Patents

Literature

166results about How to "Comply with environmental policy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase-change energy-storage solar greenhouse architectural structure system

InactiveCN101672119AReduce the temperature difference between day and nightImprove insulation effectLighting and heating apparatusAgricultural buildingsEngineeringPhase change

The invention provides a phase-change energy-storage solar greenhouse architectural structure system which can heat a phase-change energy-storage material by virtue of solar energy in the day and allow the phase-change energy-storage material to release heat at night; and the structure system meets the need of agricultural products in winter and the need of people in a working condition. The phase-change energy-storage solar greenhouse architectural structure system comprises a foundation pier, a frozen-insolating laminated plate, a slope crest truss, upright frames at two sides and a rear upright frame or a phase-change energy-storage rear upright plate and / or a phase-change energy-storage rear wallboard and a phase-change energy-storage side wallboard and a self-waterproofing phase-change energy-storage rear top plate, an external-layer fixed top membrane and an internal-layer retractable insulation membrane. In the invention, the structure system is assembled into a phase-change energy-storage solar greenhouse at a construction site.

Owner:白建国

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

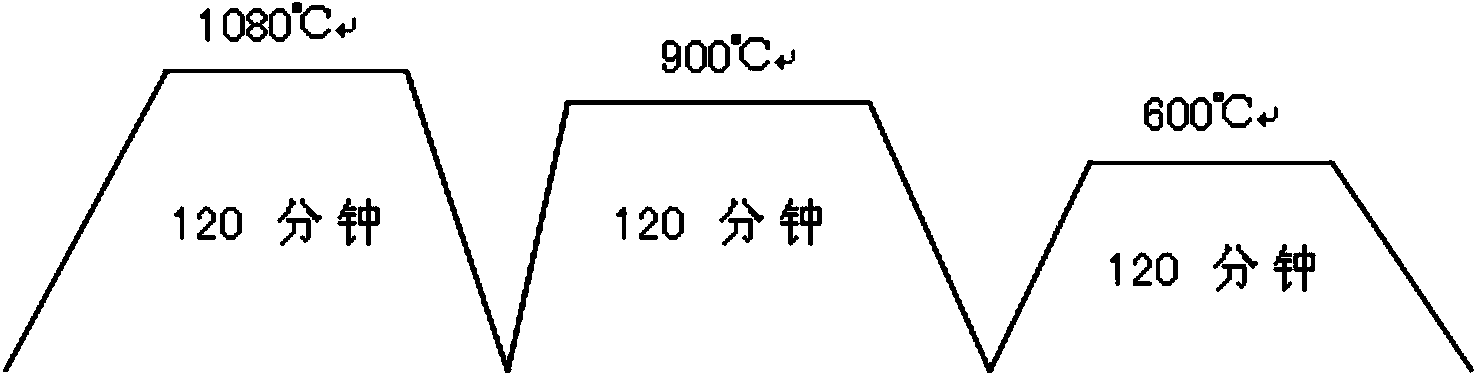

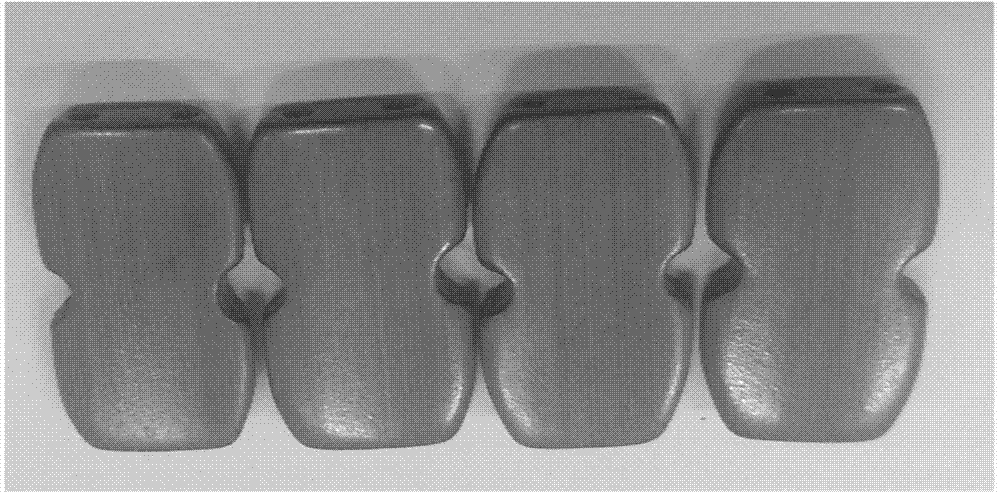

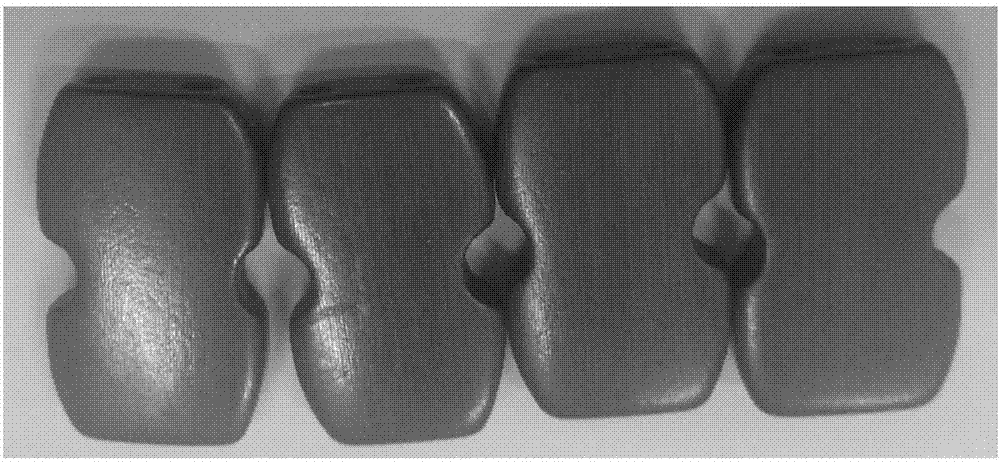

Method for preparing neodymium iron boron permanent magnet material by using associated mixed rare earth

InactiveCN103834863AReduced magnet costImprove microstructureMagnetic materialsRare-earth elementAlloy

The invention relates to a method for preparing a rare earth permanent magnet material by using Bayan Obo associated mixed rare earth and the prepared permanent magnet material, and belongs to the field of preparation of rare earth permanent magnet materials. The method is characterized in that the Bayan Obo associated mixed rare earth is used as a raw material, a dual-alloy process is used for preparing a main alloy from MM (mixed rare earth) FeB, an auxiliary alloy is PrNd, NdCu, AlCu and the like, and the main alloy and the auxiliary alloy are blended and sintered to form a magnet. The magnetic performance of the prepared permanent magnet material is equivalent to that of a neodymium iron boron permanent magnet material; and however, the associated mixed rare earth is adopted as the raw material, so that the magnet cost can be reduced by more than 30 percent, a part of rare earth extraction and separation steps are reduced, the utilization rate of high-abundance rare earth resources is increased, and pollution is reduced.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for producing medical raw material DM by using oxydol as oxidant

The invention discloses a method for producing a medical raw material DM by using oxydol as an oxidant, which comprises the following steps of: adding water and a rubber accelerator M into a reaction kettle in a weight ratio of 1-15:1; adding sodium hydroxide into the reaction kettle in a molar ratio of 1:1-3 with the rubber accelerator M; adding M sodium salt liquid generated after reaction into an oxidation kettle, and adding a solvent (water, ethanol, methanol, isopropyl alcohol, acetone, aniline, toluene and the like) into the oxidation kettle in a volume ratio of 1:1-10 with the M sodium salt liquid; under the condition that the temperature is between 40 and 70 DEG C, dropping mixed oxidant solution of which the weight ratio of sulfuric acid to the oxydol is 1:1-12 into the mixture at a flow rate of 50 to 110 ml / minute, and stopping dropping the mixed oxidant when the pH of the solution is 4 to 8; and performing suction filtration, water washing, filtration and drying to obtain a product of the medical raw material DM, wherein the yield of the medical raw material DM is over 95 percent. The method has the following advantages that: sodium sulfate in the water can be reclaimed; the water and the isopropyl alcohol can be recycled; the method accords with a national environmental protection policy; and the purity of the medical raw material DM can reach 99 percent, and the melting point can be over 178 DEG C.

Owner:KEMAI CHEM

Bamboo sheet coloring process and device based on temperature-controlled drying carbonization

InactiveCN103921327AReduce energy consumptionEliminate hazardsWood treatment detailsWood dampingTemperature controlCarbonization

The invention discloses a bamboo sheet coloring process and device based on temperature-controlled drying carbonization. The coloring process comprises the steps of preheating for detecting humidity, selecting a heating system, heating for carbonizing, and cooling, thereby obtaining a finished product. The bamboo sheet coloring device comprises a roller on a rack, a driving component for driving the roller to rotate, and an external controller, wherein the side wall of the roller is provided with a feeding hole and a movable door matched with the feeding hole, an inner cavity of the roller is internally provided with a heating component, a temperature sensor and a humidity sensor which are all connected with the controller, and the heating component is fixed on the rotating axis of the roller in a manner of not containing a bamboo sheet. The coloring process and device have the advantages of energy conservation, environment protection, uniformity in coloring, easiness in implementation, full-automatic intelligent control, labor saving and the like.

Owner:湖南品篁高新技术有限公司

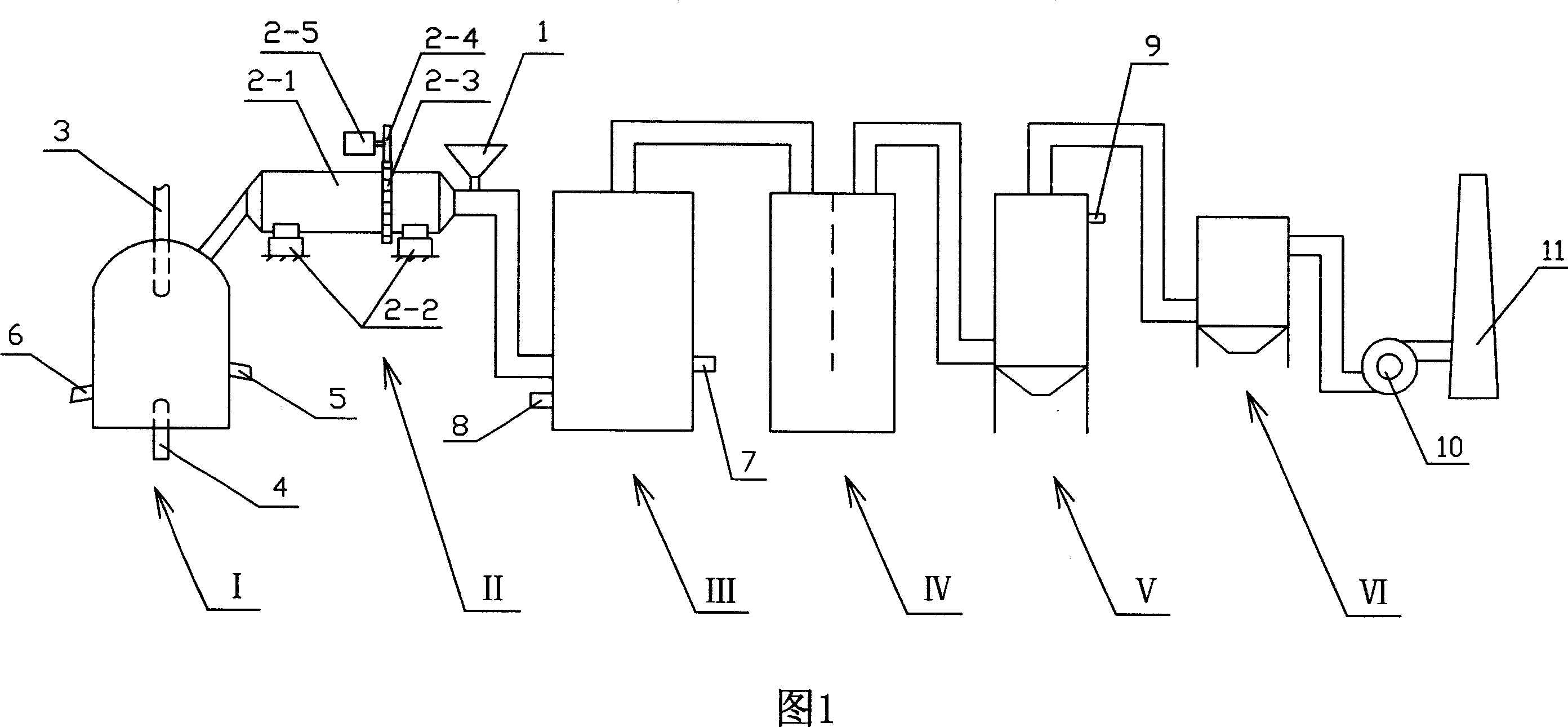

Harmless processing system and process for copper powder containing organism and glass fiber

InactiveCN101008050AImprove puritySolve the glass fiber inclusions in hard-to-melt copper powderSolid waste disposalProcess efficiency improvementCooling towerDecomposition

The invention relates to an innocent treatment system for copper powder containing organic matter and fiber glass and the treating process. Said system can not only recover valuable copper, but also can treat organic waste innocently. It is characterized by rational allocation, high purity of recovered copper powder, and thorough treatment of waste material and water gas. The innocent treatment system is characterized in that it is connected by electrode smelter, rotary retort, decomposition combustion tower, cooling tower, waste gas treating tower and jet cloth filter through conduit pipe. The invention can recover copper powder from waste wiring board, covering brass plate and other copper- containing rim leftover and can treat left waste material innocently.

Owner:王威平

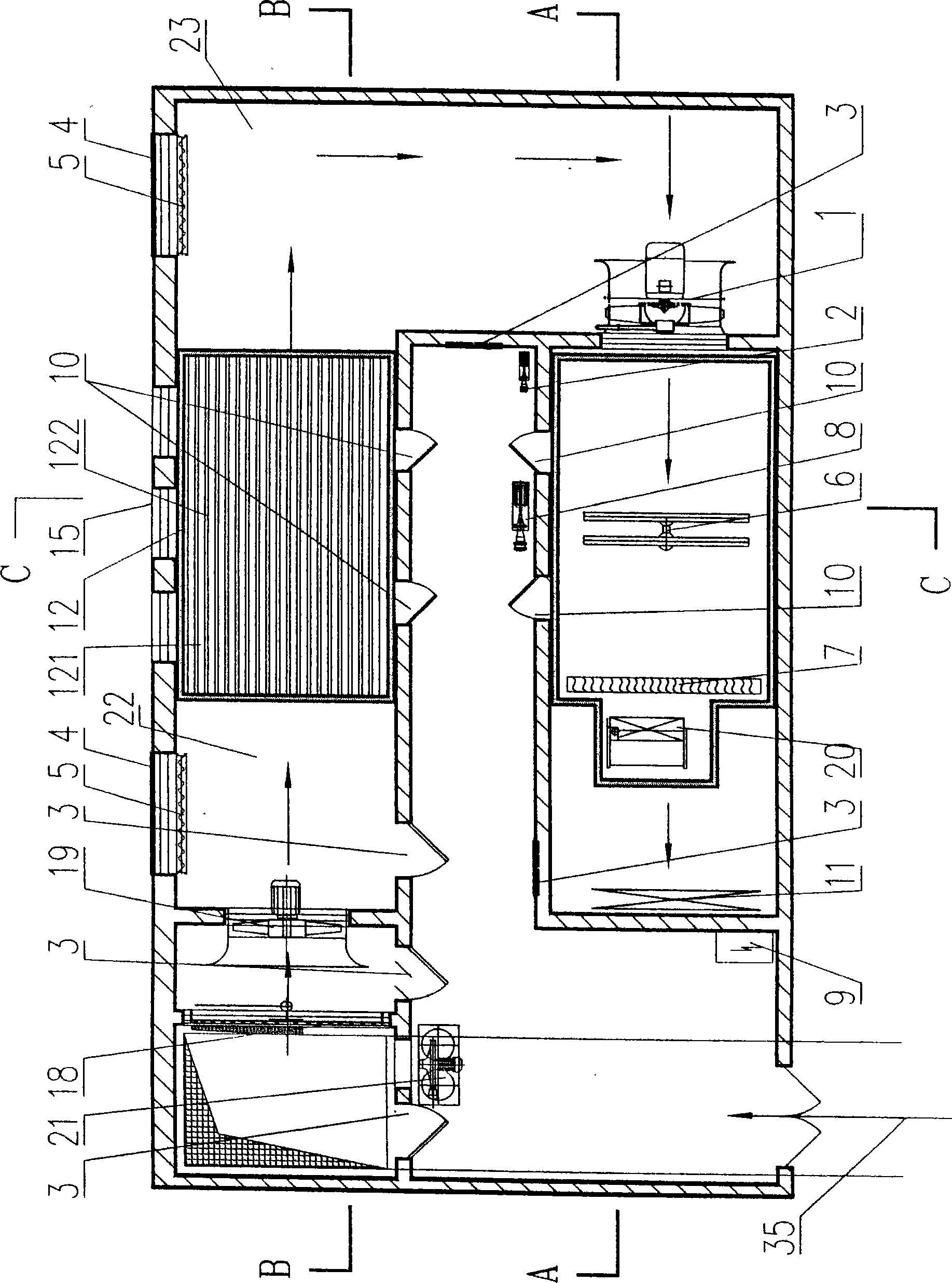

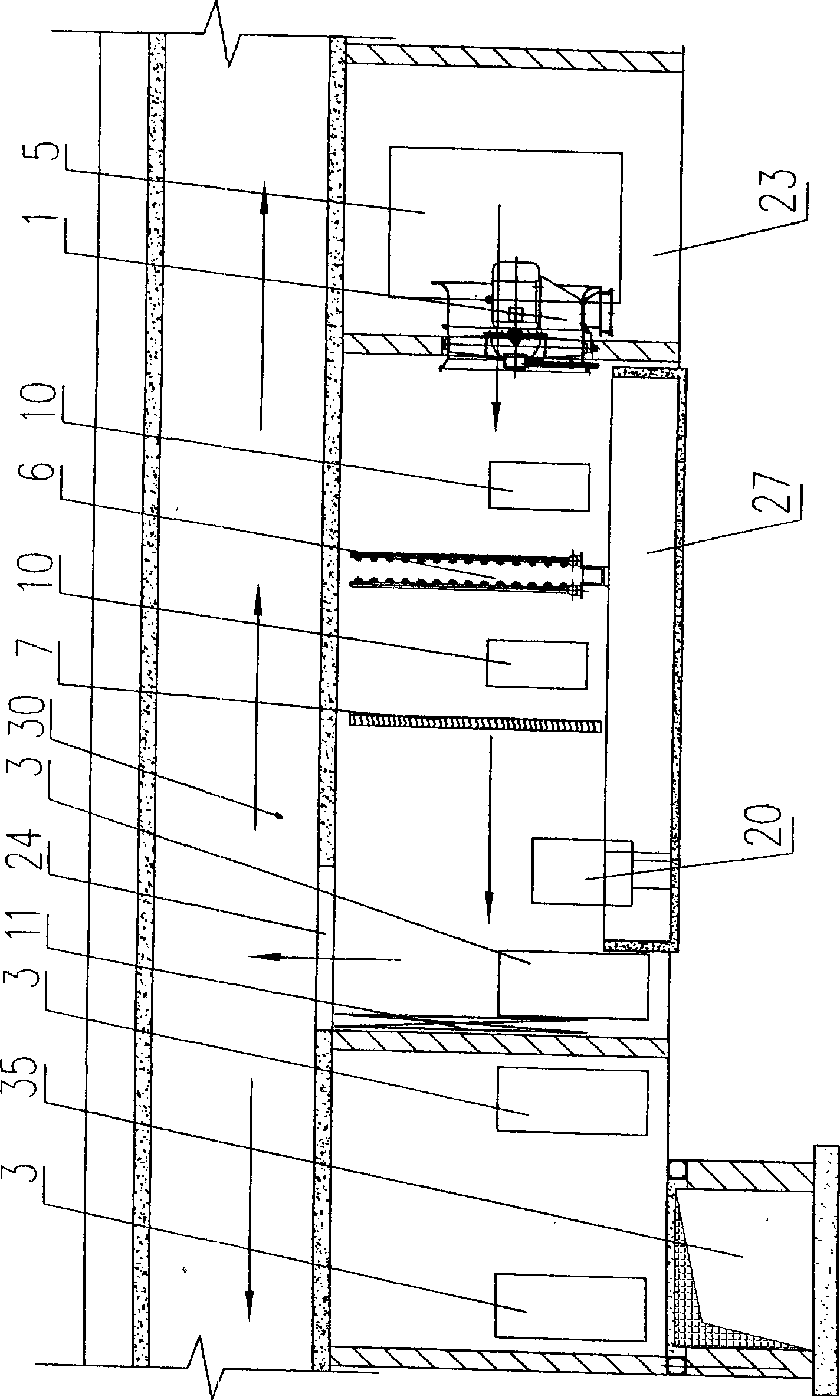

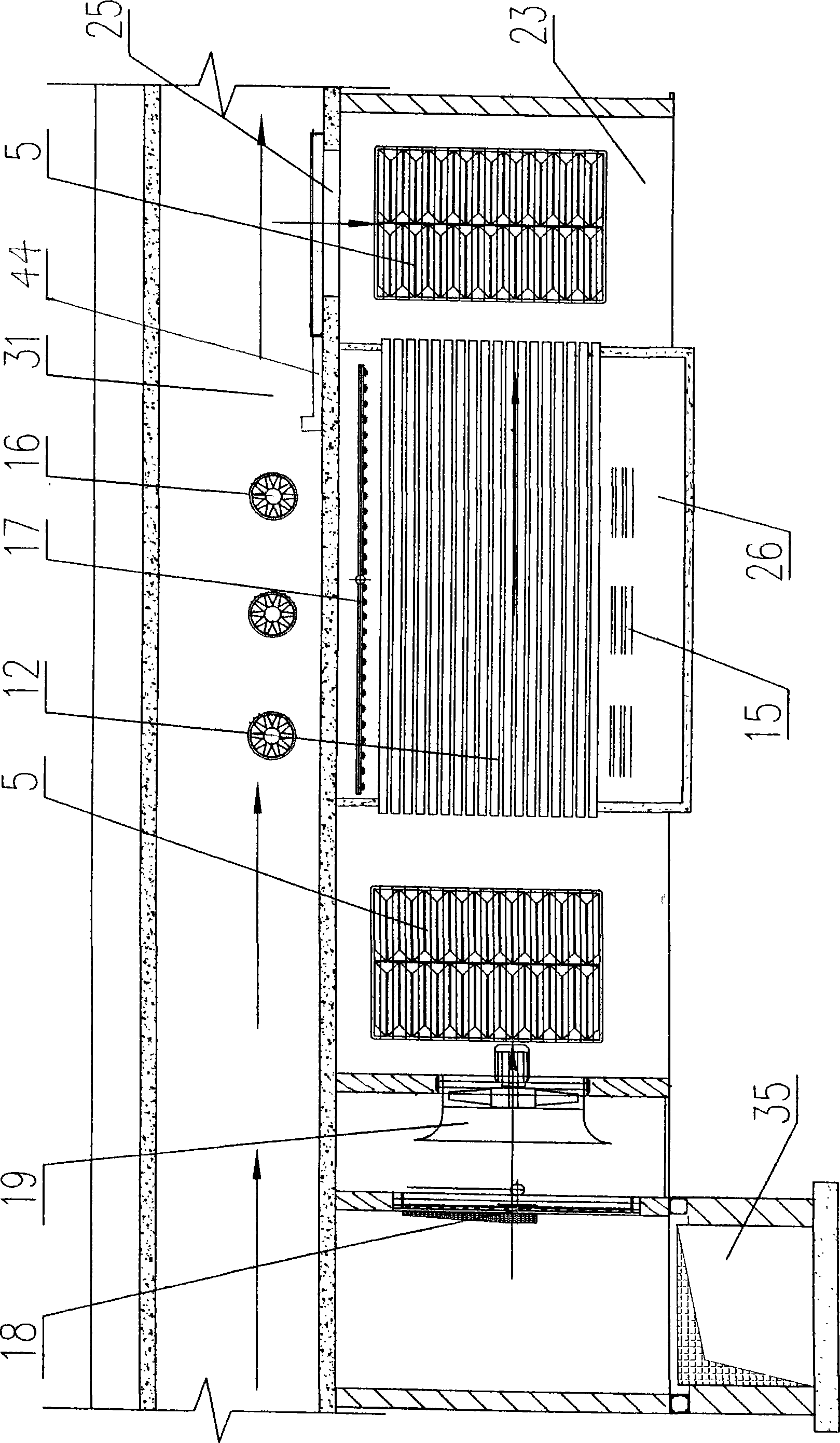

Energy-saving consumption-reducing air conditioning method and unit air conditioner of spinning factory

InactiveCN101482303AEmission reductionReduce shipping costsMechanical apparatusSpace heating and ventilation safety systemsAtmospheric airRoom temperature

The invention relates to an air conditioning method for energy-saving and consumption-reducing in a spinning plant and a unit air conditioner device thereof. The method is that normal temperature air is indirectly cooled in high temperature season to realize falling temperature air conditioner, and sirocco is discharged into the environment; in low temperature season, the device in the spinning plant gives out heat to realize heating up air conditioner in the plant. The unit air conditioner device comprises air indirect cooling control, warm and humid control room, air supply room, air supply passage, normal temperature air supply passage, hot air delivery duct, dust cleaning apparatus, and hot air draft passage. The air conditioner of the invention is environmental and protective. By adopting water as a freezing medium, the invention has non-destroy to the atmospheric ozone layer and is a perfect environment-friendly air conditioner mode. In high temperature, the hot air discharged from the workshop is purified, which is in accordance with the present environment protection policy in our country.

Owner:郑州宏大纺纱新技术咨询有限公司

Method for processing microorganism synthetic feed using animal manure as raw material and product thereof

InactiveCN102204621AFull of nutritionIncrease feed intakeFood processingAnimal feeding stuffDiseaseFeces

The invention provides a method for processing microorganism synthetic feed using animal manure as a raw material. The method comprises the following steps of: diluting bacillus flora powder in water to prepare aqueous solution containing bacillus floras, adding the obtained aqueous solution into fresh terrestrial animal manure, uniformly stirring the mixture, adding all aqueous solution containing anaerobe floras into the terrestrial animal manure treated by the step C, uniformly stirring the mixture, flipping the terrestrial animal manure, controlling the temperature rise caused by the fermentation of the terrestrial animal manure to below 80 DEG C, sterilizing the terrestrial animal manure by the temperature rise caused by the fermentation, and stacking the terrestrial animal manure for 68 to 76 hours; and mixing the synthetic feed product obtained by the treatment of the terrestrial animal manure with corn and / or soybeans. The method aims to provide a method for method for processing the microorganism synthetic feed using the animal manure as a raw material and a product thereof, and the product has the advantages of rich nutrition, rich amino acid, good palatability, big animal feed intake and low feed cost, and can improve the disease resisting ability of livestock, poultry and aquatic animals.

Owner:梁耀棠

Method for removing heavy metal in electroplating waste

InactiveCN101172688ASimple processEasy to manageWater/sewage treatment by flocculation/precipitationGramChemistry

The invention provides a method of removing the heavy metal in electroplating waste water, and belongs to the technical filed of environmental protection. Electroplating waste water is waste water containing chrome (Cr), waste water containing nickel (Ni), waste water containing cadmium (Cd), waste water containing copper (Cu), waste water containing zinc (Zn), waste water containing aurum (Au) and waste water containing argentums (Ag), or mixed-heavy metal waste water containing various heavy metals. 2 to 5 grams of tanning wet sludge is added into each liter of electroplating waste water; quickly stirring for 20 to 30 minutes and resting for 30 minutes, after the suspended sludge particles are settled, the solid is separated from the liquid; the supernatant solution can be discharged, and the sludge is dehydrated and compressed and then performed harmless treatment. The tanning wet sludge is the sludge produced during producing the raw hide, with 50 to 60 percent of water ratio, 30 to 50 percent of crude protein and 27 to 44 percent of cellulose.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

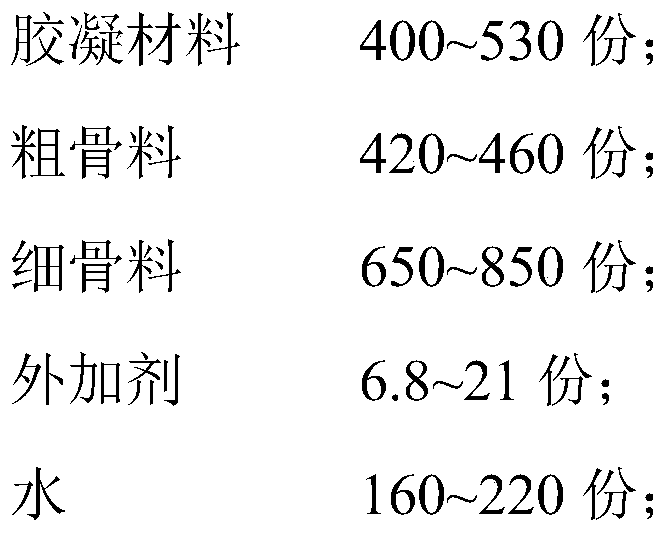

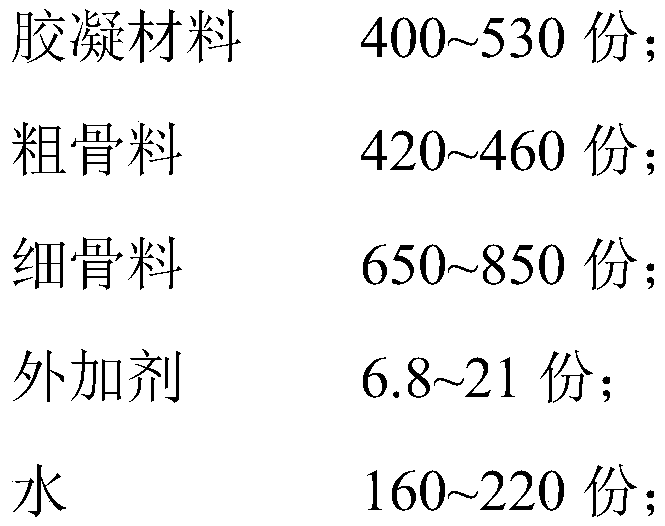

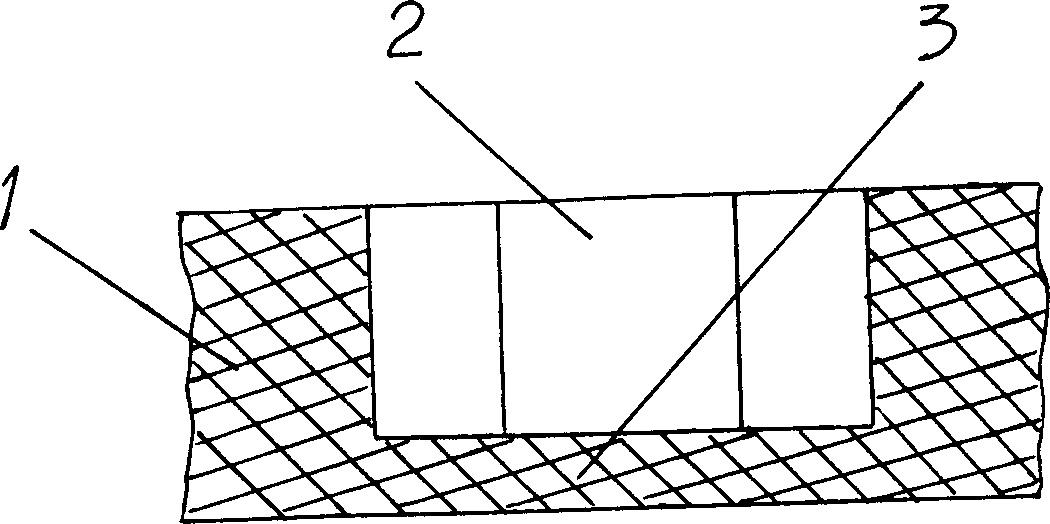

Lightweight high-strength ceramsite concrete as well as preparation method and application thereof

The invention relates to lightweight high-strength ceramsite concrete as well as a preparation method and application thereof, and relates to the field of building materials. The ceramsite concrete iscomposed of the following components in parts by weight: 400 to 530 parts of a cementing material, 420 to 460 parts of coarse aggregate, 650 to 850 parts of fine aggregate, 6.8 to 21 parts of admixtures, and 160 to 220 parts of water, wherein the coarse aggregate is fly ash ceramsite, the fine aggregate is composed of furnace slag and sand, and the admixtures include a polycarboxylic acid water reducing agent and an enhancing agent. The method uses ultra-fine modified fly ash, cement and activated silicon micropowder as the cementing material, the furnace slag and the river sand as the fine aggregate, and the fly ash ceramsite as the coarse aggregate to prepare the lightweight high-strength prefabricated component, and effectively solves the problem of ceramsite concrete layering due to asmall ceramsite density, and the prepared ceramsite concrete has high strength, is convenient for actual construction operation, and effectively uses solid waste, thereby facilitating environmental protection.

Owner:HEFEI UNIV OF TECH +1

Method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying mother solution

The invention discloses a method for synthesizing TBBS (Tertiarybutyl Benzothiazole Sulfenamide) by mechanically applying a mother solution, comprising the following steps of: adding water or mother solution and a rubber accelerator according to the mass ratio of 1:2-6 in a kettle for pulping, wherein the mechanical apply ratio of the mother solution is 20-100 percent; adding tert-butylamine, wherein the mol ratio of the tert-butylamine to the rubber accelerator is 1:1.05-5; dropping an NaCLO oxidant solution in the material at the temperature of 20-70DEG C, detecting the ending point with copper acetate and starch potassium iodide and stopping dropping the oxidant at the ending point; and carrying out the filtering, the washing and the drying to obtain the accelerator TBBS product. The invention has the advantages that: the mother solution is directly recycled, thereby not only reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption, but also according with the environment-friendly policy of the state. The accelerator TBBS has over 98 percent of yield, 98 percent of purity and over 105DEG C of melting point. The invention also has the advantages that the method has simple process and is easy to industrialize and the mother solution is directly recycled, thereby reducing the discharge of high-salinity sewage, the pressure of distilling and recovering the tert-butylamine and energy consumption; in addition, the yield of the product is improved and the consumption of the tert-butylamine is reduced, so that the invention reduces the production cost and accords with the environment-friendly policy of the state.

Owner:KEMAI CHEM

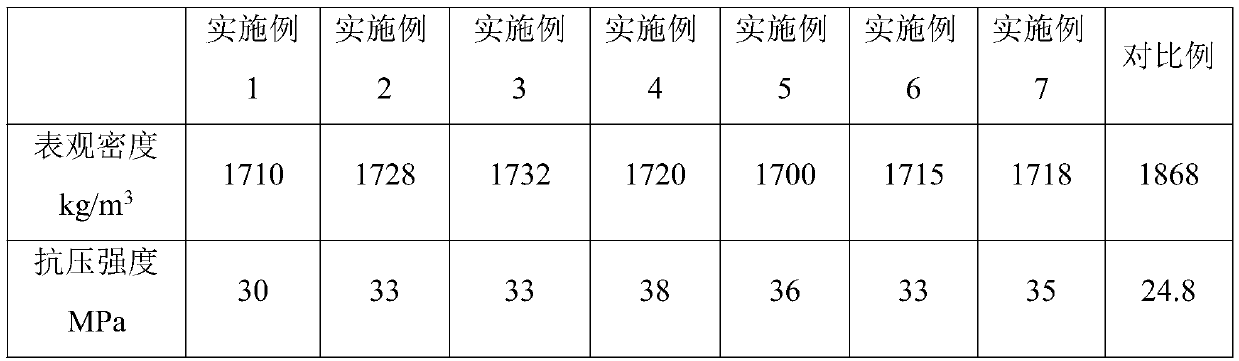

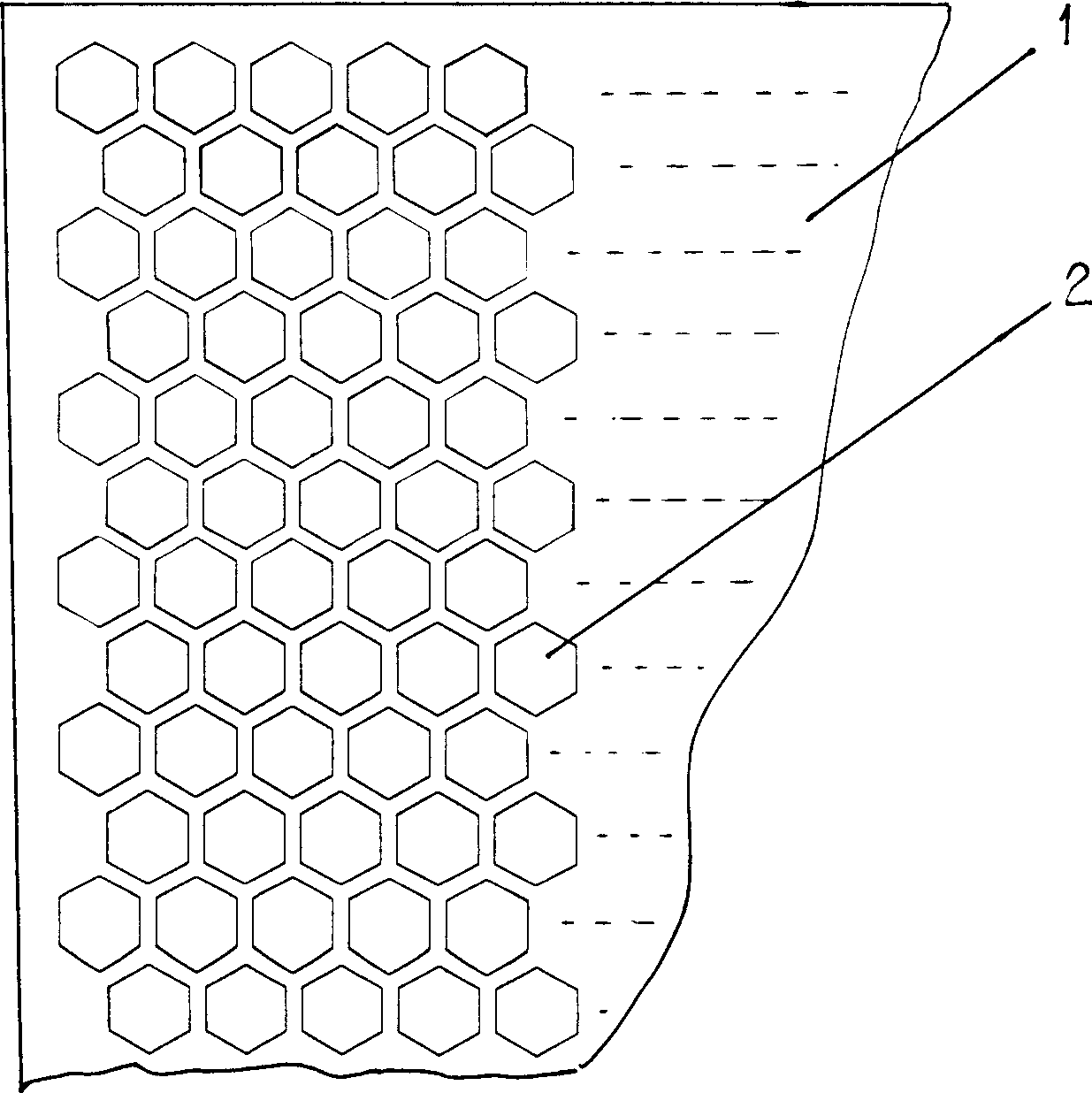

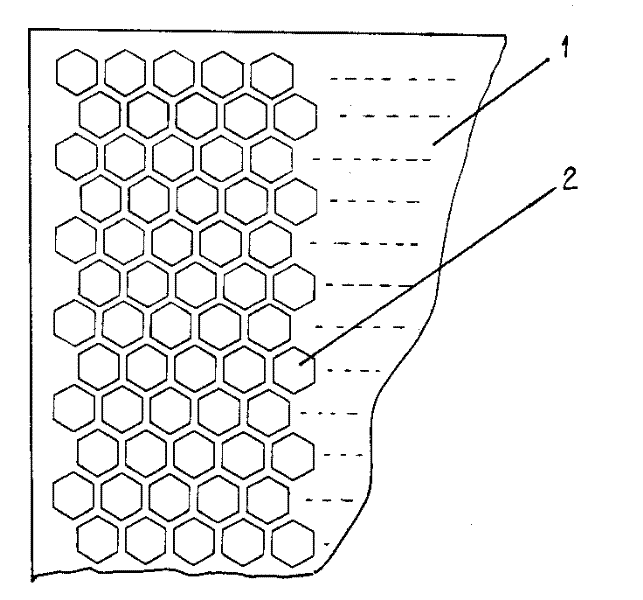

Honeycomb paper-base plate and its producing method

InactiveCN1408952ADegradableImprove bending abilityLayered productsWood working apparatusEmulsionMolding machine

The present invention is a kind timber substituting packing material and its production process. The honeycomb paper-base plate ahs regular hexagonal notches on its one side. The production process includes compounding adhesive with starch and water through mixing and curing; compounidng waterproof agent with dispersed rosin emulsion, stearic acid and paraffin emulsion, and polystyrene and polyacrylic emulsion; compounding glue-containing pulp via adding adhesive, wet strengthening agent, waterproof agent and asistant to concentrated pulp while stirring; molding in mold in the molding machine; demolding and stoving. The present invention has relatively high compressino and bending strength and is degradable, and may be used in packing, building decorating, furniture, etc.

Owner:华克勤

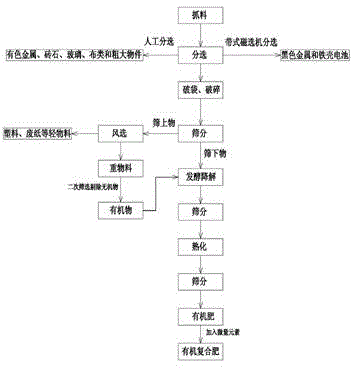

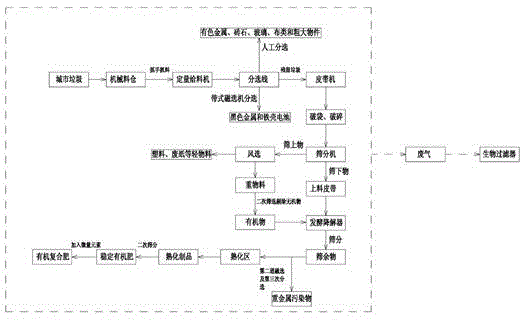

Processing technology for harmlessly reducing city garbage and converting city garbage into resources

InactiveCN106031925ASolve environmental problemsRealize resourcesSolid waste disposalTrace elementEnvironmental engineering

The invention discloses a processing technology for harmless reducing city garbage and converting city garbage into resources. The processing technology comprises the following steps: step one, grabbing garbage; step two, sorting; step three, breaking the bags and grinding city garbage; step four, sieving the city garbage; step five, carrying out fermentation to degrade the garbage; step six, sieving the garbage; step seven, aging; step eight, sieving; and step nine, adding trace elements. The processing technology has the following advantages: (1) the environment pollution is eliminated, and the garbage is converted into resources; (2) the problem that the city is surrounded by garbage is solved, and the garbage is converted into resources and reduced harmlessly; (3) the cyclic utilization of resources is realized, the energy is saved, the discharge is reduced, the resources is maximally utilized, the environment is protected, the garbage is recovered and converted into resources, and no secondary pollution is generated.

Owner:北京昌东科技有限公司

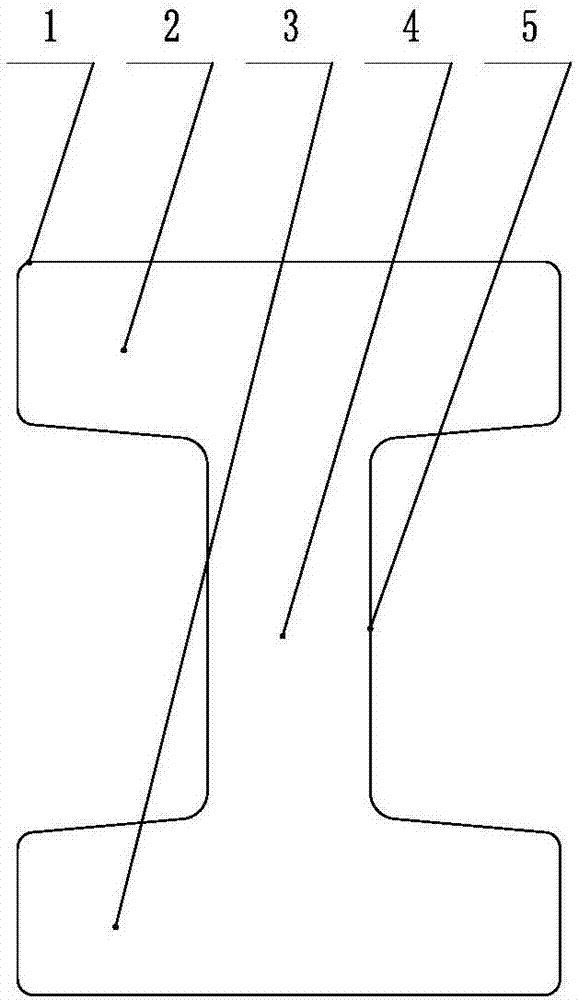

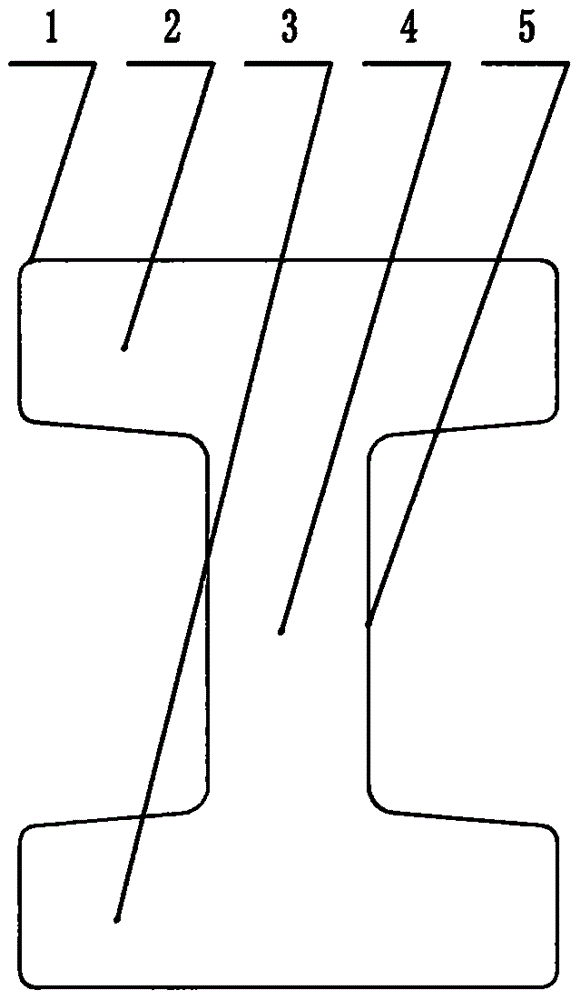

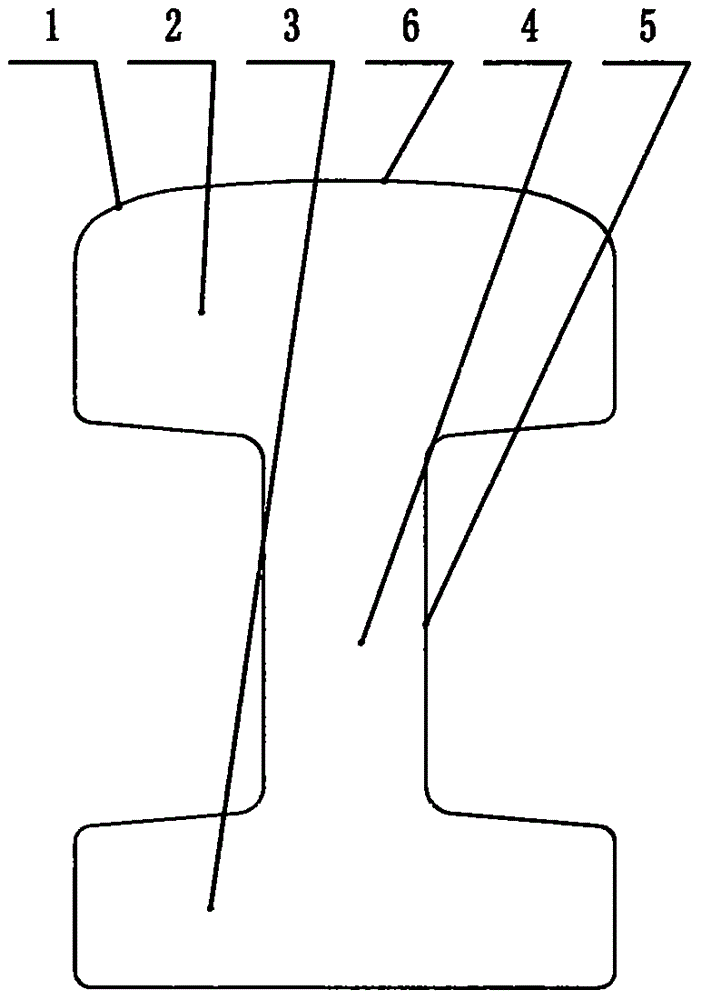

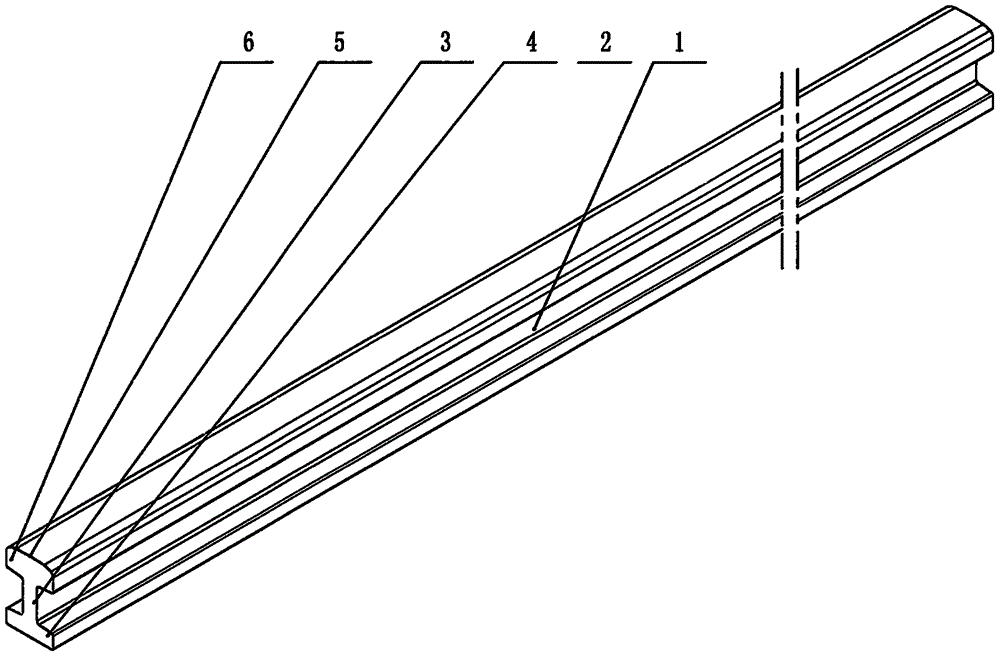

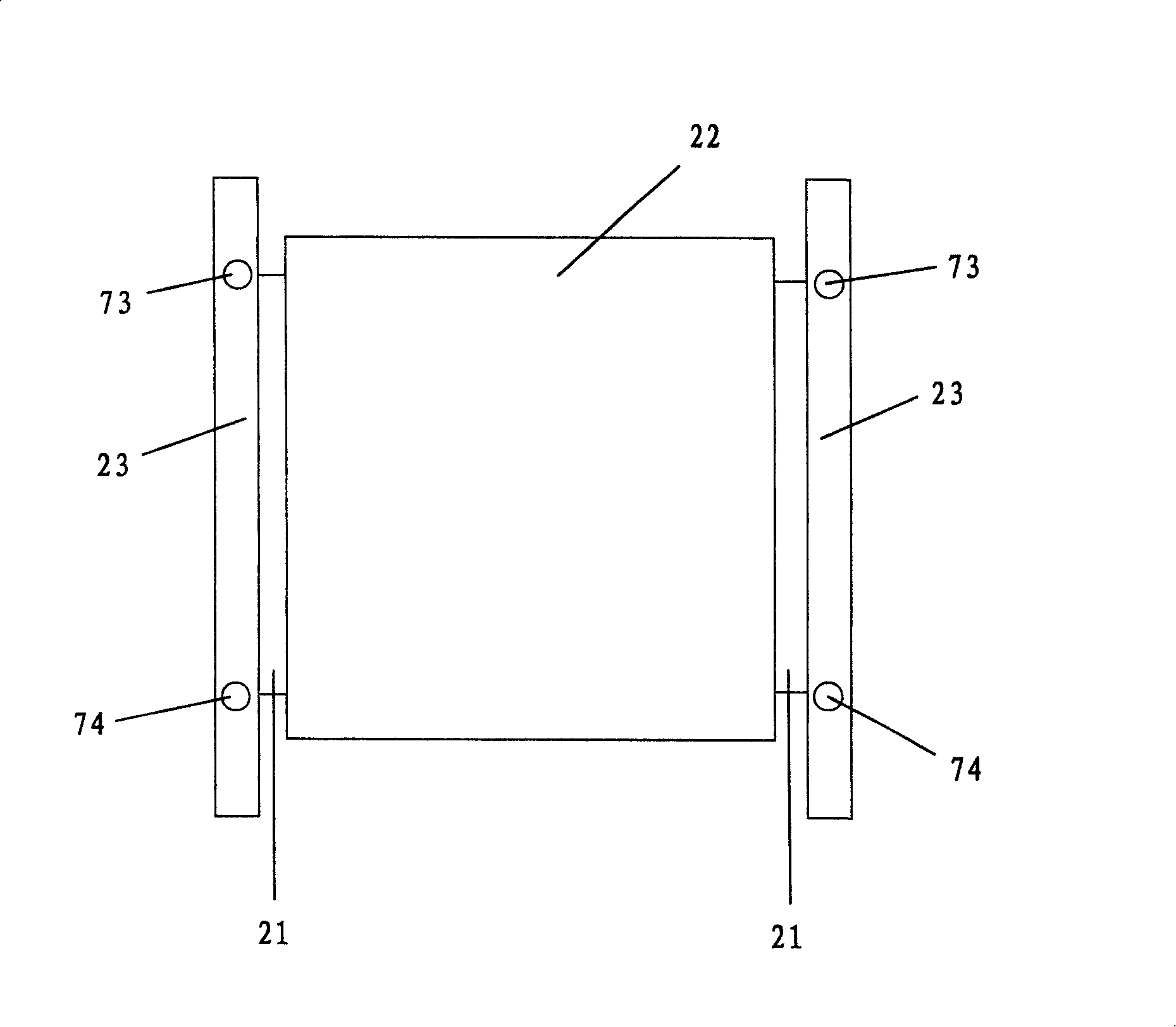

Permanent magnet suspension train track system

ActiveCN107190595AAchieving passive levitationSlight contact forceRailway tracksElectric propulsionUltra high speedPermanent magnet linear motor

The invention provides a permanent magnet suspension train track system, specifically discloses a permanent magnet suspension track system, which is formed by suspension steel rails, a permanent magnet suspension track and permanent magnet suspension components, and introduces a permanent magnet suspension train system, which is formed in such a way that a train runs on the permanent magnet suspension track system, wherein the permanent magnet suspension track is arranged by using the suspension steel rails, and the permanent magnet suspension components are arranged on two sides of the suspension steel rails. The permanent magnet suspension components comprise upper magnetism collection boards, lower magnetism collection boards and suspension permanent magnets; and the magnetic gap between the permanent magnet suspension components is equal to the magnetic gaps between the left end surfaces and the right end surfaces of upper and lower yoke plates of the suspension steel rails. When the train matches with the track to run in a suspended manner, a bilateral permanent magnet linear motor efficient tractor train is formed by horizontal guide wheels, a traction coil of linear motor and a traction permanent magnet to build a safe, ultra high-speed and energy-saving novel rail transit system, wherein the horizontal guide wheels are arranged on the left side and the right side of the train, the traction coil of the linear motor is arranged on the track and the traction permanent magnet is arranged on the train. The permanent magnet suspension train track system has the advantages that automatic balancing passive suspension can be achieved, the traction driving efficiency is high, the cost is low, the permanent magnet suspension train track system is economic and energy-saving, the service life of the track is long, the permanent magnet suspension train track system is convenient to mount and adjust, and the permanent magnet suspension train track system is compatible with the existing wheel-rail track and is much safer than the existing wheel-rail track.

Owner:DALIAN WHIM SCI & TECH LTD CO

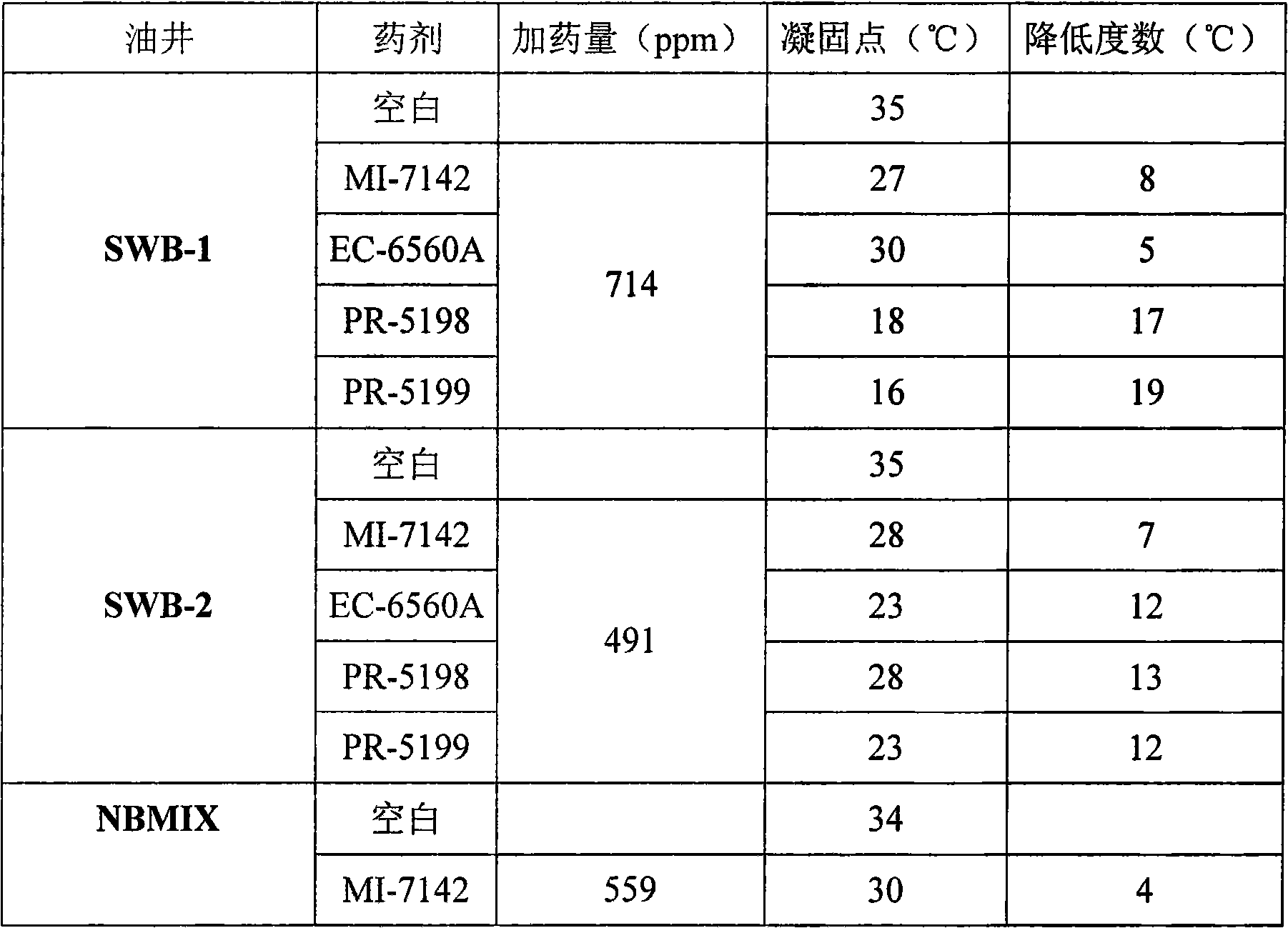

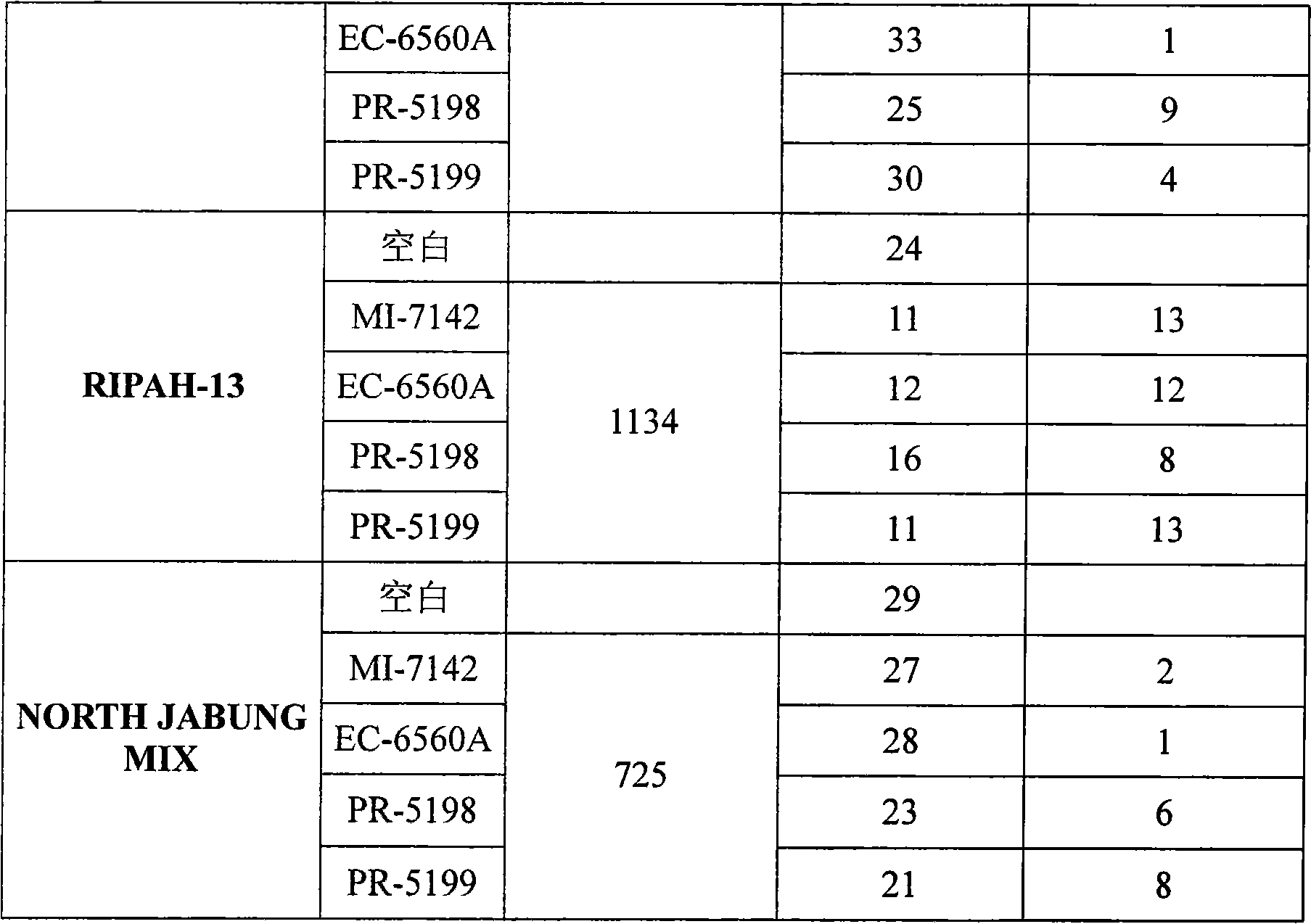

Broad-spectrum wax-proof pour point depressant for crude oil

The invention provides a broad-spectrum wax-proof pour point depressant for crude oil. Octadecyl acrylate, methacrylic acid docosane ester, styrene and maleic anhydride are mixed according to certain proportion and then react for 4 to 4.5 hours at a temperature of between 120 and 125 DEG C to form an agent A; 3-ethyl toluene and fatty alcohol-polyoxyethylene ether are mixed according to certain proportion and then react for 2 to 2.5 hours at a temperature of between 60 and 65 DEG C to form an agent B; and the agent A and the agent B are mixed, the temperature of the mixture is kept constant for 1 to 1.5 hours at a temperature of between 80 and 85 DEG C, and then the mixture is permitted to stand for 1.5 to 2 hours to form the pour point depressant. The pour point depressant has wide application range and good pour point depression effect, effectively improves the liquidity of the crude oil, is safe and reliable, has good environmental benefit, and can increase the yield of the crude oil, reduce the times of thermally washing the well and reduce the production cost of oilfields.

Owner:PANJIN LIAOHE OILFIELD YULONG RUIDA PETROLEUM TECH CO LTD

Symmetric permanent-magnetic suspension system and permanent-magnetic suspension train rail system

ActiveCN106012716ARealize automatic balanceAchieving passive levitationRailway tracksElectric propulsionAutomotive engineeringMagnetic suspension system

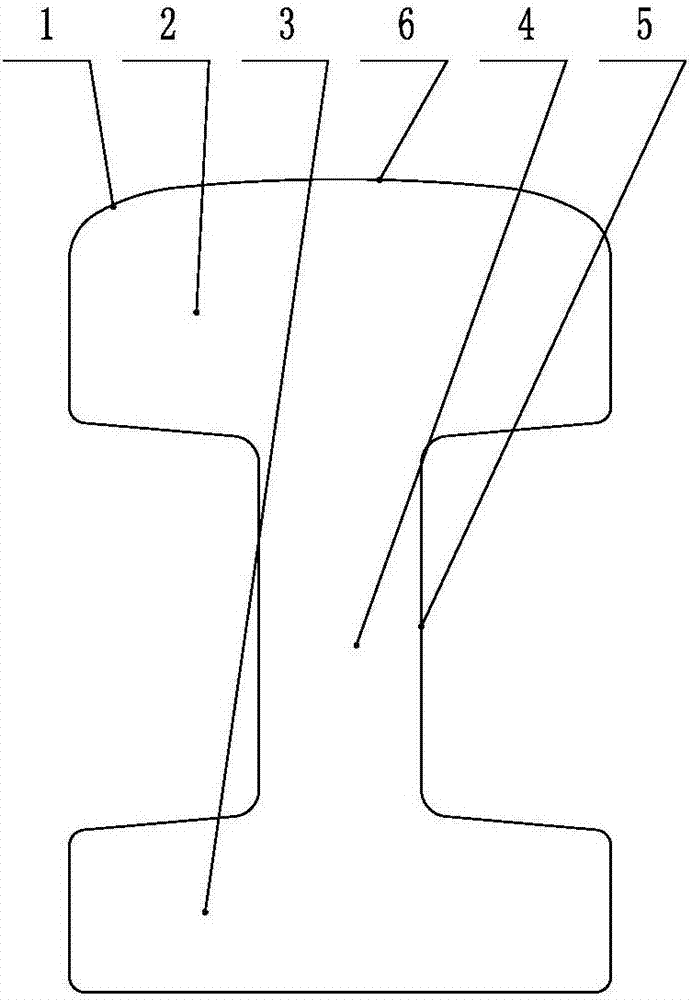

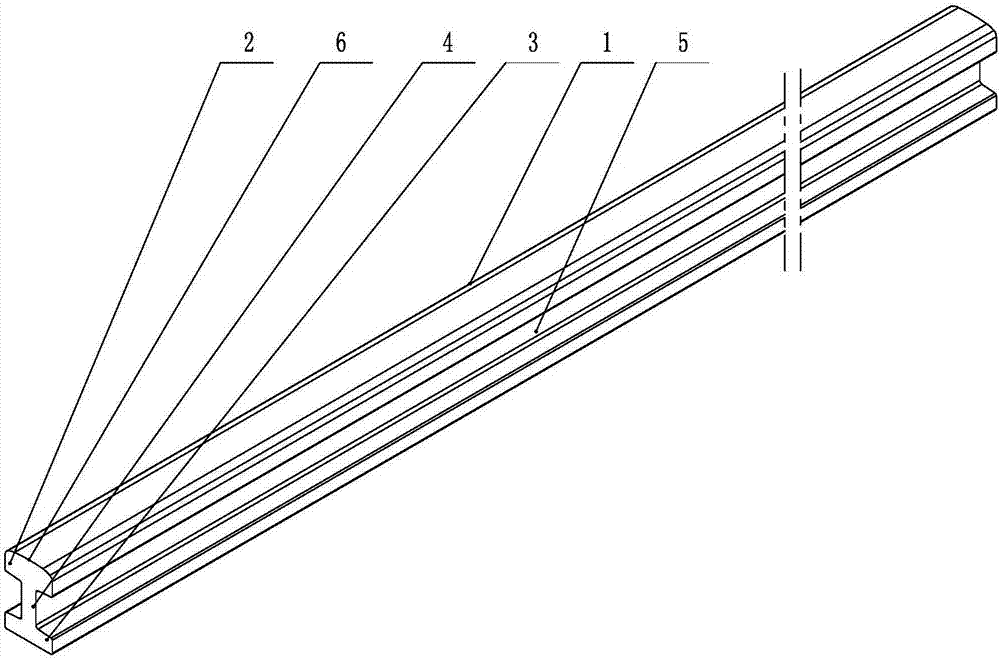

The invention provides a symmetric permanent-magnetic suspension system and a permanent-magnetic suspension train rail system. The symmetric permanent-magnetic suspension system is characterized in that I-shaped suspension steel rails 1 made of a magnetic conductive material are arranged in the middle of the system; permanent-magnetic suspension assemblies 15 are symmetrically arranged on two sides of each I-shaped suspension steel rail 1; each permanent-magnetic suspension assembly 15 comprises an upper magnetism collection plate 12, a lower magnetism collection plate 14 and a suspension permanent magnet 13 arranged between the upper magnetism collection plate 12 and the lower magnetism collection plate 14; the magnetic gap of left and right end faces of the upper magnetism collection plates 12 and the lower magnetism collection plates 14 of left and right permanent-magnetic suspension assemblies is equal to that of left and right end faces of the upper yoke plates 2 and lower yoke plates 3 of the I-shaped steel rails 1, and upper and lower directions of the upper and lower magnetism collection plates and upper and lower yoke plates are staggered at a certain interval, so that passive suspension can be realized; left and right I-shaped suspension steel rails 1 are arranged at two ends of a sleeper 11, horizontal guide wheels (8) are arranged on left and right sides of a train; linear motor driving coils (8) are arranged on the rail, and form a two-sided permanent-magnetic linear motor high-efficiency traction train with a traction permanent-magnet on the train, and a safe, superspeed and energy-saving novel rail transition system is constructed.

Owner:DALIAN WHIM SCI & TECH LTD CO

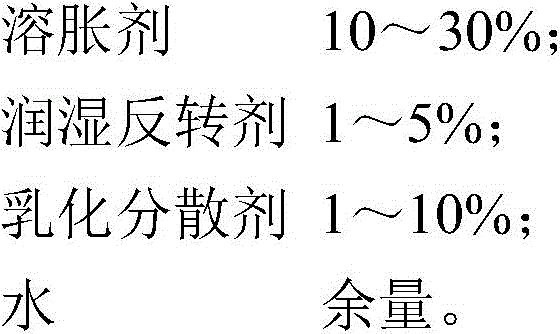

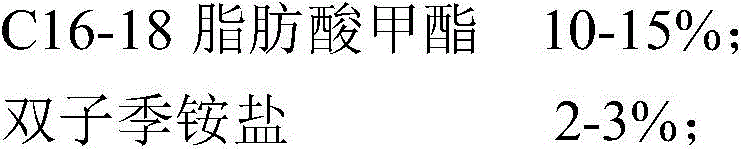

Environment-friendly microemulsion paraffin removal and control agent and preparation method

InactiveCN106190078APromote degradationComply with environmental policySurface-active detergent compositionsDetergent mixture composition preparationWaxOrganic solvent

The invention relates to an environment-friendly microemulsion paraffin removal and control agent. The environment-friendly microemulsion paraffin removal and control agent is prepared from, by mass, 10%-30% of swelling agent, 1%-5% of reverse wetting agent, 1%-10% of emulsion dispersant and the balance water, wherein the total mass percent of the swelling agent, the reverse wetting agent and the emulsion dispersant ranges from 20% to 40%. The environment-friendly microemulsion paraffin removal and control agent has the advantages that the biodegradability is good, no organic solvent is contained, paraffin removal and control are both achieved, the paraffin removal and control agent is suitable for oil wells which are different in degree of mineralization and temperature, stable in storage and convenient to use, and the product is neutral and does not corrode oil pipes.

Owner:BEIJING SHENGCHANG CENTURY PETROLEUM TECH

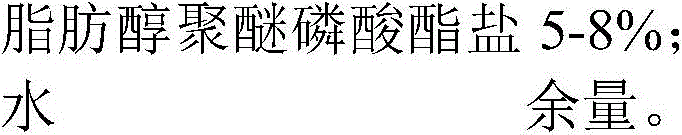

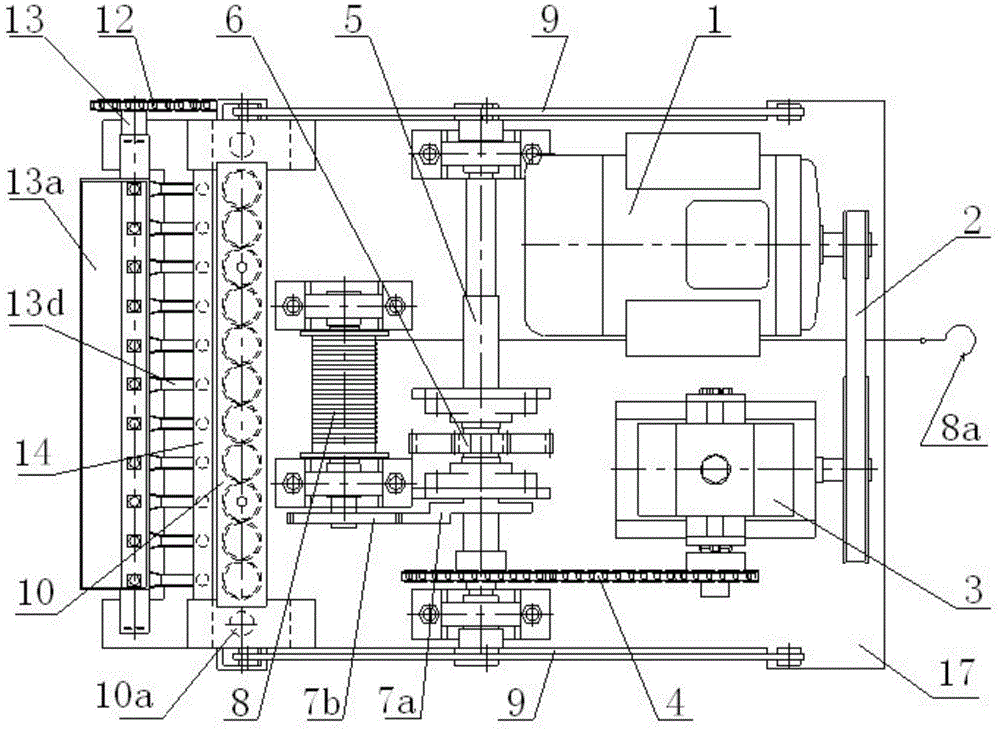

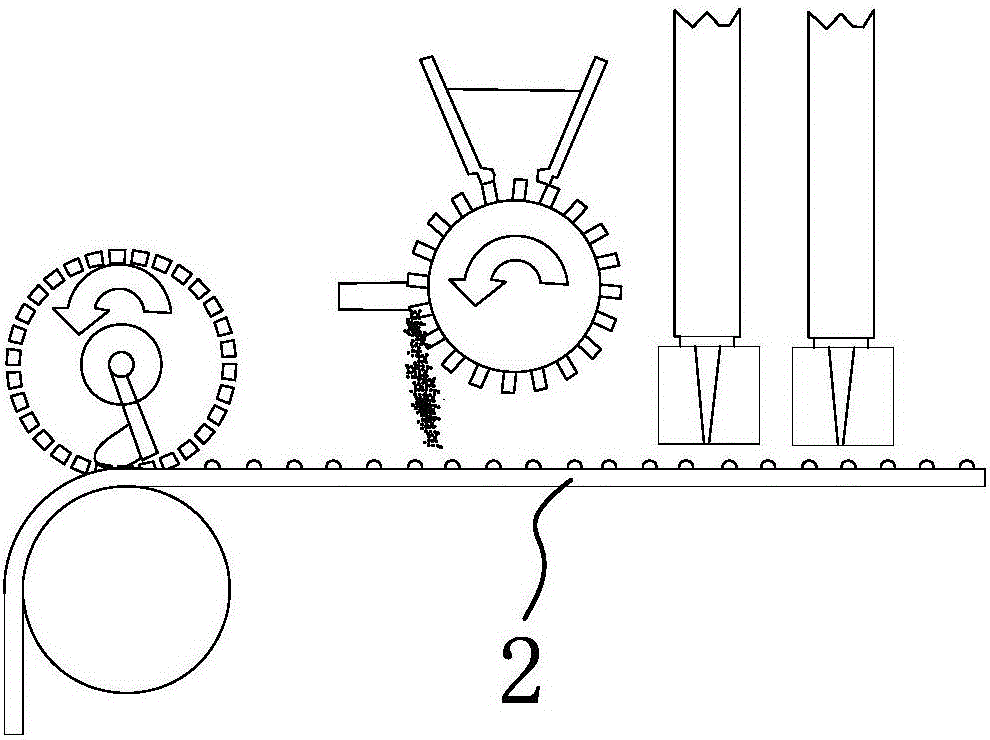

Nutrition pot continuous manufacturing machine

The invention discloses a nutrition pot continuous manufacturing machine comprising a belt transmission mechanism, chain transmission mechanisms, a gear transmission mechanism, a ratchet transmission mechanism, a connection rod transmission mechanism, and the like. A power part adopts an AC motor 1. The AC motor 1 is connected with the belt transmission mechanism 2. Through speed reducing of a reducer 3, a first chain transmission mechanism 4 drives a main transmission shaft 5. The main transmission shaft 5 drives a reel 8 through the gear transmission mechanism 6 and the ratchet transmission mechanism 7. The reel rolls up a steel wire rope hanged by a hook. An entire nutrition pot manufacturing machine travels forward along the direction of the steel wire rope. The main transmission shaft 5 drives the connection rod transmission mechanism 9 to move downwards. A nutrition pot manufacturing mechanism 10 presses to form nutrition soil. The main transmission shaft 5 drives the connection rod transmission mechanism 9 to move upwards. A push plate mechanism 11 pushes out formed nutrition soil. A second chain transmission mechanism 12 acts synchronously with the nutrition pot manufacturing mechanism 10, such that a seed distribution shaft 13b is driven and performs seed distribution when the nutrition pot manufacturing mechanism 10 moves downwards.

Owner:武汉长江控制设备研究所有限公司

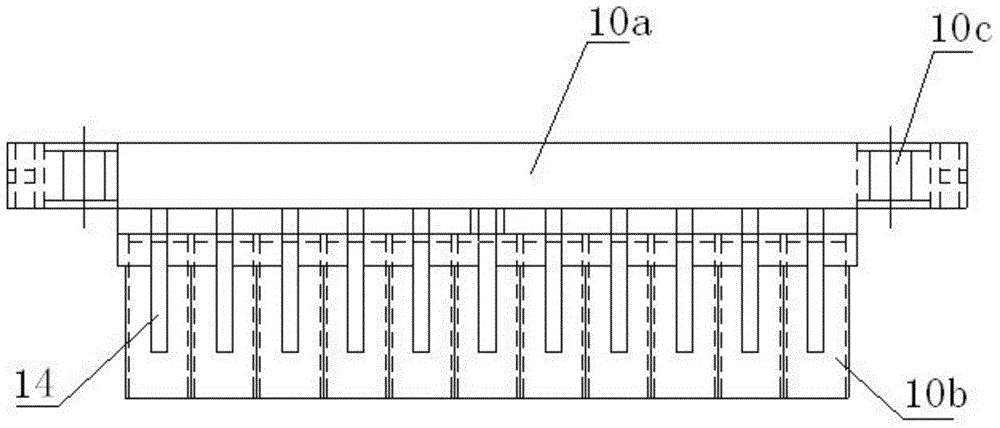

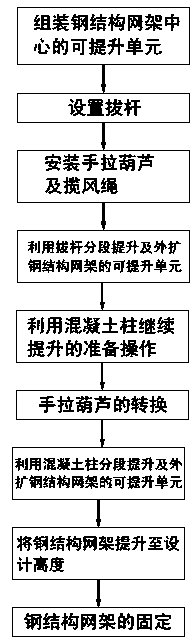

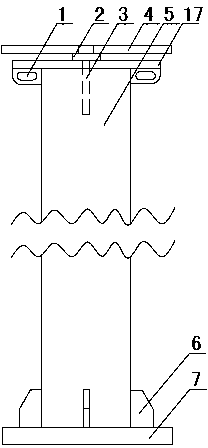

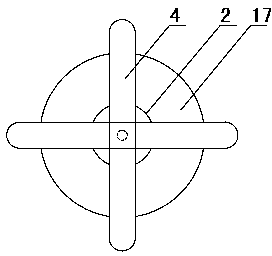

Externally expanding, assembling, converting and lifting method for medium/small span steel structure roof net rack

InactiveCN103352576ASolve lifting construction problemsImprove securityBuilding material handlingArchitectural engineeringLifting equipment

An externally expanding, assembling, converting and lifting method for a medium / small span steel structure roof net rack belongs to the field of site construction in building construction engineering. The method comprises the following steps of assembling a lifting unit in the center of the steel structure roof net rack, arranging a shifting rod, installing a chain block and a cable rope, using the shifting rod to lift, externally expand and assemble the lifting unit of the steel structure net rack in a subsection mode, utilizing a concrete column (13) to continue lifting preparation operation, converting the chain block (12), utilizing the concrete column (13) to lift, externally expand and assemble the lifting unit of the steel structure net rack in a subsection mode, lifting the steel structure net rack to the design height, and fixing the steel structure net rack. The externally expanding, assembling, converting and lifting method for a medium / small span steel structure roof net rack solves the difficult problem that when the steel structure net rack is lifted in a medium / small span building, the steel structure net rack cannot be wholly lifted on the ground due to the fact that large lifting equipment cannot enter the medium / small span building and further solves the difficult problem that when only the shifting rod is utilized to lift the steel structure net rack, the difficult problems of the lifting construction the steel structure net rack cannot be solved.

Owner:SHANDONG JINCHENG STEEL STRUCTURE +1

Safe-type plant washing liquid and preparation method therefor

InactiveCN103361208ARaise the level of full serviceHumanized use effectSurface-active non-soap compounds and soap mixture detergentsSodium bicarbonateWarm water

The invention relates to a safe-type plant washing liquid, especially relates to a safe-type plant washing liquid used for washing of tableware and a preparation method, belongs to the field of civil environmentally-friendly-type washing products, aims to provide a safe-type plant washing liquid and a preparation method therefor. Cassia seeds, ginkgo leaves, soybeans, tea seeds and loofah sponge are crushed, placed into warm water with the temperature of 40-50 DEG C at certain ratios, soaked for hours, and filtered to obtain a mixing liquid. The mixing liquid is added with appropriate amounts of salt and sodium bicarbonate to form a safe-type plant washing liquid. The safe-type plant washing liquid can be used to wash tableware and wipe cooker. The safe-type plant washing liquid not only has strong washing and degreasing abilities, but also has hand-caring functions.

Owner:杨月滢

Coal chemical gasified slag sintered brick and preparation method thereof

The invention discloses a coal chemical gasified slag sintered brick. The coal chemical gasified slag sintered brick is mainly prepared from following raw materials in percentage by weight: 15%-45% ofgasified slag coarse slag, 8%-15% of gasified slag fine slag, 39%-75% of building waste soil, 0.1%-1% of additives. The invention further provides a method for preparing the coal chemical gasified slag sintered brick. According to the coal chemical gasified slag sintered brick, the gasified slag and the building waste soil are adopted as the raw materials of the coal chemical gasified slag sintered brick, thus the cost is low, pollution caused by gasified slag discarding to the environment can be reduced, the purposes of fuel saving, natural land resource saving and waste-utilizing environmental protection are achieved, the finished product rate of the sintered brick prepared by the method reaches 90% or above, the compressive strength of the sintered brick exceeds 20 MPa, the high void ratio and good water absorption are achieved, and heat preservation and insulation properties of the sintered brick are both significantly improved.

Owner:陕西万伟恒业科技有限公司

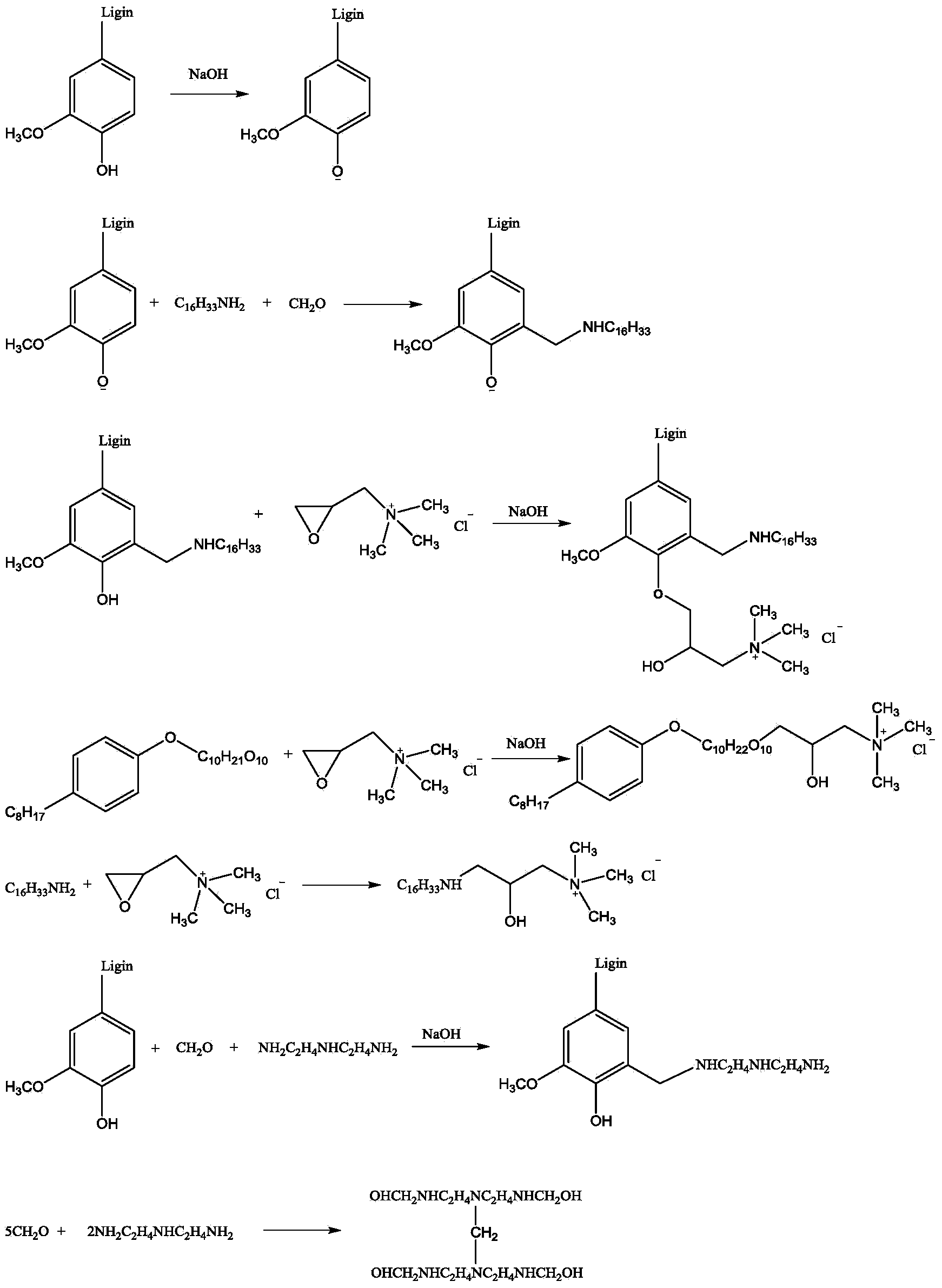

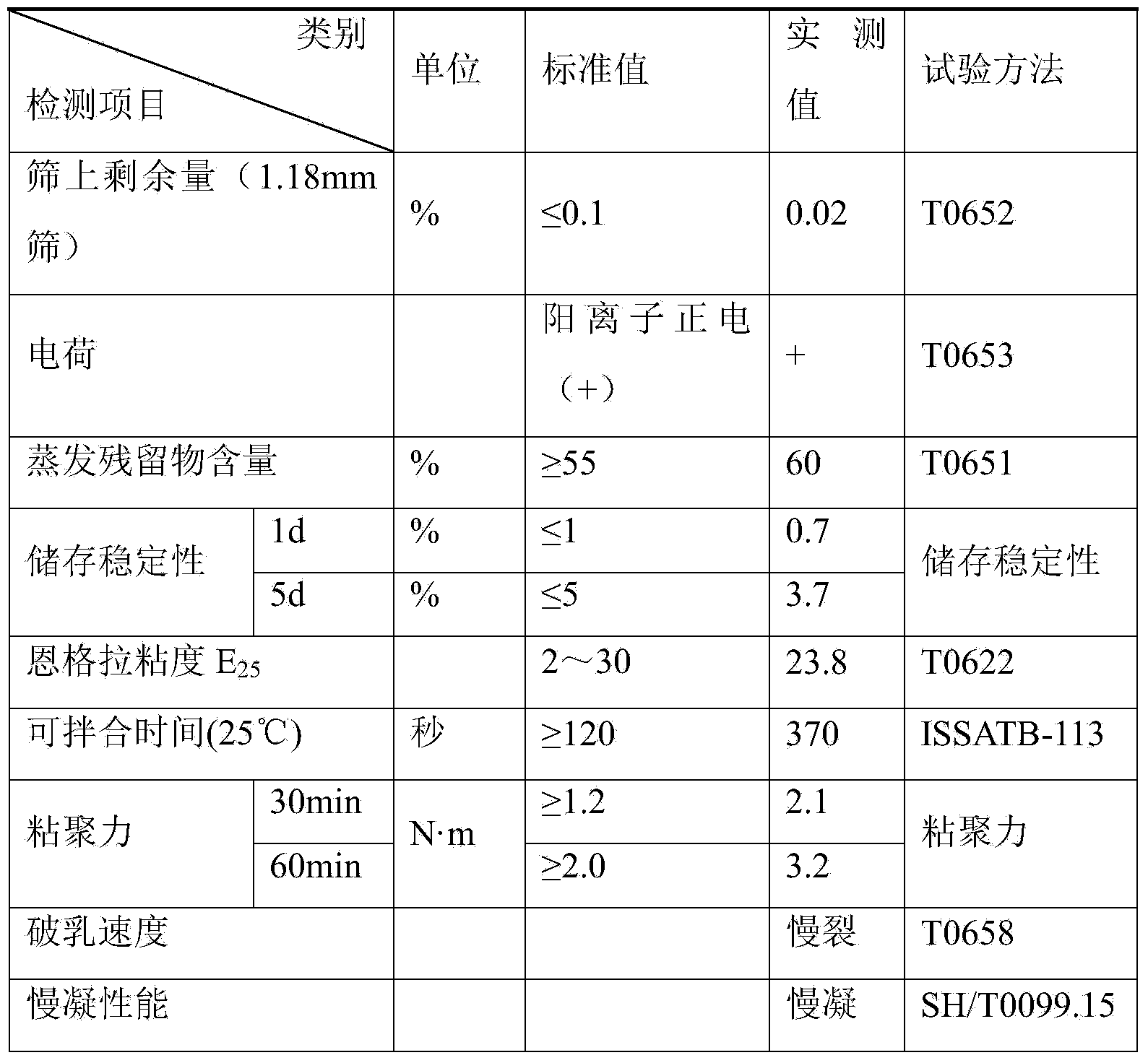

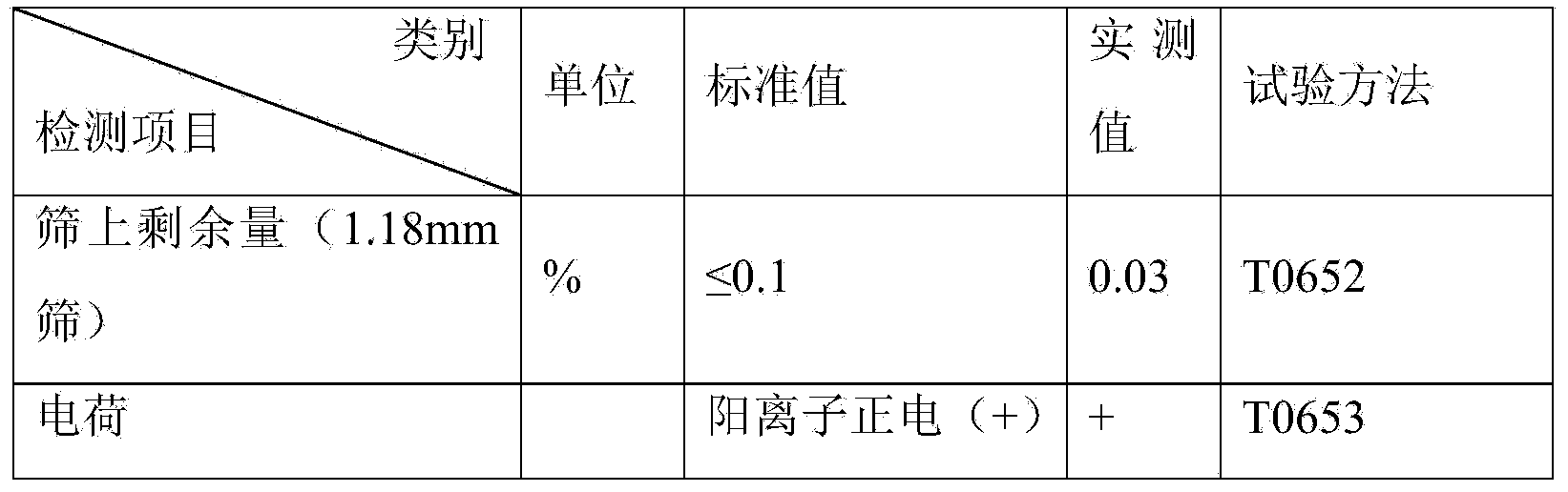

Preparation method of compound slow-breaking slow-curing positive ion asphalt emulsifier

The invention relates to the field of organic fine chemicals, in particular to a preparation method of a compound slow-breaking slow-curing positive ion asphalt emulsifier. The preparation method is characterized by comprising the following steps: dissolving lignin in a sodium hydroxide solution, and adding aliphatic amine; heating the sodium hydroxide solution and then adding formaldehyde for reaction; adding glycidyl trimethyl ammonium chloride for reaction; adding a polyoxyethylene ether nonionic surfactant for reaction; adding formaldehyde and polyethylene polyamine to continue reaction, and then adding a diluent for dilution to obtain the emulsifier. When the emulsifier prepared by the method is used for preparing an asphalt emulsion, the usage amount of the emulsifier is small, and the emulsifier is applicable to various stone and can be widely applied to the prime coat oil, the slurry seal and the like of an asphalt road.

Owner:CHINA PHARM UNIV +1

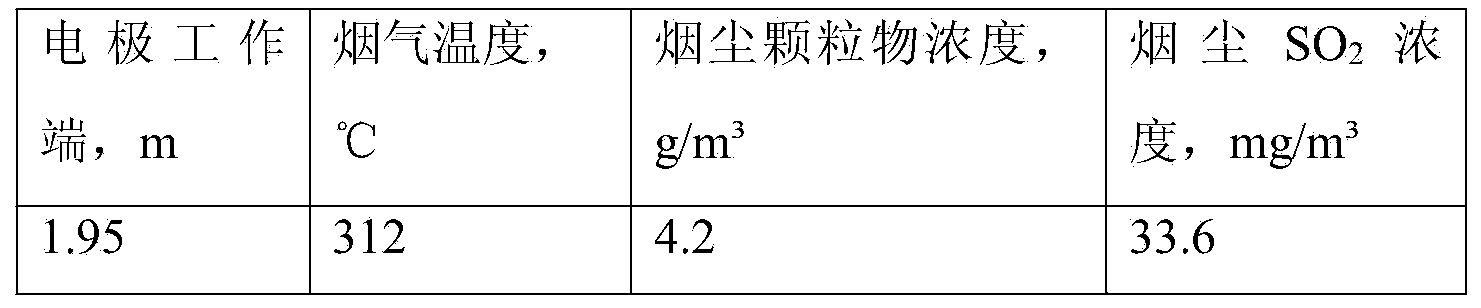

Desulfuration process for sintering flue gas

InactiveCN101862590ANot perishableLong storage periodDispersed particle separationCalcium sulfiteBuilding material

The invention discloses a desulfuration process for sintering flue gas, which adopts a desulfuration agent preparation system, a desulfuration system and a reclamation treatment system. The desulfuration agent is sodium bicarbonate, the 0.045mm standard sieve passing rate of which is no less than 75 percent. Compared with the prior art, the desulfuration process has the advantages that: the processing cost is over 30 percent lower than the cost of slaked lime; the prepared solid desulfuration agent is not easy to deteriorate, and has longer storage life compared with calcium hydroxide; the desulfuration efficiency is improved, and the running cost is reduced; the operation process is simplified; the desulfurized byproducts can be conveniently processed and utilized; and the produced mixture of calcium sulfate, calcium sulfite and calcium carbonate can be conveniently used for producing environment-friendly building materials such as lightweight building blocks, is far more stable than the current desulfurized byproducts and is easier to utilize so as to furthest reduce the discharge of solid wastes and the subsequent treatment expense and meet the current environment-friendly policy.

Owner:MAANSHAN IRON & STEEL CO LTD

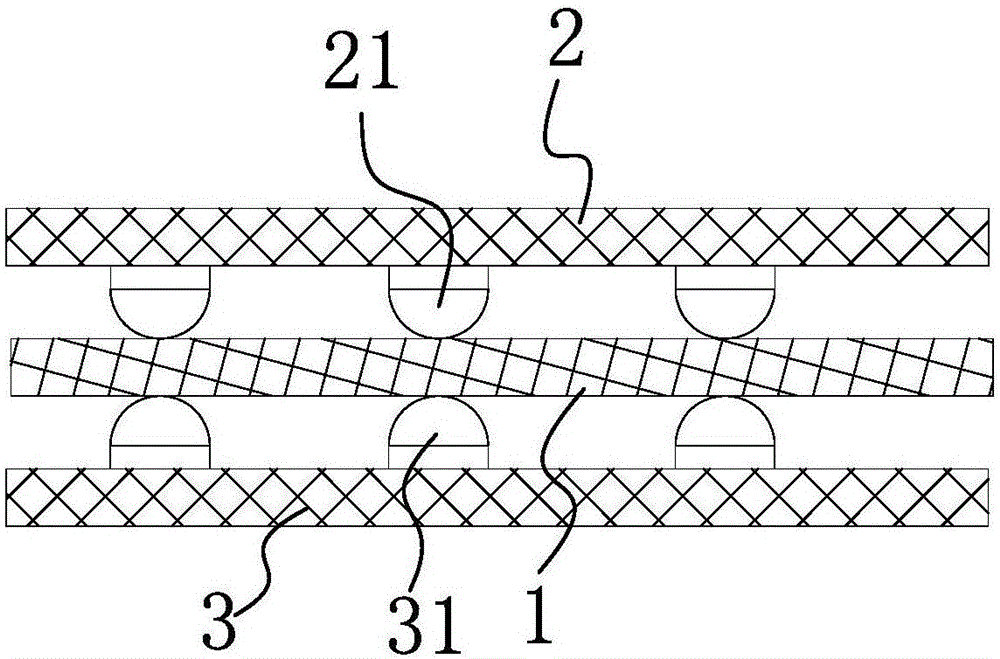

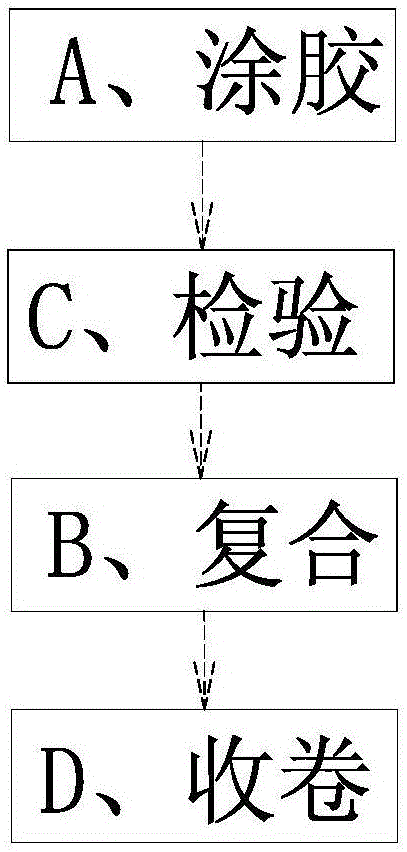

Three-layered composite automotive interior fabric and production process thereof

ActiveCN106183134AIncreasing the thicknessEasy dischargeLaminationLamination apparatusManufacturing cost reductionNonwoven fabric

The invention belongs to the technical field of fabrics and in particular relates to a three-layered composite automotive interior fabric and a production process thereof, and aims at solving the problems in the prior art that pocks are easy to generate and the fabric is not environment-friendly and the like. The three-layered composite automotive interior fabric comprises sponge, a water-repelling automotive fabric and a non-woven fabric; a first double-point coating is arranged on one face of the water-repelling automotive fabric and the water-repelling automotive fabric is compounded on one face of the sponge through the first double-point coating; a second double-point coating is arranged on one face of the non-woven fabric and the non-woven fabric is compounded on the other face of the sponge through the second double-point coating. The production process of the three-layered composite automotive interior fabric comprises the following steps: A, gluing; B, compounding. The three-layered composite automotive interior fabric and the production process thereof have the advantages that the manufacturing cost can be reduced and the pocks can be avoided; the peeling strength can be improved and the fabric is more environment-friendly.

Owner:CPL NEW MATERIAL TECH CO LTD

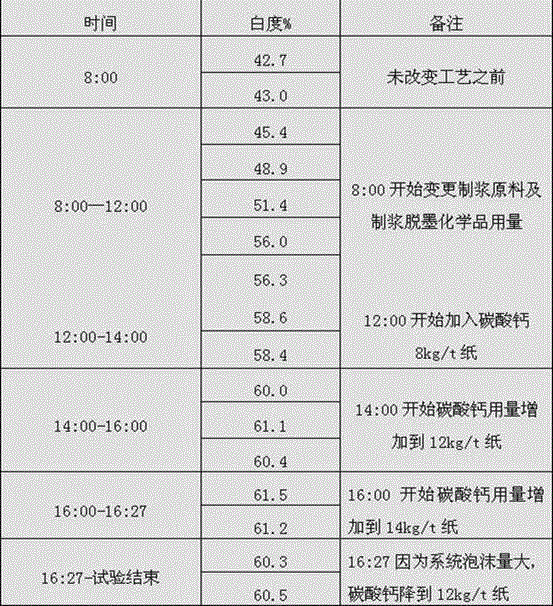

Production process of high-white-degree plasterboard surface protection paper

ActiveCN106638110ASave raw materialsReduce consumptionPaper recyclingSecondary cellulose fibresProduction linePulp and paper industry

The invention relates to a gypsum board surface protection paper preparation technology, in particular to a production process of high-white-degree plasterboard surface protection paper. The effect of improving the white degree of the gypsum board surface protection paper is achieved. The process comprises the steps of (1) pulp preparation: two production lines including a deinked pulp production line and an OCC production line which are respectively used for producing deinked pulp and OCC are used for pulp preparation; (2) paper making: the high-white-degree plasterboard surface protection paper is formed by compounding four layers of nets; (3) forming: the four layers of pulp are sprayed onto the four-layer forming net through a pulp flowing box; vacuum squeezing, pre-baking, surface gluing, post-baking and coiling are performed; and final recoiling is performed through a recoiling machine to form a paper roll. The product obtained by the process provided by the invention can reach high white degree, and the quality of the product is improved.

Owner:山西强伟纸业有限公司

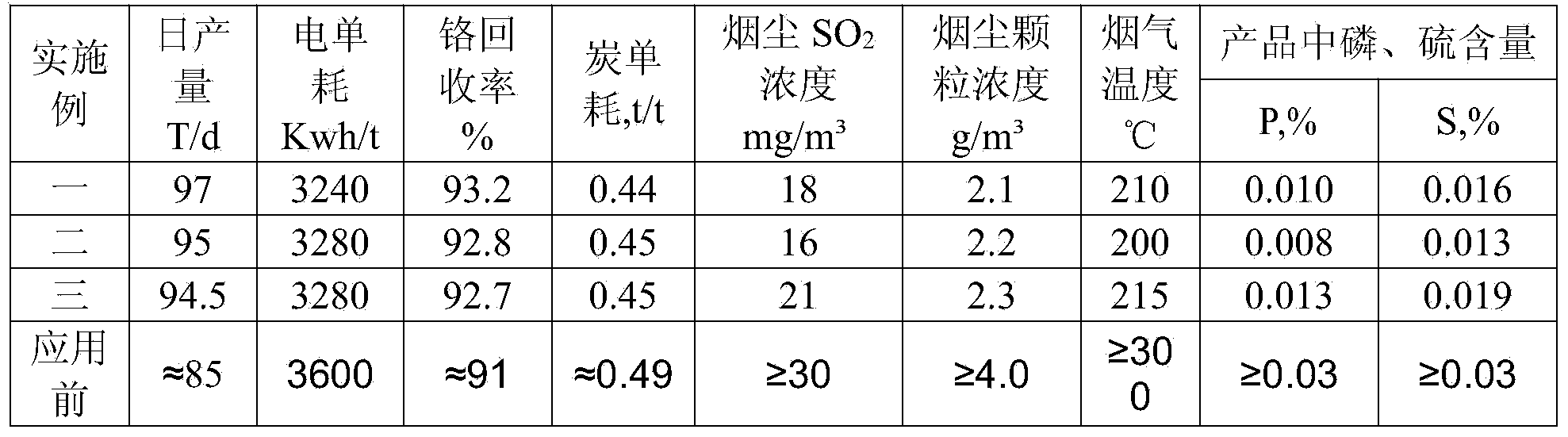

Production method for smelting high carbon chromium iron by using carbonaceous combination reducing agent

The invention discloses a production method for smelting high carbon chromium iron, belonging to the technical field of ferroalloy smelting. By adopting the production method, the consumption and comprehensive energy consumption of a carbonaceous reducing agent can be reduced. The production method is characterized in that the particle size, moisture and volatile matters are controlled by pretreatment measures through the reasonable matching of semi-coke, anthracite and metallurgical coke; the air permeability of furnace charge is ensured through the agglomeration treatment of ores so as to provide conditions for the matching of lots of semi-coke and coal; the uniformity is improved through batch-wise quantity control burdening and two-times mixing; the burdening error is reduced; the thickness of feed is controlled so as to ensure that the thickness of an in-furnace raw material layer is within 600mm, and the air permeability of the material layer is ensured; meanwhile, moisture in raw materials added to a furnace is timely dried under the effect of the high temperature of a charge level, the raw materials are preheated very well, and the air permeability of the furnace charge is further improved by pricking holes on the charge level. According to the production method, the carbonaceous combination reducing agent can be used for the smelting of slag-process high carbon chromium iron through the comprehensive measures, meanwhile, the consumption cost of the reducing cost is reduced, and the power consumption is reduced.

Owner:青海金广镍铬材料有限公司

Wear-resistant aluminum alloy section and preparation method thereof

ActiveCN106752713AImprove wear resistanceGood compatibilityAnodisationEpoxy resin coatingsEpoxyWear resistant

The invention discloses a wear-resistant aluminum alloy section and a preparation method thereof. The aluminum alloy material comprises an aluminum alloy substrate and a wear-resistant coating which coats the surface of the aluminum alloy substrate, wherein the wear-resistant coating is prepared from epoxy resin, an abrasive material, filler, a curing agent, a toughening agent, polyoxyethylene alcohol ether, solydimethyl siloxane, carboxymethyl cellulose and benzalacetone in a weight ratio. The preparation method for the wear-resistant aluminum alloy section comprises the following steps: firstly, cleaning and treating the surface of the aluminum alloy substrate; coating the wear-resistant coating, wherein the coating operation comprises the following steps: uniformly coating the surface of the aluminum alloy substrate with the prepared wear-resistant coating; pretreating at the temperature of 80 to 90 DEG C for 10 to 15 minutes; heating to 180 to 200 DEG C; performing thermal treatment for 2 to 3 hours; lastly, naturally cooling to the room temperature to obtain a final product. The wear-resistant aluminum alloy section is simple in process, and has a good friction resisting effect; meanwhile, a formed coating is environment-friendly, and conforms to the environmental protection policy.

Owner:力同铝业(上海)有限公司

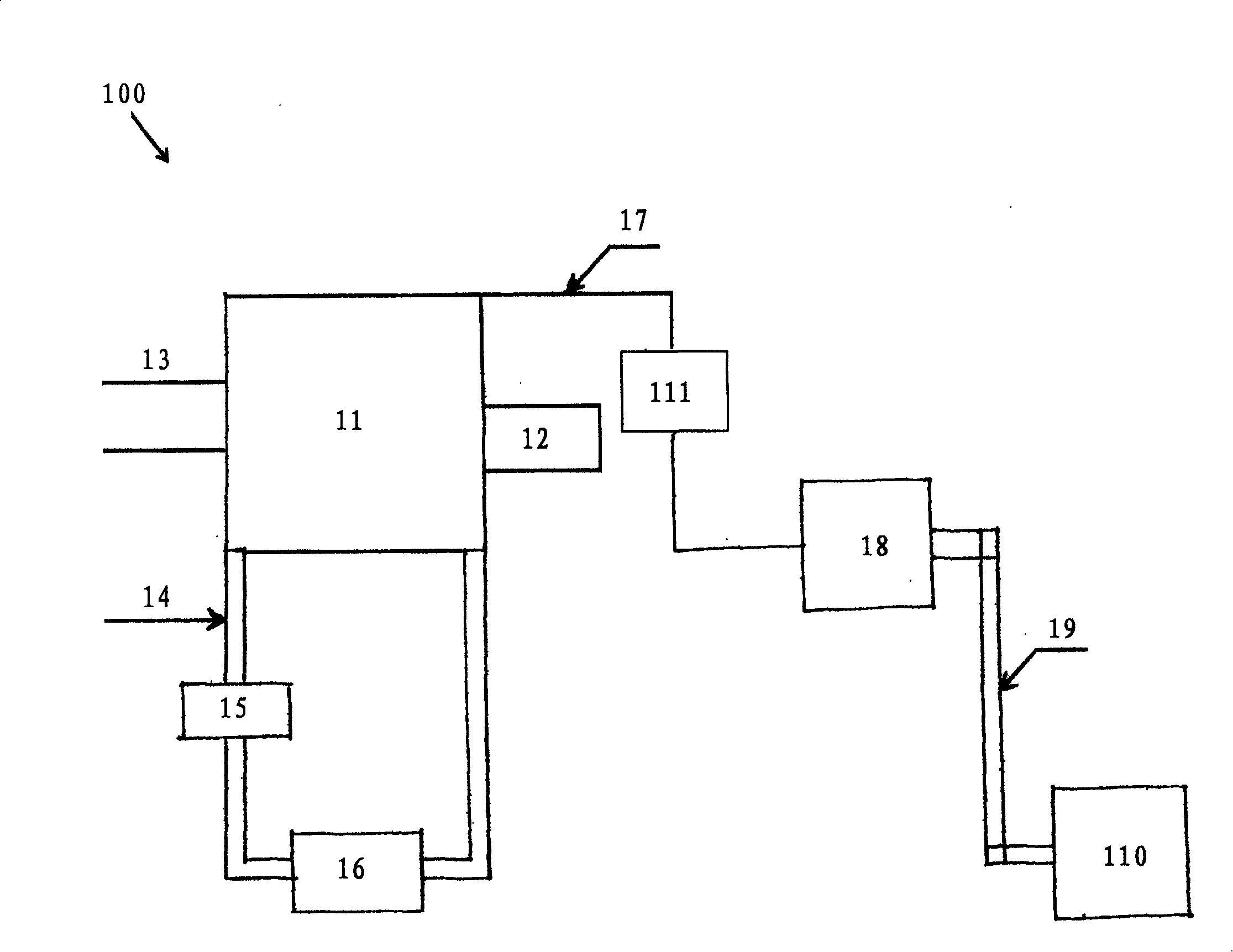

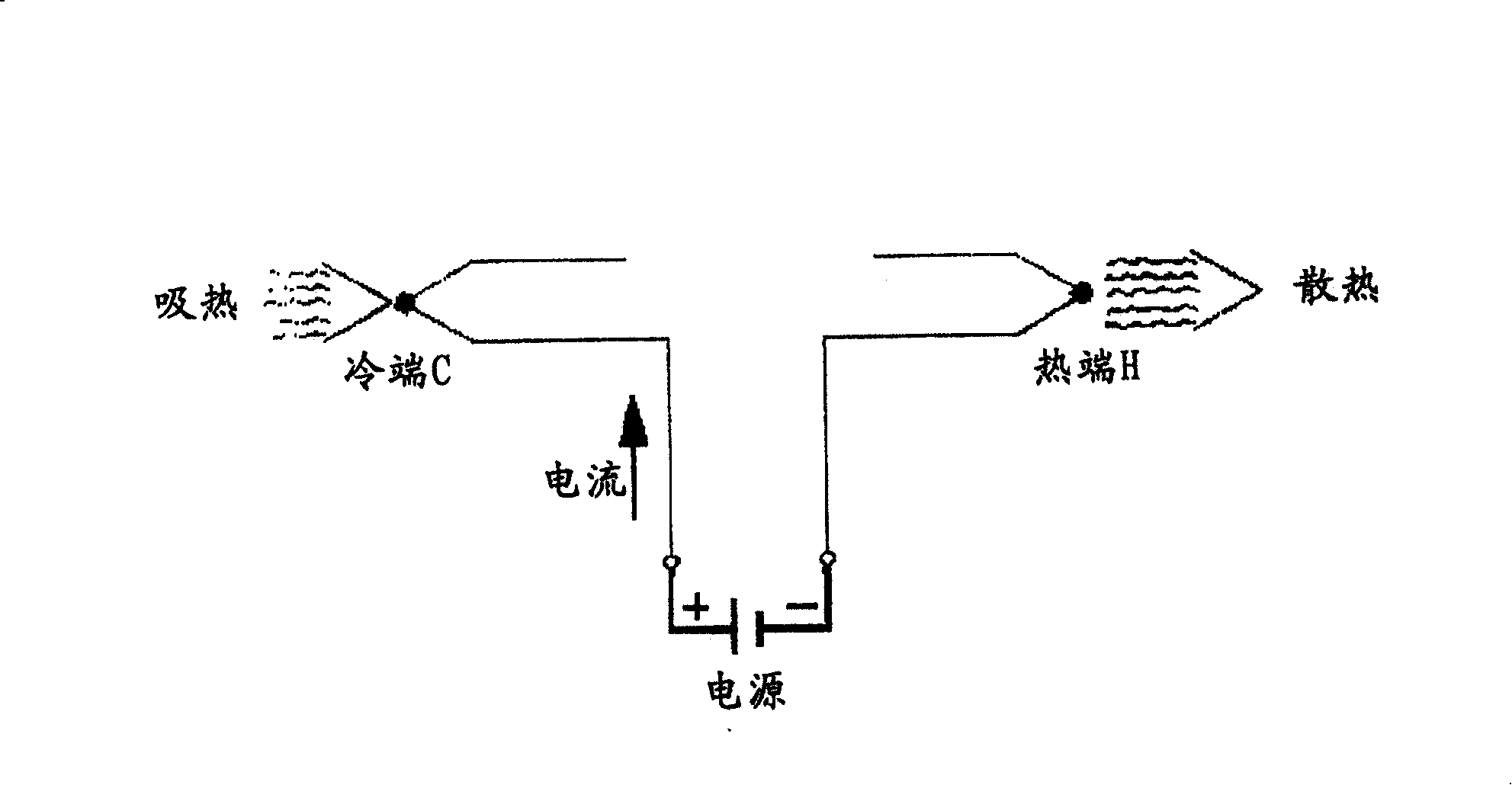

Automobile electronic warming-cooling air conditioner

InactiveCN101240924AComply with environmental policyDoes not affect power transmissionAir-treating devicesVehicle heating/cooling devicesElectricityRefrigeration

The present invention provides an auto electronic heating / ventilation air condition, including a generator, an electronic cooler / heater, a heat pipe, a water pump and a radiating tank. Kinetic energy generated by auto engine drives engine working, supplies electricity to auto electronic heating / ventilation air condition, and semiconductor refrigeration plate in the electronic cooler / heater cools or heats air in auto by circling water or antifreeze. This system need not refrigerant, has no pollution, small noise and lower efficiency, protects environment and saves energy.

Owner:BEIJING JIANXIANG CULTURE

Quick-drying self-flowing castable used for blast furnace casting runner and made from reclaimed waste castable

InactiveCN108046814AReduce manufacturing costComply with environmental policySilicon dioxideWater reducer

The invention discloses quick-drying self-flowing castable used for a blast furnace casting runner and made from reclaimed waste castable. The quick-drying self-flowing castable is mainly made from, by weight, 48-52% of reclaimed waste castable, 15-20% of compact corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water reducer, 1-2% of a composite anti-knock agent, 1-3% of SiO2 sol, 1-3% of silicon dioxide micropowder, 2-4% of activated aluminium oxide micropowder and 2-4% of silica micropowder. Waste self-flowing castable used for an iron runner is taken as a main raw material to prepare quick-drying self-flowing castable which is high in additional value and good in performance, is superior and is used for a blast furnace casting runner. The production cost of an enterprise is reduced, the natural environment is protected, the national environmental protection policy is met, and a great amount of energy is saved. The quick-drying self-flowing castable is significant in economic and social benefit.

Owner:河南欣昌耐材股份有限公司

Production process of low-basis-weight damp-proof waterproof coveying paper

InactiveCN107313300ASave raw materialsReduce consumptionSurface covering paperWater-repelling agents additionHigh concentrationState of art

The invention relates to a production process of low-basis-weight damp-proof waterproof coveying paper, which belongs to the technical field of the preparation of gypsum board coveing paper, and can solve the problems in the prior art that the performance of the gypsum board coveing paper is influenced and the cost is high due to the addition of additives in the gypsum board coveing paper production process. The production process comprises two steps, i.e. pulping and papermaking, wherein in a papermaking OCC production line, a process for pulping short fibers at a high concentration is adopted, the papermaking adopts four-layer mesh composite molding, deinked pulp is smeared on a surface layer, four layers of pulp are injected onto a four-layer molding mesh by virtue of a pulp flowing box, then the pulp is subjected to one vacuum pressing, twice large-roller pressing, primary drying, surface gluing, later drying and winding, and finally the pulp is rewound into paper rolls with different specifications by virtue of a rewinding machine. The production process saves the energy, reduces the pollution, improves the paper strength, reduces the basis weight of the paper, and improves the damp-proof and waterproof characteristics of the paper.

Owner:山西强伟纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com