Harmless processing system and process for copper powder containing organism and glass fiber

A harmless treatment, glass fiber technology, applied to the improvement of process efficiency, the removal of solid waste, etc., can solve the problems of harmful volatiles, environmental secondary pollution, etc., to achieve thorough waste gas treatment, high purity, and systematic Reasonable configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

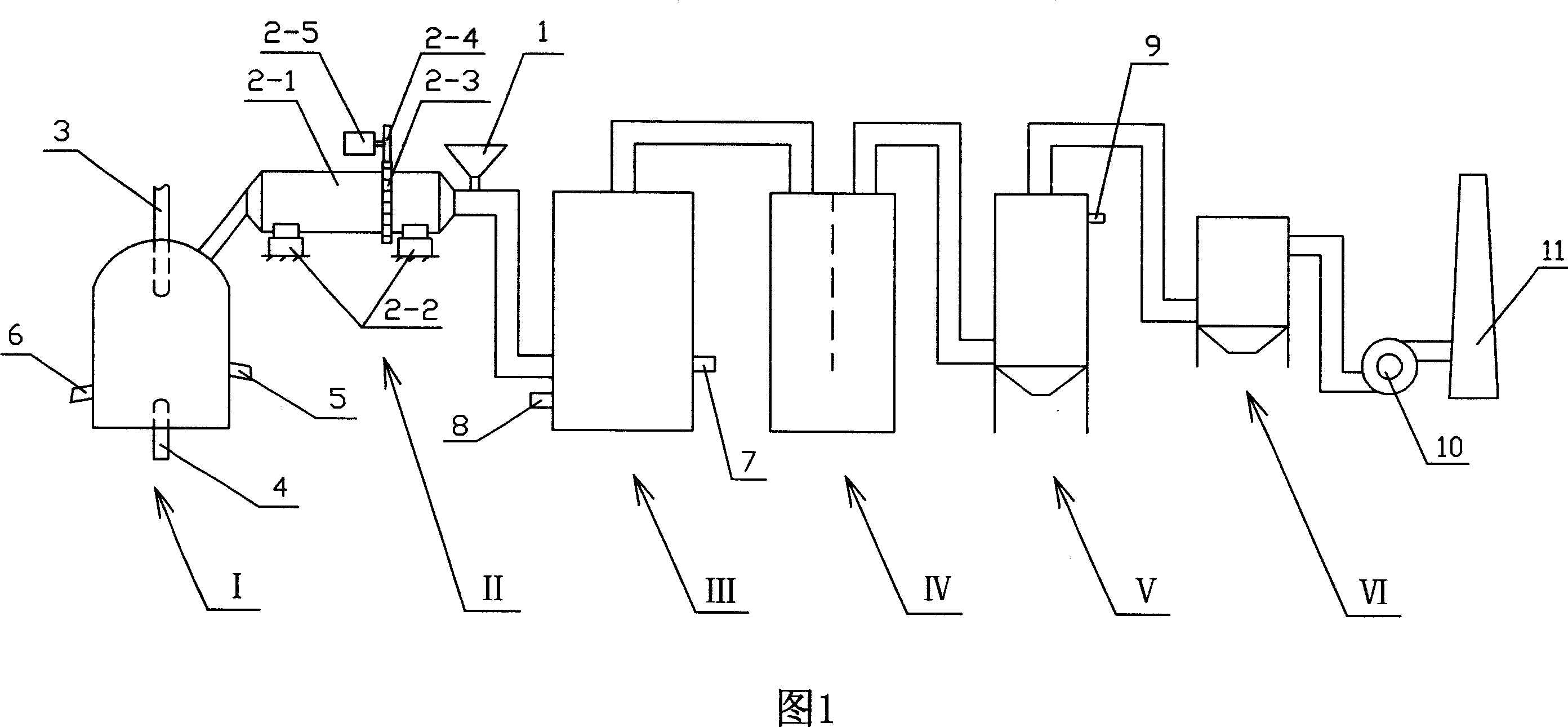

[0018] As shown in Figure 1, the processing system described in this embodiment is composed of electrode melting furnace I, rotary retort II, decomposition combustion tower III, cooling tower IV, exhaust gas treatment tower V, and bag filter VI connected through pipelines.

[0019] Described electrode smelting furnace 1 is vertically provided with graphite upper electrode 3 and graphite lower electrode 4 on the same longitudinal axis in the middle of the furnace hall, the upper electrode can move up and down, the power supply mode of graphite electrode is DC or AC, and the working voltage is at 40 ~70 volts. A slag outlet 5 is provided at the bottom of one side of the furnace, and a copper outlet 6 is provided at the bottom of the other side of the furnace.

[0020] The rotary retort II has a hollow cylindrical barrel 2-1, which is supported by two supporting rollers 2-2 at the front and rear, and a ring gear 2-3 is welded on the barrel, and the ring gear is rotated by the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com