Biogas purification method and system

A purification system and biogas technology, applied in chemical instruments and methods, methods for chemical changes of substances by atmospheric pressure, separation methods, etc., can solve the problems of large-scale industrial application of biogas, complex processes, and large water consumption. , to achieve the effect of convenient large-scale industrial production, simple separation equipment, and reliable separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the biogas purification method of the present invention, at the same temperature, the pressure is first controlled to be lower than the pressure generated by methane hydrate, so that carbon dioxide and hydrogen sulfide form hydrates, and the temperature and pressure are maintained at carbon dioxide hydrate and hydrogen sulfide hydrate. Maintain the temperature and pressure of the phase equilibrium, and then separate the methane gas from the biogas.

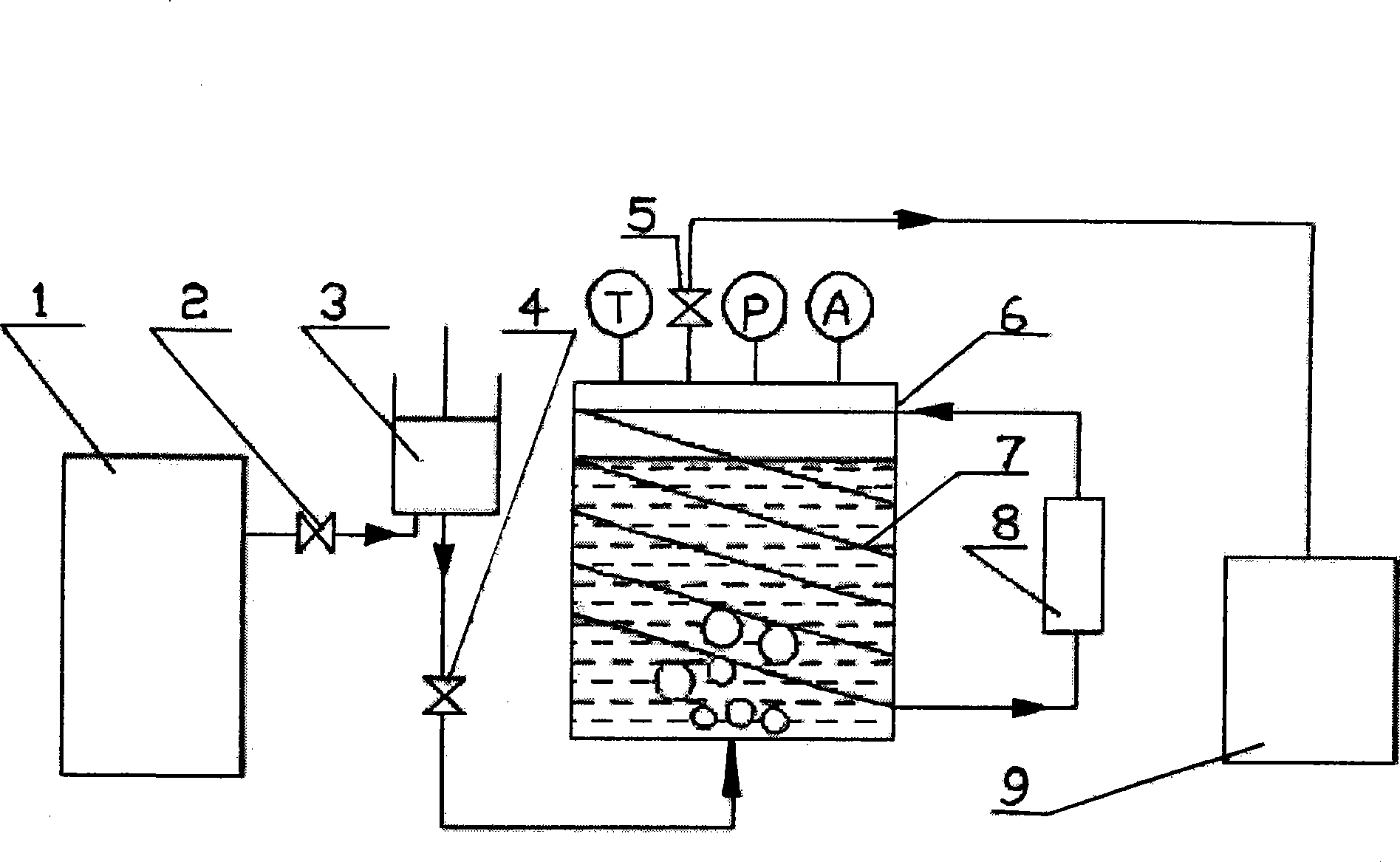

[0015] Such as figure 1 As shown, in the biogas purification system that implements the above method, liquid water is stored in the biogas separation tank 6. The biogas storage tank 1 is connected to the compressor 2 through a pipeline equipped with a valve 3, and the compressor 2 is connected to a compressor 2 through a pipeline equipped with a valve 4 The pipeline is connected to the biogas separation tank 6, and a refrigeration tube 7 is coiled on the inner wall of the biogas separation tank 6. The material of the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com