Energy-saving consumption-reducing air conditioning method and unit air conditioner of spinning factory

An air-conditioning device and air-conditioning technology, applied in air-conditioning systems, heating methods, energy industries, etc., can solve the problems of many equipment, large air-conditioning energy consumption, and large heat dissipation, and achieve the effects of less investment, simple structure, and reduced dust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

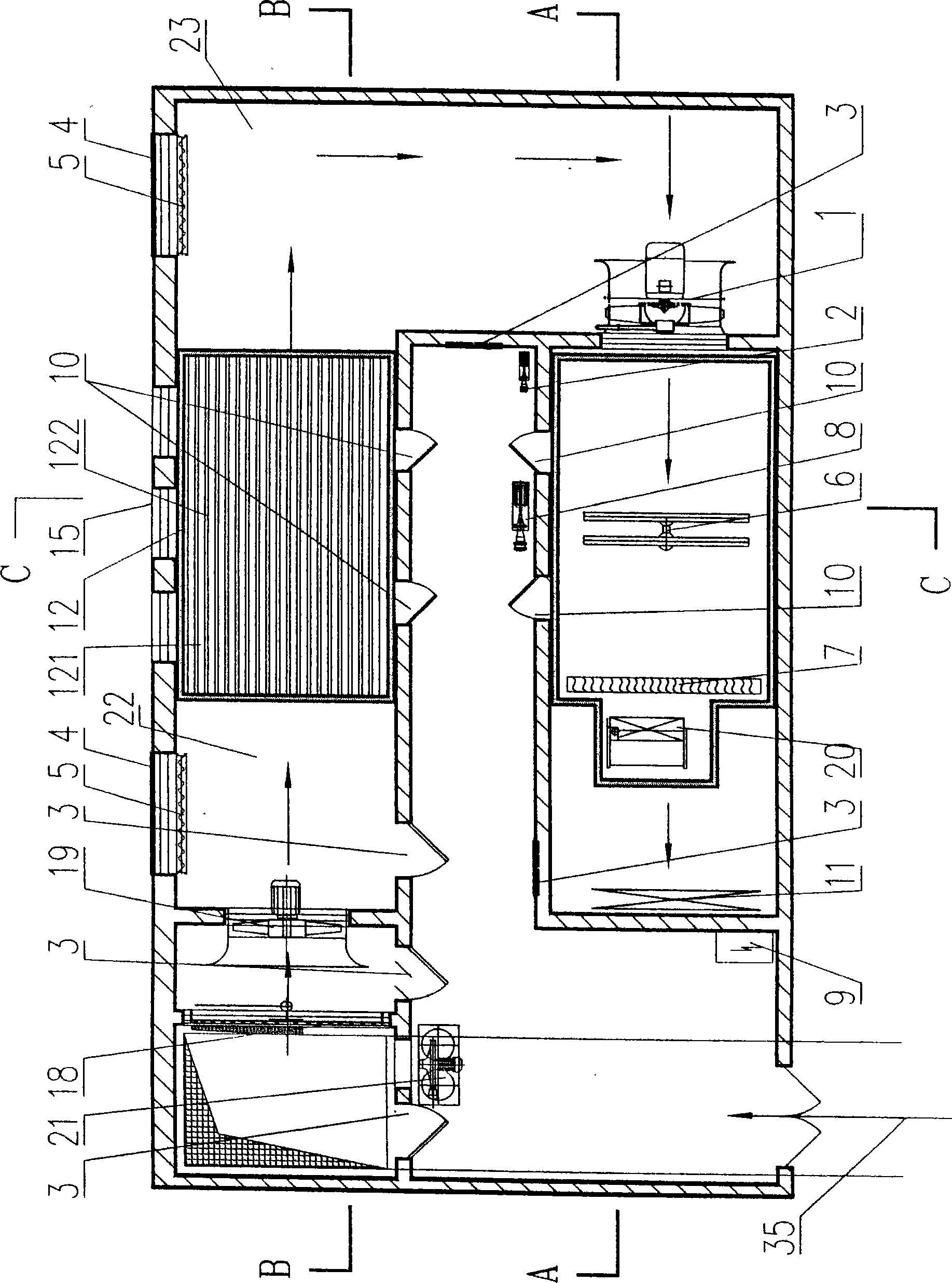

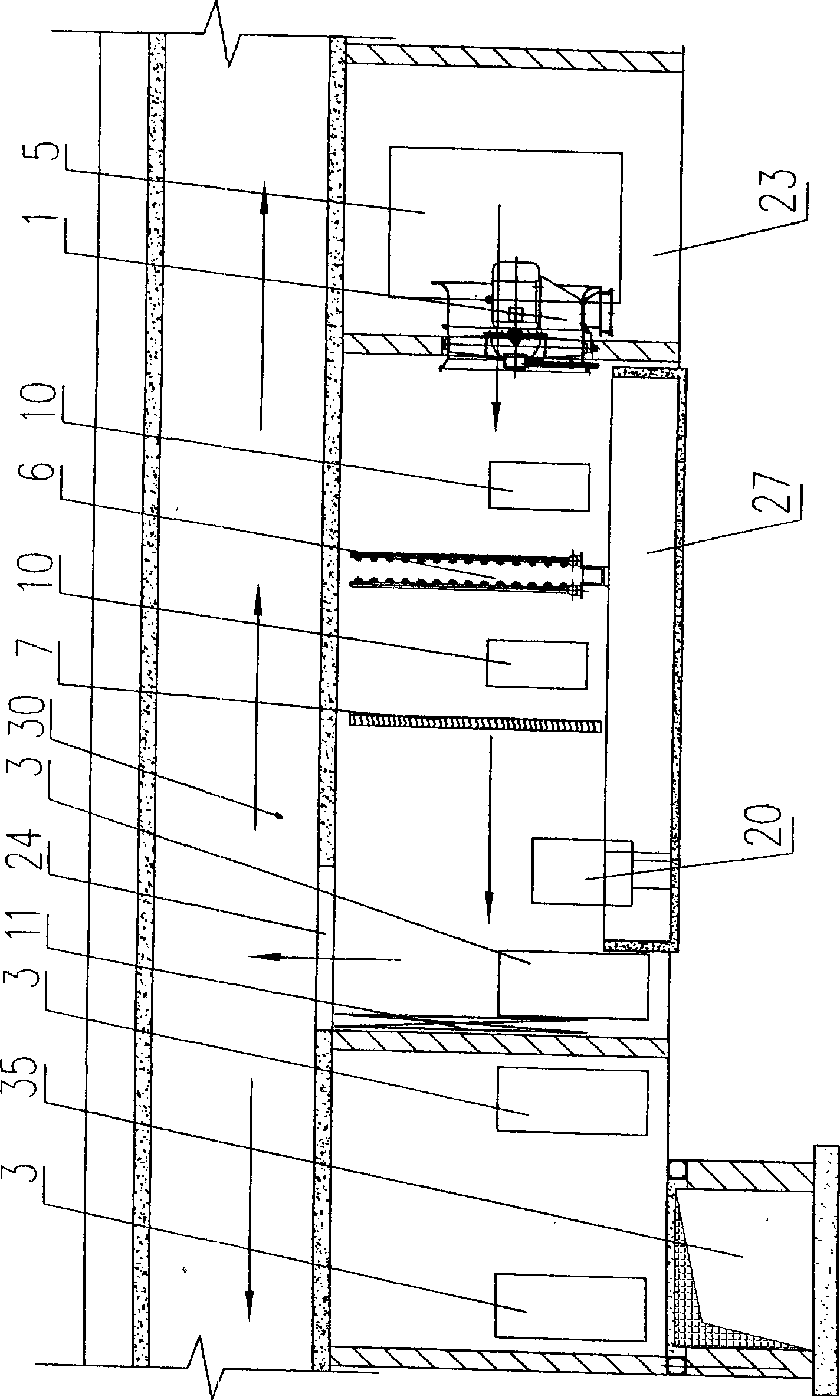

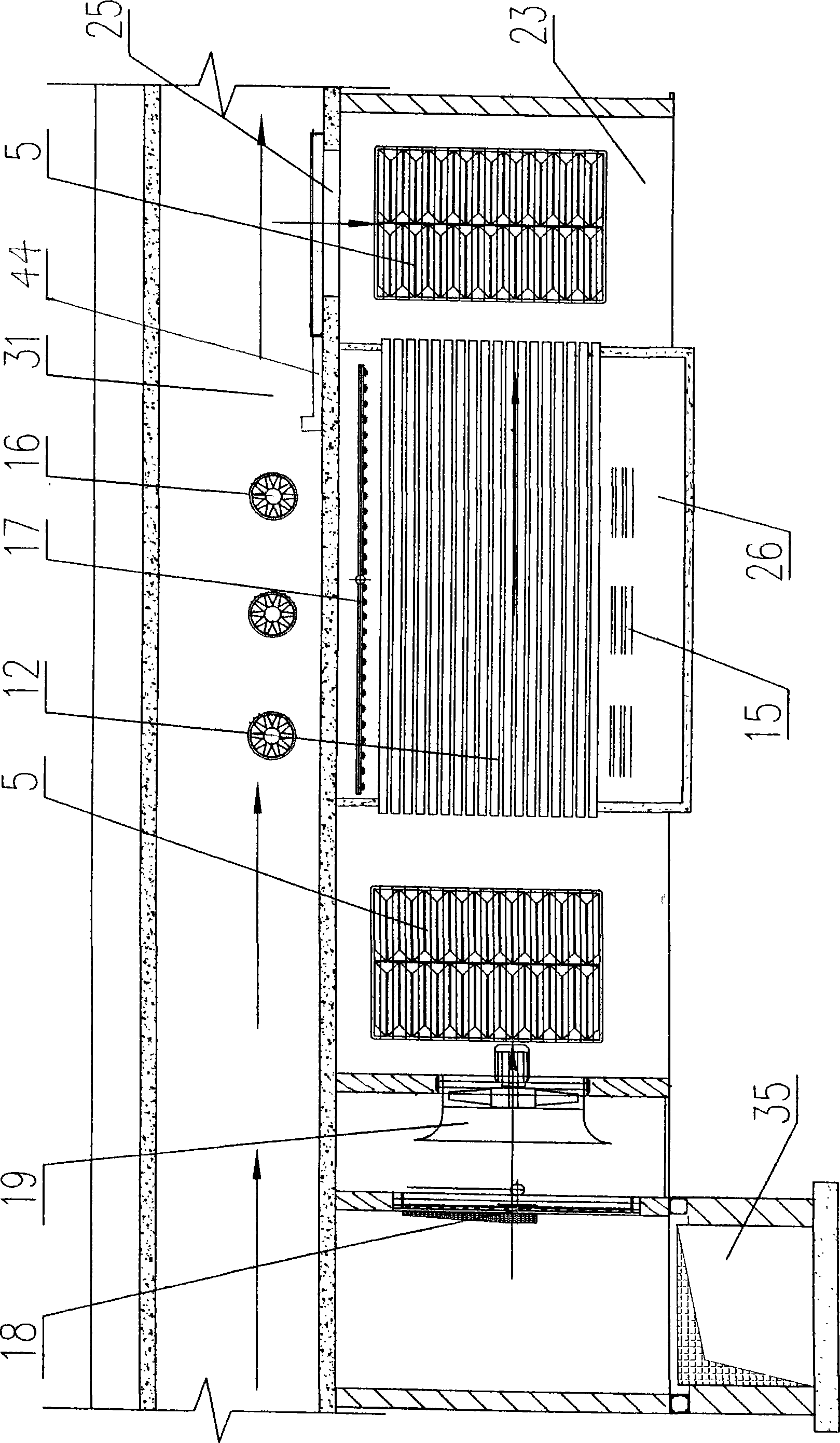

[0049] Embodiment 1, the experimental textile factory A of the present invention has a production scale of about 60,000 spindles. The air-conditioning method and the unit air-conditioning device of the present invention are adopted for transformation, so that the energy saving and consumption reduction are very obvious. see Figure 1~4 , Figure 9 , Figure 13 , Figure 14 , the specific implementation is:

[0050] In one of the schematic diagrams of the main unit structure of the unit air conditioner, for the temperature and humidity control room, each equipment is a well-known and public technical equipment, which is obtained by purchase, among which 1 is an axial flow spray fan, and its power model is based on the unit air conditioner The unit air conditioning area of the device depends on the unit air conditioning area. It is generally used in winter when the difference between the humidity of the workshop and the temperature required by the design is small. During t...

Embodiment 2

[0055] Embodiment two, three: see Figure 5-8 , Figure 10-11 , Figure 13 or Figure 14 , the numbers in the figure are the same as those in Embodiment 1, which have the same meanings and will not be repeated. The normal temperature air-conditioning in the unit air-conditioning area is the same as in Embodiment 1 and will not be repeated. Or the hot-blast exhaust duct is the hot-blast exhaust ditch 36 and the hot-blast exhaust opening 37 of the present embodiment, and the hot-blast confluence air exhaust duct is the hot-air confluence exhaust ditch 40 . The difference between the second embodiment and the third embodiment is that the position of the hot air exhausting ditch 40 is a little different, and everything else is the same. In the high temperature season, start the hot air axial flow fan 19 connected to the hot air exhaust channel 40, pass through the hot air exhaust ditch 36, the hot air exhaust port 37, and the inspection port 38 of the hot air exhaust ditch 36, ...

Embodiment 4

[0057] Embodiment four: see Figure 12 , Figure 12-1 , Figure 13 or Figure 14 , in the figure, the numbers identical to those in Embodiments 1, 2, and 3 have the same meaning and will not be repeated. What is a little different is that in this embodiment, there are two normal temperature confluence air exhaust ditches 35, and the normal temperature exhaust ditches 32 of the normal temperature confluence air exhaust ditches 35 on the right are on the side of the normal temperature confluence air ditches 35, while the other normal temperature confluence The both sides of air-drawing ditch 35 are all provided with normal temperature blowing ditch 32, and two normal-temperature converging wind-pumping ditches meet together and enter the unit air-conditioning device main frame, and normal temperature converging wind-pumping ditch 35 and hot-blast converging wind-pumping ditch 40, both have Three-dimensional intersection, do not meet each other. The black block in the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com