Device and method for efficiently exploiting natural gas hydrate by adopting flue gas of power plant

A technology for hydrates and natural gas, which is applied in the fields of mining fluids, separation methods, chemical instruments and methods, etc., can solve the problems of low methane concentration, poor economy, and low energy efficiency in the produced gas, and achieve low energy consumption and high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

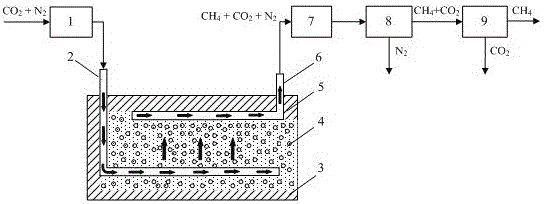

[0034] This embodiment provides a method for efficiently exploiting natural gas hydrate reservoirs with reservoir conditions of 4°C and 12MPa by flue gas from a power plant. The operation process is as follows:

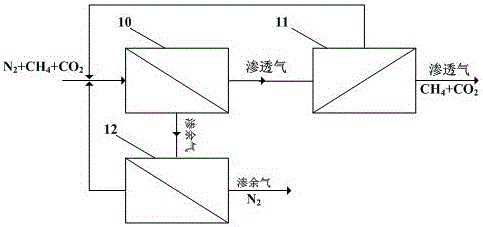

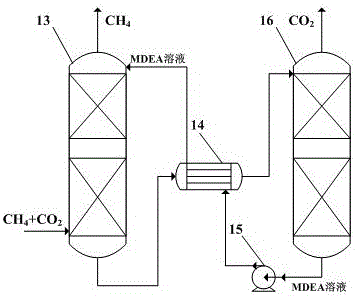

[0035] Firstly, one horizontal well is drilled in the middle and the edge of the hydrate reservoir, and the decompression mining method is used for mining. When the hydrate reservoir pressure drops to 4.3MPa, inject 8MPa flue gas (volume fraction 0.16CO 2 +0.84N 2 ). The flue gas injected into the formation reacts with the hydrate in the hydrate reservoir to obtain a mixed gas containing methane, which is directly transported to the turbo expander to recover part of the pressure energy through the production well and pipeline, and the pressure of the mixed gas is reduced to 2MPa and transported to the membrane The first-stage hollow fiber membrane module of the separation device. The permeate gas of the first-stage hollow fiber membrane module enters the second-sta...

Embodiment 2

[0037] This embodiment provides a method for efficiently exploiting natural gas hydrate reservoirs with a reservoir condition of 1°C and 12MPa by flue gas from a power plant. The operation process is as follows:

[0038] Firstly, one horizontal well is drilled in the middle and the edge of the hydrate reservoir, and the decompression mining method is used for mining. When the hydrate reservoir pressure drops to 3.3MPa, inject 7MPa flue gas (volume fraction 0.16CO 2 +0.84N 2 ). The flue gas injected into the formation reacts with the hydrate in the hydrate reservoir to obtain a mixed gas containing methane, which is directly transported to the turbo expander to recover part of the pressure energy through the production well and pipeline, and the pressure of the mixed gas is reduced to 2MPa and transported to the membrane The first-stage hollow fiber membrane module of the separation device. The permeate gas of the first-stage hollow fiber membrane module enters the second-st...

Embodiment 3

[0040] This embodiment provides a method for efficiently exploiting natural gas hydrate reservoirs with a reservoir condition of 1°C and 10MPa by flue gas from a power plant. The operation process is as follows:

[0041] Firstly, one horizontal well is drilled in the middle and the edge of the hydrate reservoir, and the decompression mining method is used for mining. When the hydrate reservoir pressure drops to 3.3MPa, inject 6MPa flue gas (volume fraction 0.16CO 2 +0.84N 2 ). The flue gas injected into the formation reacts with the hydrate in the hydrate reservoir to obtain a mixed gas containing methane, which is directly transported to the turbo expander to recover part of the pressure energy through the production well and pipeline, and the pressure of the mixed gas is reduced to 2MPa and transported to the membrane The first-stage hollow fiber membrane module of the separation device. The permeate gas of the first-stage hollow fiber membrane module enters the second-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com