Environment-friendly microemulsion paraffin removal and control agent and preparation method

A microemulsion, environment-friendly technology, applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent materials, etc., can solve the problems of non-environmental protection, poor biodegradability, large dosage, etc., and achieve stable storage, Good salt and calcium resistance, good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

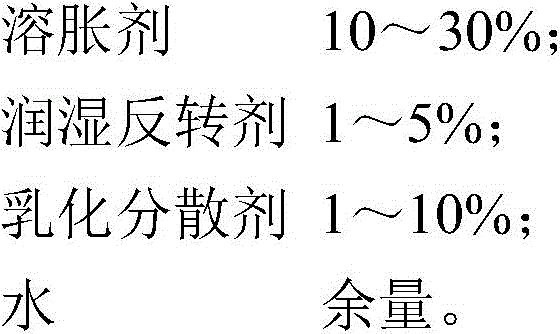

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the environment-friendly microemulsion wax clearing and anti-waxing agent: first add the formula amount of water into the reaction kettle, start stirring, raise the temperature to 50°C, and add the formula amount of emulsifying dispersant and wetting reaction in turn under stirring. Transfer agent, stir at this temperature until uniform, then add the swelling agent in the formula amount under stirring, continue to stir evenly, and obtain the product.

[0025] The formula of the present invention is illustrated below by specific examples.

Embodiment 1

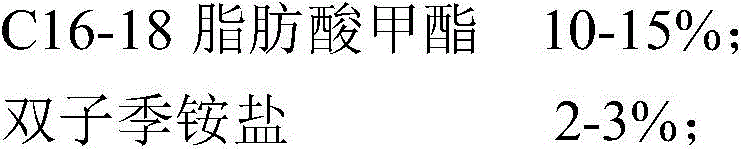

[0027] The swelling agent is C16-18 fatty acid methyl ester, the wetting reversal agent is gemini quaternary ammonium salt, and the emulsifying and dispersing agent is fatty alcohol polyether phosphate salt, and its proportioning is as follows (by mass percentage):

[0028]

[0029] The total mass percentage of the swelling agent, the wetting inversion agent and the emulsifying and dispersing agent is 20%.

[0030] Preparation method: first add 800kg of water to the reaction kettle, start stirring, raise the temperature to 50°C, add 70kg of emulsifying and dispersing agent fatty alcohol polyether phosphate salt, 30kg of wetting reversal agent gemini quaternary ammonium salt in turn under stirring, After stirring at this temperature until uniform, 100 kg of swelling agent gemini quaternary ammonium salt is added under stirring, and the stirring is continued to obtain the product. When the use concentration of this product is 0.3wt‰, the wax-repellent rate of crude oil with 5...

Embodiment 2

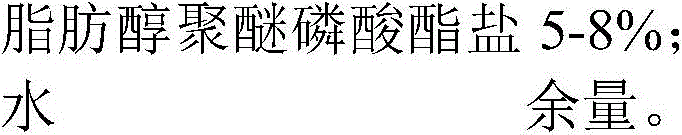

[0032] The swelling agent is C12-14 fatty alcohol, the wetting reversal agent is gemini quaternary ammonium salt, and the emulsifying and dispersing agent is fatty alcohol polyether sulfate ester salt, and its proportioning is as follows (by mass percentage):

[0033]

[0034] The total mass percentage of the swelling agent, wetting reversal agent and emulsifying dispersant is 40%.

[0035] Preparation method: first add 600Kg of water into the reaction kettle, start stirring, raise the temperature to 50°C, add 100kg of emulsifying and dispersing agent fatty alcohol polyether sulfate salt and 50kg of wetting reversal agent gemini quaternary ammonium salt successively under stirring, After stirring at this temperature until uniform, add swelling agent C1214 fatty alcohol 250kg under stirring, and continue to stir uniformly to obtain the product. When the concentration of this product is 0.3wt‰, the wax prevention rate of crude oil with 50wt% water content reaches 98.1%, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com