Pressing method for methane hydrate containing rock core sample

A technology for methane hydrate and core samples, applied in the oil and gas field, can solve problems such as the inability to ensure the consistency of the basic characteristics of the core and the target reservoir.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in combination with specific embodiments.

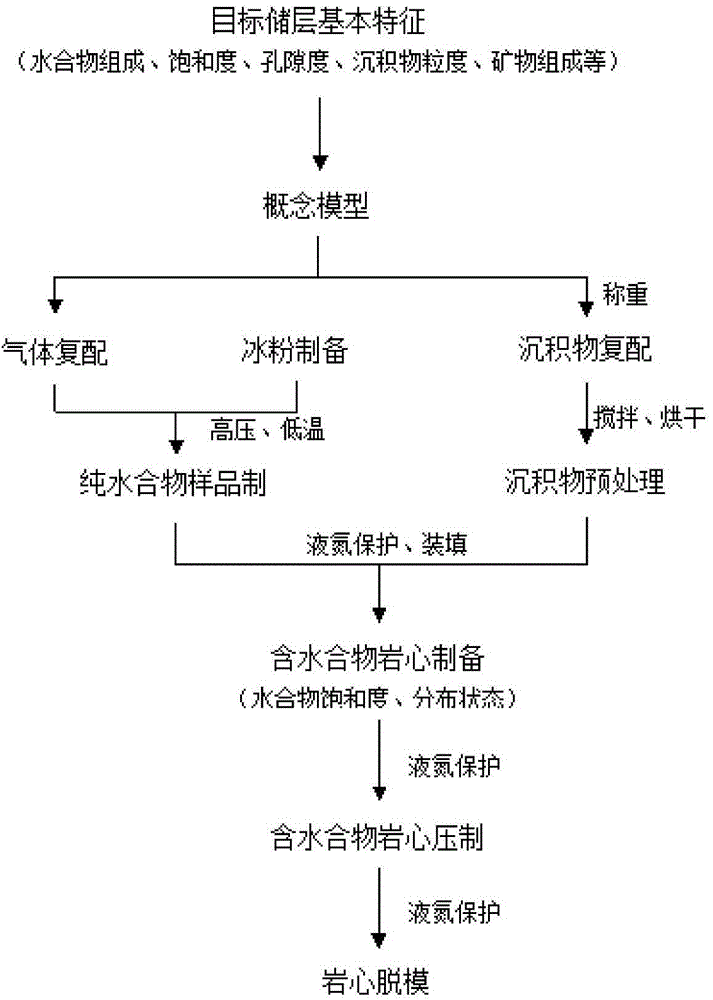

[0058] figure 1 Be the schematic diagram of this technological process, the step of technological process of the embodiment of the present invention is as follows:

[0059] (1) Determine the basic characteristics of the pressed core:

[0060] Hydrate-bearing sediment core SH2B in the Shenhu area of the South China Sea is used as the target hydrate reservoir sample, and its basic characteristics are used to determine the actual physical model characteristics of this implementation case. Since the mineral composition of the target reservoir is very complex, it is simplified in the examples: the hydrate saturation in this area is 20%-49%, and the average value is 34.5%; the average porosity is 32%; The core sediments are mainly composed of clastic minerals, clay minerals and carbonate minerals, and the overall content is 63%, 20% and 17% respectively; the clastic mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com