Pressurized direct contact heat exchange process

a heat exchange process and pressurized technology, applied in heat exchange apparatus, heat transfer modification, steam engine plants, etc., can solve the problems of low thermal efficiency and large energy loss, and achieve the effect of approving 90% of the thermal efficiency of the process and much higher thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

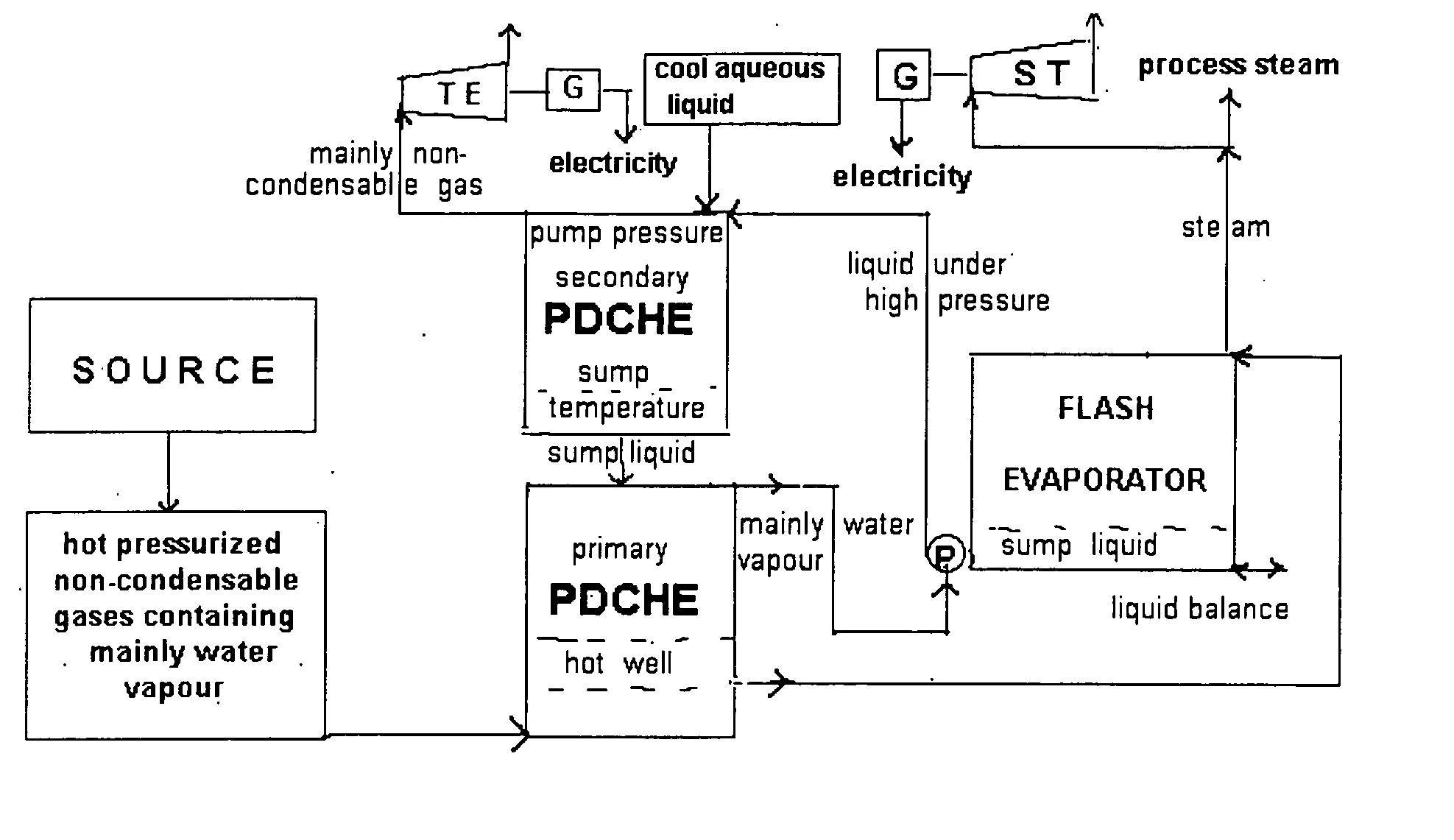

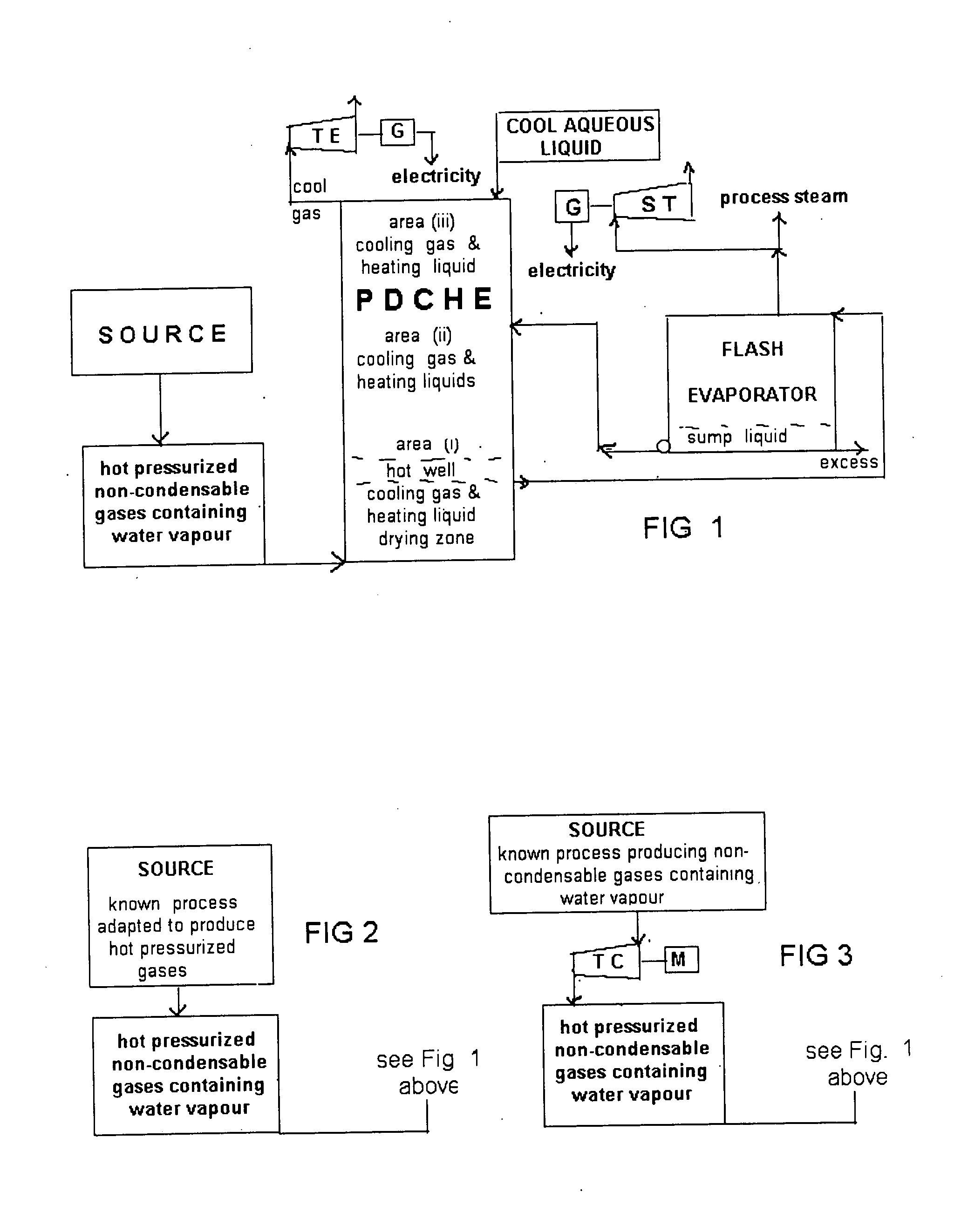

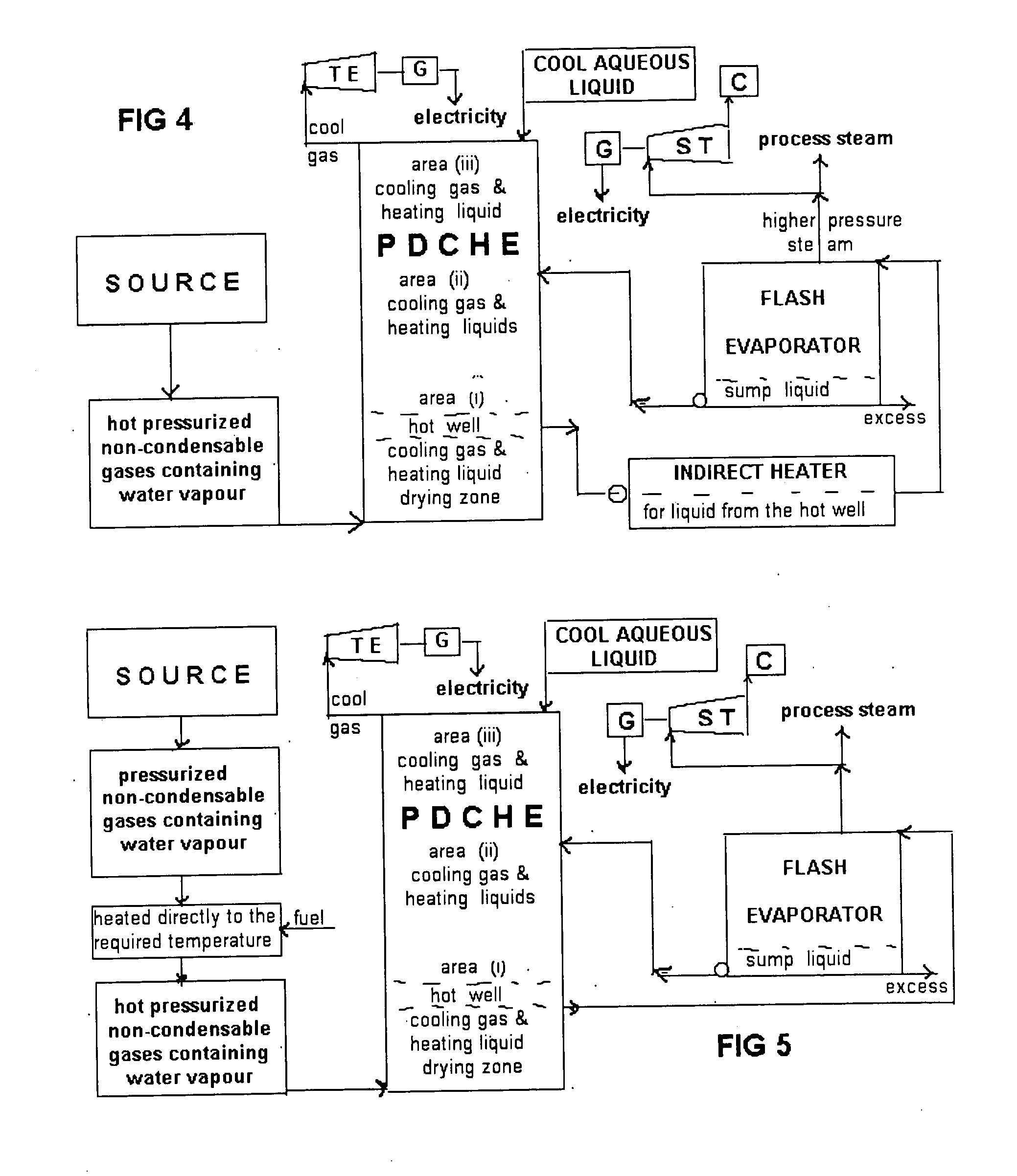

[0028] The following embodiments are process sequences that provide a wide range of choice to fit a wide variety of circumstances, applications and available technologies. Because of the wide range of process variables involved and technologies to choose from it is understood that in most cases, computer simulation would normally be utilized to balance the various variables such as the rate of: recirculation of the hot well liquid; cool liquid supply and excess liquid removal.

[0029] The embodiments as illustrated and described is such as to obtain maximum thermal efficiency, noting that, the higher the pressure and the lower the temperature of the gas leaving the pressurized direct contact heat exchanger the higher the thermal efficiency Embodiments involving lower efficiencies are also included.

[0030] Referring to the accompaning drawings, the symbols used have the following meaning:

GGenerator for electricityGTGas TurbineTCTurbine CompressorTETurbine ExpanderPRParticulate Remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com