Methane hydrate collecting device for shallow stratum

A methane hydrate and collector technology, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of uncontrolled leakage, automatic decomposition, and formation temperature rise, and achieves increased contact advance. , prolong the service life, improve the mining rate and the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

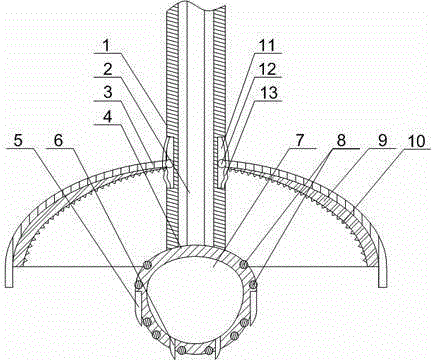

[0021] Such as figure 1 As shown, this embodiment includes an air extraction pipe 1 and a central rod 2 placed inside the air extraction pipe 1. A moving block 4 with a circular cross section is fixed at the end of the central rod 2. On the outer wall of the moving block 4 A plurality of heating pipes 8 connected in parallel are fixed, cables for powering the heating pipes 8 are fixed on the inner wall of the exhaust pipe 1, and a gathering cover 3 with an arc-shaped cross section is also included. Groove 11, the middle part of gathering cover 3 is provided with through hole, and a plurality of balls 12 are installed on the inner wall of through hole, and ball 12 is in contact with the inner wall of annular groove 11, and the upper and lower sides of gathering cover 3 pass elastic rubber ring 13 and ring respectively. The inner walls of both sides of the groove 11 are connected, and a matching reflector 9 is installed on the inner wall of the collection cover 3, and the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com