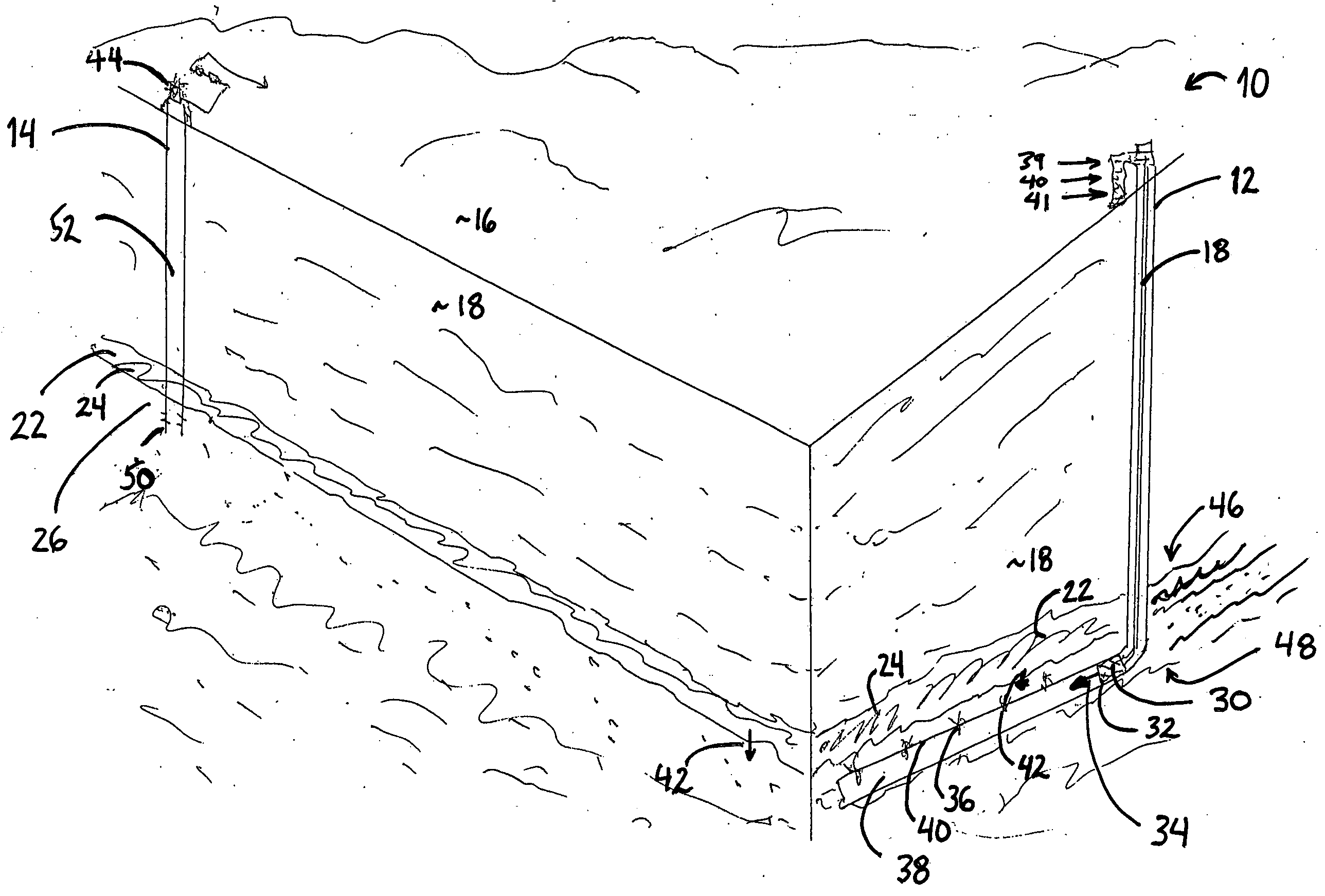

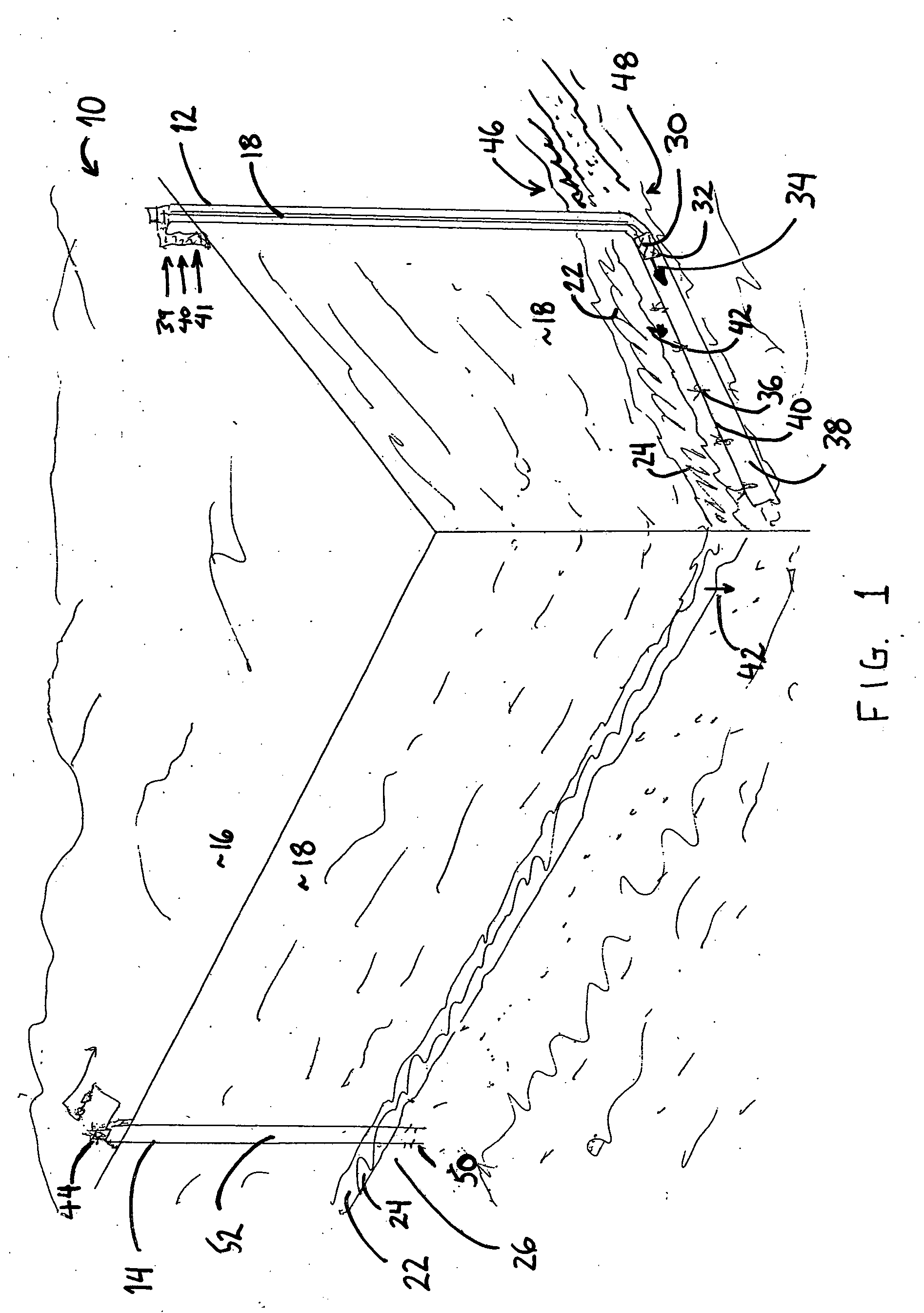

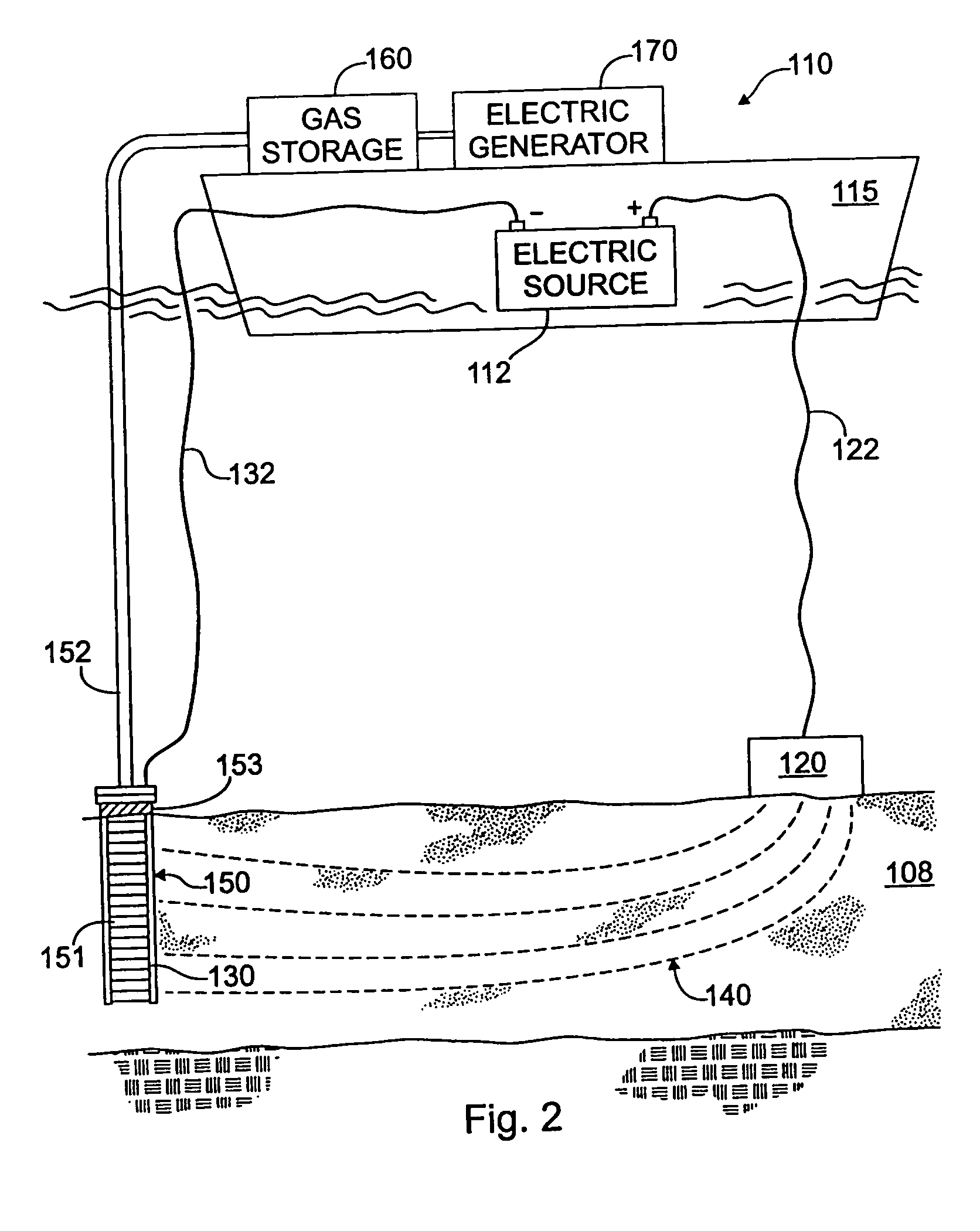

In-situ method of producing oil shale and gas (methane) hydrates, on-shore and off-shore

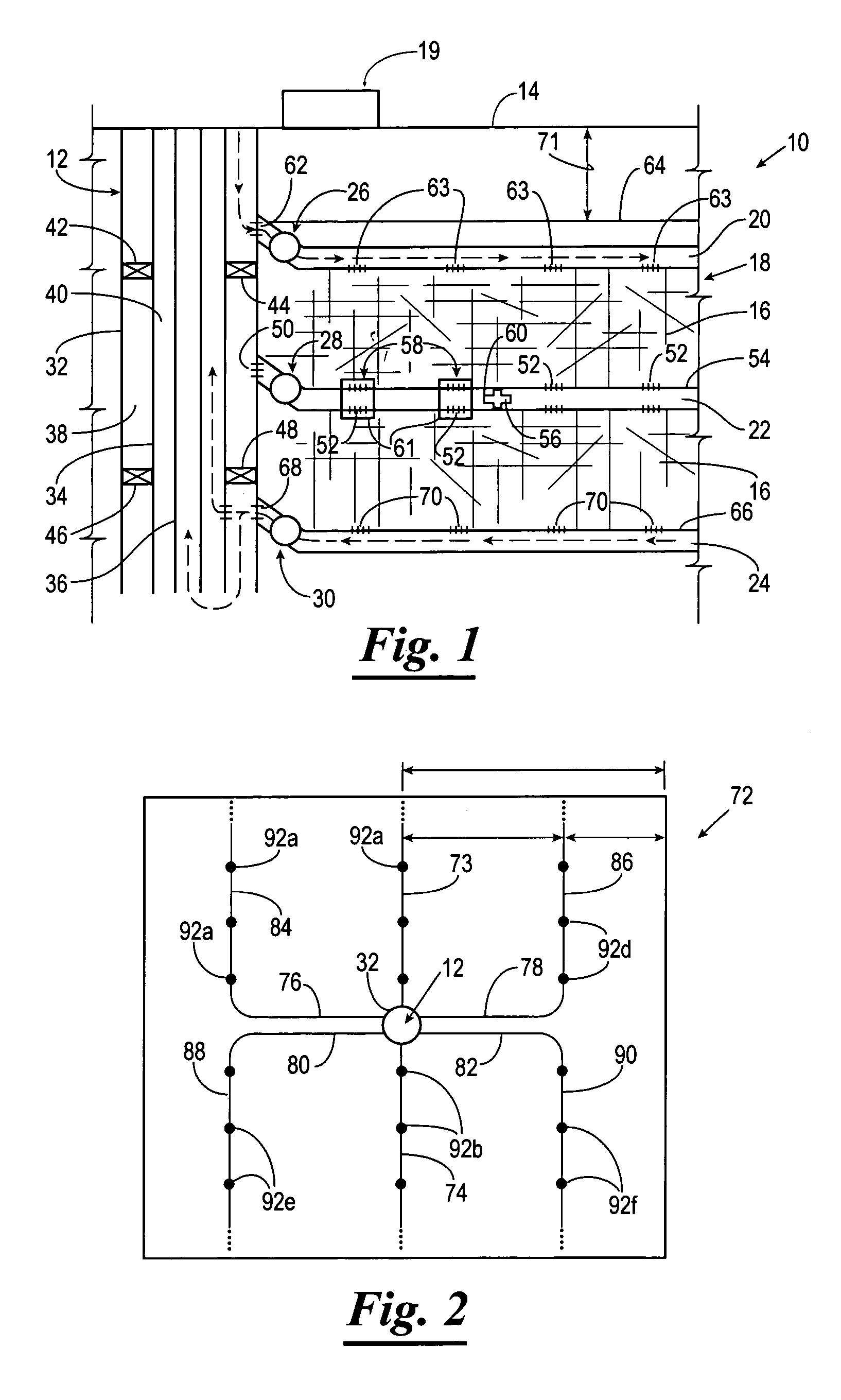

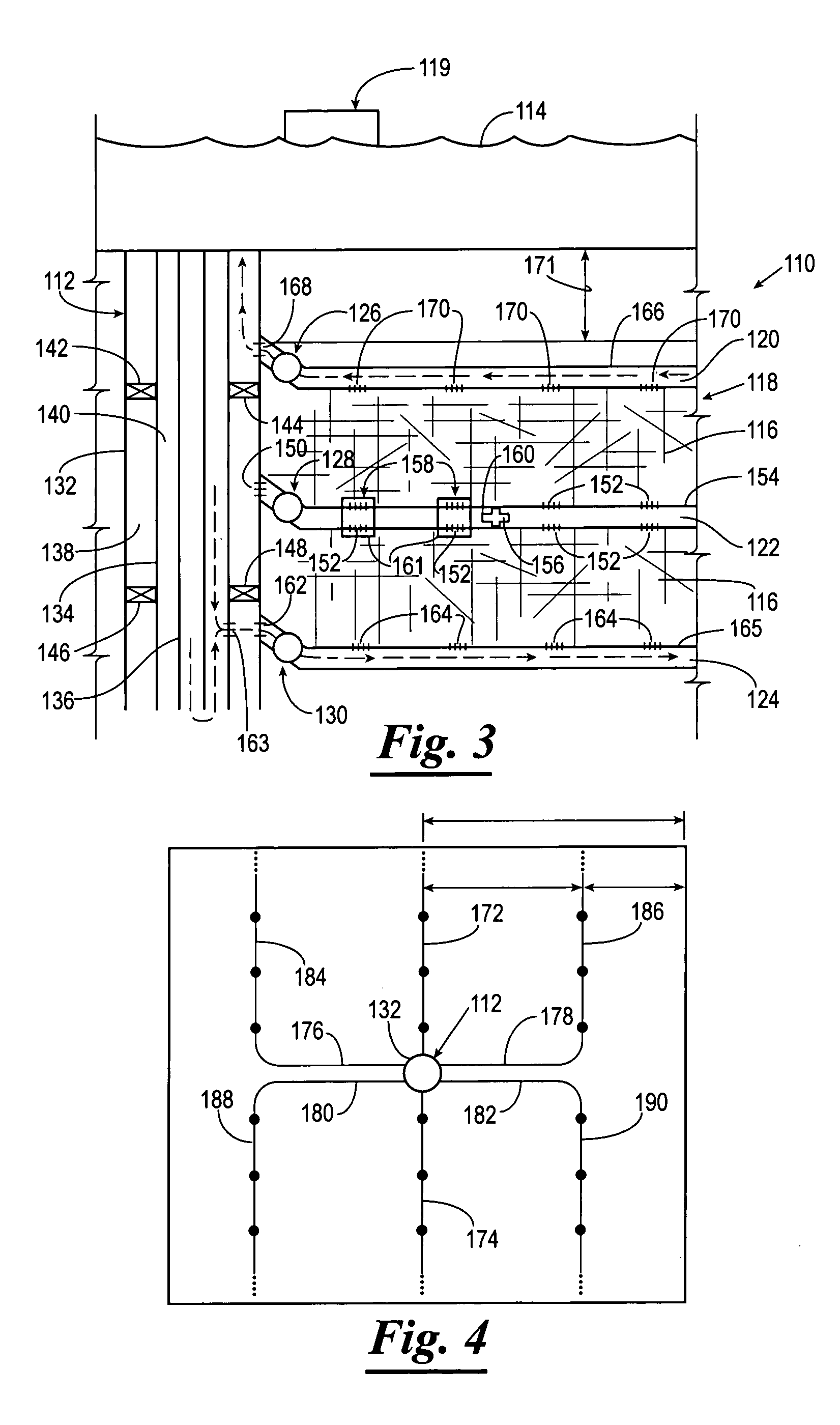

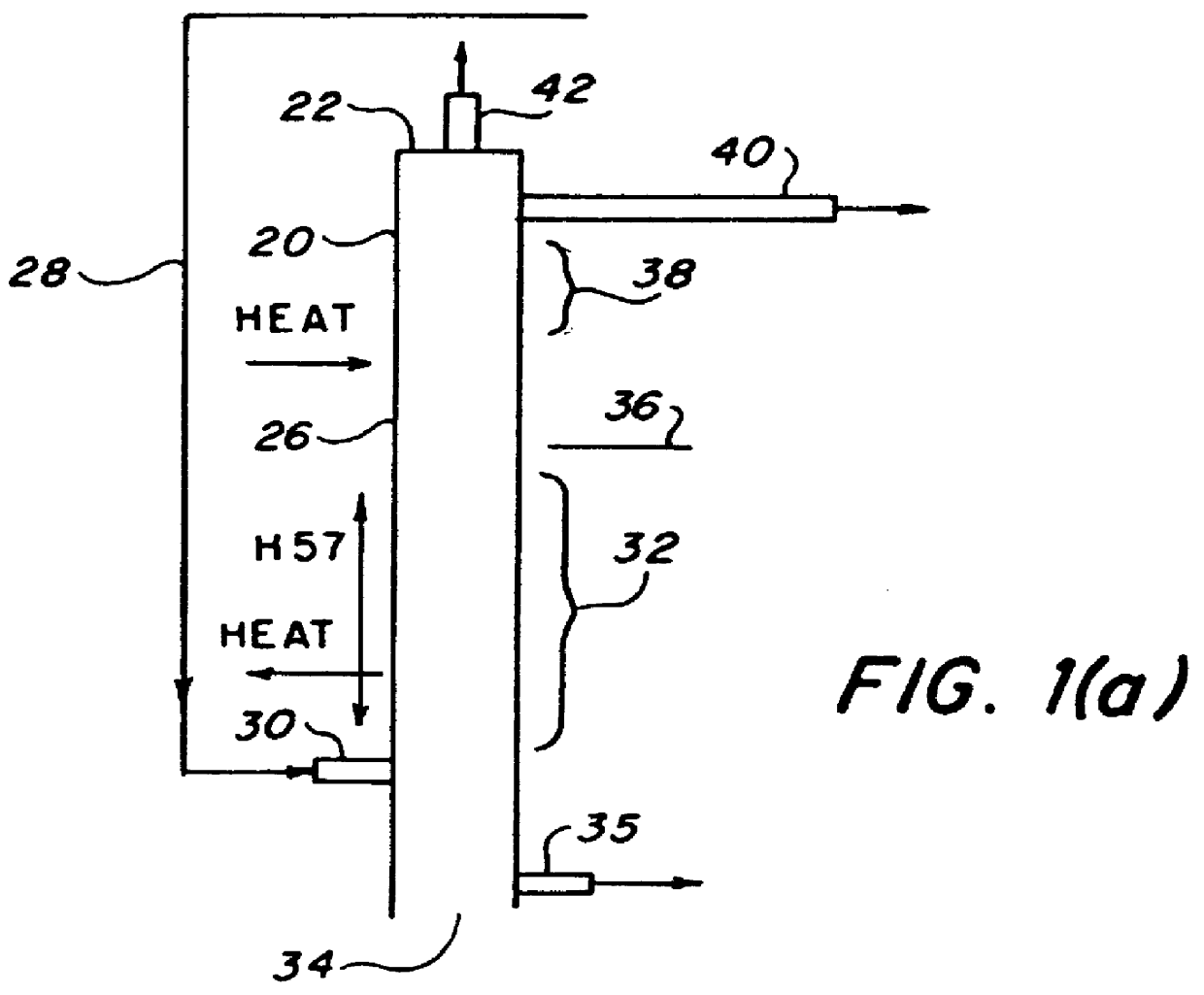

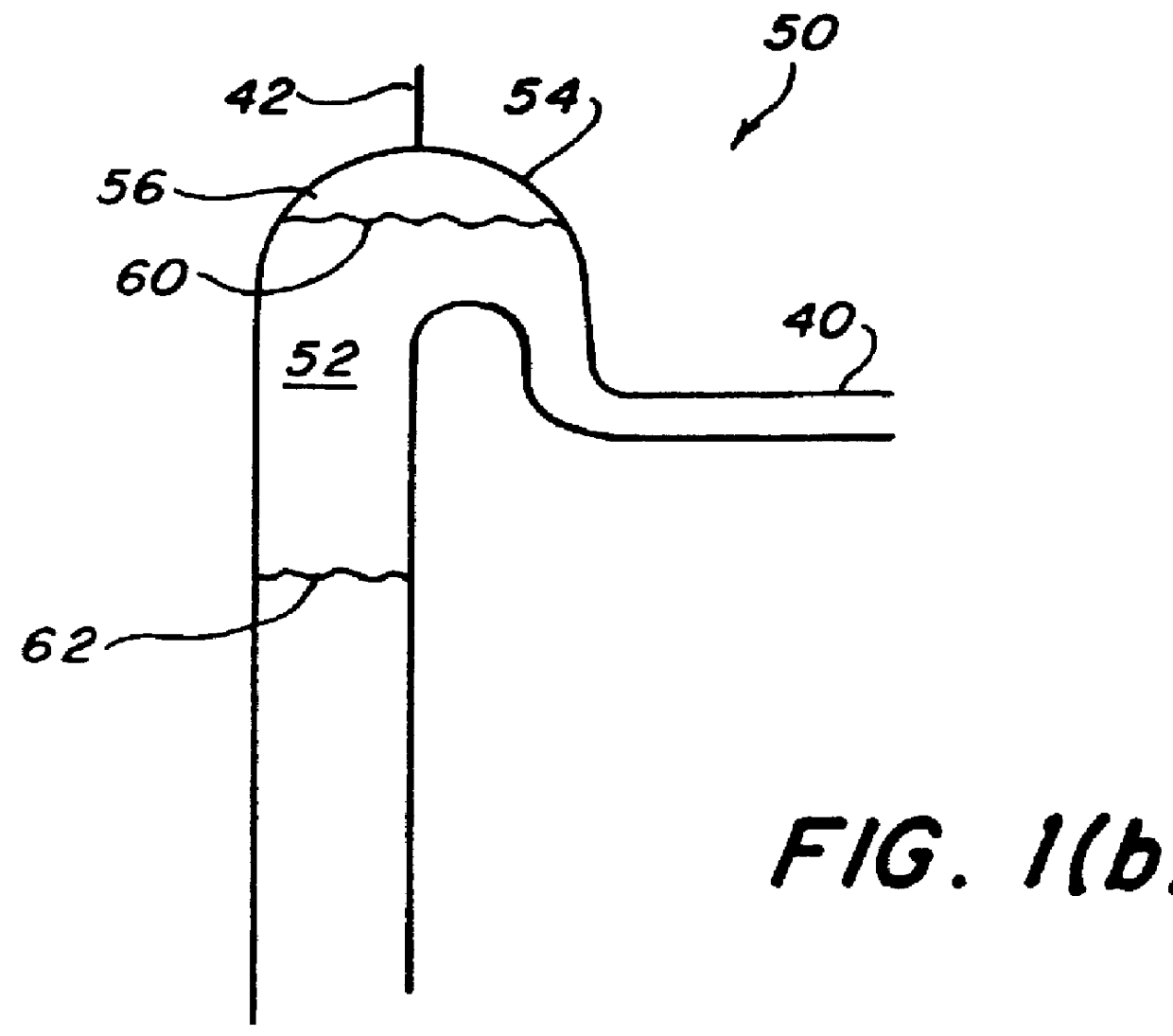

A method is provided for in-situ production of oil shale and gas (methane) hydrates wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Heat is thereafter applied to liquify the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

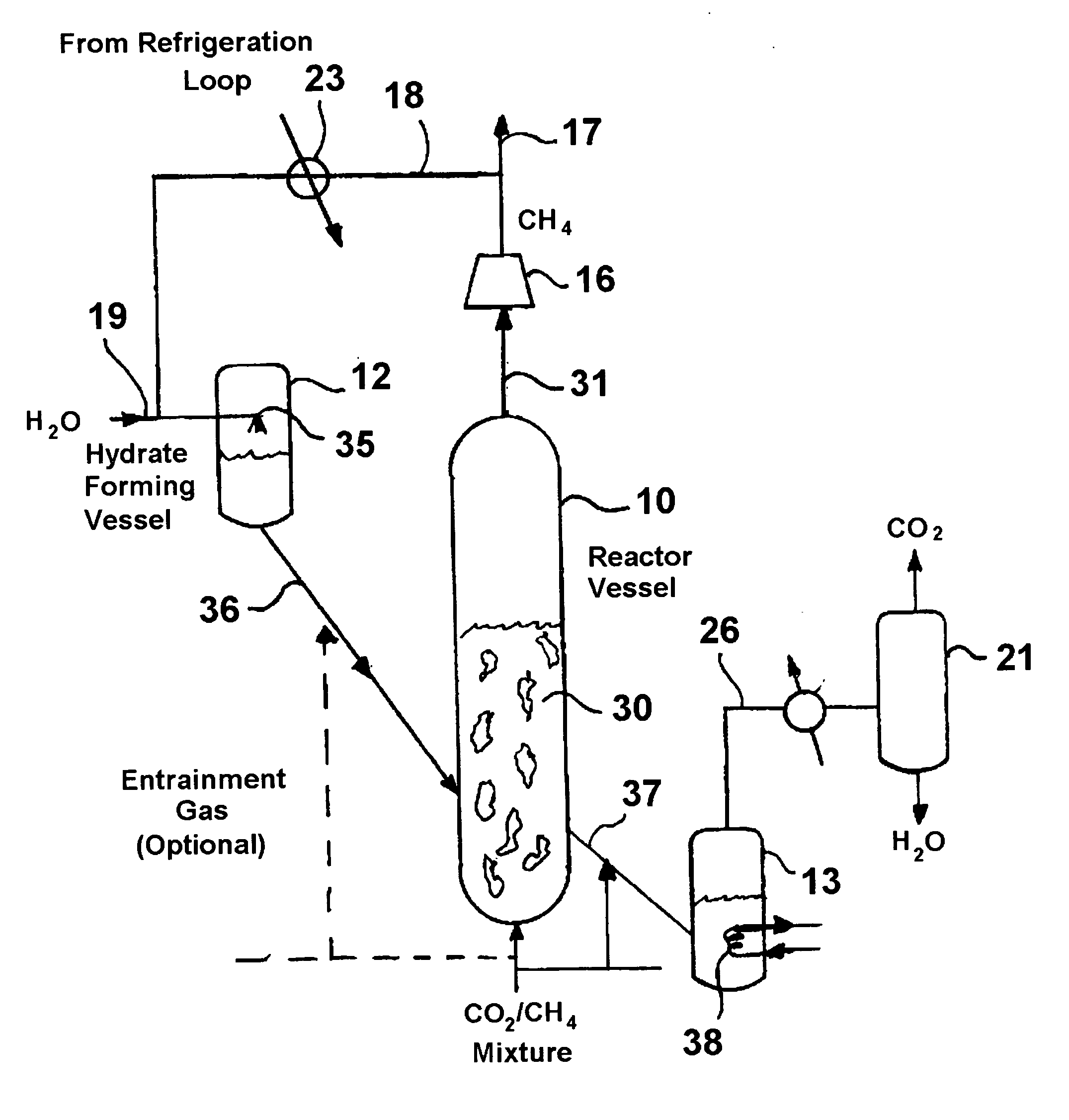

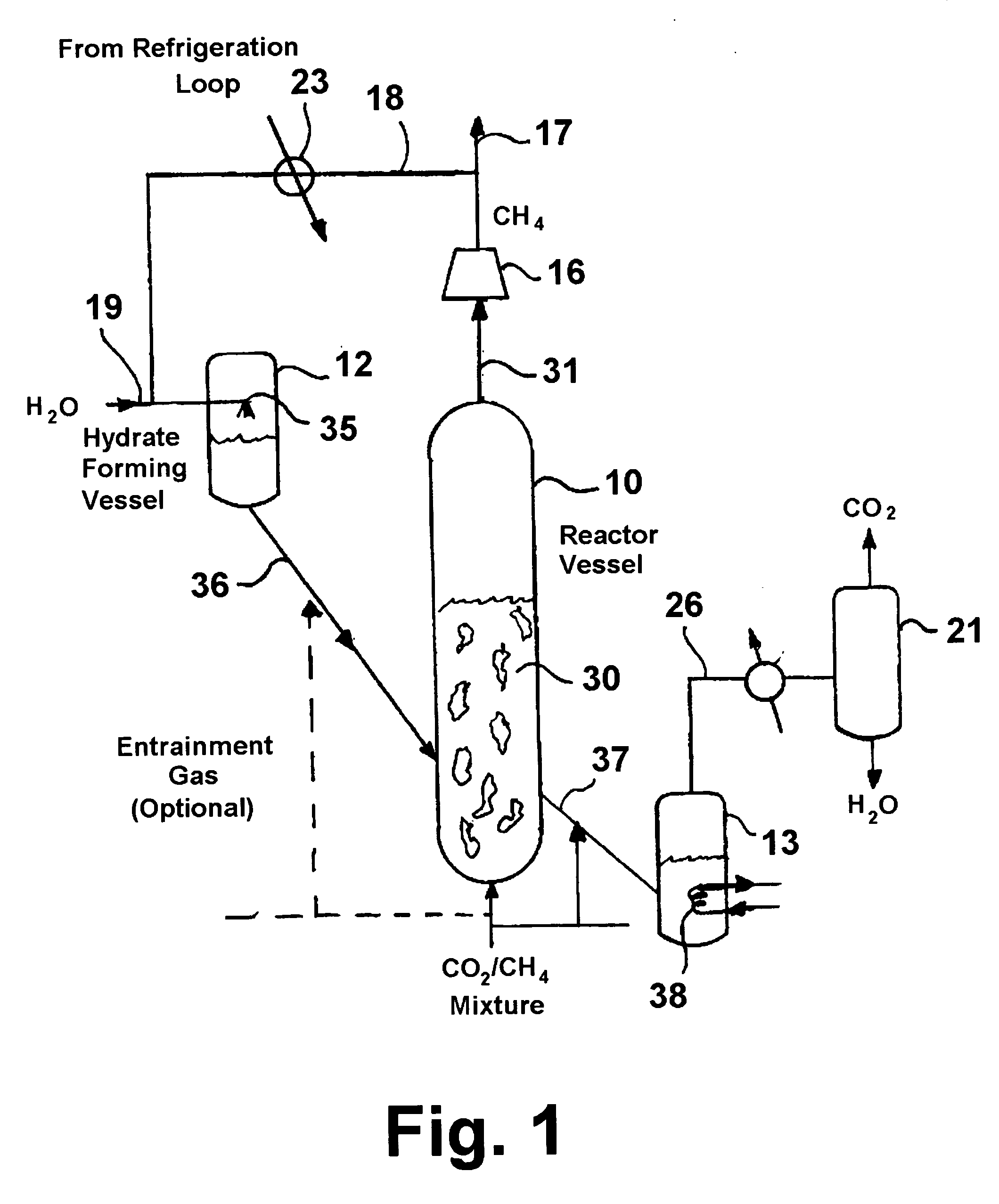

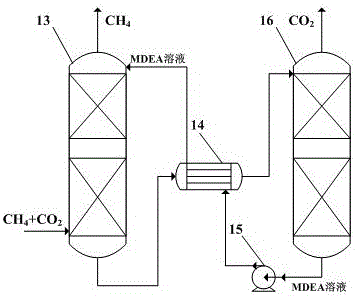

Process for separating carbon dioxide and methane

ActiveUS6946017B2Easy to separateOrganic chemistryUsing liquid separation agentMethane clathrateMethane

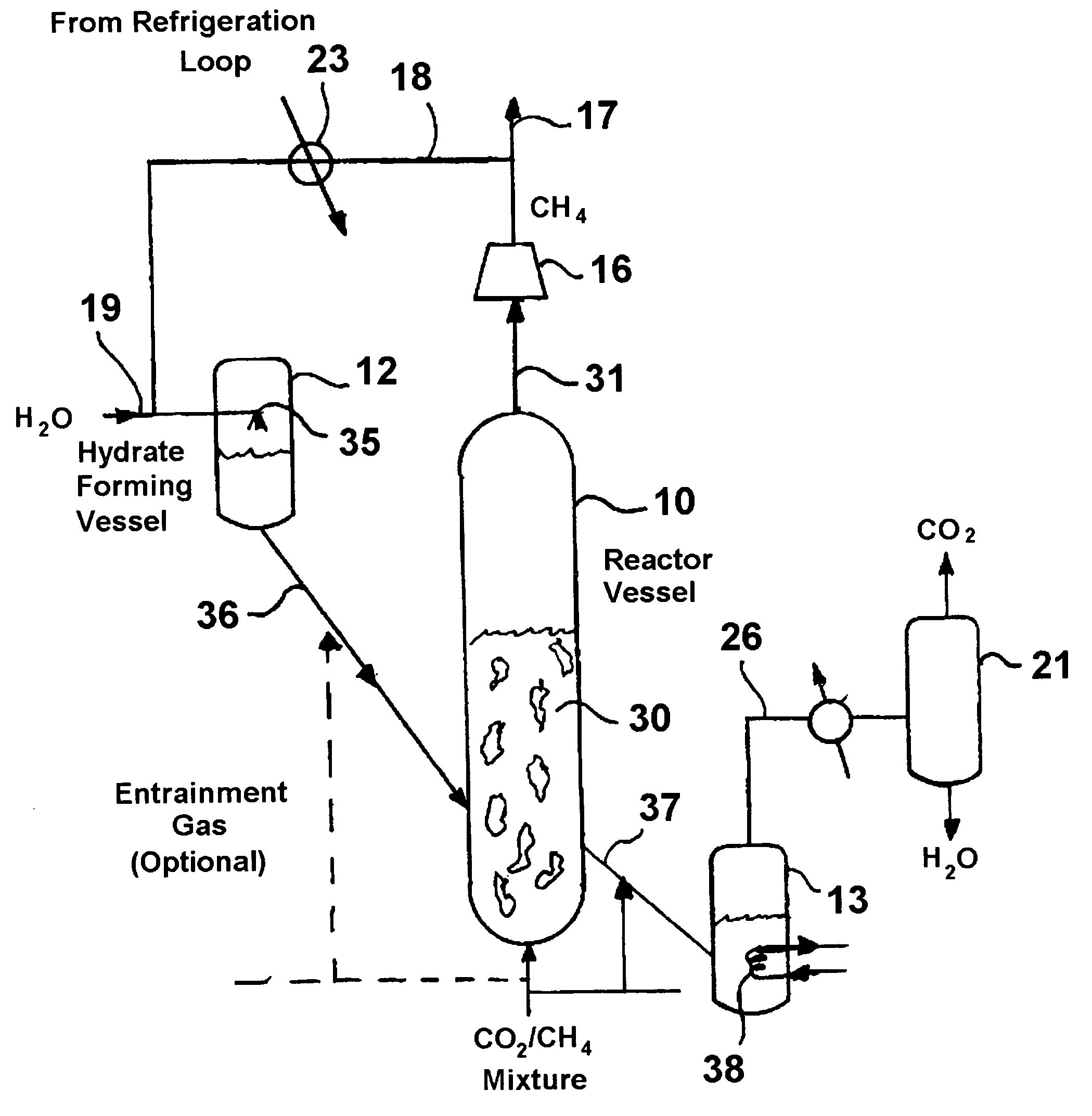

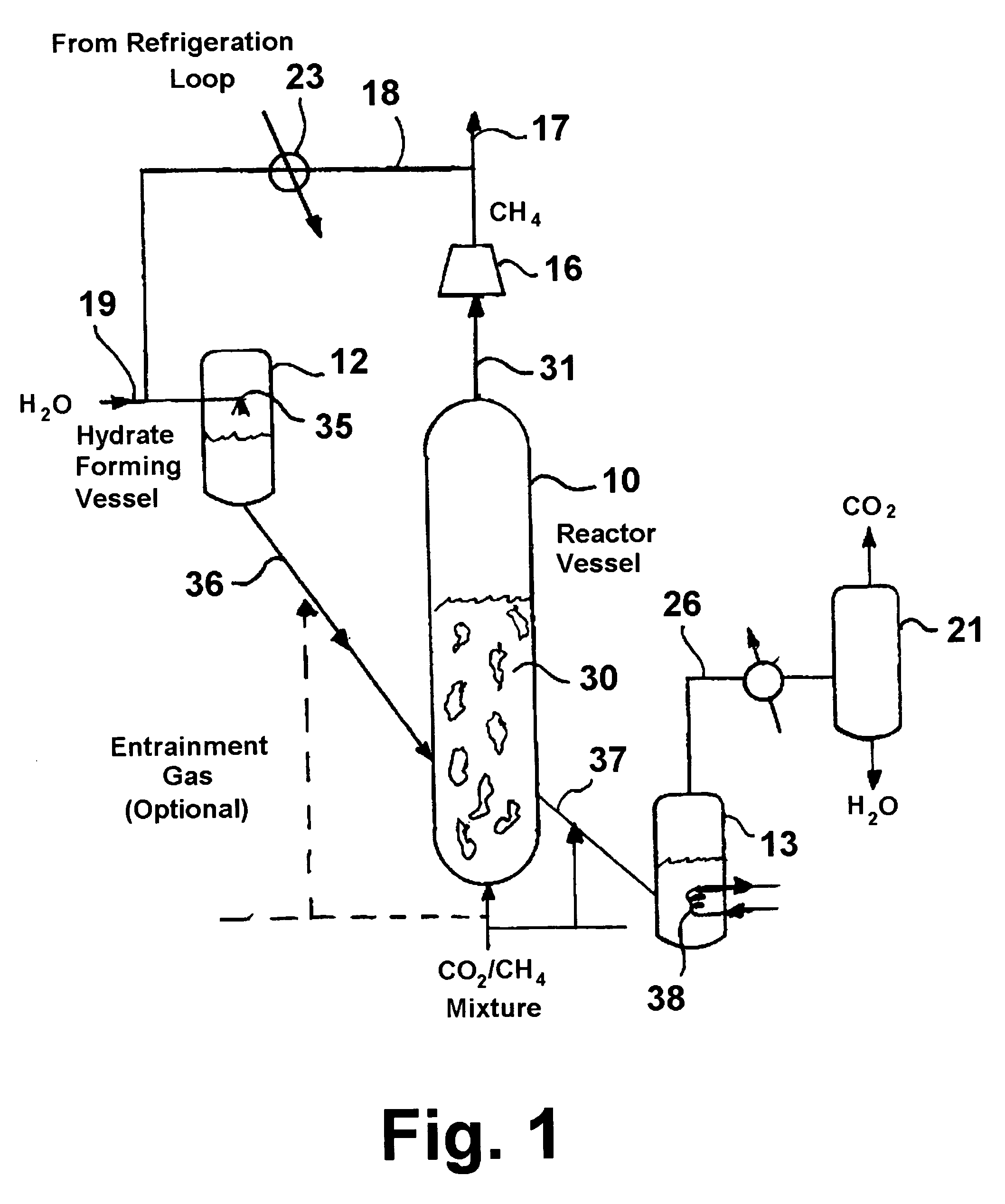

A process for separation of carbon dioxide and methane in which a gas mixture comprising carbon dioxide and methane is brought into contact with a methane hydrate solid material disposed in a reactor vessel, whereby the methane hydrate is displaced by carbon dioxide hydrate, thereby freeing the methane, which is then removed from the reactor vessel.

Owner:GAS TECH INST

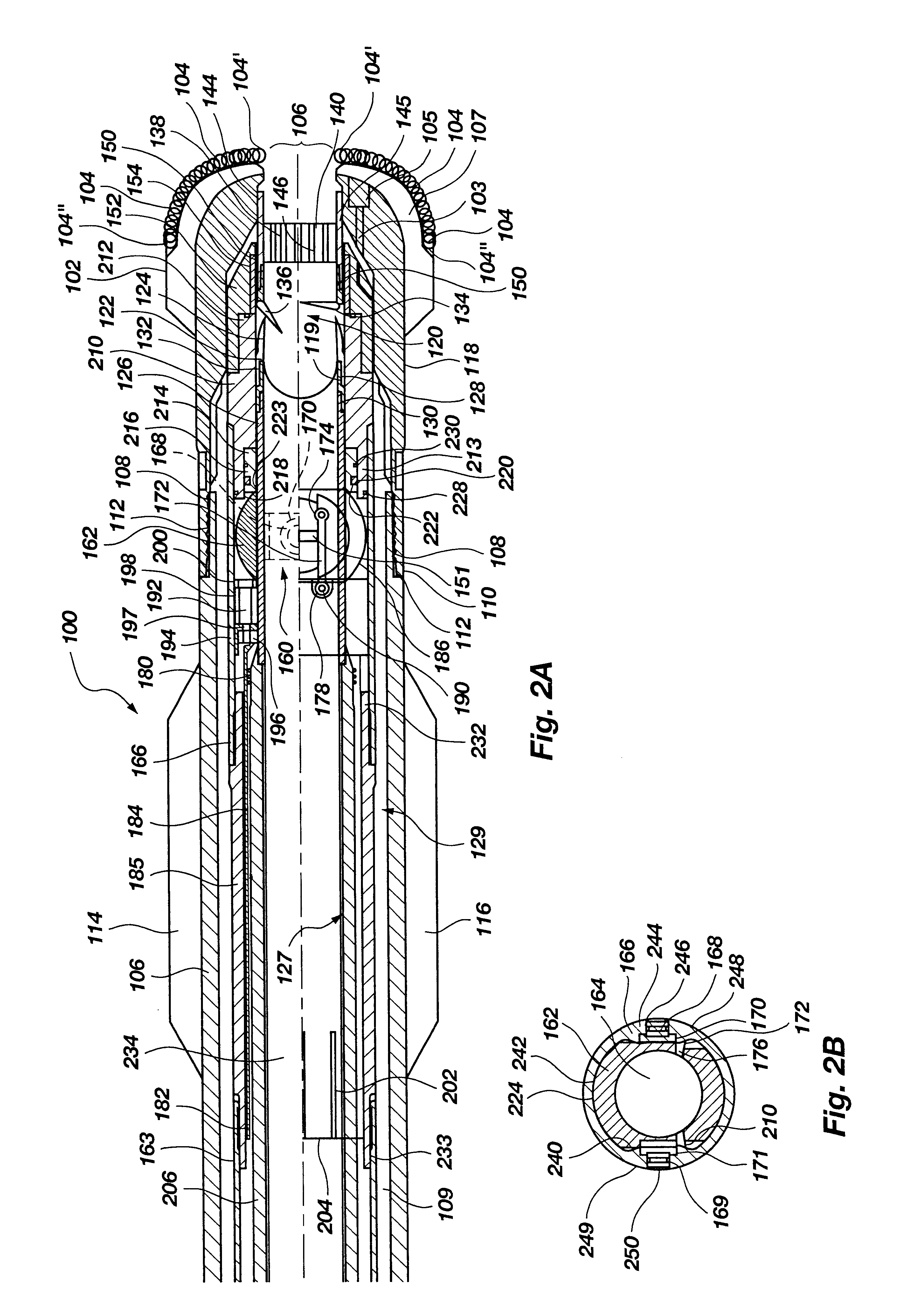

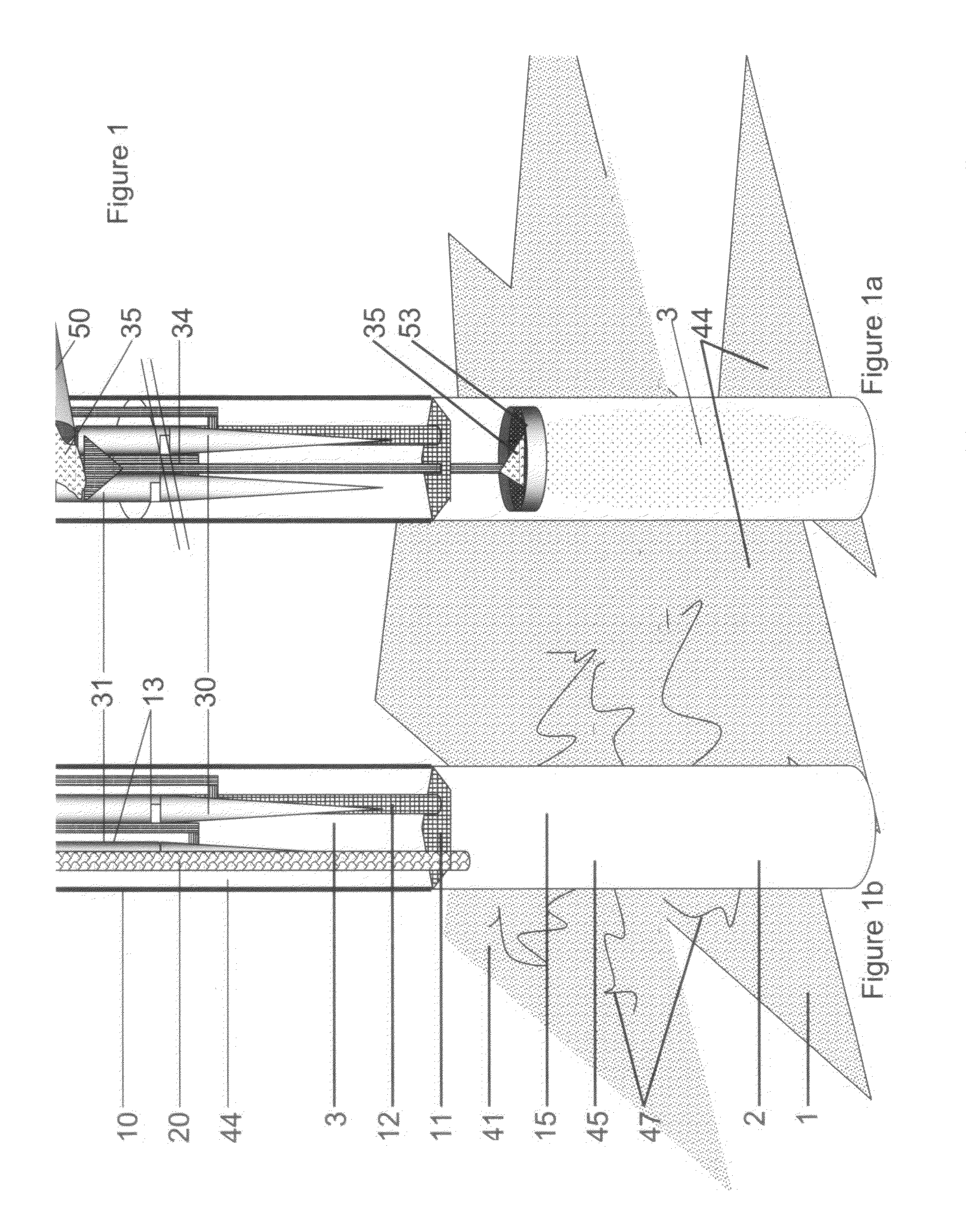

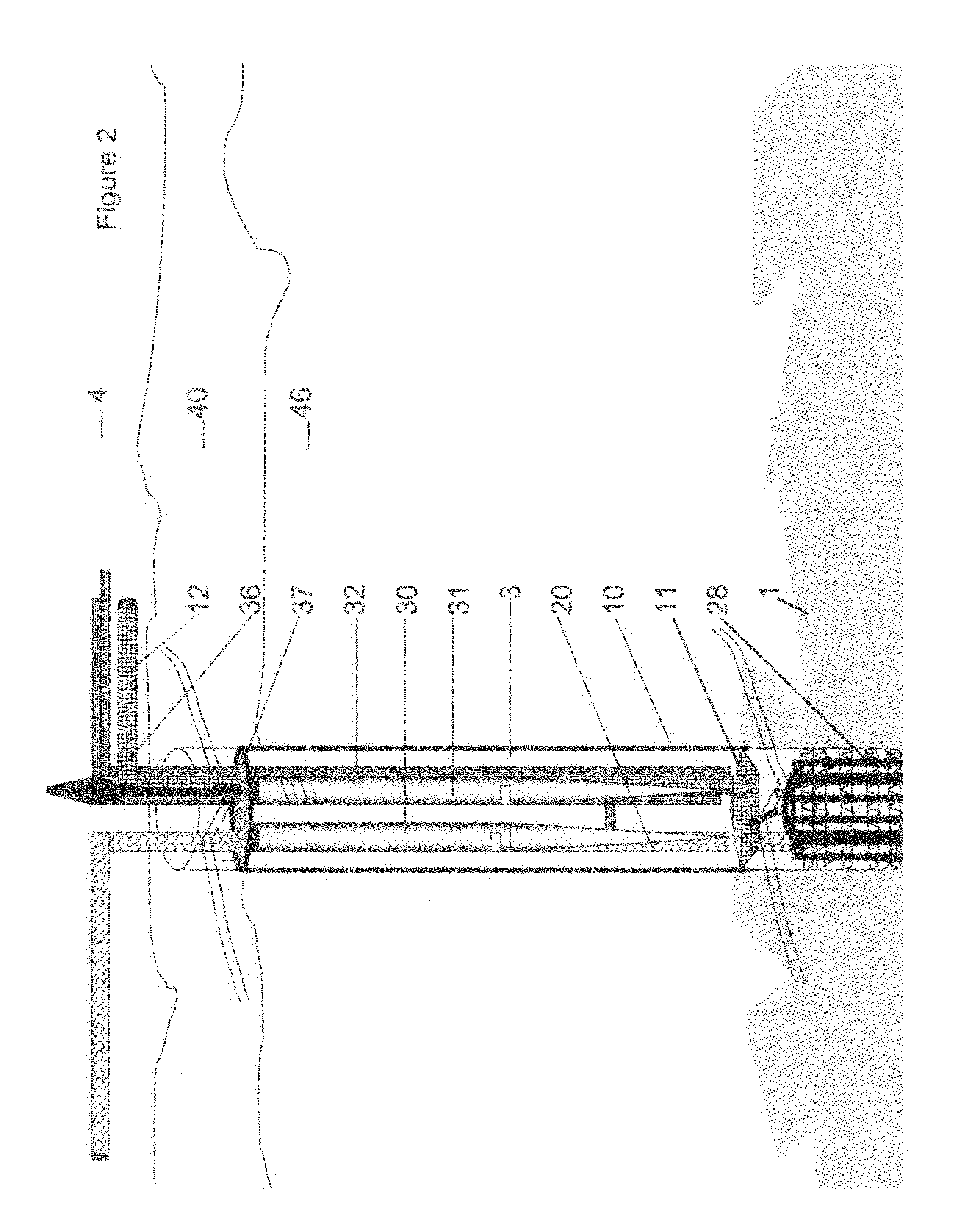

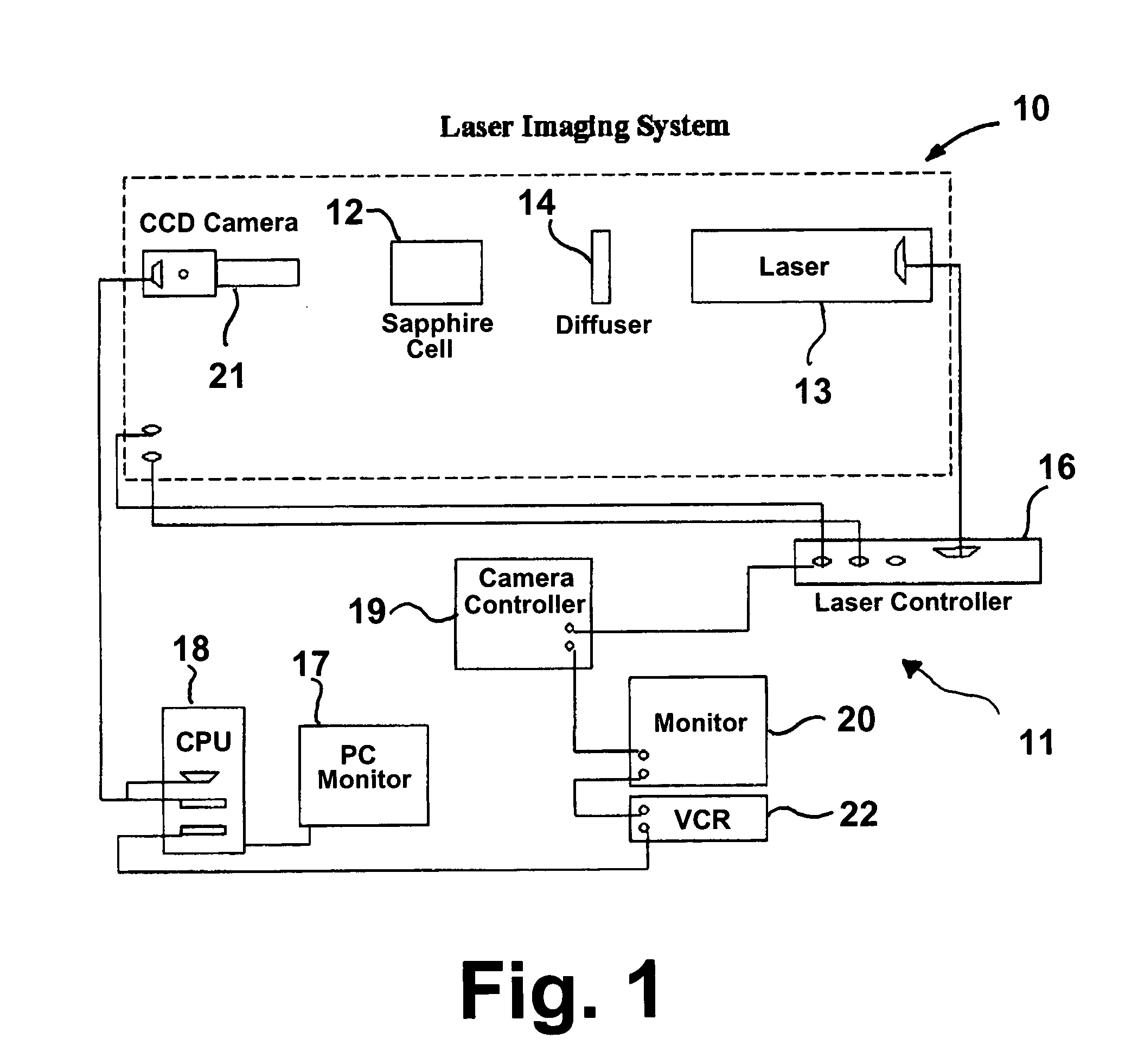

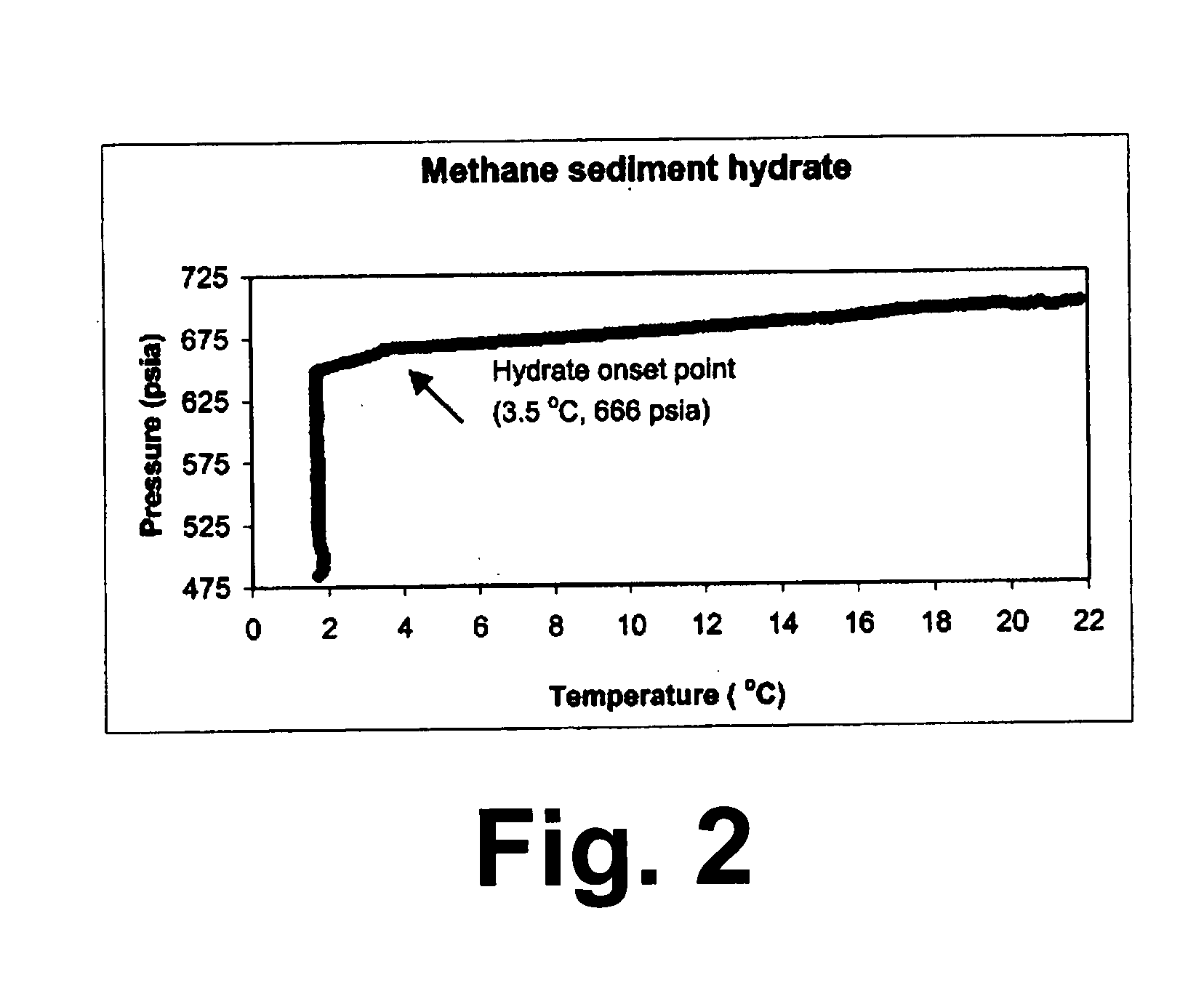

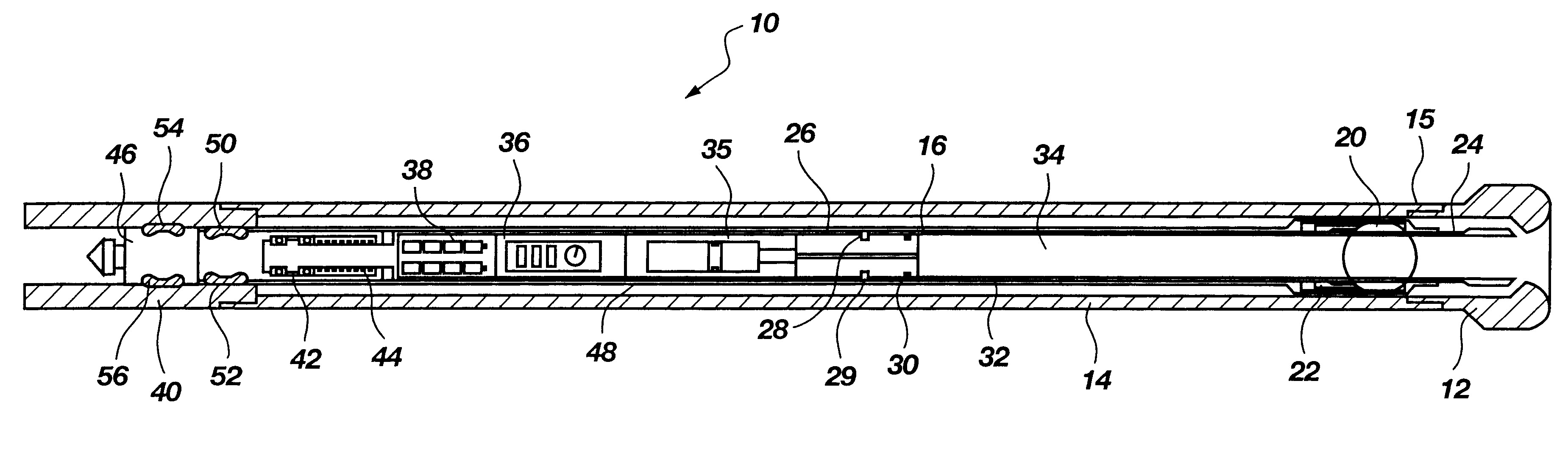

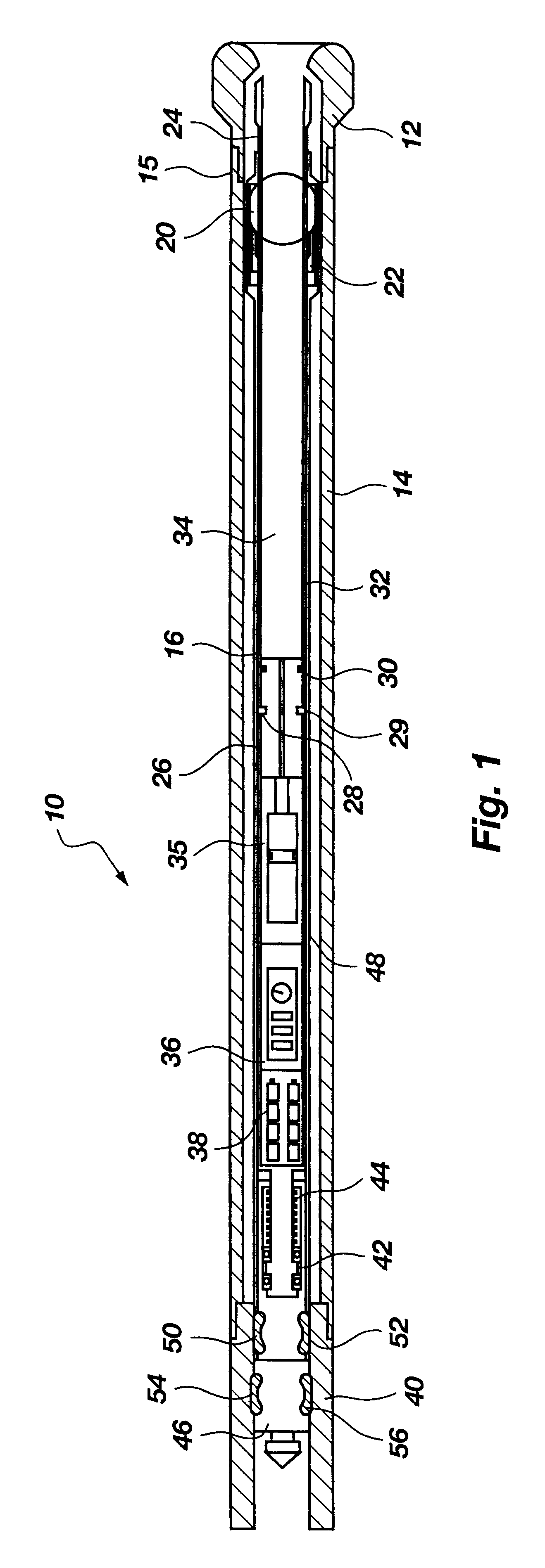

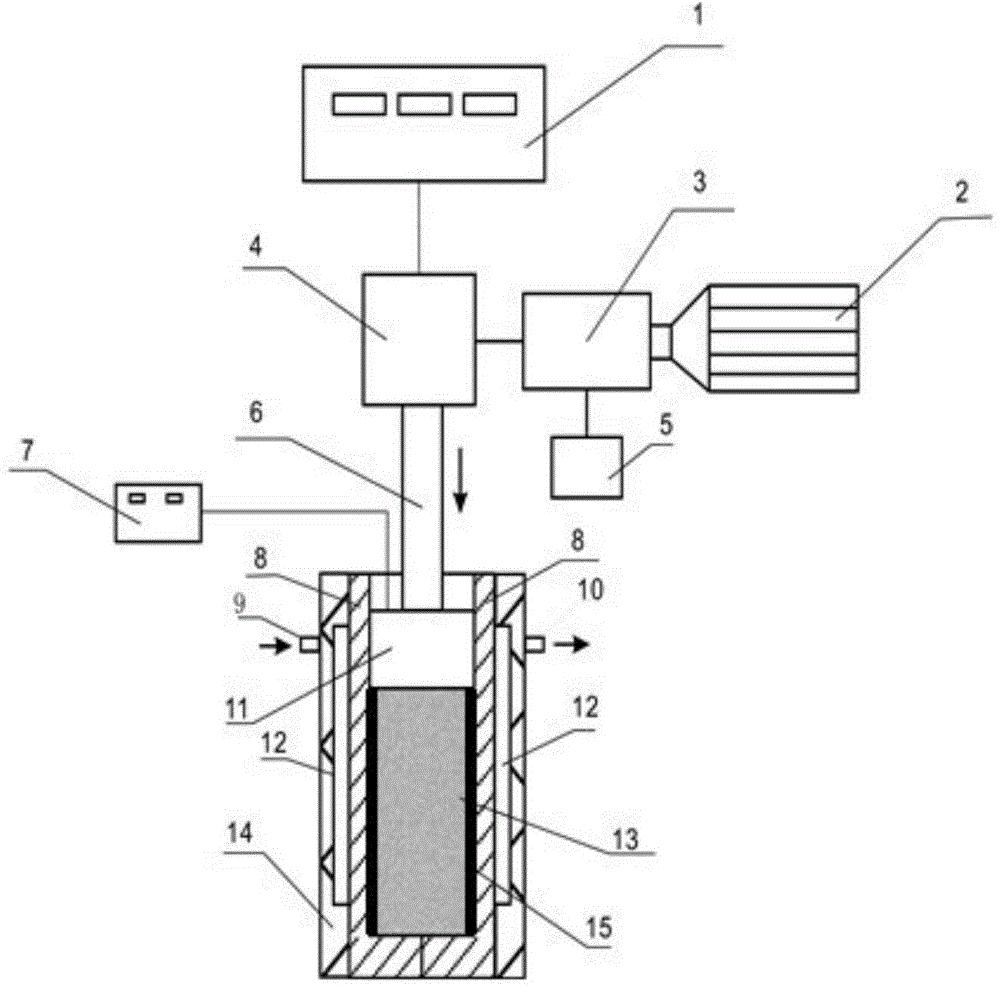

Methane extraction method and apparatus using high-energy diode lasers or diode-pumped solid state lasers

InactiveUS20070267220A1Efficient productionConstructionsDisloding machinesFiberDiode-pumped solid-state laser

A method and apparatus for extracting methane gas from methane hydrate. The method includes heating the methane hydrate with a laser apparatus. The laser apparatus includes a diode laser or a solid state laser that is pumped with a diode laser. The laser is guided to a working end of a tool with a fiber optic bundle. The tool is guided to heat the methane hydrate with the laser, which emanates from a beam expander at the working end of the tool. The tool can be modified for removing obstructions of methane hydrate in pipelines. Also, the tool can be modified for extracting methane from mined methane hydrate, which is in a container. The characteristics of diode lasers or diode-pumped solid state lasers such as efficiency, size, nature of operation, environmental impact and durability, make methane gas extraction from methane hydrate economically feasible.

Owner:NORTHROP GRUMAN CORP

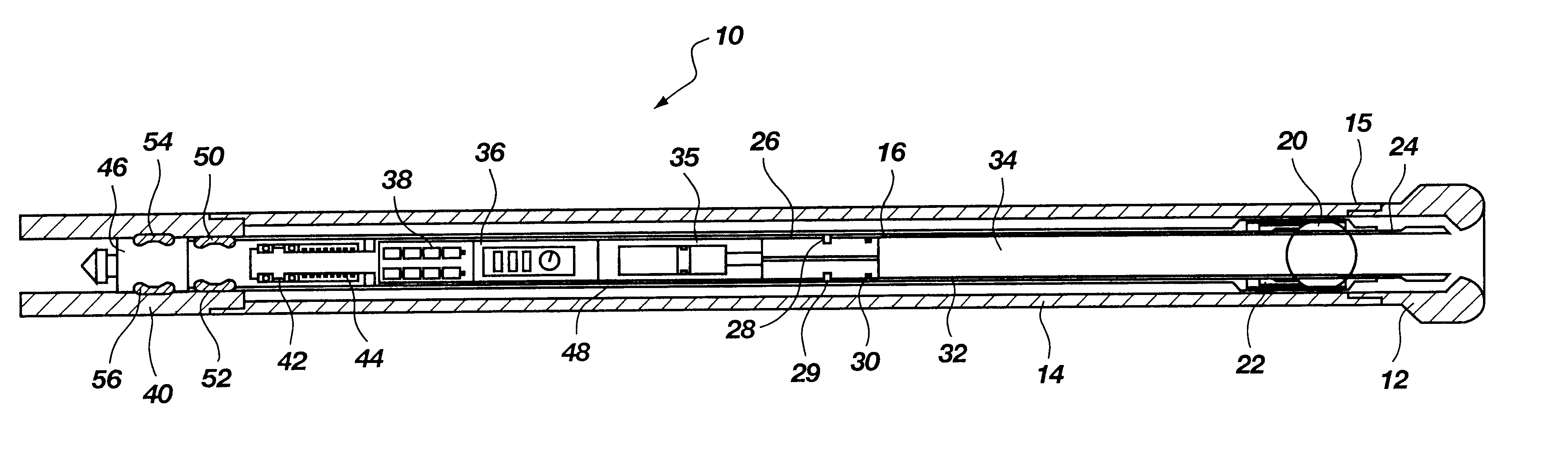

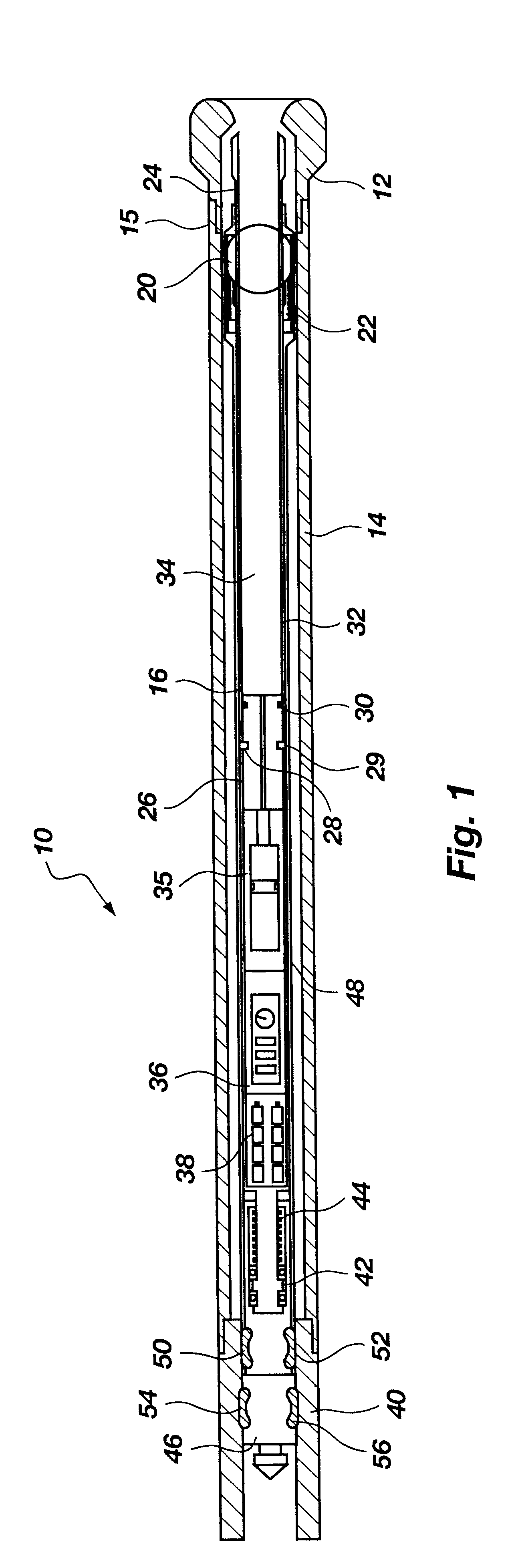

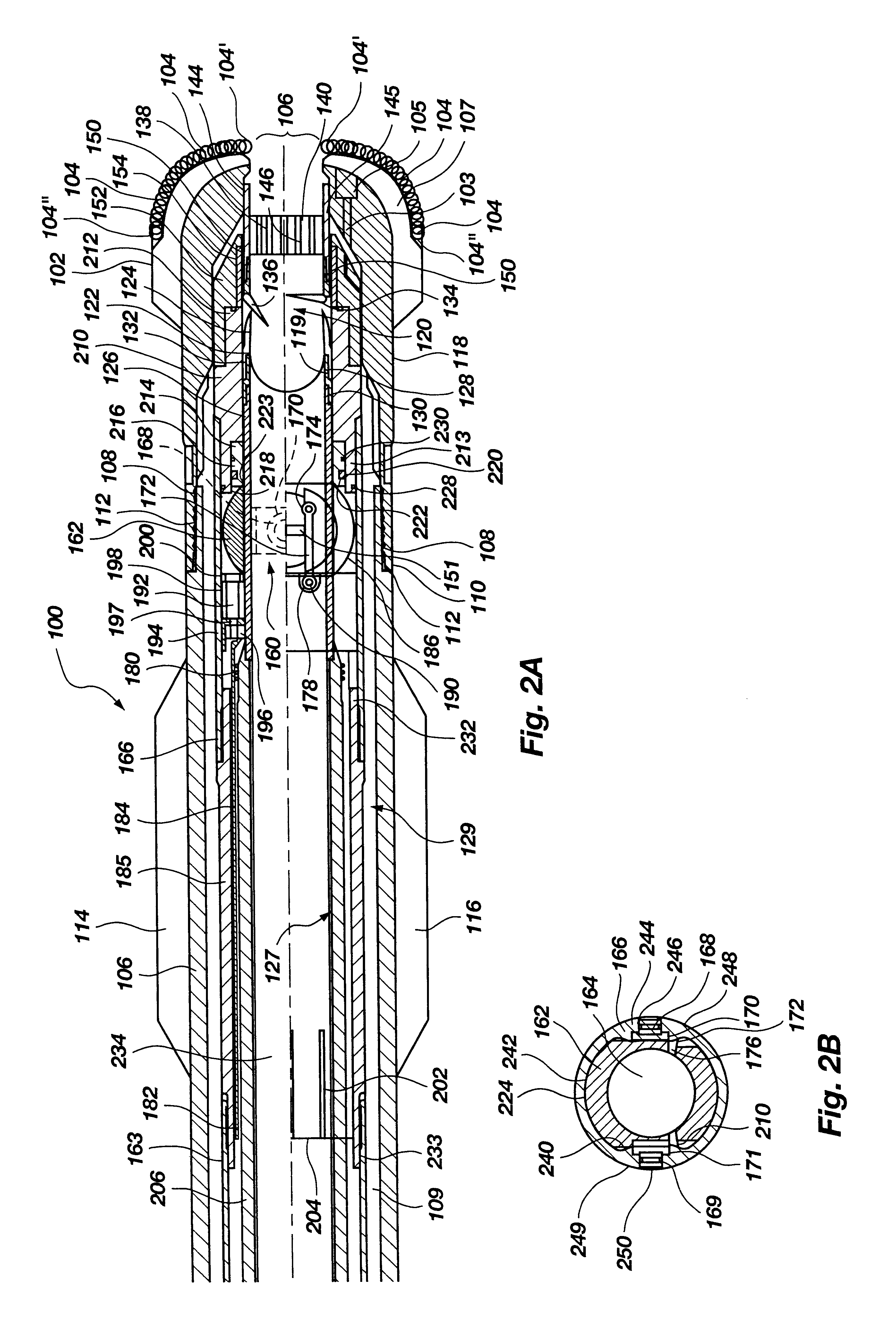

Apparatus for recovering core samples under pressure

A pressure and temperature core sampler comprises a tool for recovering cores specifically enabling the evaluation of methane hydrate resources. Because methane hydrate tends to decompose under conditions of pressure decrease and / or temperature increase as the samples are retrieved to the surfaces a coring tool in accordance with the present invention provides a self-contained system for retrieving core samples at or near in situ pressure while cooling the core sample. The coring tool is preferably a wire line retrievable device that provides for nearly continuous coring during the drilling operation.

Owner:JAPAN OIL GAS & METALS NAT CORP

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

Method of natural gas production

A method and system for dissociating methane hydrate deposits in-situ is provided wherein an oxidizer fluid and a supply of fuel, both at a pressure higher than that of the methane hydrate deposit, are supplied and delivered to the methane hydrate deposit. The fuel is combusted downhole by reacting it with the oxidizer fluid to provide combustion products. The combustion products are placed in contact with a diluent fluid to produce a heated product fluid. The heated product fluid is injected into the methane hydrate deposit whereby methane is dissociated from the methane hydrate and made available for extraction. In addition, carbon dioxide may be made available to promote the formation of carbon dioxide hydrates from the liberated methane hydrate water.

Owner:PRECISION COMBUSTION

Desalination through gas hydrate

In one embodiment, this invention pertains to desalination of seawater by feeding methane into seawater at a depth generally exceeding 100 meters to form methane hydrate which rises to where it is decomposed into methane and water, and recoverig water. Methane is recycled to depth to form more buoyant hydrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Process to sequester CO2 in natural gas hydrate fields and simultaneously recover methane

A method for sequestering and storing CO2 in which gaseous carbon dioxide is injected into a subterranean methane hydrate field, displacing methane in the methane hydrate field with the carbon dioxide and forming carbon dioxide hydrate. The displaced methane may then be collected.

Owner:GAS TECH INST

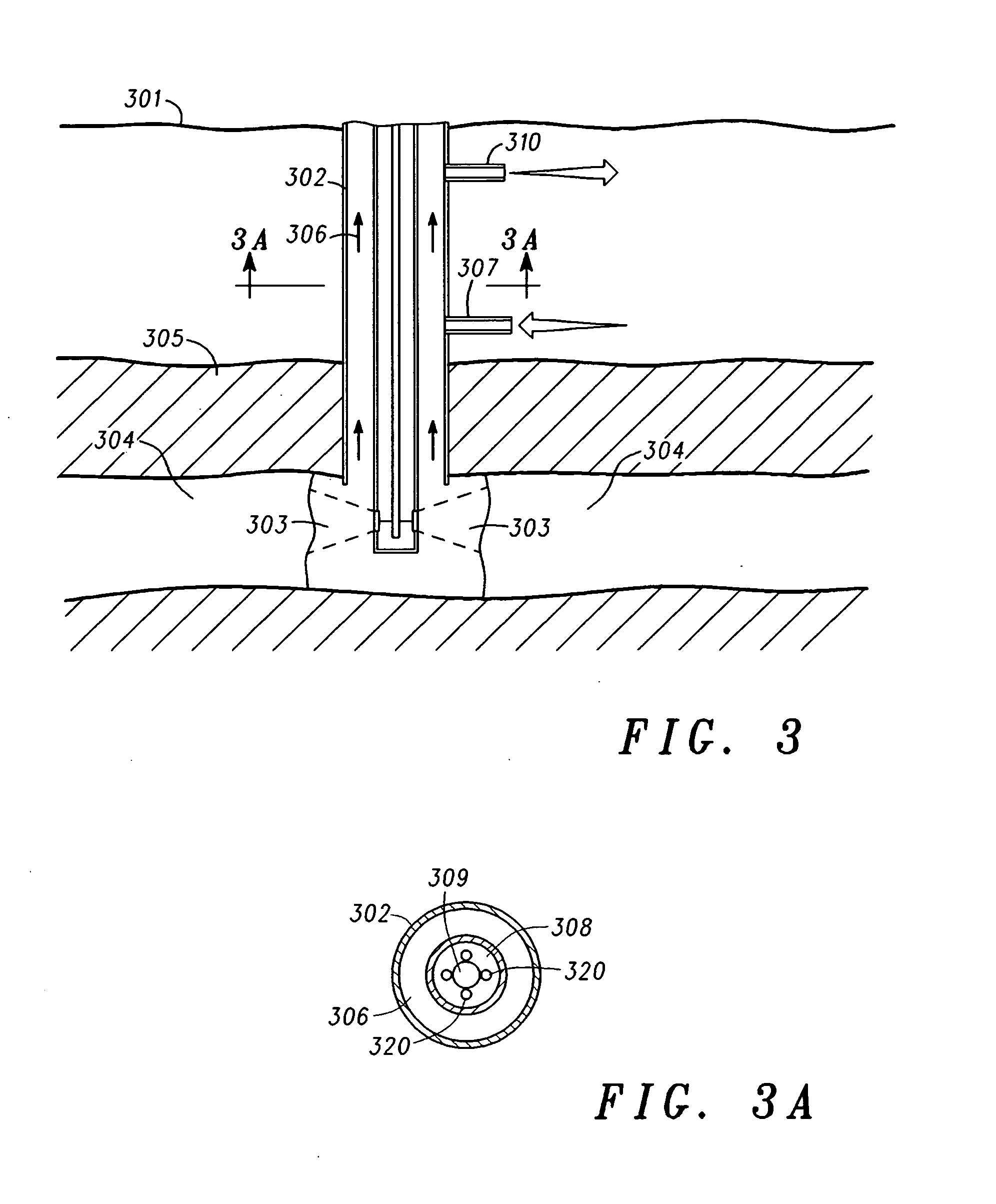

In-situ method of fracturing gas shale and geothermal areas

InactiveUS20070107901A1Promote recoveryOther heat production devicesGeothermal energy generationKerogenShale gas

A method is provided for in-situ production of oil shale, gas via gas (methane) hydrates and gas shale, and steam via geothermal formations wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Thereafter, heat can be applied to liquefy the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

Apparatus for recovering core samples under pressure

Owner:JAPAN OIL GAS & METALS NAT CORP

Process for separating carbon dioxide and methane

ActiveUS20050120878A1Easy to separateOrganic chemistryUsing liquid separation agentMethane clathrateMethane

A process for separation of carbon dioxide and methane in which a gas mixture comprising carbon dioxide and methane is brought into contact with a methane hydrate solid material disposed in a reactor vessel, whereby the methane hydrate is displaced by carbon dioxide hydrate, thereby freeing the methane, which is then removed from the reactor vessel.

Owner:GAS TECH INST

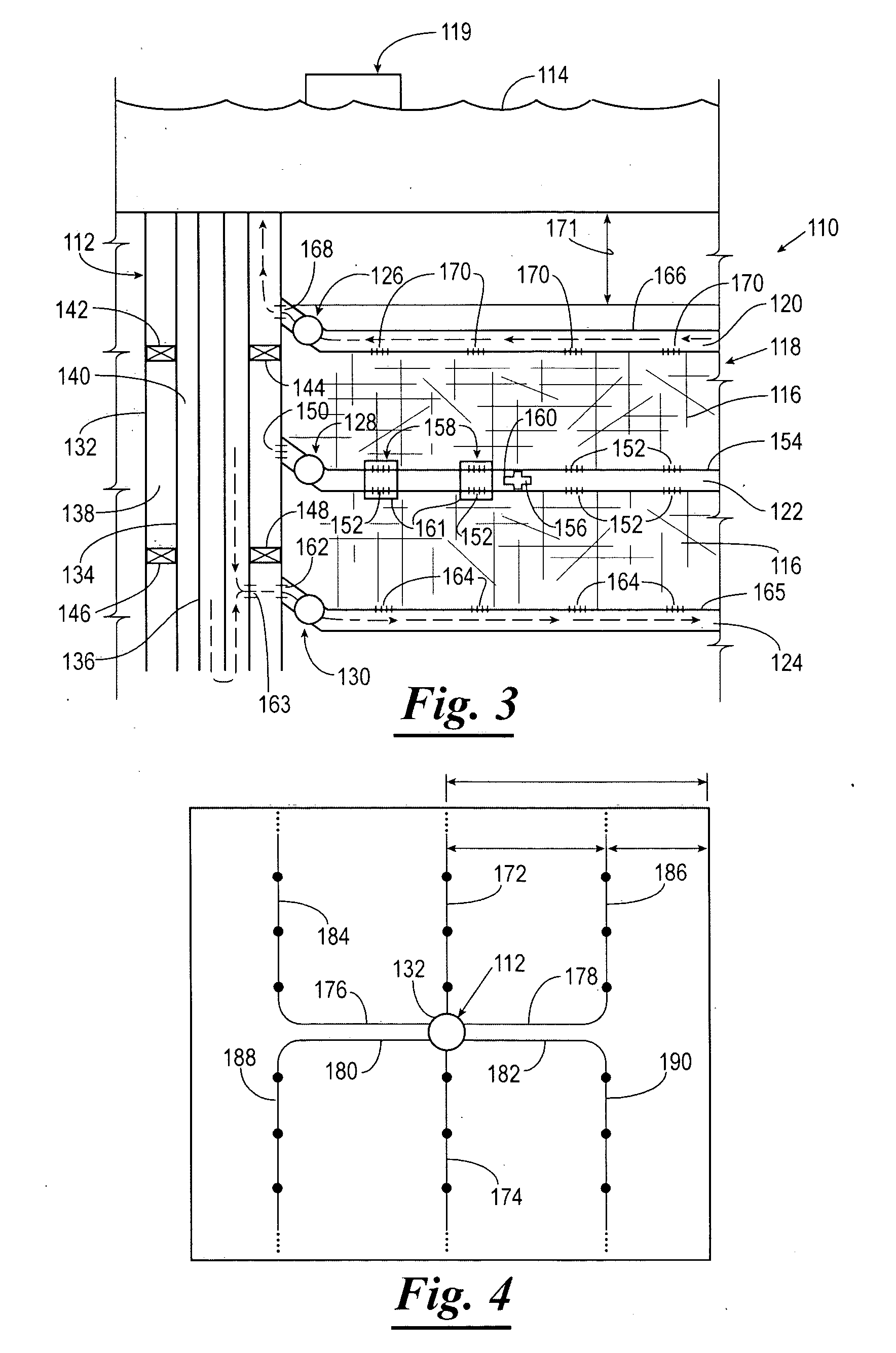

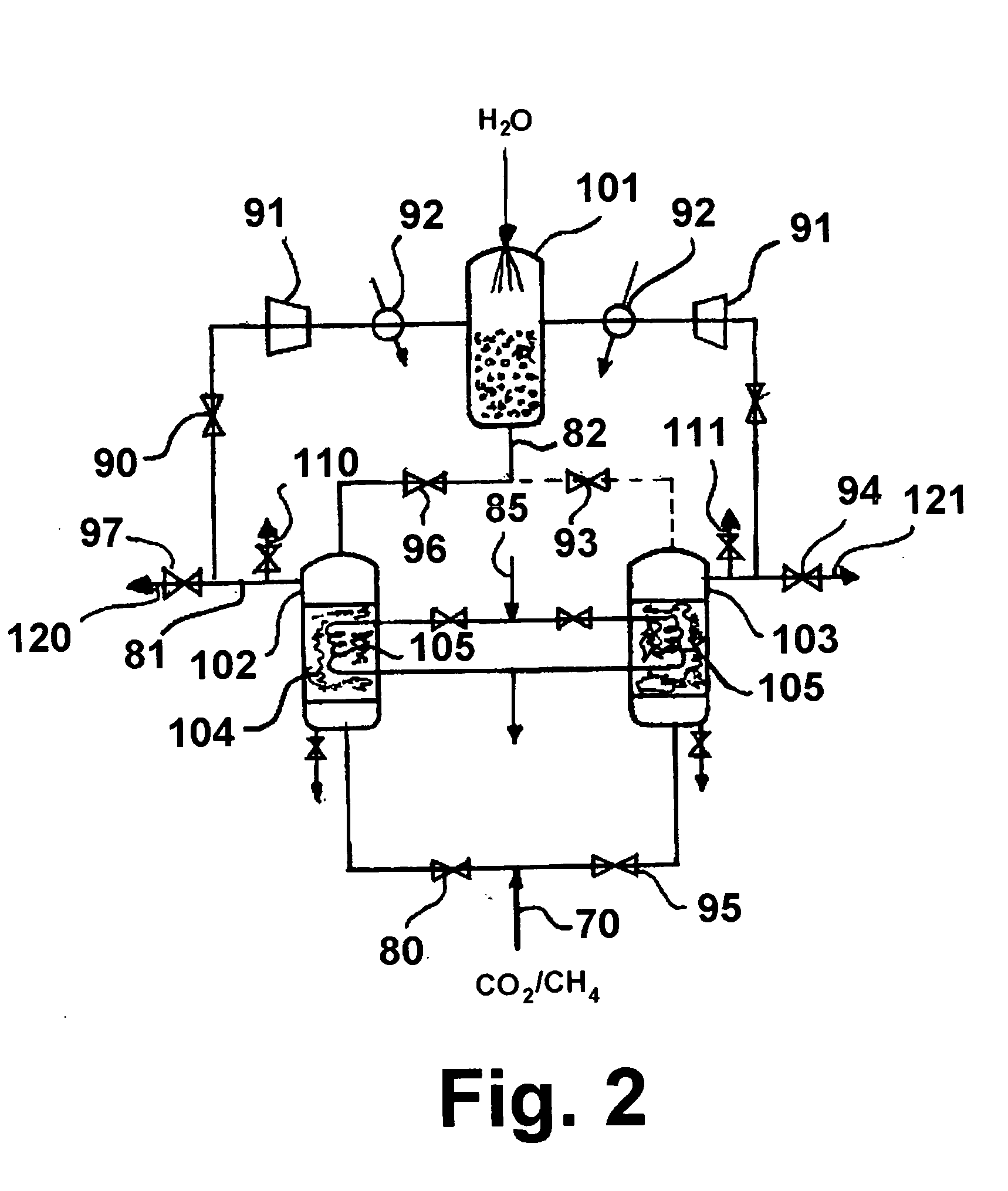

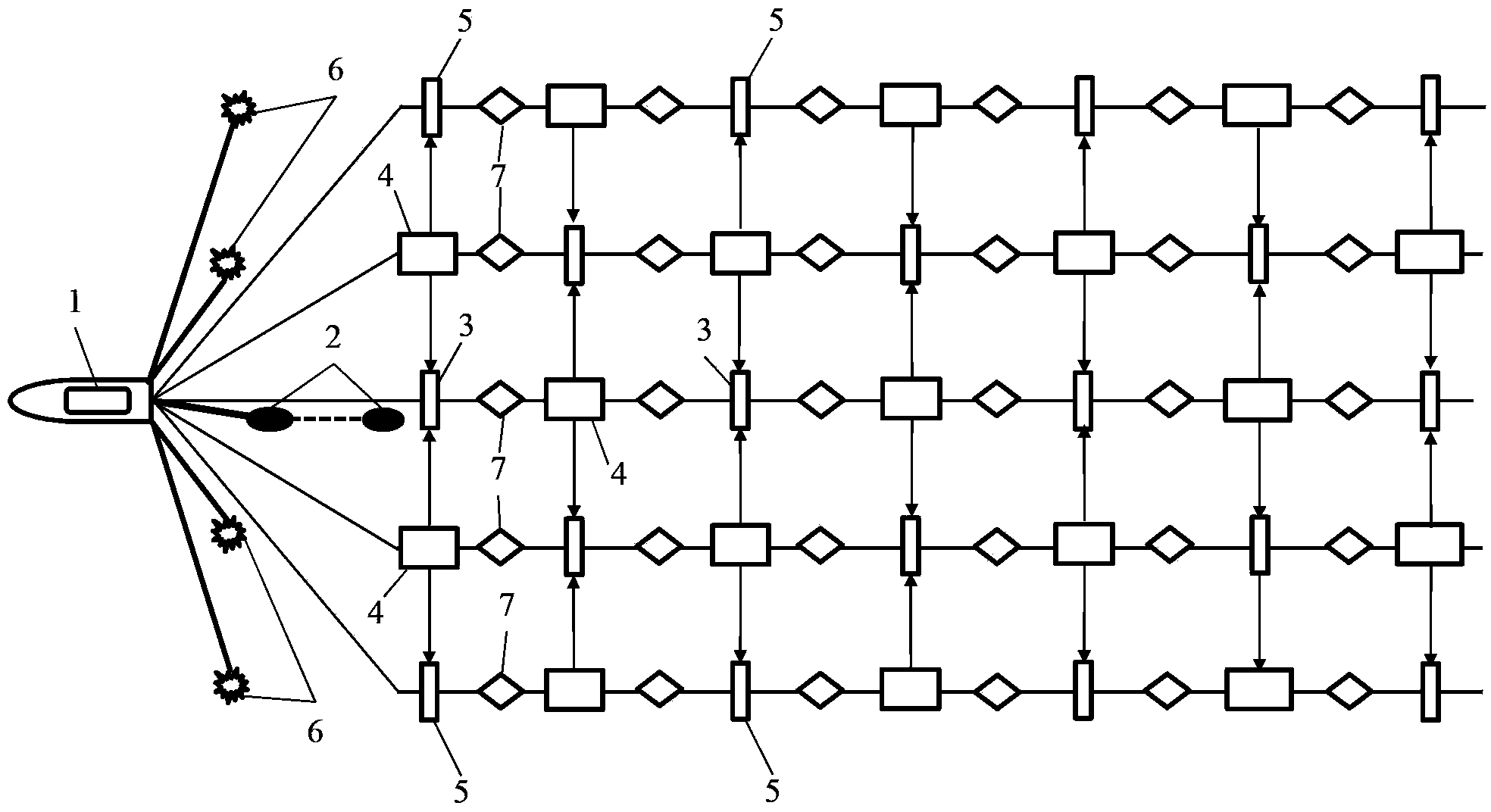

Towrope type ocean controllable source electromagnetism and earthquake data collection system

InactiveCN104280781AImprove reliabilityIncrease the amount of data collectedSeismic signal receiversElectric/magnetic detectionElectric field sensorAccelerometer

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

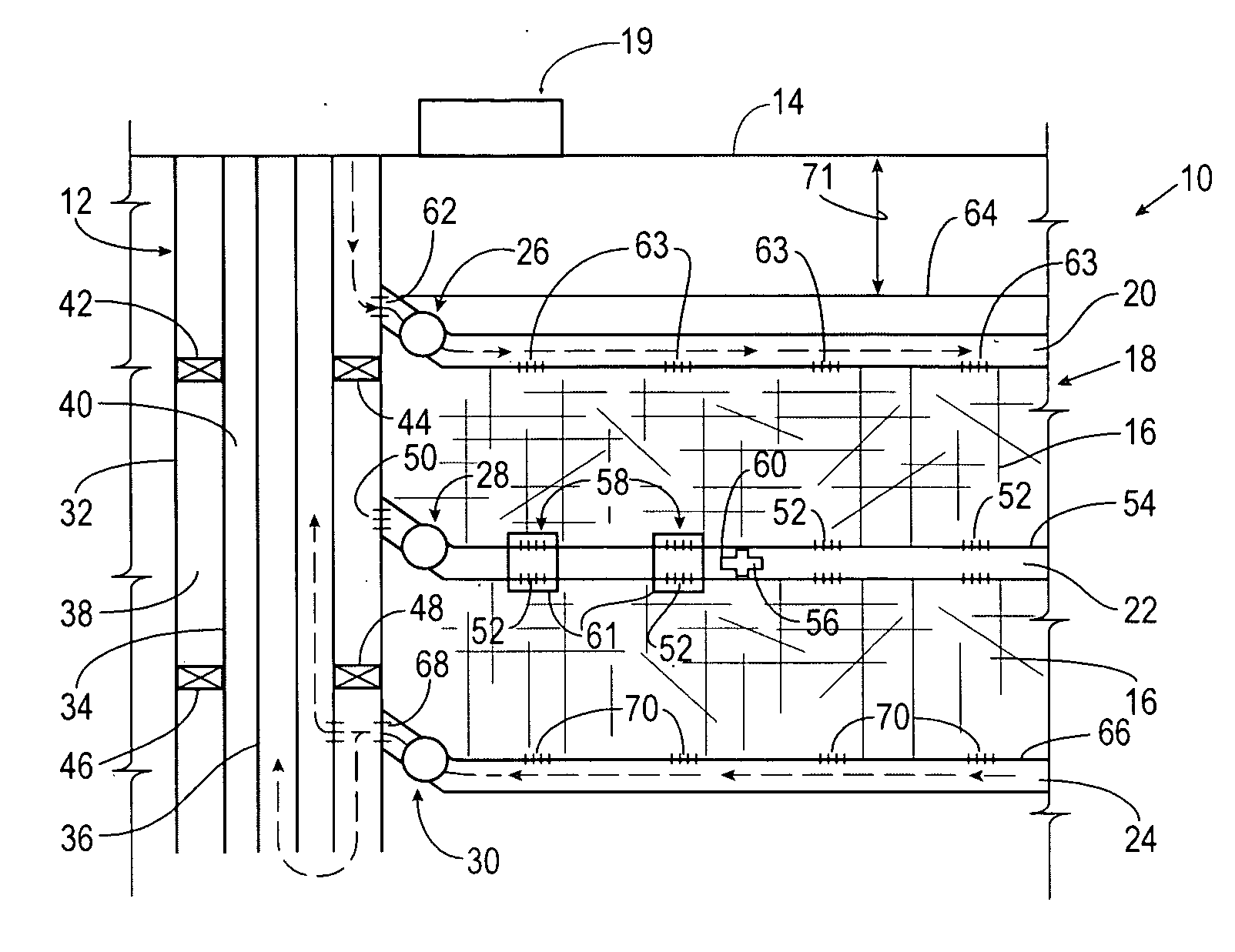

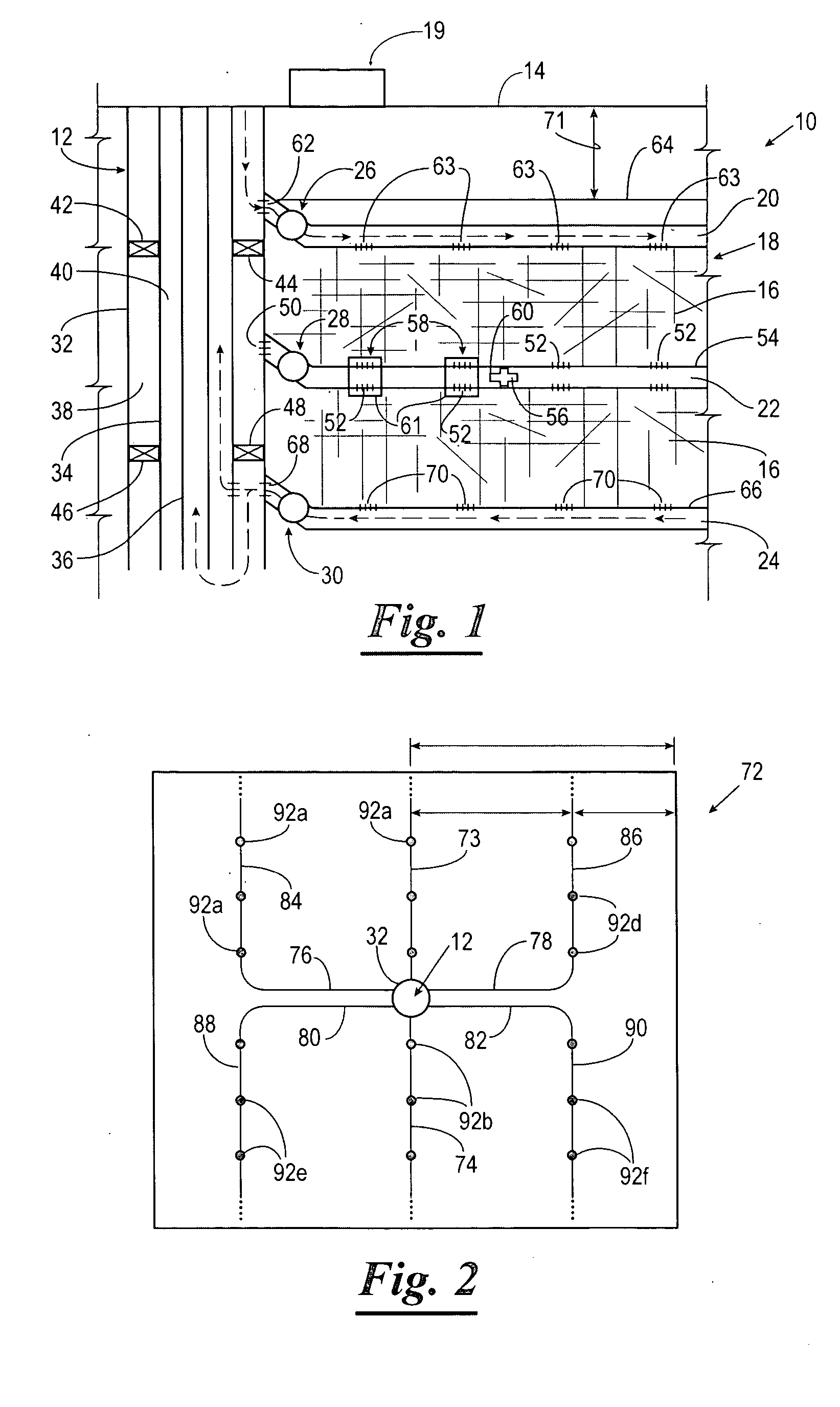

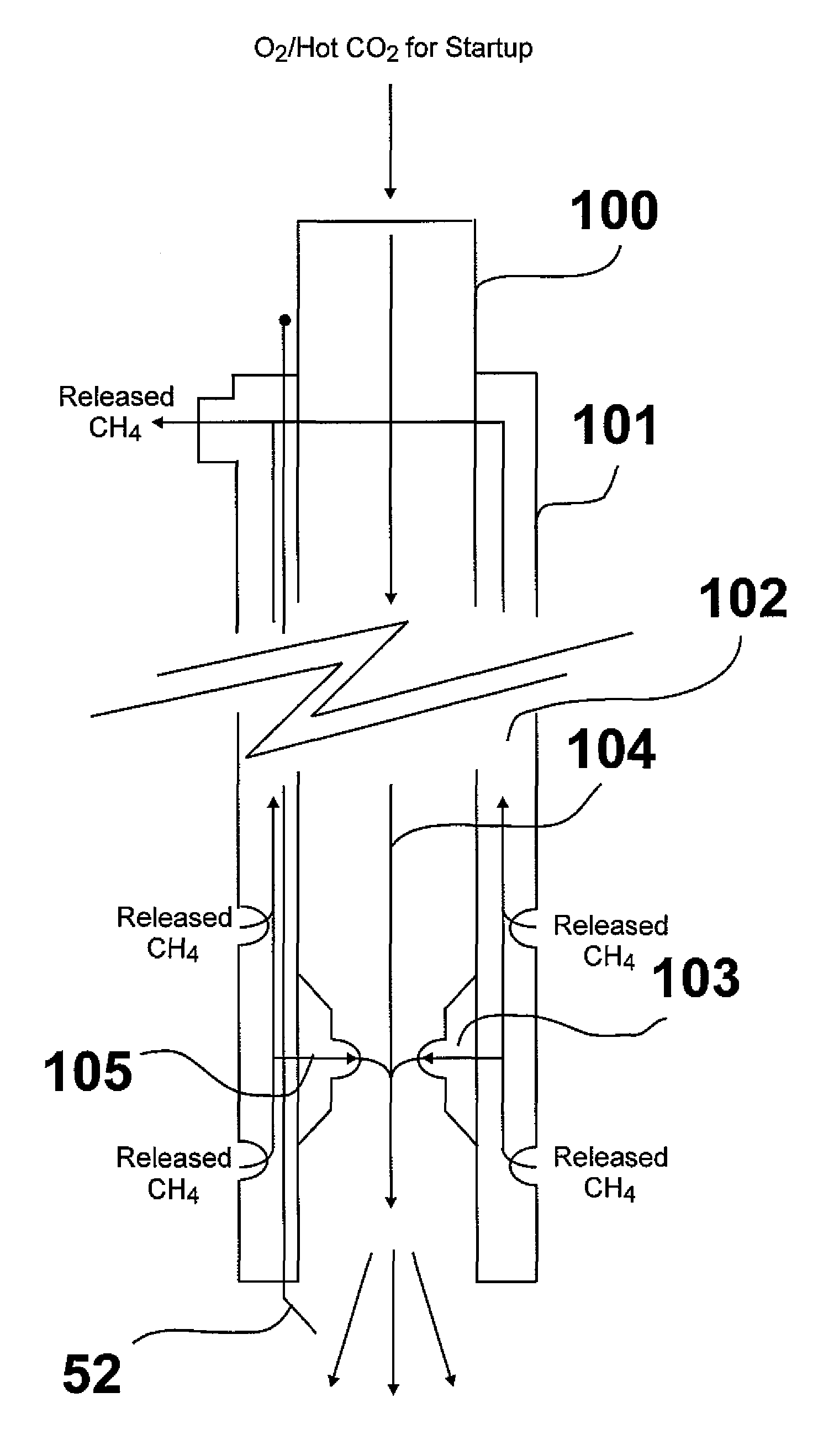

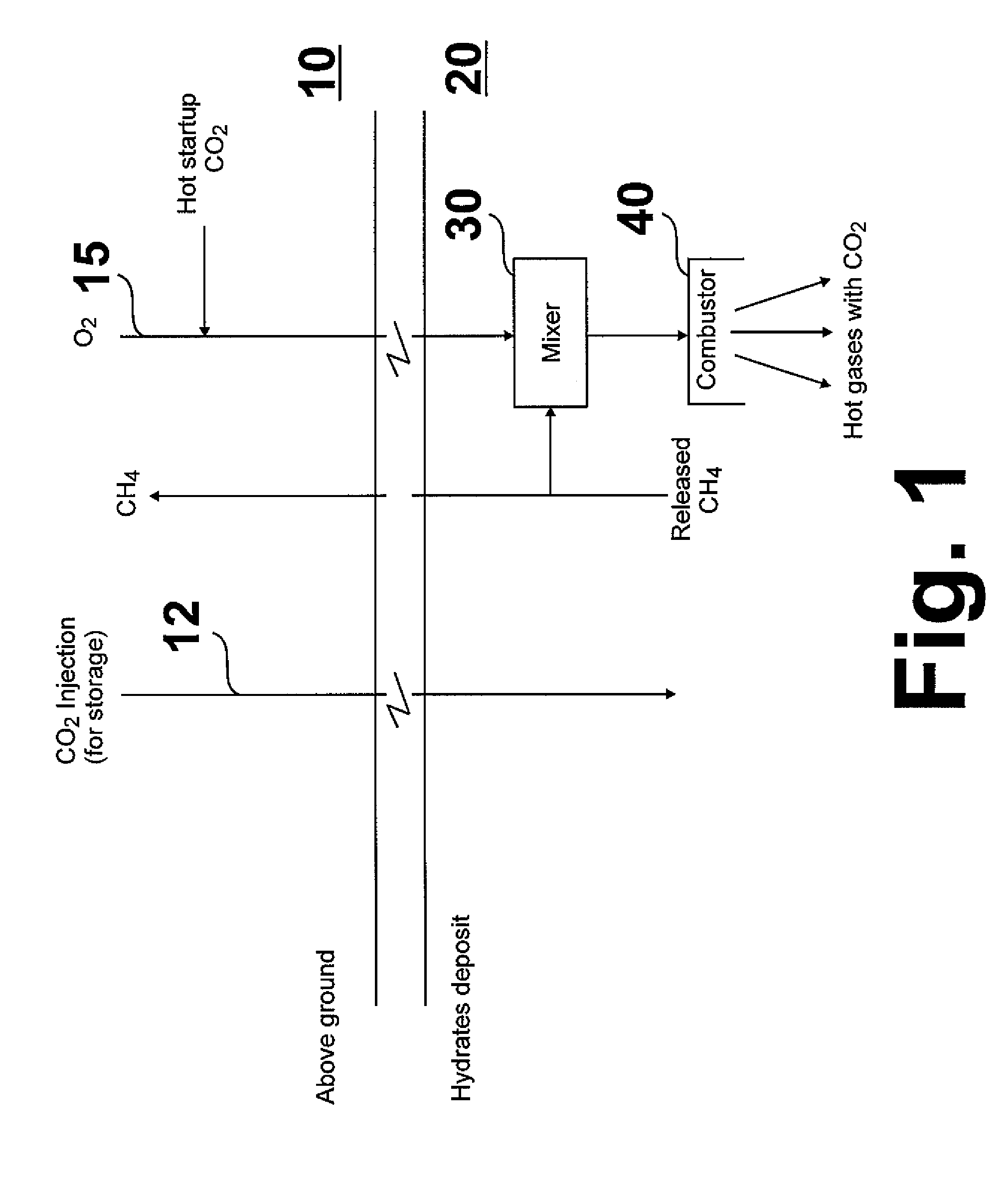

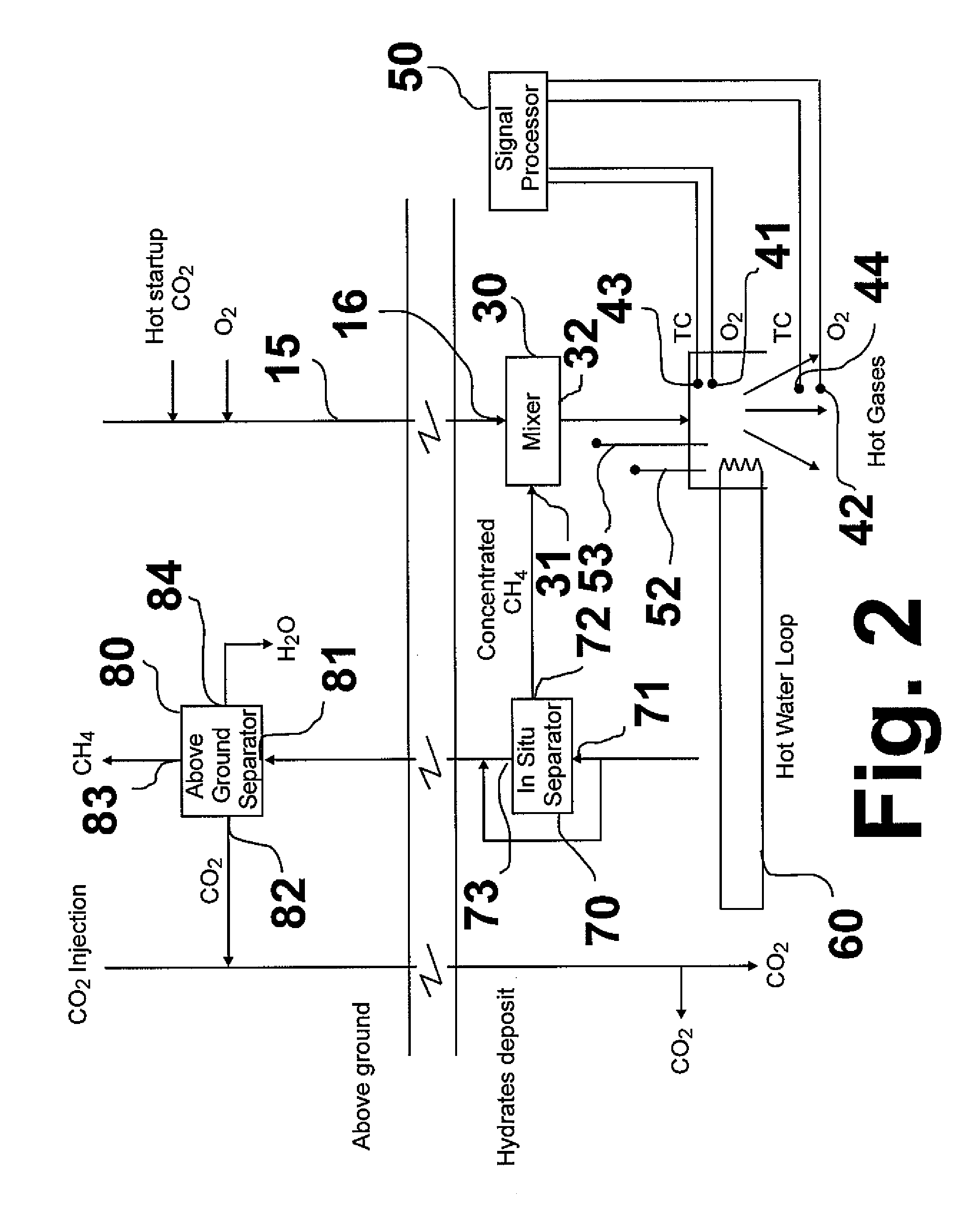

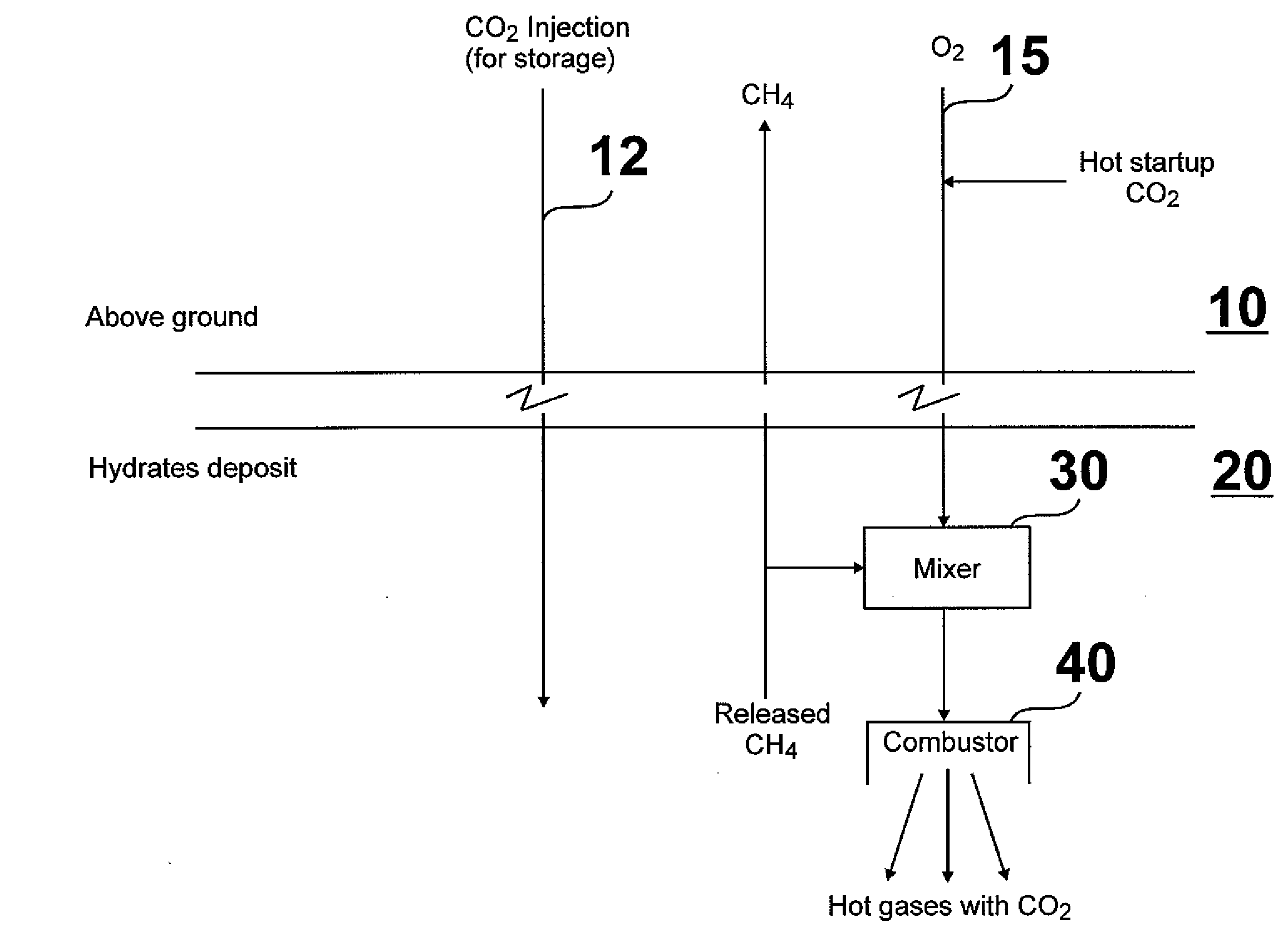

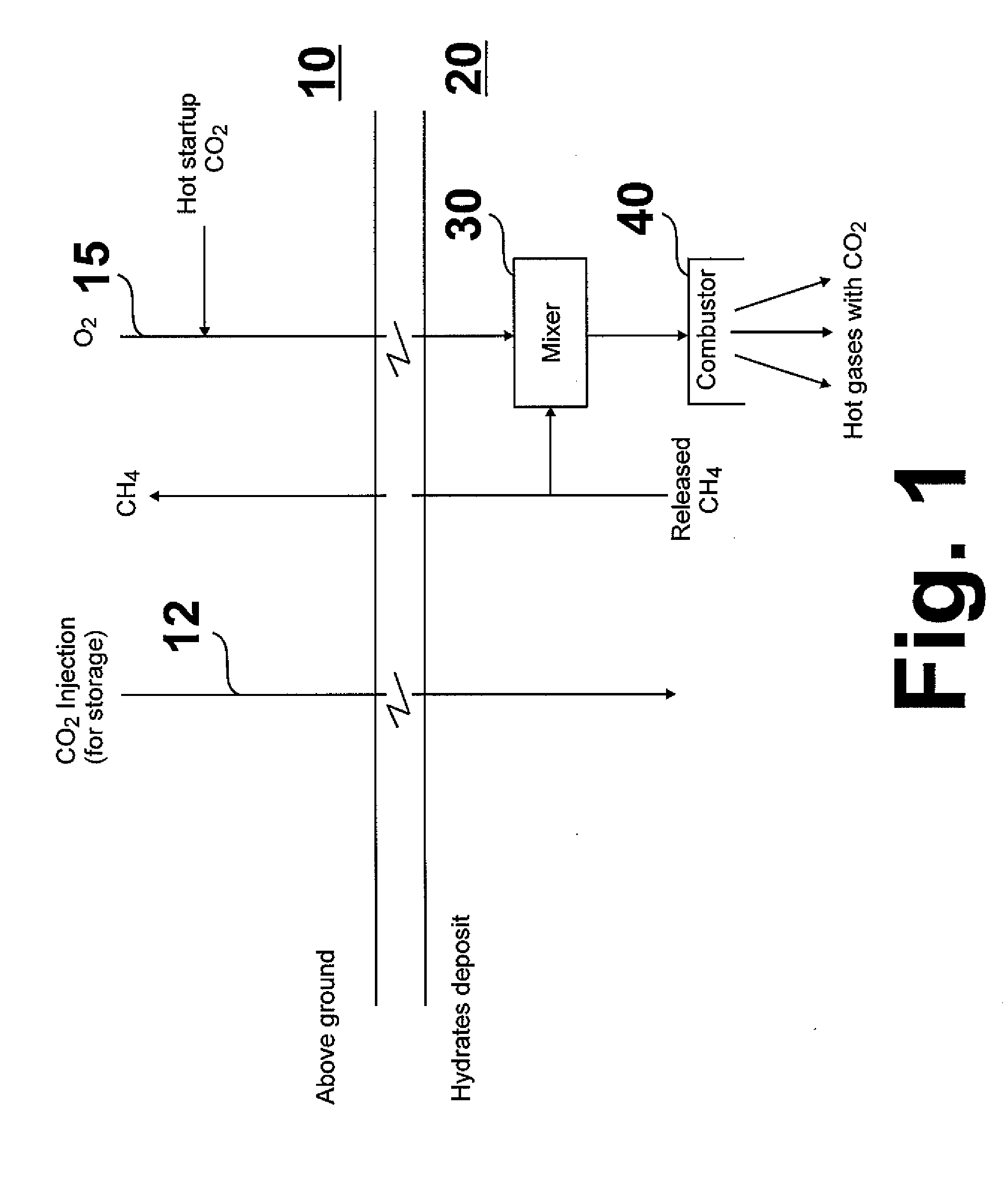

Process and apparatus for release and recovery of methane from methane hydrates

A process and system for release and recovery of methane from subterranean methane hydrate deposits in which heated CO2 is used to displace methane from the methane hydrate deposits and a portion of the displaced methane is routed to a combustion device proximate the deposit for combustion in-situ, generating heated CO2 which is introduced into the deposit, displacing additional methane, a portion of which is routed to the combustion device, thereby providing a substantially self-sustaining process. Portions of the displace methane not routed to the combustion device are captured for use elsewhere.

Owner:GAS TECH INST

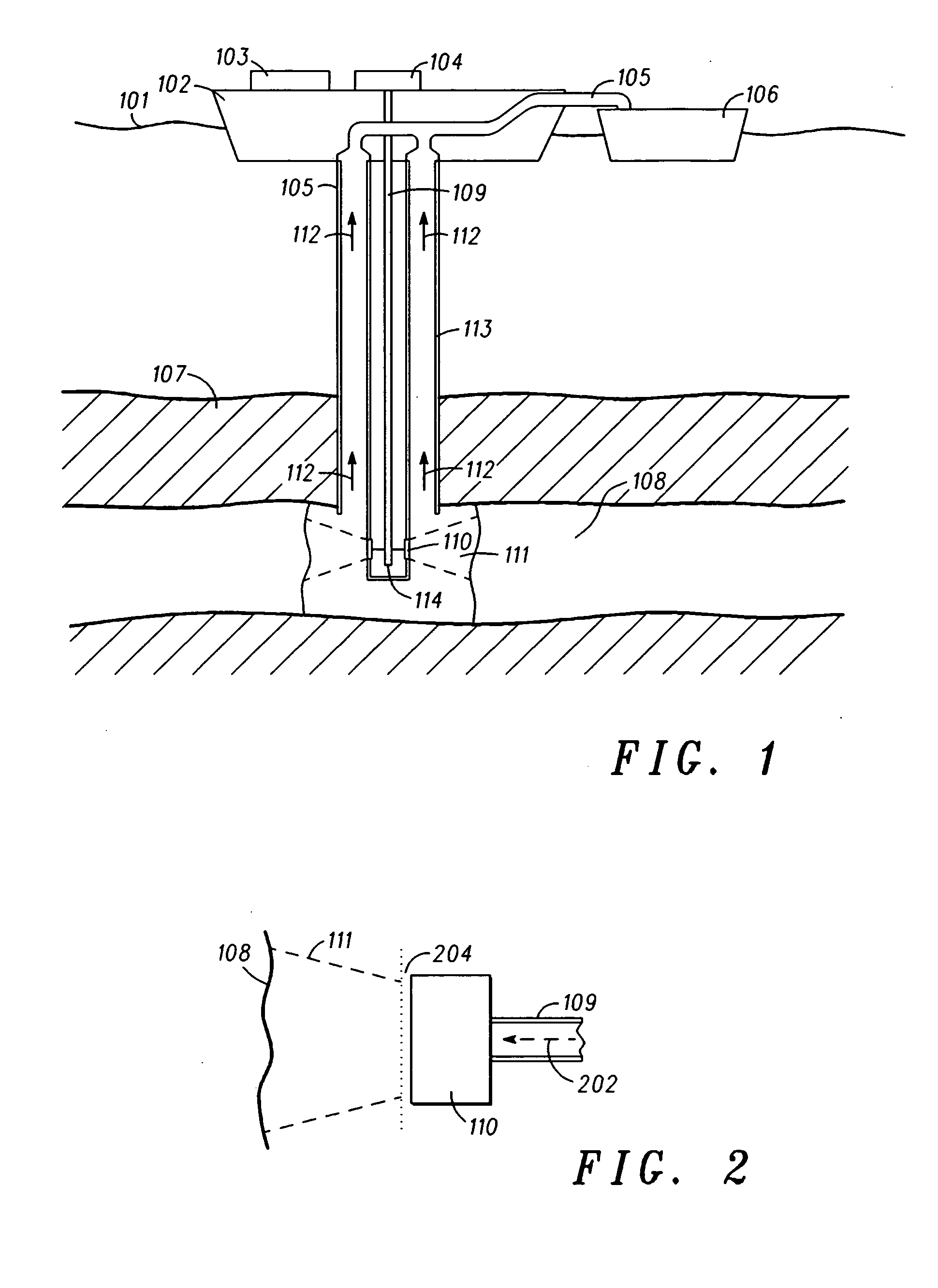

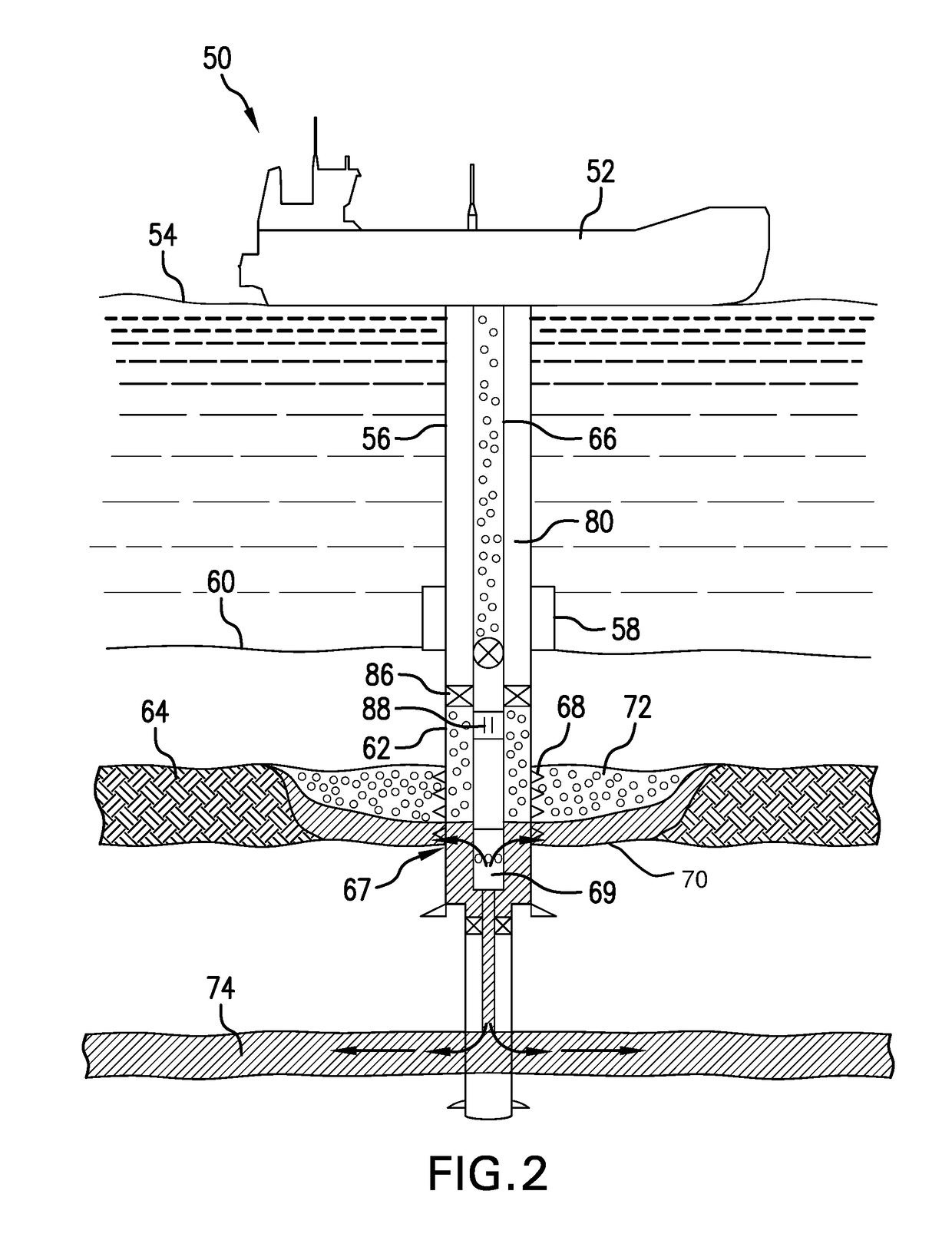

Method for natural gas production

ActiveUS20050016725A1Prevent heat lossWeaken energyConstructionsFluid removalDiluentMethane clathrate

The present invention is a method and system for dissociating methane hydrate deposits in-situ. An oxidizer fluid and a supply of fuel, both at a pressure higher than that of the methane hydrate deposit, are supplied and delivered to the methane hydrate deposit. The fuel is combusted downhole by reacting it with the oxidizer fluid to provide combustion products. The combustion products are placed in contact with a diluent fluid to produce a heated product fluid. The heated product fluid is injected into the methane hydrate deposit whereby methane is dissociated from the methane hydrate and made available for extraction. In addition, carbon dioxide may be made available to promote the formation of carbon dioxide hydrates from the liberated methane hydrate water.

Owner:PRECISION COMBUSTION

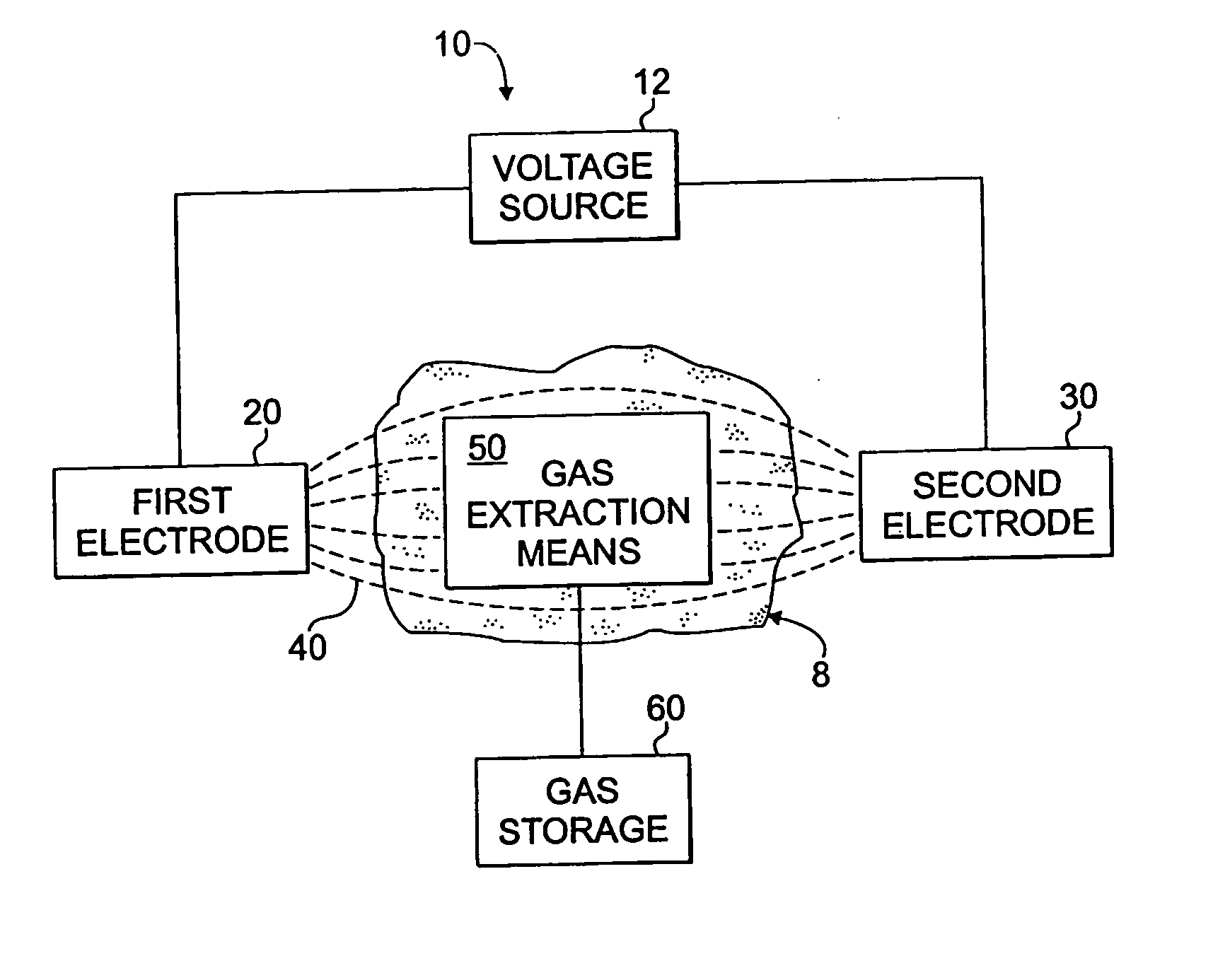

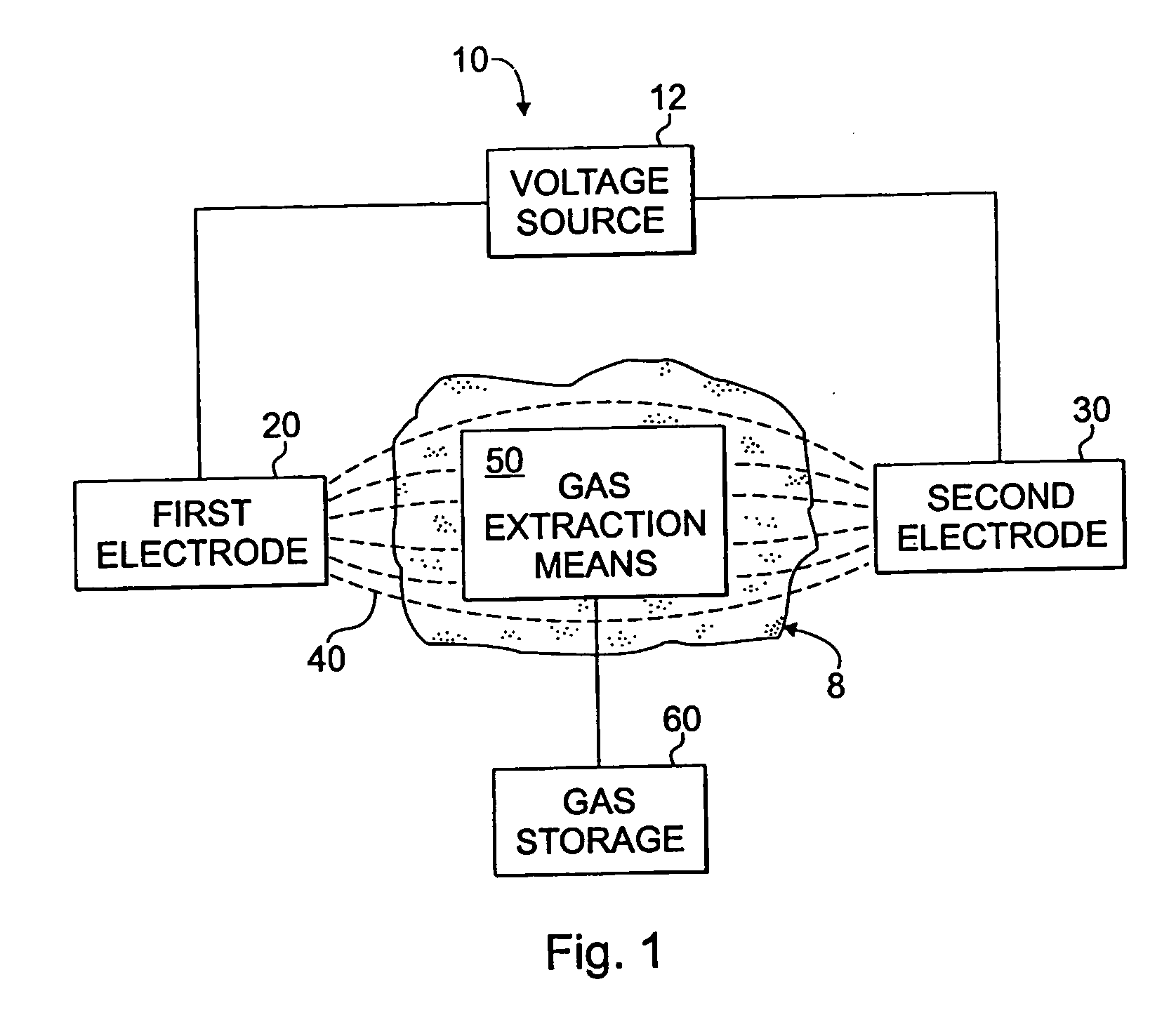

Method and system for producing methane gas from methane hydrate formations

Owner:ELECTRO PETROLEUM INC

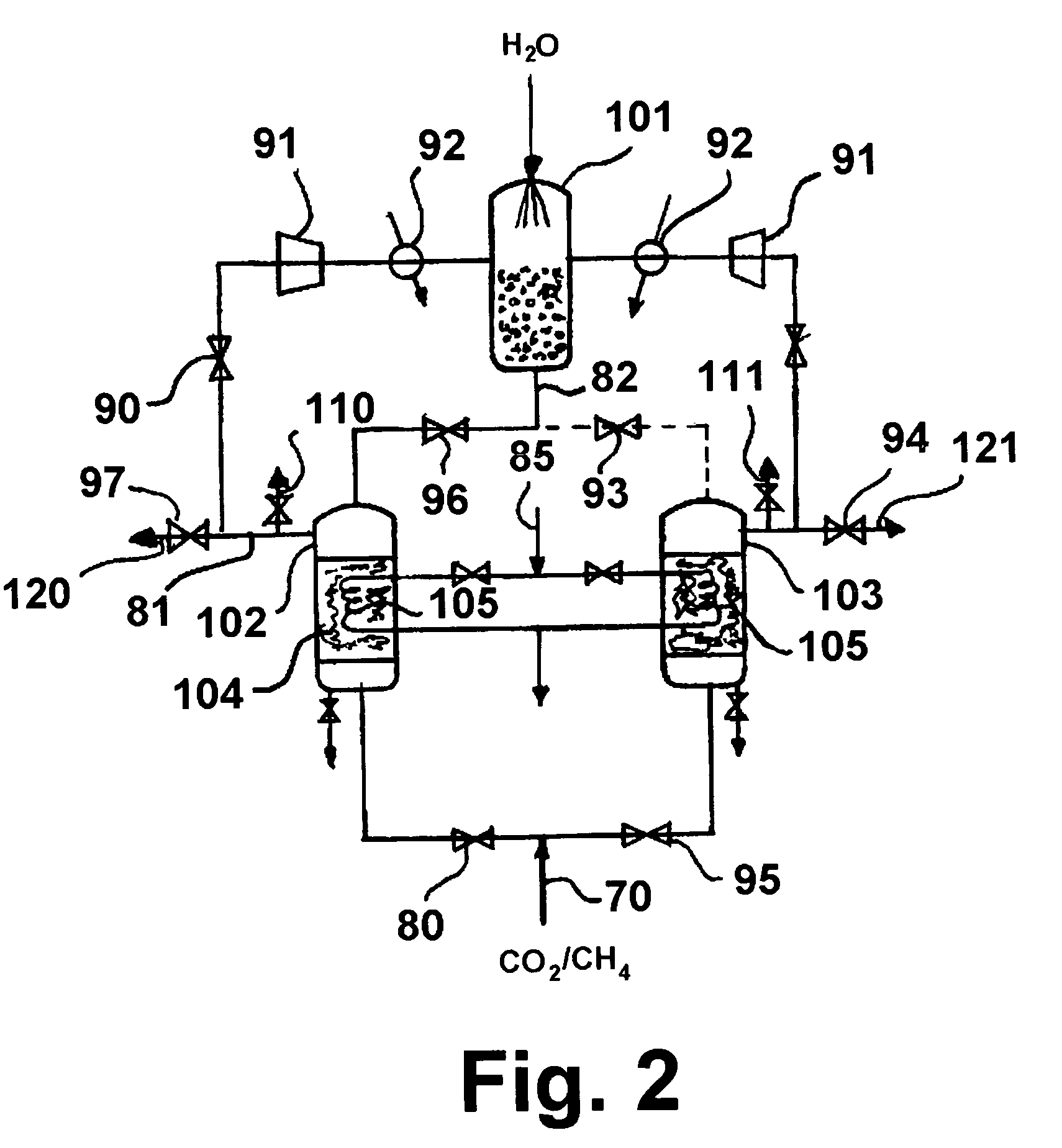

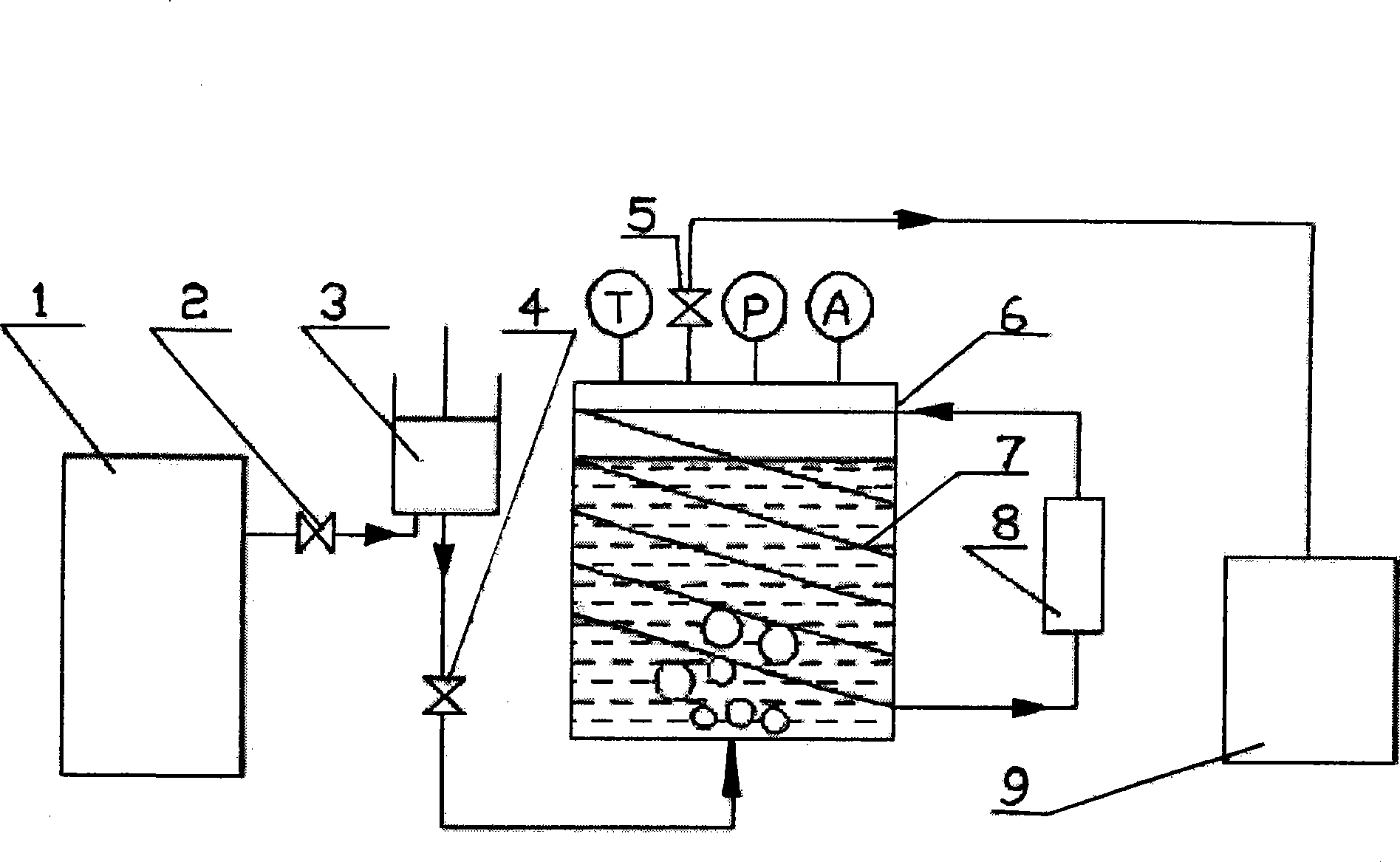

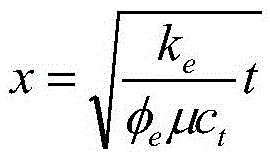

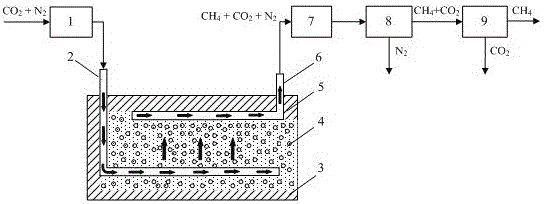

Biogas purification method and system

InactiveCN101428190AHigh purityLow purityPressurized chemical processDispersed particle separationPurification methodsLiquid water

The invention relates to a marsh gas purification method and a system thereof. The method comprises the following steps: keeping pressure below the pressure for the production of methane hydrate for the purpose of enabling carbon dioxide to react with sulfureted hydrogen to produce hydrate, and then separating methane gas from marsh gas. The marsh gas purification system comprises a marsh gas separating tank 6 and a marsh gas storage tank 1; liquid water is stored in the marsh gas separating tank 6; the marsh gas storage tank 1 is communicated with a compressor 2 through a pipeline equipped with a valve; the compressor 2 is communicated with the marsh gas separating tank 6 through a pipeline equipped with a valve; a refrigeration pipe 7 is coiled on the inner wall of the marsh gas separating tank 6; two ends of the refrigeration pipe 7 are mounted respectively on a refrigerator 8 positioned outside the marsh gas separating tank 6; the marsh gas separating tank 6 is communicated with a methane storage tank 9 through a pipeline equipped with a valve; and a marsh gas sampler A, a pressure sensor P, and a temperature sensor T are separately mounted on the marsh gas separating tank 6.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

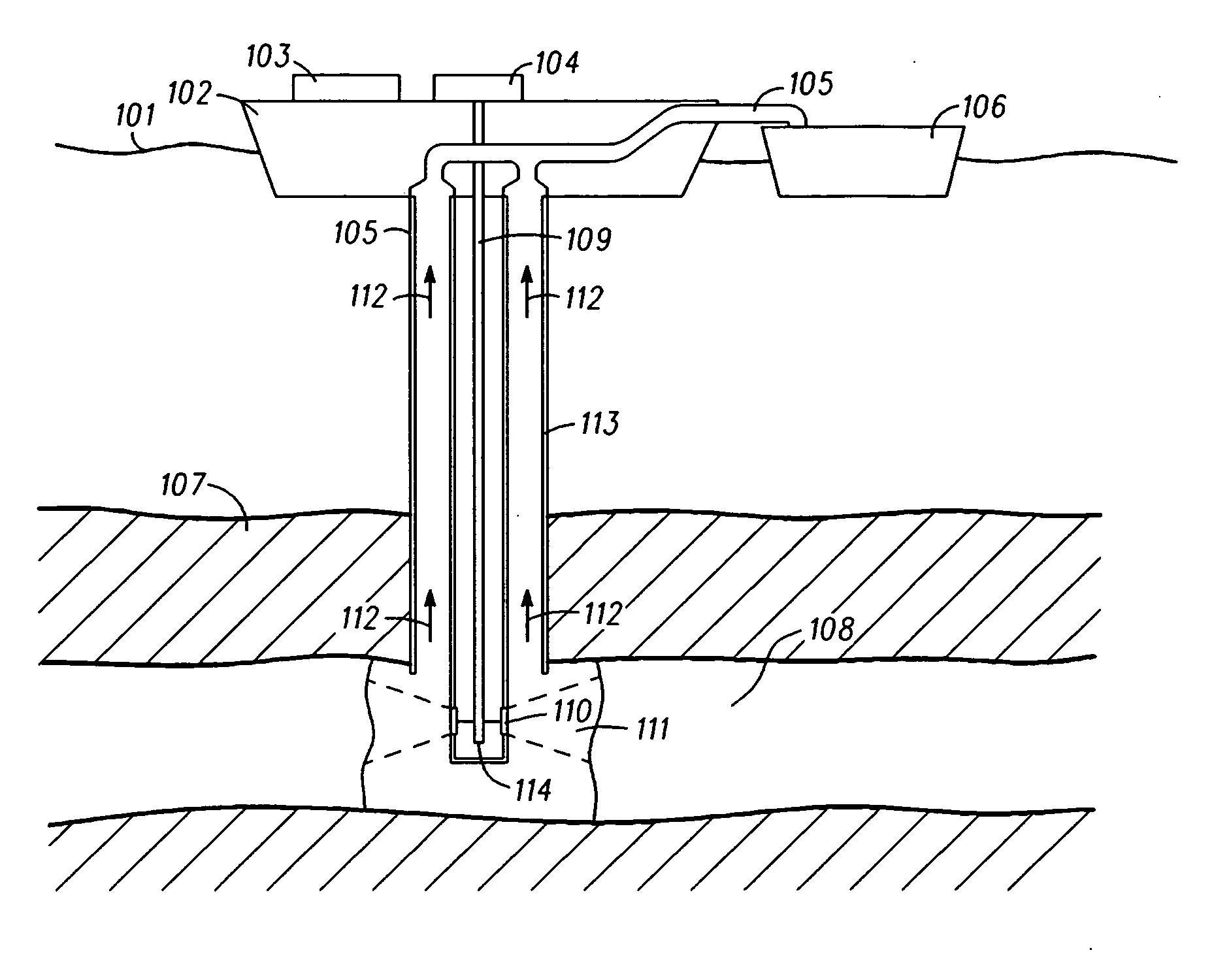

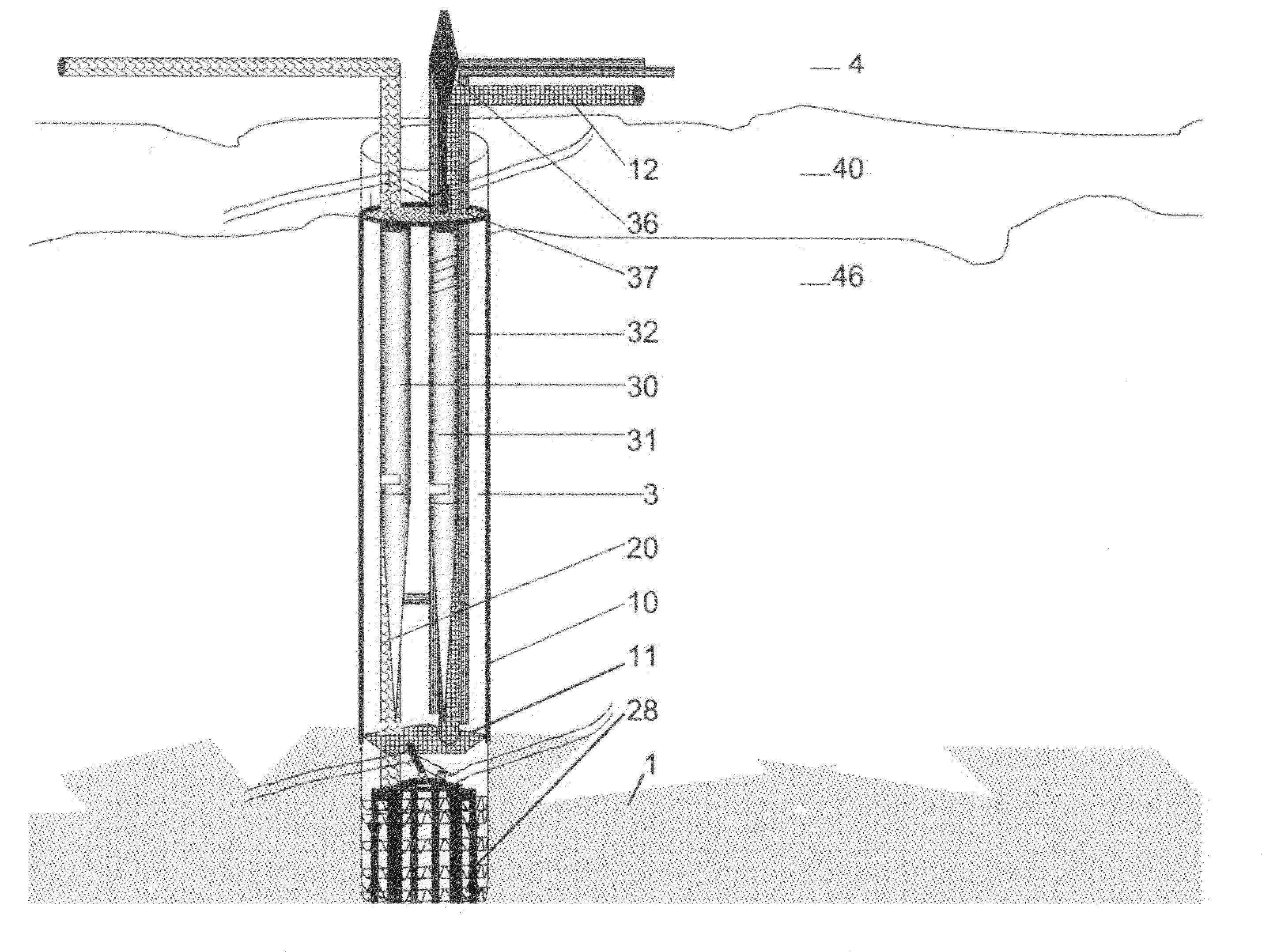

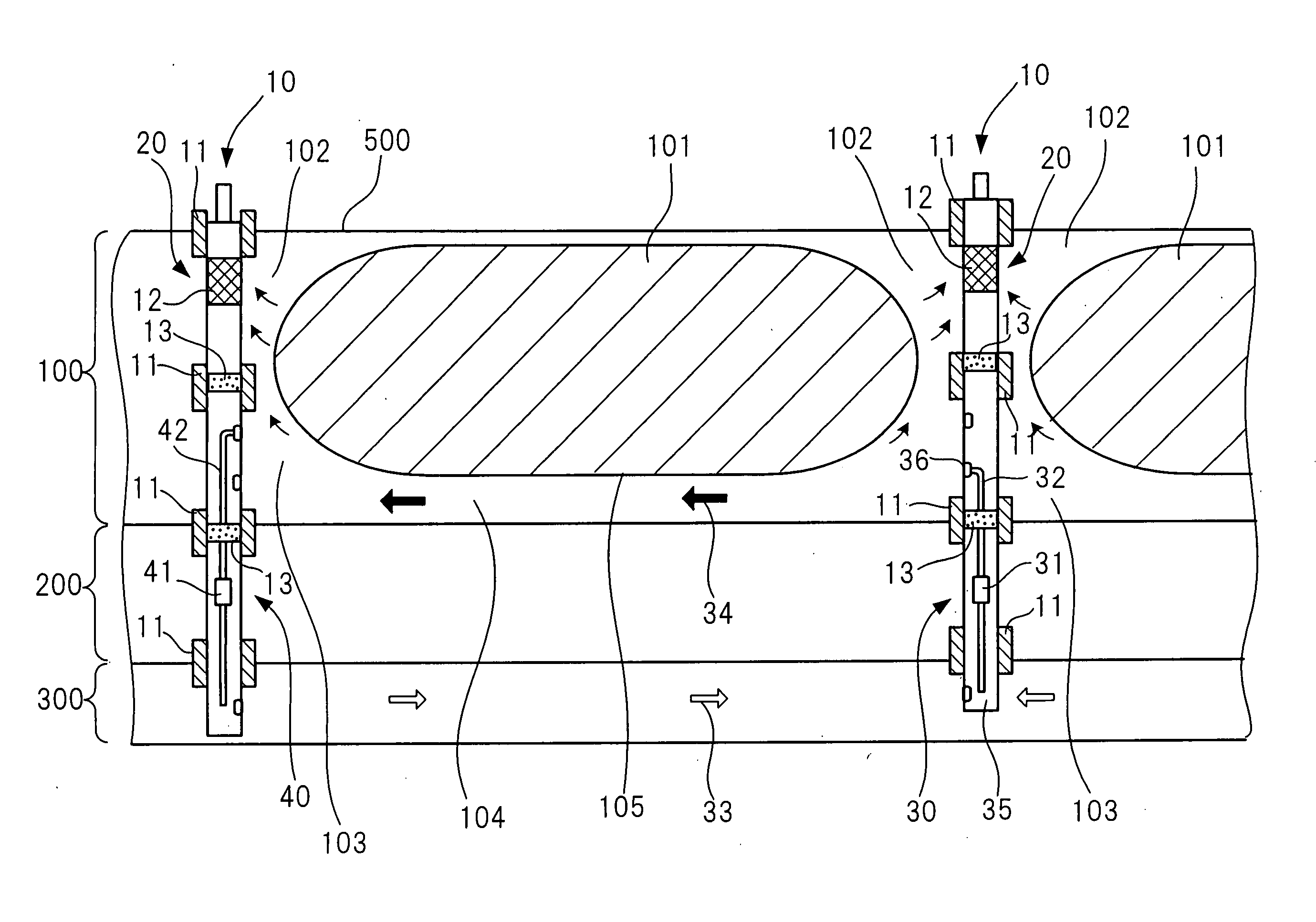

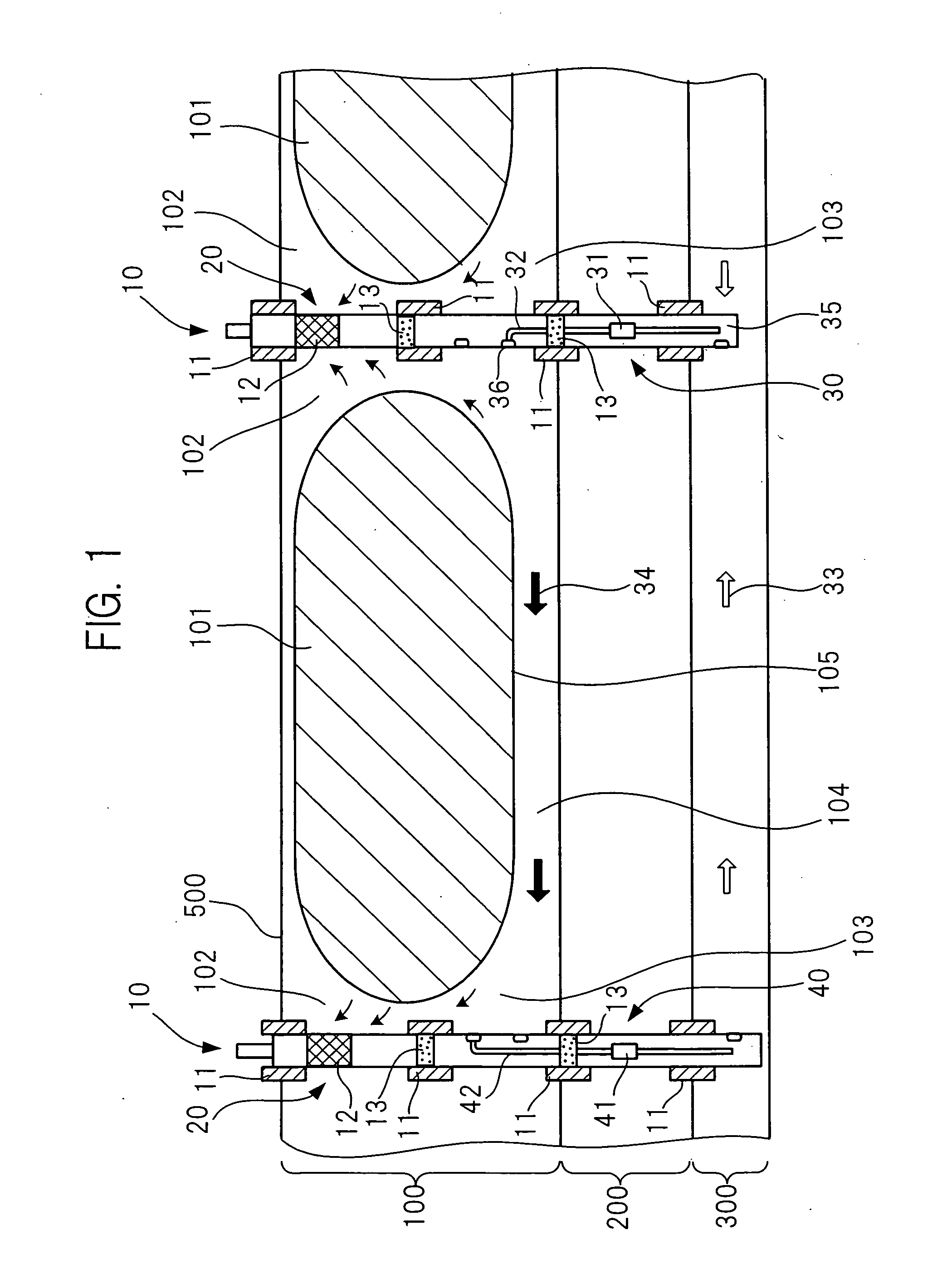

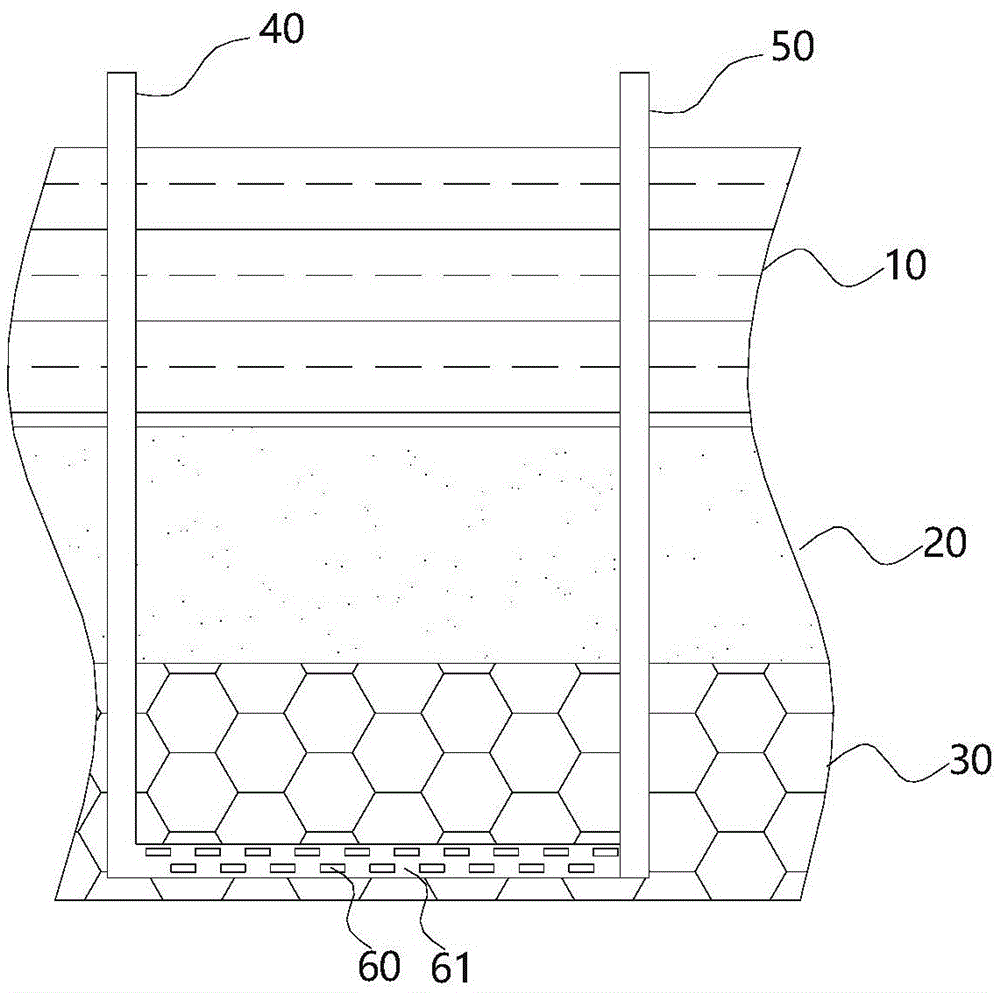

Methane hydrate dissociation accelerating and methane gas deriving system

ActiveUS20100132933A1Stable supplyHigh fuel costConstructionsGeothermal energy generationHydrate dissociationWarm water

It is an object of the present invention to provide a deriving technique with economy and technical difficulty improved without depending on fuel consumption for a heat source when methane gas is derived from a methane hydrate layer. Warm water is pumped up by a pump from an underground aquifer present 1000 to 1500 m below the seabed, geothermal energy is caused to flow through a permeable layer below a methane hydrate layer, a dissociation boundary surface of an un-dissociated area of the methane hydrate layer is dissociated to generate methane gas, the methane gas is led into a production well from peripheral areas and through a gas inlet screen and caused to rise so that the methane gas is collected on the sea.

Owner:JAPAN DRILLING CO LTD +1

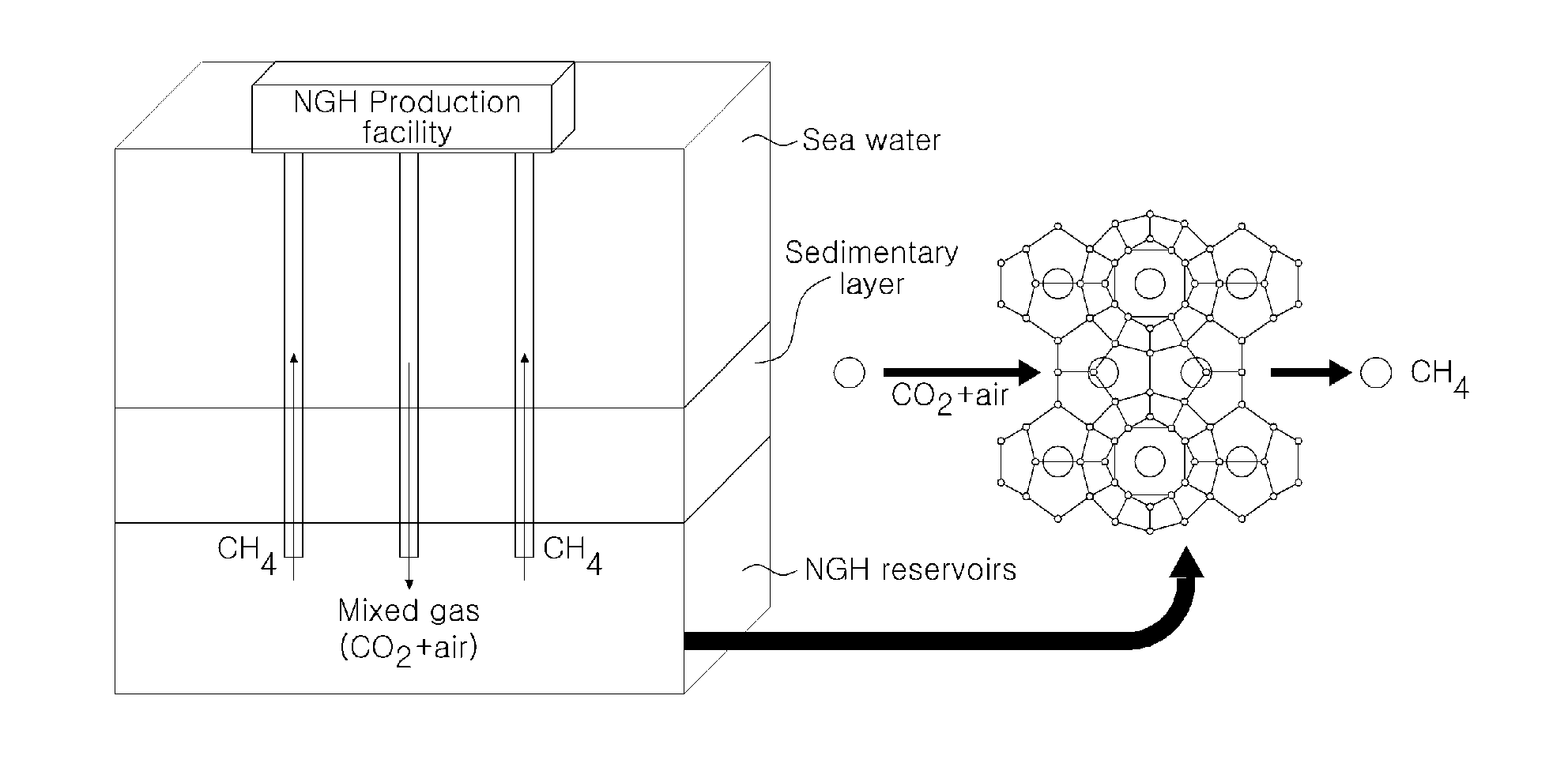

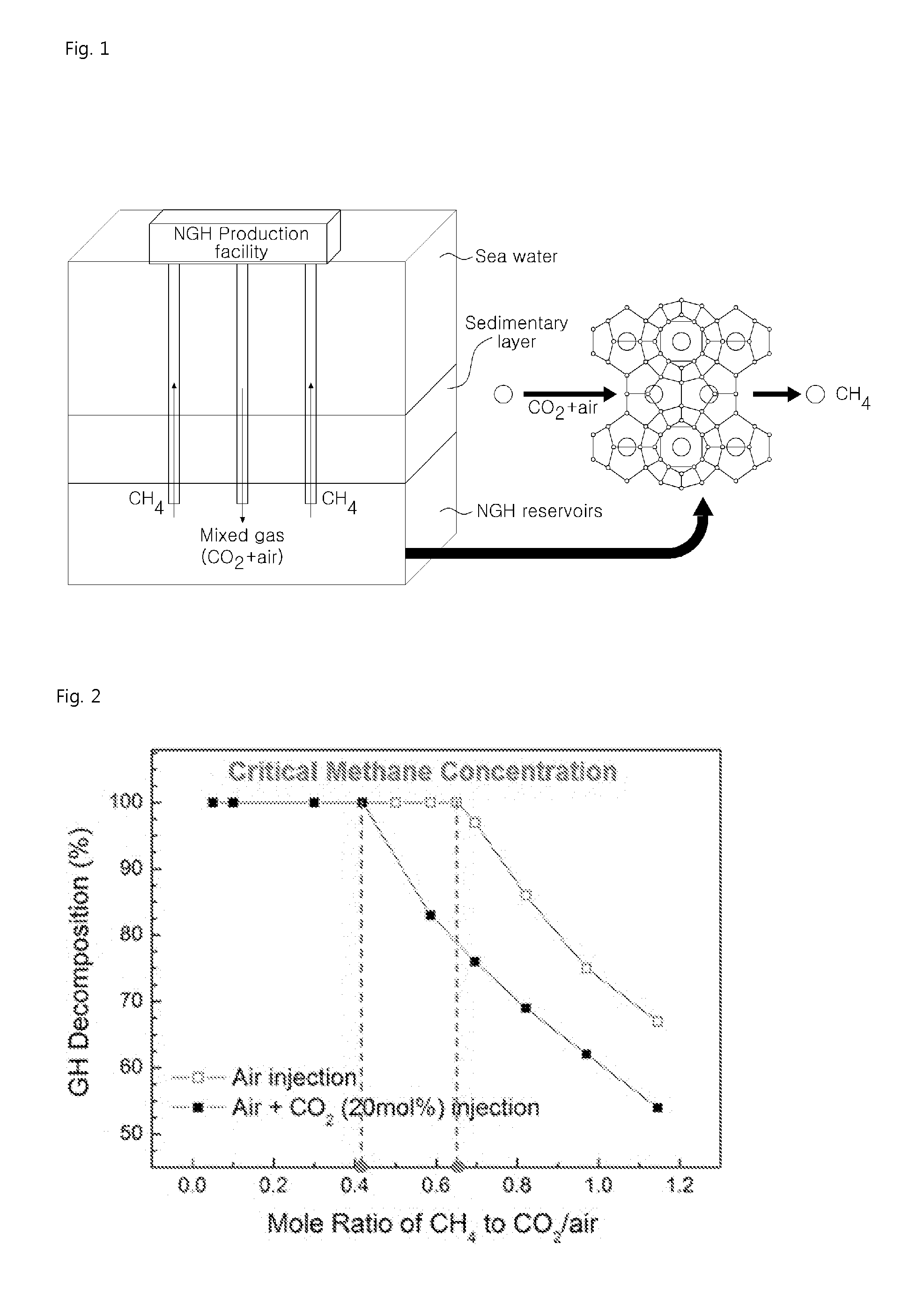

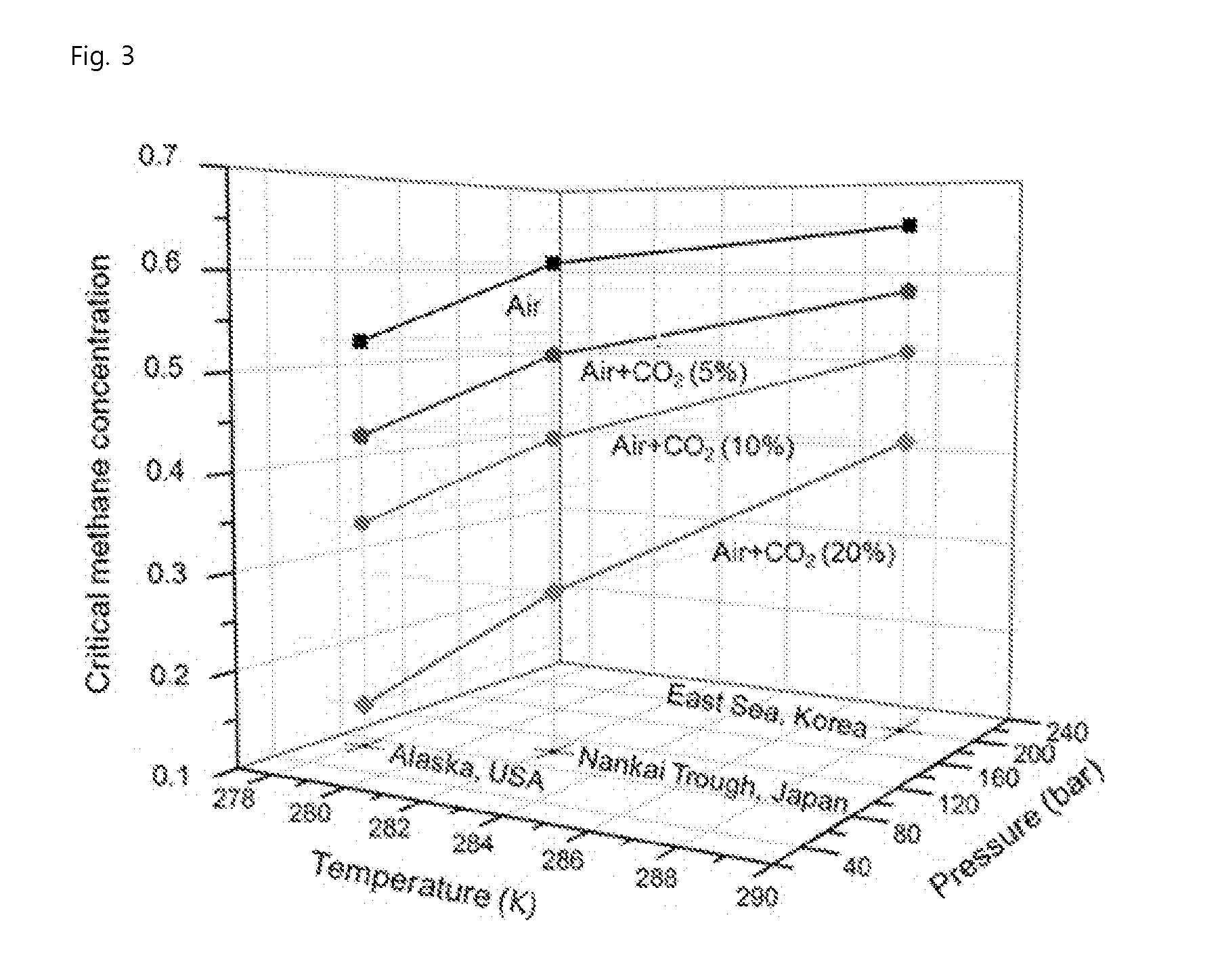

Method for Recovering Methane Gas from Natural Gas Hydrate by Injecting CO2 and Air Mixed Gas

The present invention relates to a method for recovering methane gas from natural gas hydrates. In particular, it includes the step of adding a gas mixture containing air and carbon dioxide to an NGH of deep sea and the step of replacing the methane gas with gas mixture and the step of decomposition-replacement of methane hydrate.In accordance with the present invention, the invention is possible use as a technique for recovery of methane gas in the all-weather to induce replacement reaction using a gas mixture when the temperature of the technology applied is low and to induce degradation of solid methane hydrate by mixing gas when the temperature of the region technique is applied is high.Further, the method makes it possible to reduce costs than using conventional methods because the air is collected directly from the NGH reservoirs and compressed and is injected as a mixture with carbon dioxide and, there is no need to transport the infusion another gas. The invention may be widely used in the production of natural gas more effectively.

Owner:KOREA ADVANCED INST OF SCI & TECH

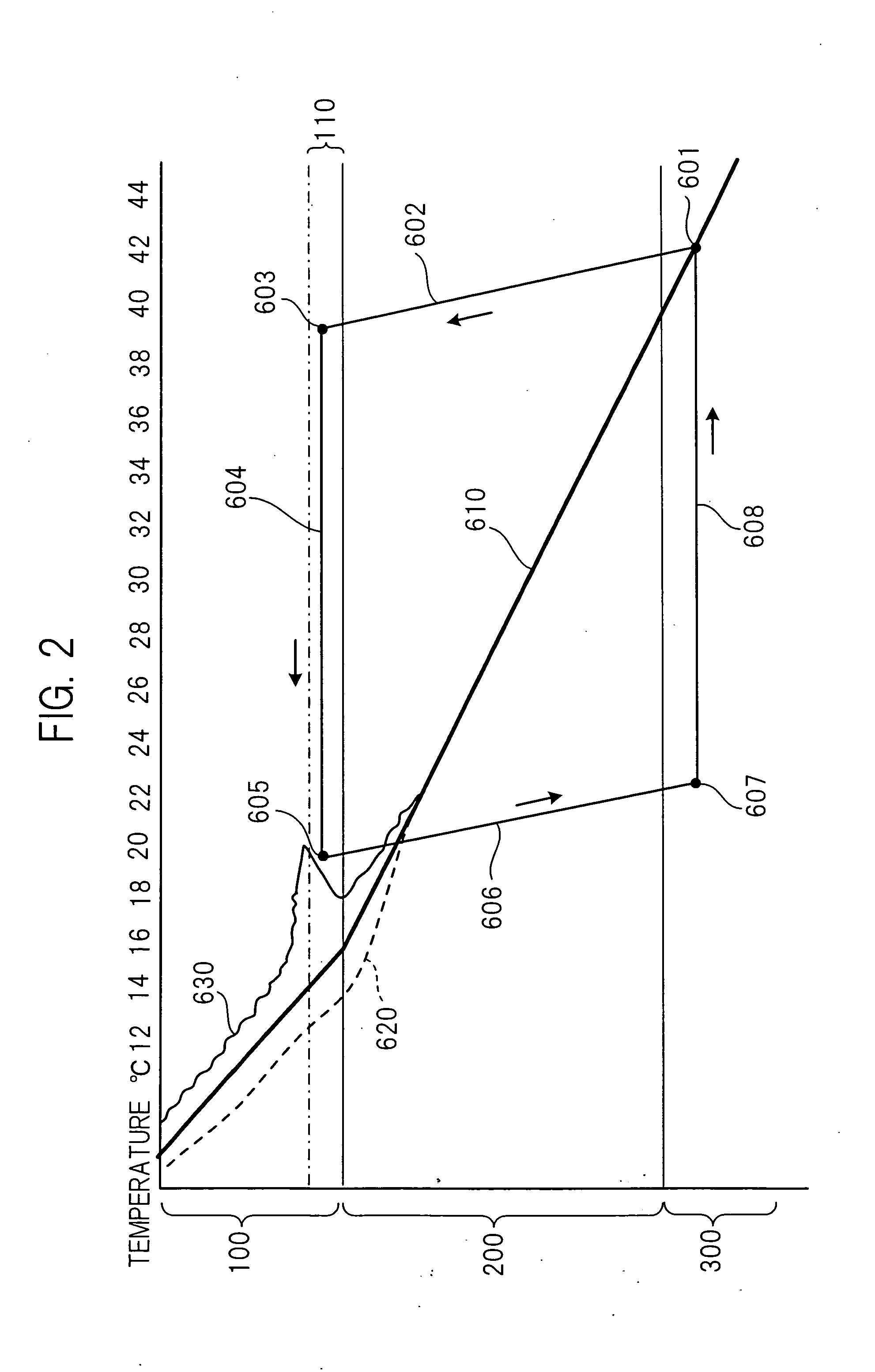

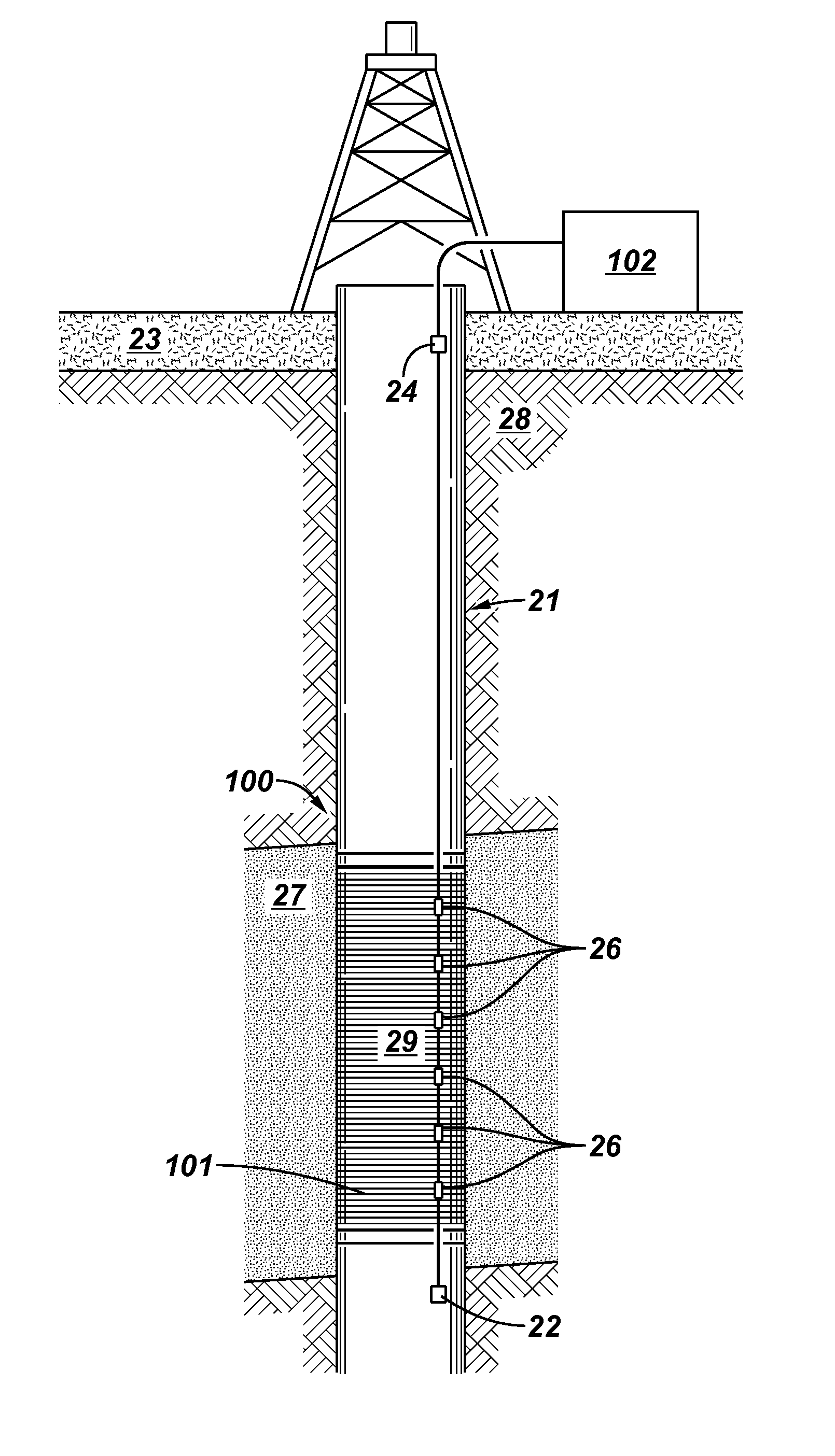

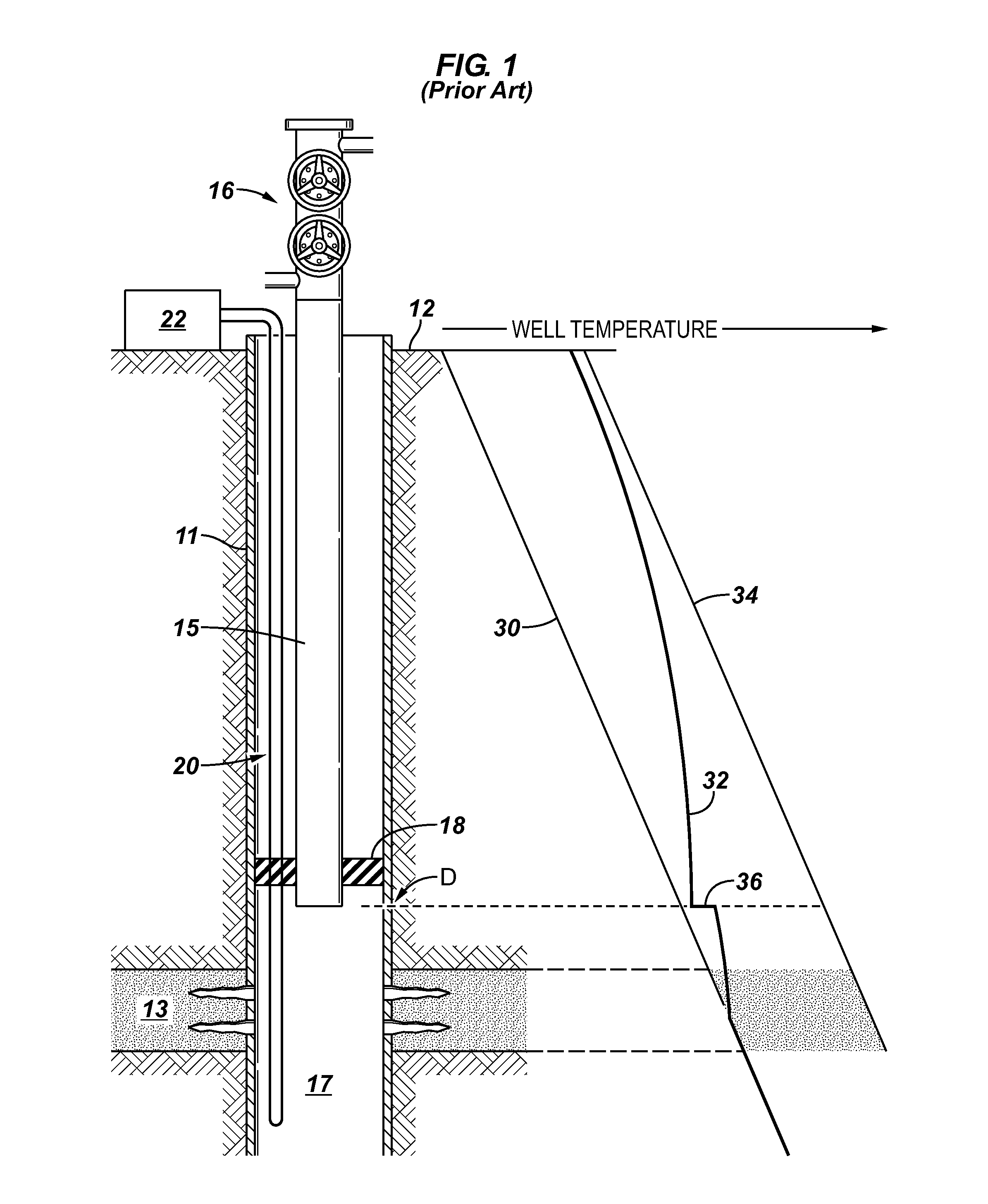

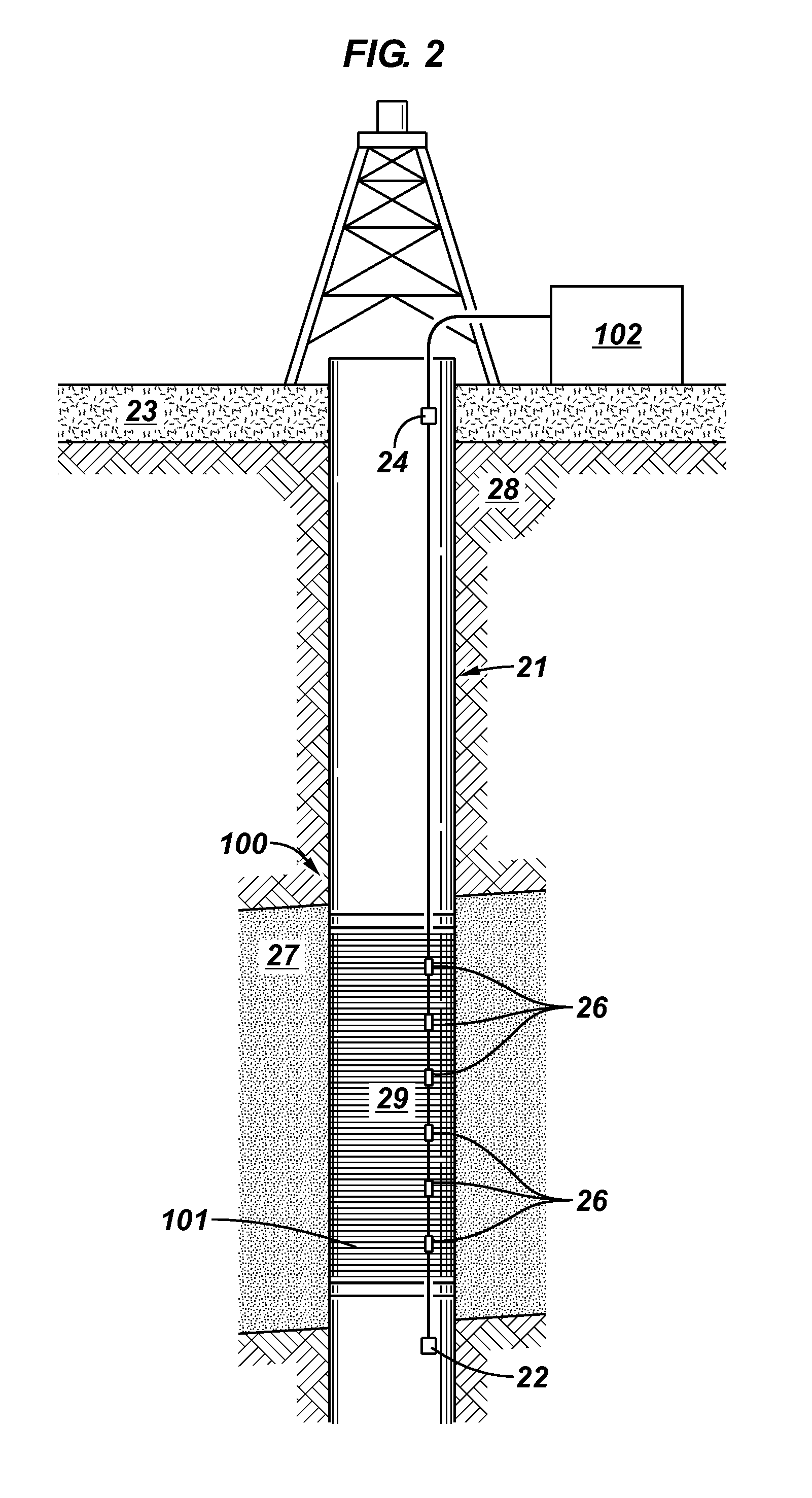

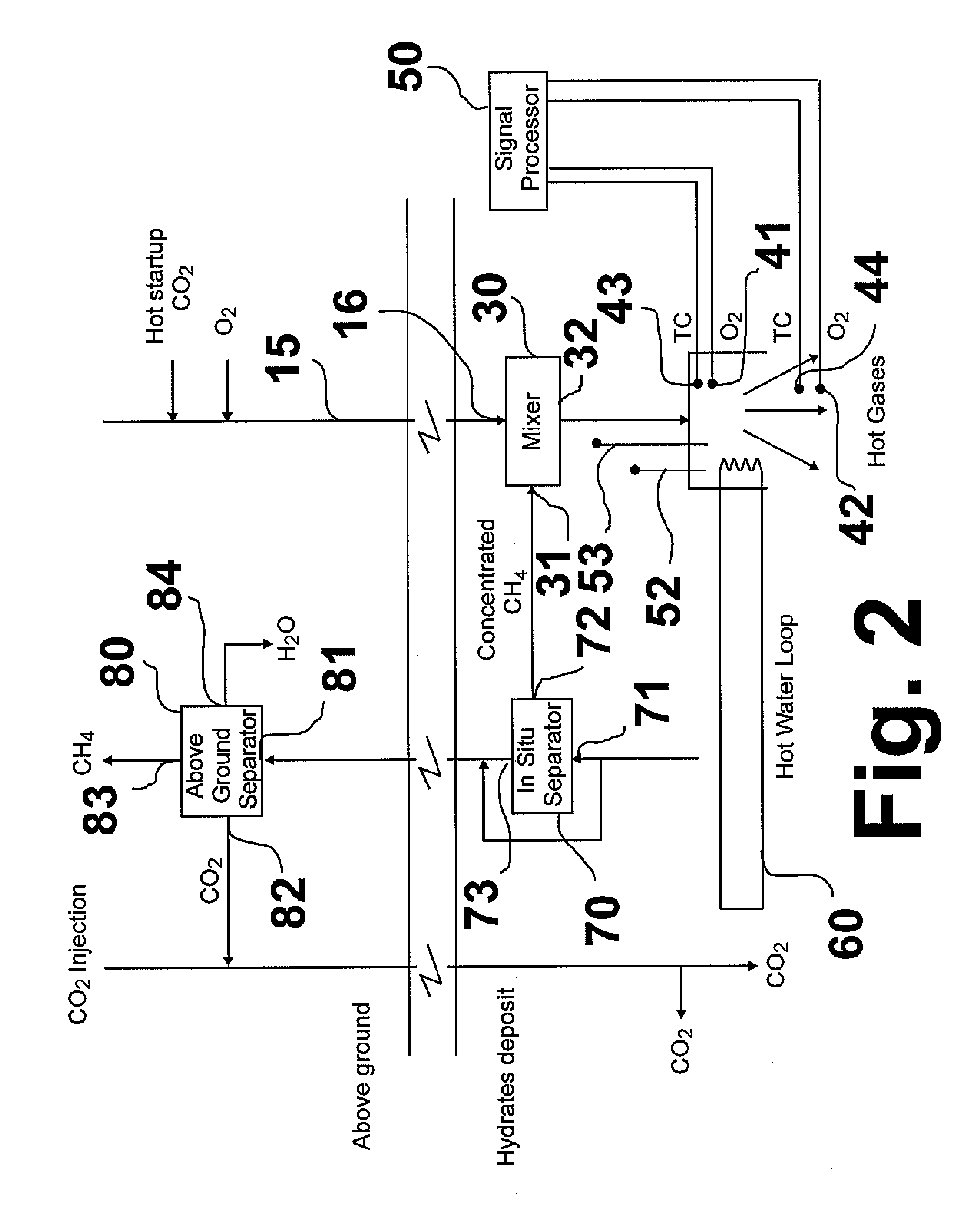

Method and apparatus to monitor reformation and replacement of co2/ch4 gas hydrates

A method for monitoring production from a methane hydrate reservoir includes obtaining a plurality of temperature measurements in a wellbore connected with the methane hydrate reservoir; and deriving a parameter relating to conversion of methane hydrate to carbon dioxide (CO2) hydrate by injection of liquid CO2, wherein the deriving uses a modeling program and the plurality of temperature measurements, wherein the modeling program uses at least one parameter relating to a thermodynamic properties that are substantially different between methane and CO2. The at least one parameter relating to thermodynamic properties may include Joule-Thomson coefficients of methane and CO2. The parameter relating to the conversion of methane hydrate to CO2 hydrate may include a ratio of methane and CO2 in a mixed fluid.

Owner:SCHLUMBERGER TECH CORP

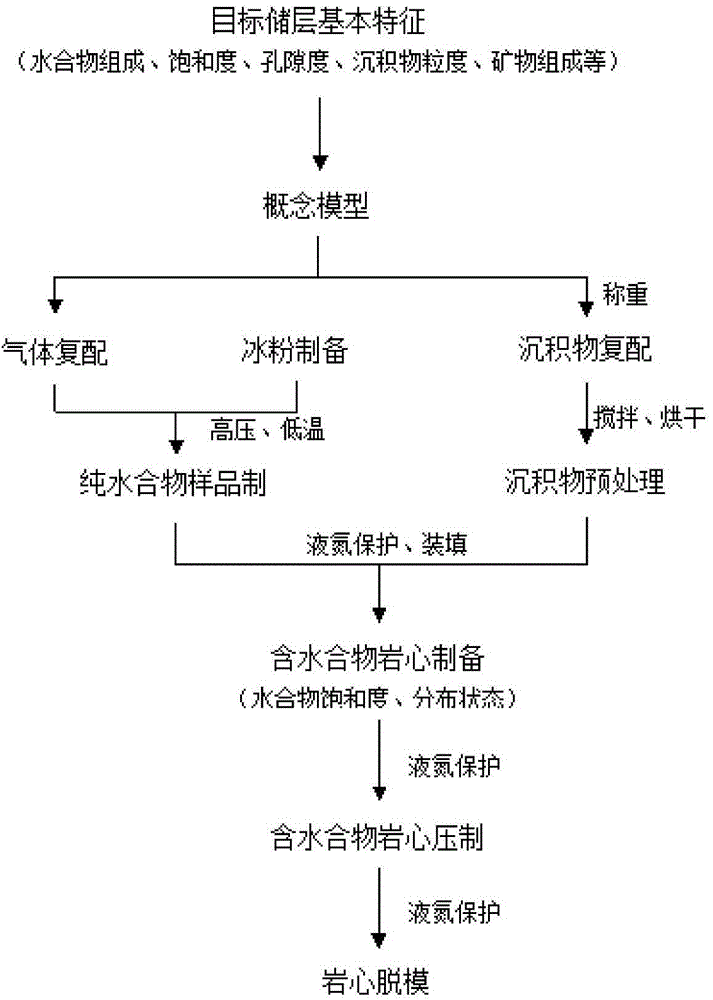

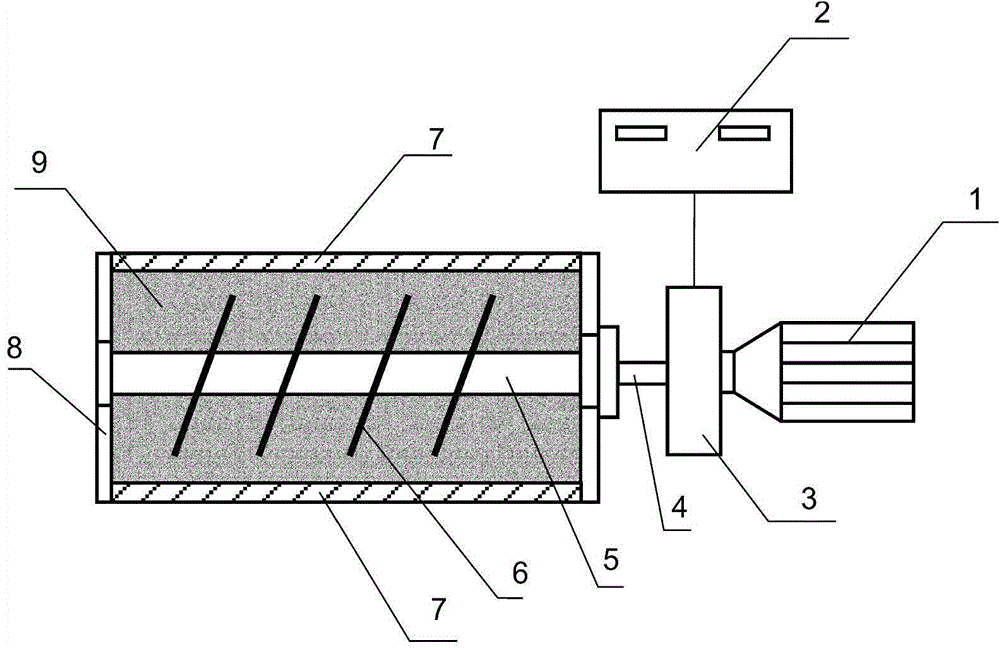

Pressing method for methane hydrate containing rock core sample

ActiveCN104949870AThe basic characteristics are the samePreparing sample for investigationRock corePre treatment

The invention discloses a pressing method for a methane hydrate containing rock core sample. The pressing method comprises the following steps: firstly, confirming the basic characteristics of an actual physical model; secondly, carrying out sediment compounding; thirdly, carrying out sediment pretreatment; fourthly, stirring and mixing a hydrate and the compound and pretreated sediment at low temperature; fifthly, manually pressing a rock core; finally, demoulding the pressed iron core. The pressing method has the benefit of better ensuring that the basic characteristics of the pressed methane hydrate containing rock core sample are basically consistent with those of a target reservoir.

Owner:QINGDAO INST OF MARINE GEOLOGY

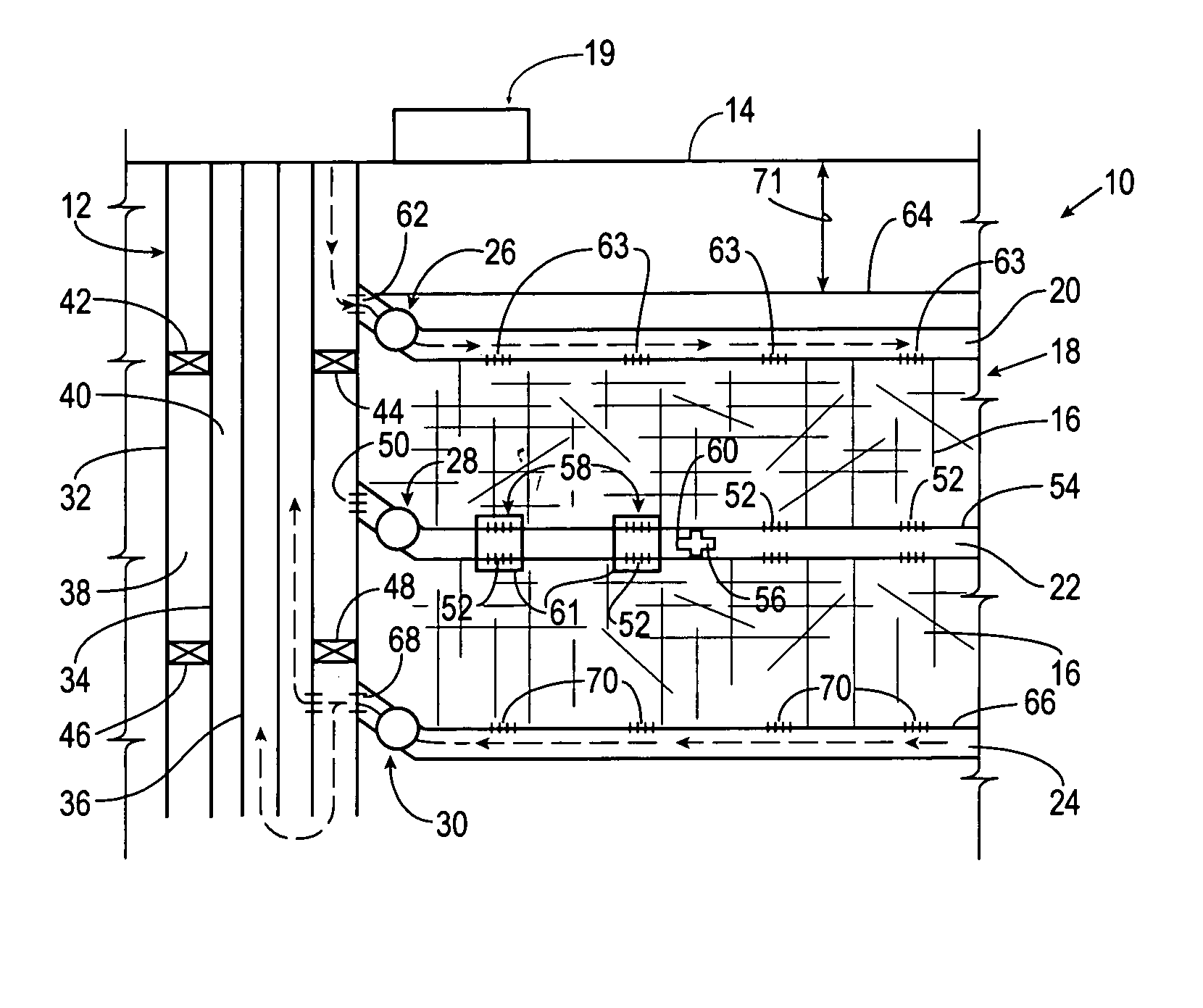

Process and apparatus for release and recovery of methane from methane hydrates

InactiveUS20100243245A1Reduce expenditureIncreases net heating valueSurveyConstructionsCombustionMethane clathrate

A process and system for release and recovery of methane from subterranean methane hydrate deposits in which heated CO2 is used to displace methane from the methane hydrate deposits and a portion of the displaced methane is routed to a combustion device proximate the deposit for combustion in-situ, generating heated CO2 which is introduced into the deposit, displacing additional methane, a portion of which is routed to the combustion device, thereby providing a substantially self-sustaining process. Portions of the displace methane not routed to the combustion device are captured for use elsewhere.

Owner:GAS TECH INST

Method and system for collecting seabed combustible ice

ActiveCN104278975AWon't leakNo wasteOther gas emission reduction technologiesFluid removalCompressed natural gasWater vapor

The invention provides a method and system for collecting seabed combustible ice. An inverted funnel-shaped methane collector is released to the bottom of water through an offshore methane collecting boat, in other words, the collector is reversely buckled on a methane hydrate accumulation layer on the a seabed, and a hot water injection pipeline is arranged at the bottom in the collector. High-temperature seawater or steam is injected into the bottom of the collector constantly, the combustible ice is heated and decomposed, decomposed methane is continuously conveyed to the methane collecting boat through a collecting pipeline at the top end in the collector and is cooled and pressurized to be made into liquefied natural gas (LNG) or compressed natural gas (CNG) or the combustible ice again to be stored, part of the methane is used for heating seawater, the methane collecting boat is used for dragging the methane collector at the bottom of the water, and continuous large-scale production can be achieved in the whole collecting process. The method and system for collecting the seabed combustible ice have the advantages that methane hydrates can stop being decomposed only if injection of the high-temperature water is stopped, insulation measures are taken on the pipelines and container pots, and emissions only contain carbon dioxide.

Owner:NINGBO CHENGDA MACHINERY RES INST

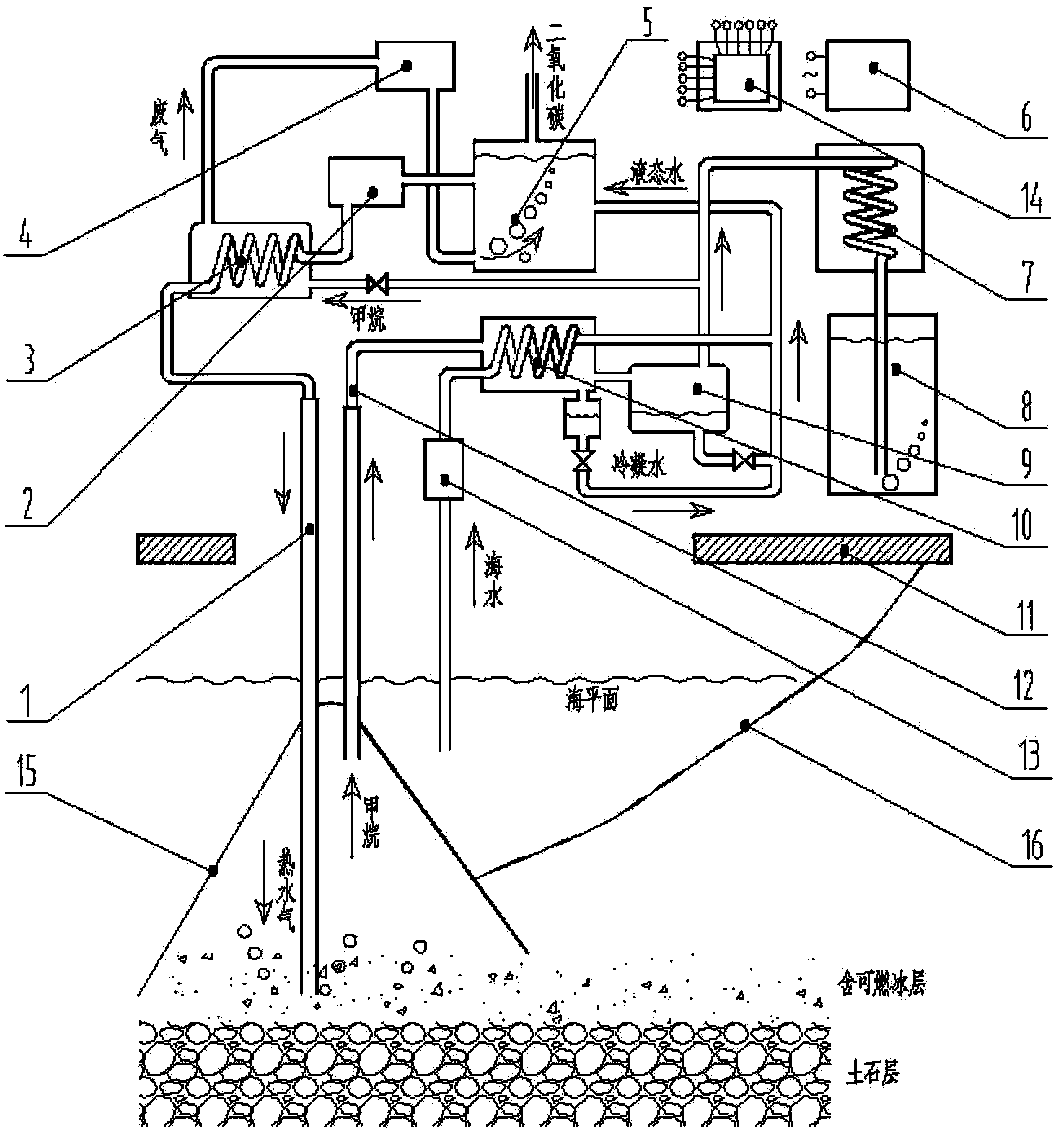

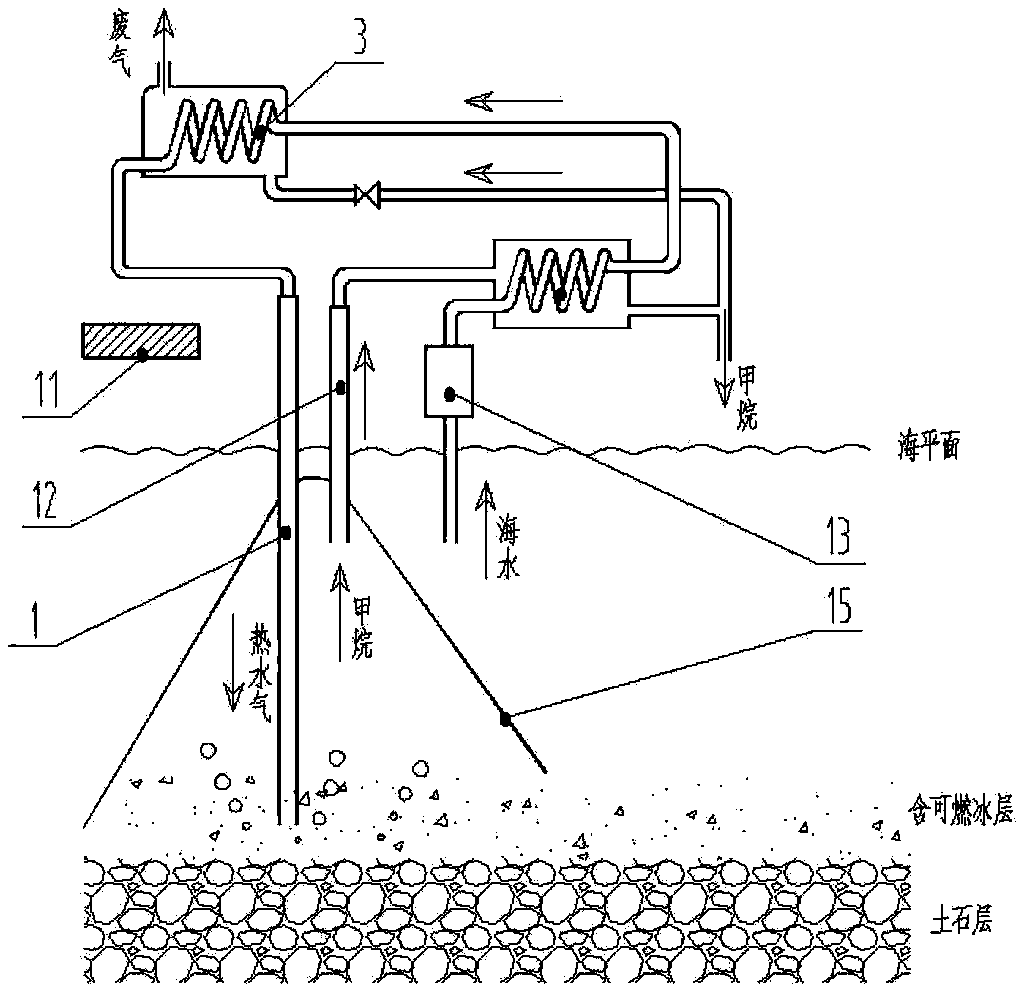

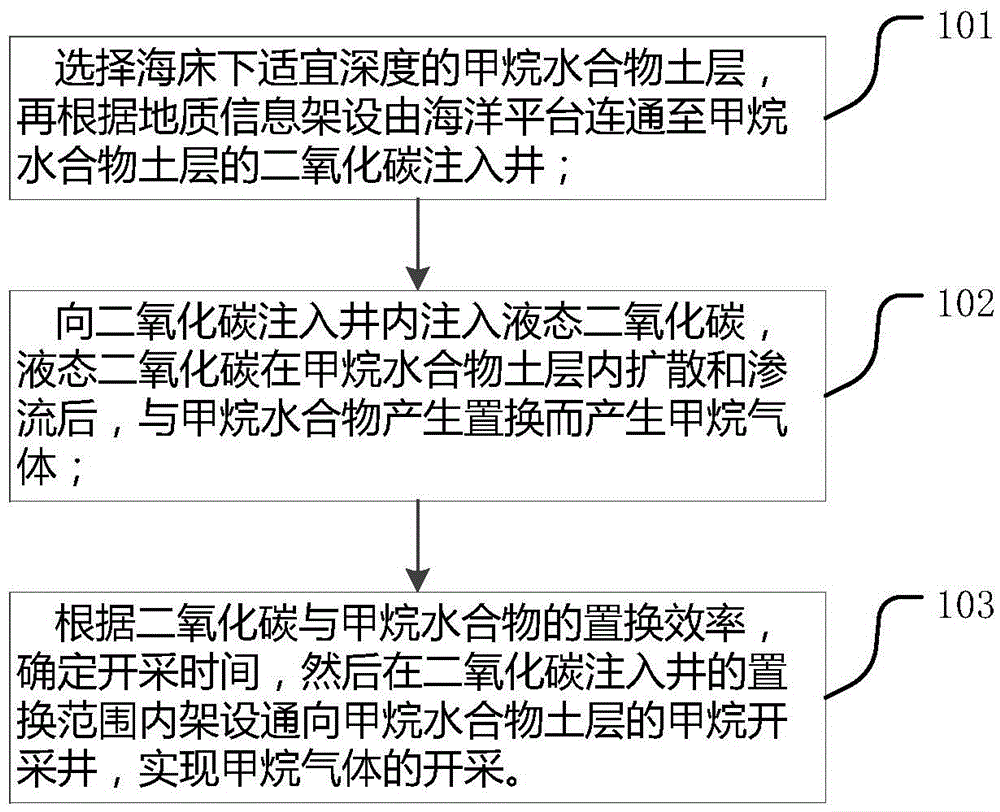

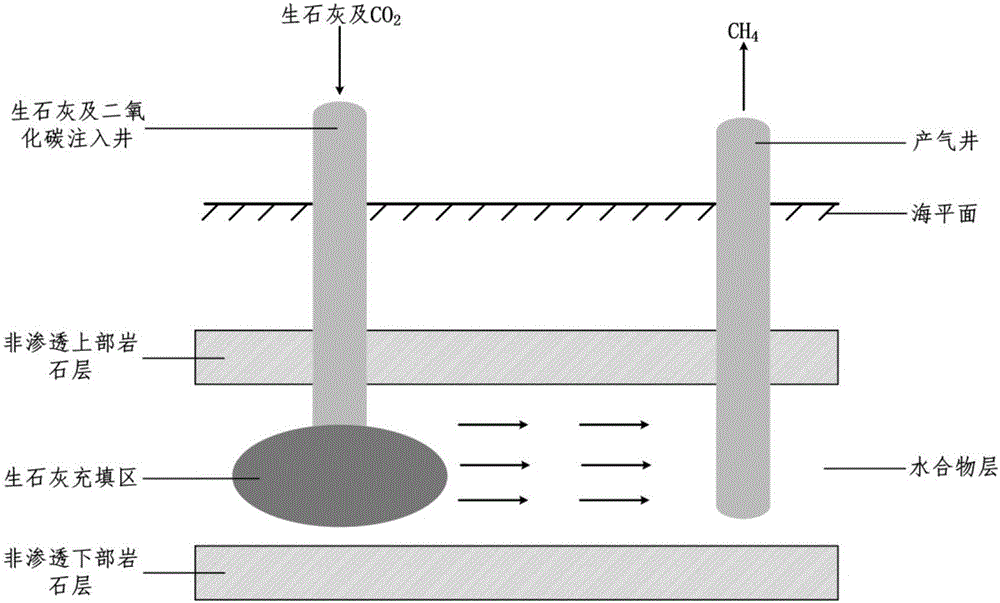

Method for exploiting methane hydrate by using stored carbon dioxide

InactiveCN105464634ALittle change in mechanical propertiesAvoid geological disastersConstructionsFluid removalMethane gasSoil horizon

The invention provides a method for exploiting methane hydrate by using stored carbon dioxide. The method comprises the following steps: selecting a methane hydrate soil layer at proper depth in a seabed, according to geological information, setting up a carbon dioxide injection well communicating from an ocean platform to the methane hydrate soil layer; injecting liquid state carbon dioxide into the carbon dioxide injection well, after the liquid state carbon dioxide diffuses and permeates into the methane hydrate soil layer, the liquid state carbon dioxide replaces with the methane hydrate, to generate methane gas; according to displacement efficiency of the carbon dioxide and the methane hydrate, determining exploitation time, and setting up a methane exploited well in the replacement range of the carbon dioxide injection well, the methane exploited well communicating with the methane hydrate soil layer, so as to realize exploitation of methane gas. After the carbon dioxide is injected and stored, the carbon dioxide would replace the methane hydrate in the regions in a permeating and flowing process, mechanical property variation of the stratum in the process is little, and geological disasters caused by air exhaust exploitation of the methane hydrate are prevented, and greenhouse gases are reduced.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

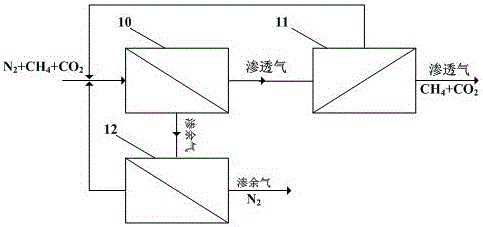

Device and method for efficiently exploiting natural gas hydrate by adopting flue gas of power plant

InactiveCN105971581AHigh recovery rateMining methods are environmentally friendlyGas treatmentConstructionsFlue gasProcess engineering

The invention discloses a device for efficiently exploiting natural gas hydrate by adopting flue gas of a power plant. The device comprises a gas booster, an injection well, an overlying formation, an exploiting well, a turbine expansion device, a membrane separation device and a decarburization device, wherein the gas booster is connected with the injection well; the exploiting well is connected with the turbine expansion device, the membrane separation device and the decarburization device sequentially. With the adoption of the method for exploiting the hydrate, the recovery rate of methane is higher; the exploiting mode is more environment-friendly, and CO2 is sealed and stored while methane hydrate is exploited; energy consumption is lower.

Owner:SOUTH CHINA UNIV OF TECH

Method for jointly exploiting hydrates and hermetically storing carbon dioxide by aid of quicklime and carbon dioxide injection processes

ActiveCN106437653AIncrease temperatureBreak phase balanceGas treatmentMethane captureGreenhouseInstability

The invention provides a method for jointly exploiting hydrates and hermetically storing carbon dioxide by the aid of quicklime and carbon dioxide injection processes. The method includes selecting hydrate occurrence regions as target regions and drilling quicklime and carbon dioxide injection wells and gas production wells; injecting quicklime into hydrate layers from the quicklime and carbon dioxide injection wells to form quicklime filling regions; completely carrying out reaction on the quicklime and water in the hydrate layers and then injecting the carbon dioxide from the quicklime and carbon dioxide injection wells; controlling outlet pressures of the gas production wells to allow gas production pressures to be higher than carbon dioxide and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers and lower than methane and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers; collecting methane gas at well mouths of the gas production wells. The method has the advantages that the hydrates can be safely and efficiently exploited, environmental problems such as decrease of the strength of existing hydrate layers and instability of strata in natural gas hydrate exploitation procedures can be effectively solved, and the purposes of hermetically storing the carbon dioxide and abating greenhouse effects can be achieved.

Owner:DALIAN UNIV OF TECH

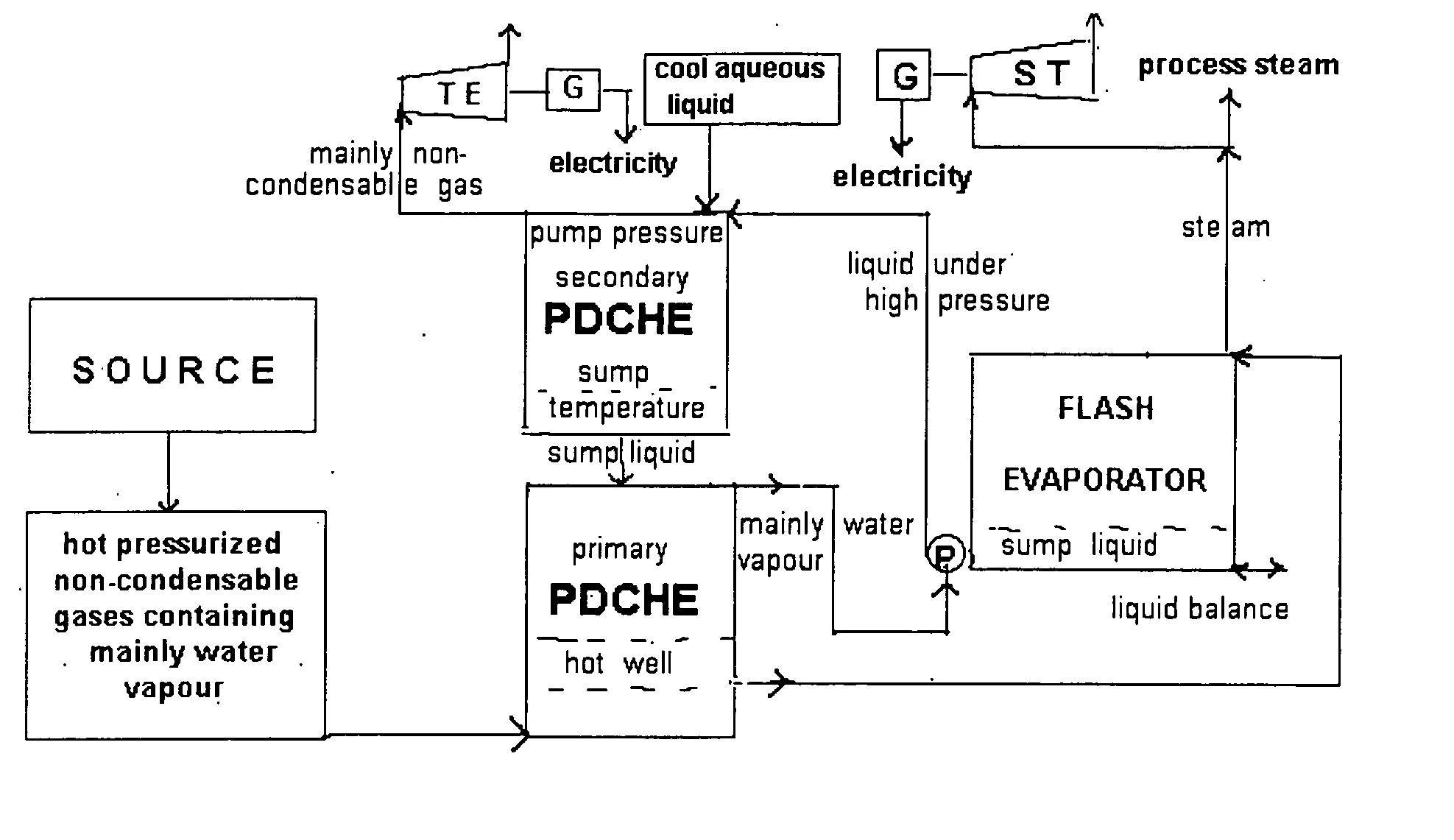

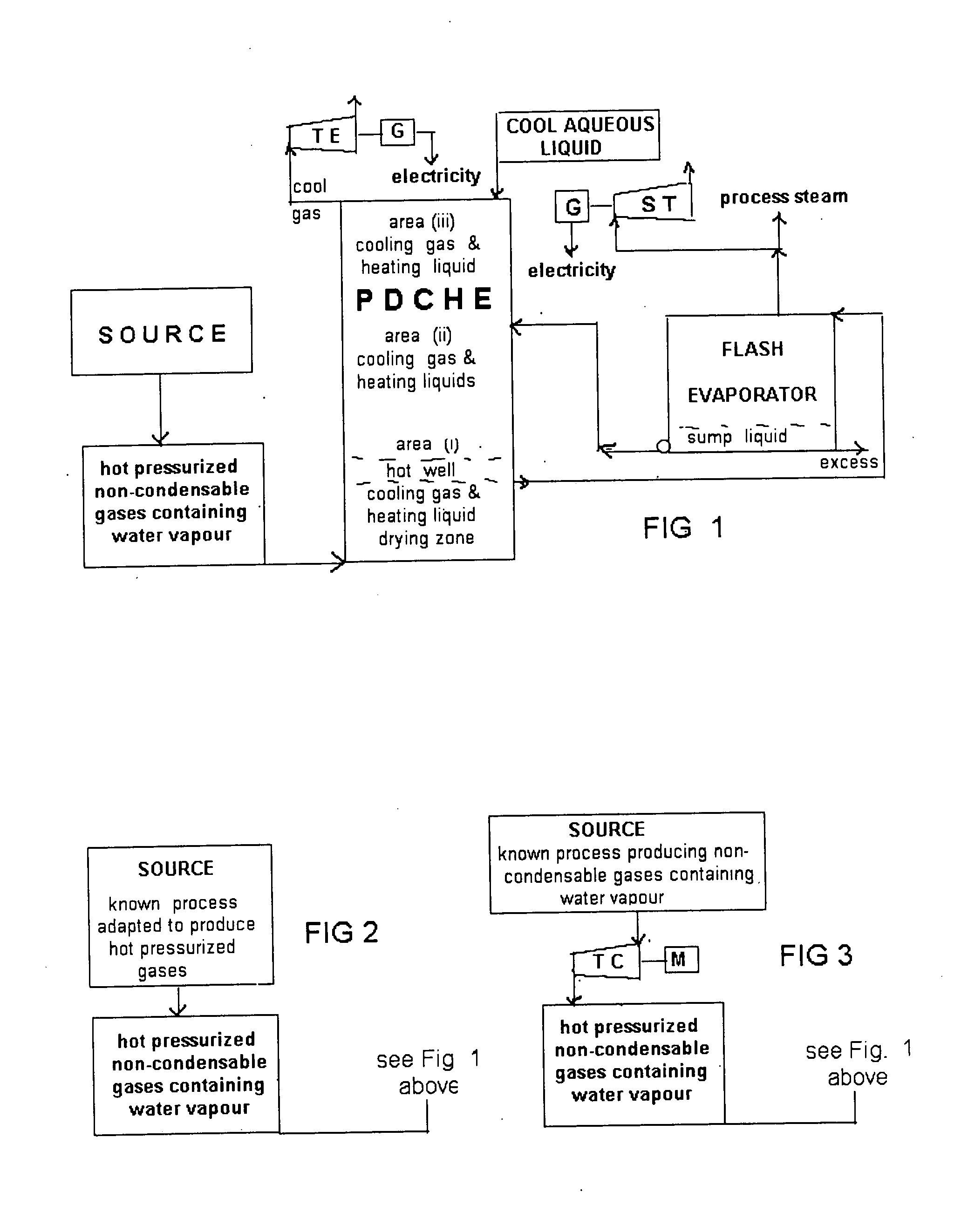

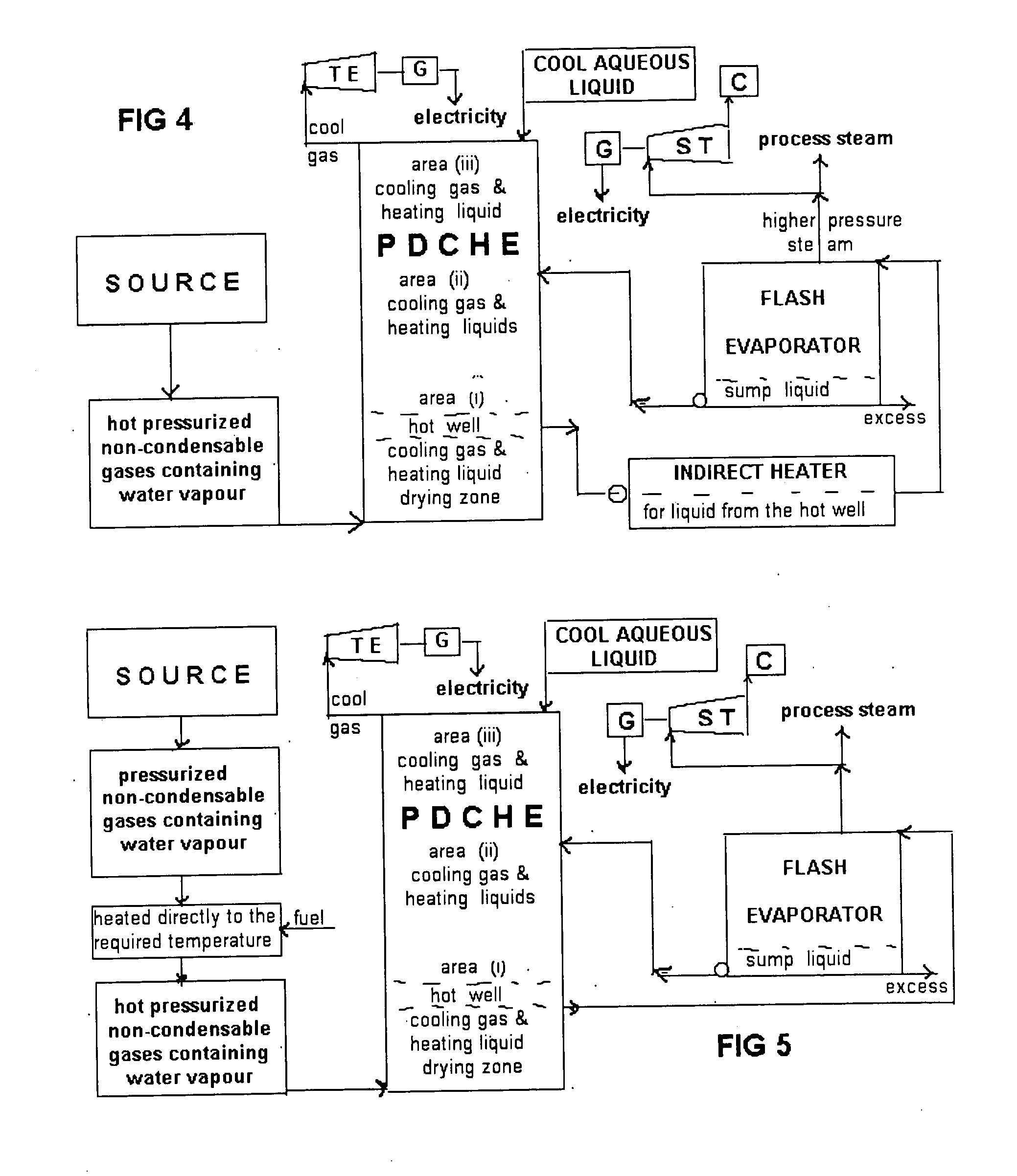

Pressurized direct contact heat exchange process

InactiveUS20050022981A1Improve thermal efficiencyEfficient processingSteam engine plantsHeat transfer modificationElectrolysisCombustion

A process for converting latent heat of water vapor, appearing with non-condensable gases expelled into the atmosphere, into more useful forms of energy, such as process steam / electricity. It uses pressurized direct contact heat exchange systems to achieve this conversion at high thermal efficiencies. When pressure combustion is used in combination with pressurized water electrolysis it produces pressurized by-product hydrogen which can be used to extract methane from methane hydrate ice located below the earth and sea.

Owner:HELLEUR DONALD

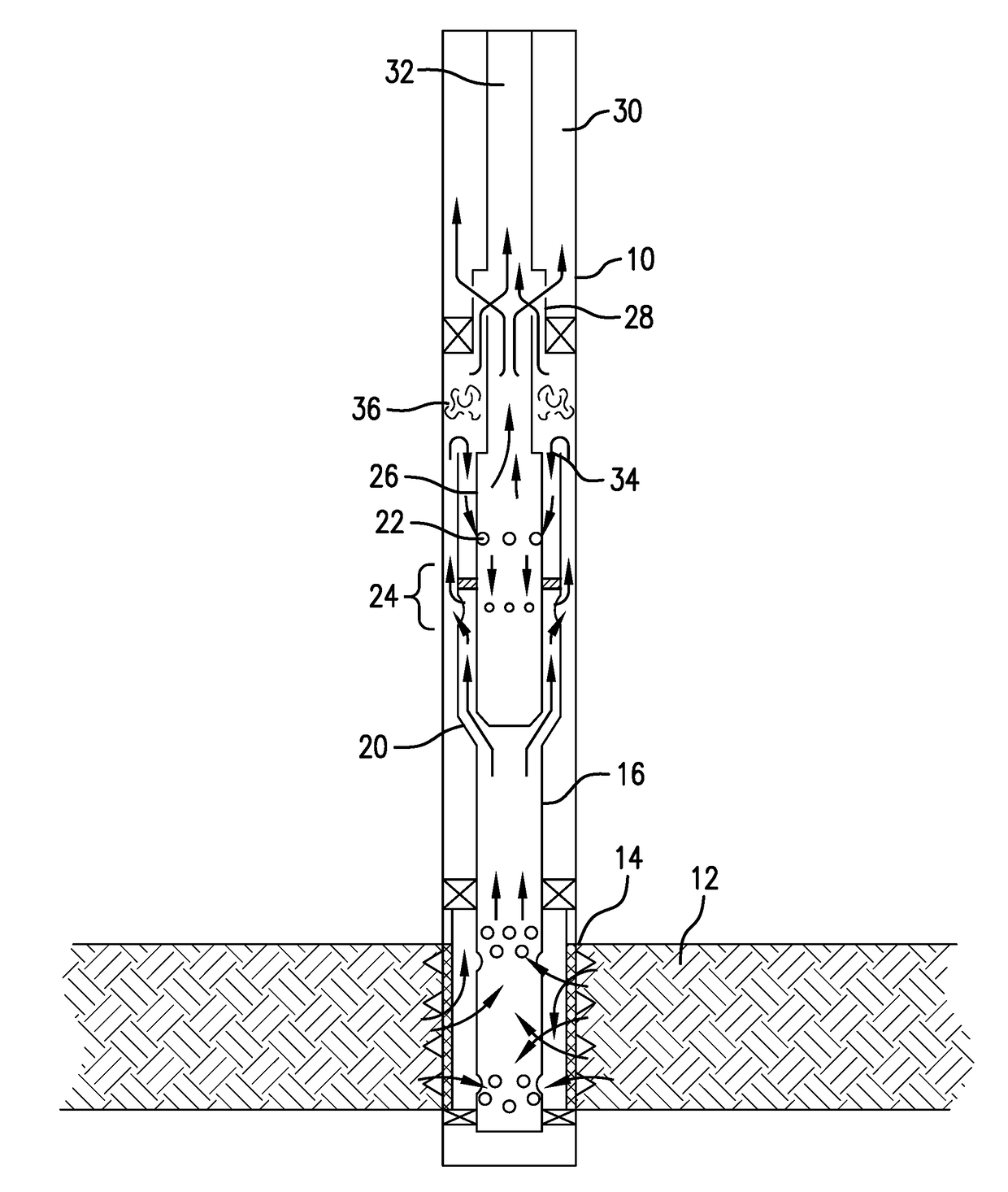

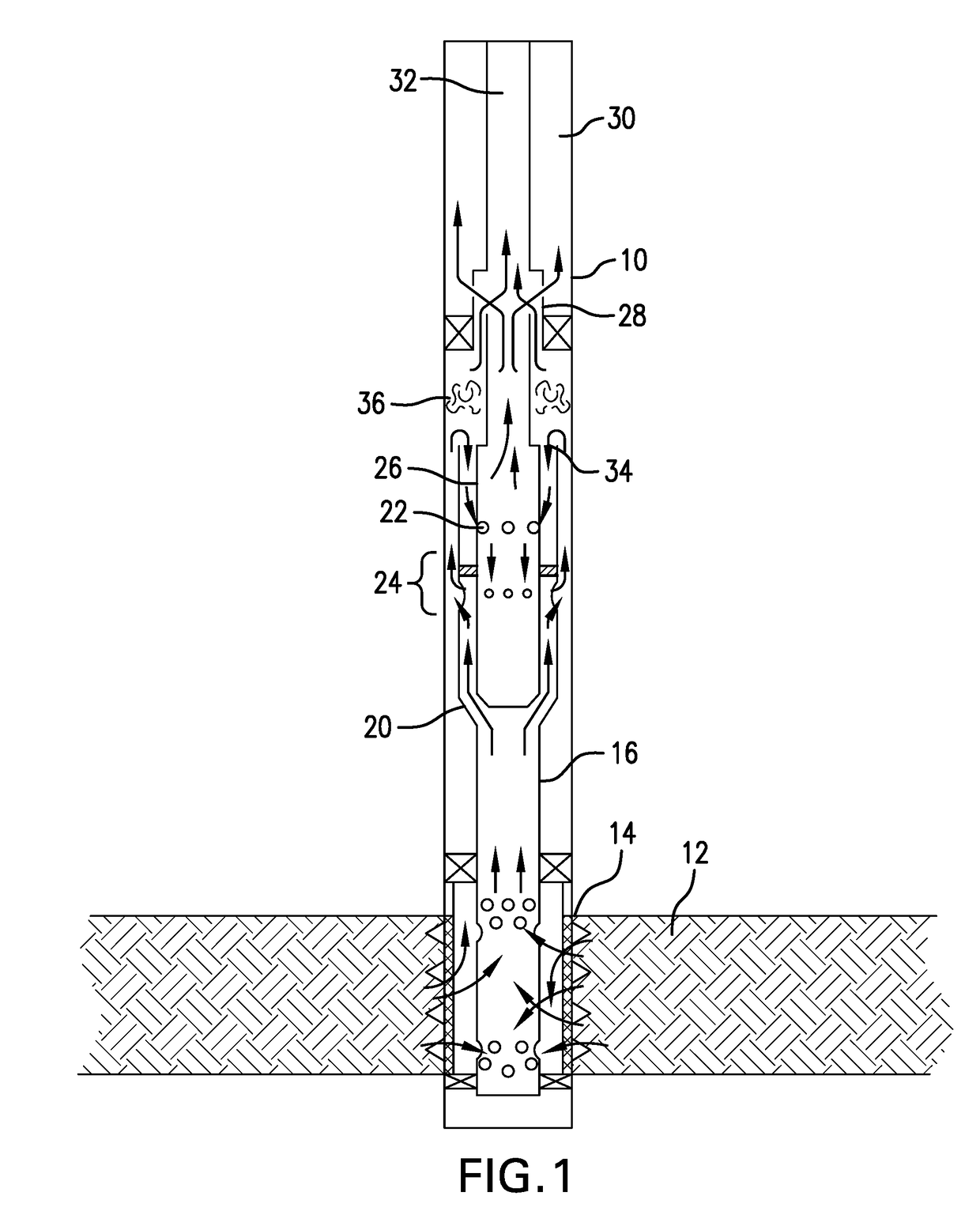

System and method for producing methane from a methane hydrate formation

A system for producing Methane from a Methane Hydrate formation including a completion that is disposed through a Methane Hydrate formation. An inlet of the completion disposed in the Methane Hydrate formation; and a drain for water located in a direction proximate a direction of gravity relative to the Methane Hydrate formation and gravitationally beneath the Methane Hydrate formation. A method for producing methane from a Methane Hydrate formation

Owner:BAKER HUGHES INC

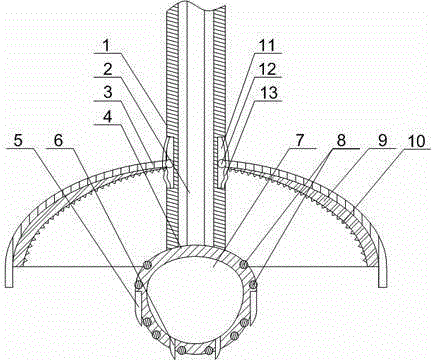

Methane hydrate collecting device for shallow stratum

The invention discloses a methane hydrate collecting device for a shallow stratum. The device comprises a gas pumping tube and a central rod; a moving block is fixed to the tail end of the central rod; a plurality of heating tubes which are connected in parallel are fixed on the outer wall of the moving block. The device further comprises a collecting cover with an arc-shaped cross section; an annular groove is formed in the outer wall of the gas pumping tube; a plurality of balls are mounted on the inner wall of a through hole; the upper side and the lower side of the collecting cover are respectively connected with the inner walls of two sides of the annular groove through elastic rubber rings; a reflecting plate is mounted on the inner wall of the collecting cover; the thickness of the reflecting plate is gradually increased from the center to two ends; a plurality of reflecting bulges with triangular longitudinal sections are arranged on the inner wall of the reflecting plate. According to the device, combustible ice can be decomposed by grades through the collecting cover and the moving block, so that the heat of the combustible ice can be slowly diffused, the combustible ice cannot be overflowed due to excessively fast decomposing while continuously pumping methane through the gas pumping tube, the influence of production of combustible ice on the environment can be avoided, and as a result, the purposes of increasing the production rate and improving the safety and reliability can be achieved.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

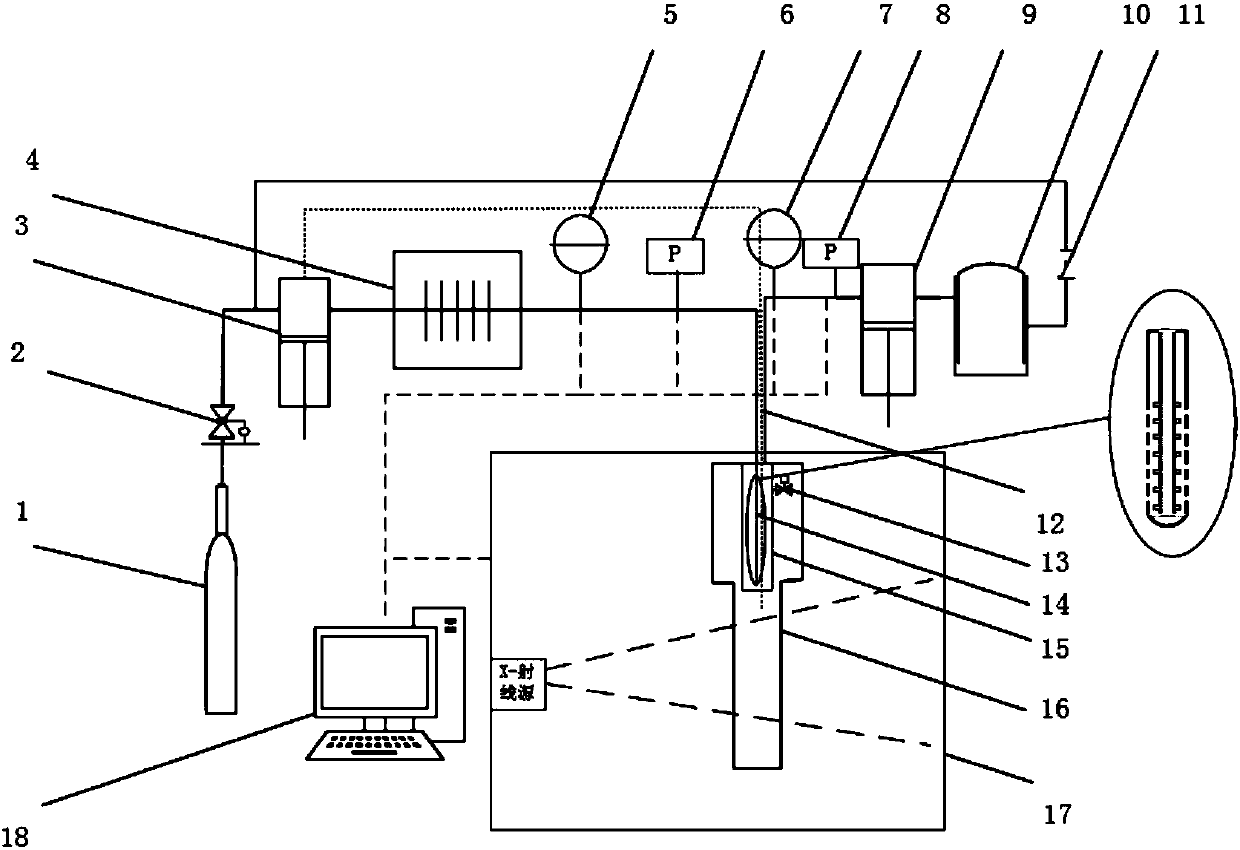

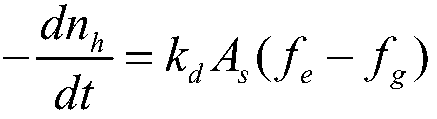

Hydrate phase change process visualization CT (computer tomography) device based on high pressure throttling temperature control technology

ActiveCN107807140ASolve the difficult problem of rotating temperature controlPrecise temperature controlMaterial analysis using wave/particle radiationPorous mediumDecomposition

The invention provides a hydrate phase change process visualization CT (computer tomography) device based on a high pressure throttling temperature control technology, which belongs to the technical field of basic research on hydrates. High pressure gas enters a temperature control pool through a gas pump and a low temperature probe; the high pressure gas can be used for realizing temperature control through throttling expansion heat absorption of the low temperature probe; the temperature control pool is connected with a reaction pool by a self-operated pressure regulating valve; the pressurein the reaction pool can be controlled by the self-operated pressure regulating valve, so that the generation and decomposition of methane hydrate can be controlled. An outlet gas pump is connected with the temperature control pool, so as to control the pressure in the temperature control pool. The generation and decomposition process of the methane hydrate is scanned by X-ray CT timely. A high pressure gas throttling low temperature device is combined with the X-ray CT, so that the temperature can be controlled by throttling expansion of high pressure methane, and the problem that the temperature is relatively difficult to control as a reaction kettle rotates in the X-ray CT scanning process is solved. A three-dimensional structure of the generation and decomposition process of the methane hydrate on the surface of a porous medium can be visually observed through combination with the X-ray CT scanning, so as to provide basic data for a research on numerical simulation of generation and decomposition of the hydrate.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com