Patents

Literature

933 results about "Organic solvent free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lyophilized solid taxane composition, a process for preparing said solid composition, a pharmaceutical formulation and a kit for said formulation

InactiveUS20090215882A1High level of chemical degradationImprove solid solubilityOrganic active ingredientsBiocideDocetaxel-PNPDocetaxel

A lyophilized solid composition of taxane (preferably docetaxel and paclitaxel), is suitable to prepare a pharmaceutical formulation to be administered to mammals, particularly humans, comprising a taxane, a tensoactive, a lyophilizing excipient, and acid; also essentially free from organic solvents. The solid composition is free from polysorbate 80 and polyoxyethylated castor oil; it is sterile; it is soluble in aqueous solutions in the absence of organic solvent and it has an apparent density from 0.05 g / ml to 0.45 g / ml. A procedure of double lyophilization obtains a solid composition of taxane. A pharmaceutical formulation of a taxane comprises a solid composition of lyophilized taxane and a solubilizing composition. A kit comprises the compositions and a syringe.

Owner:ERIOCHEM SA

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

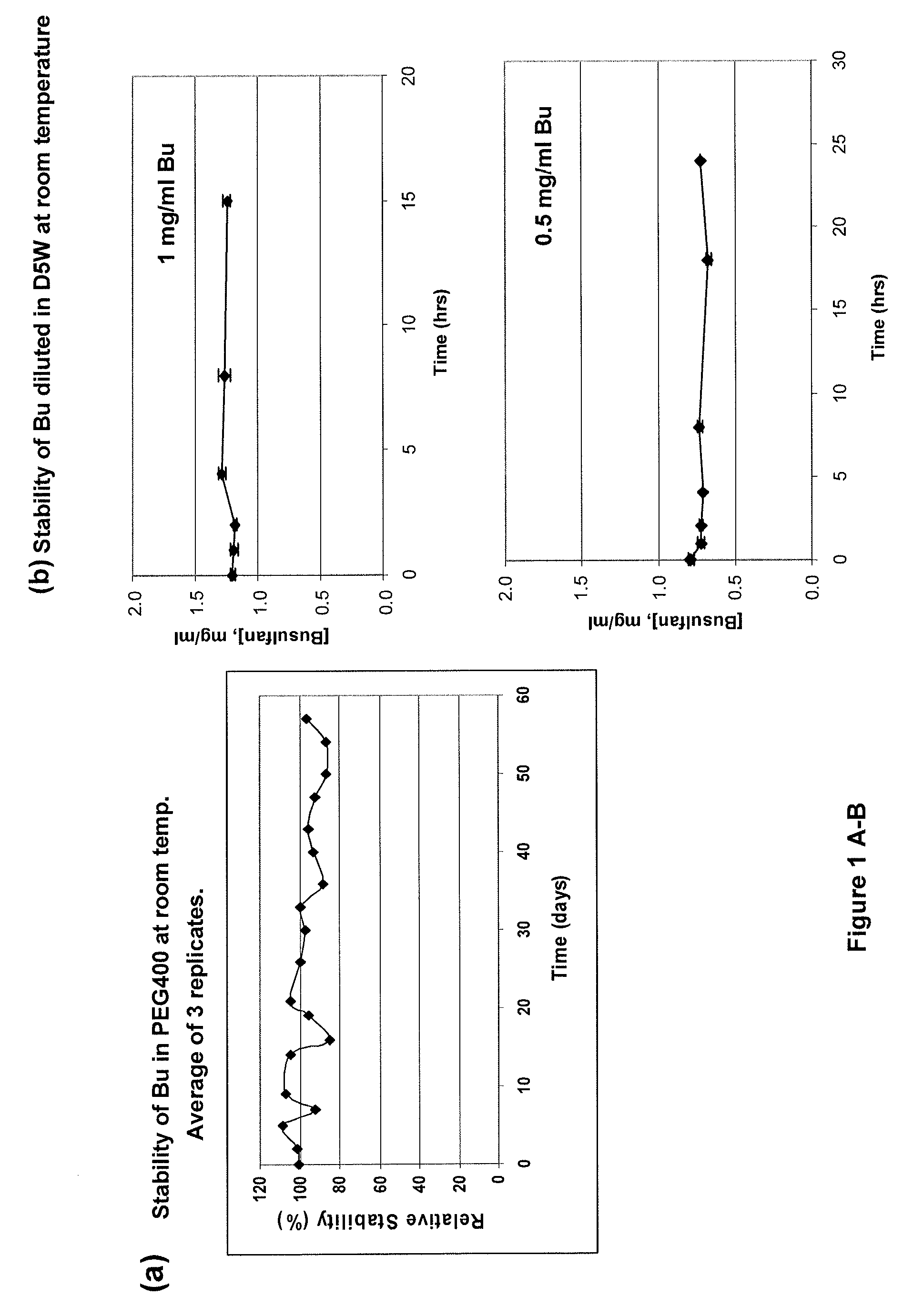

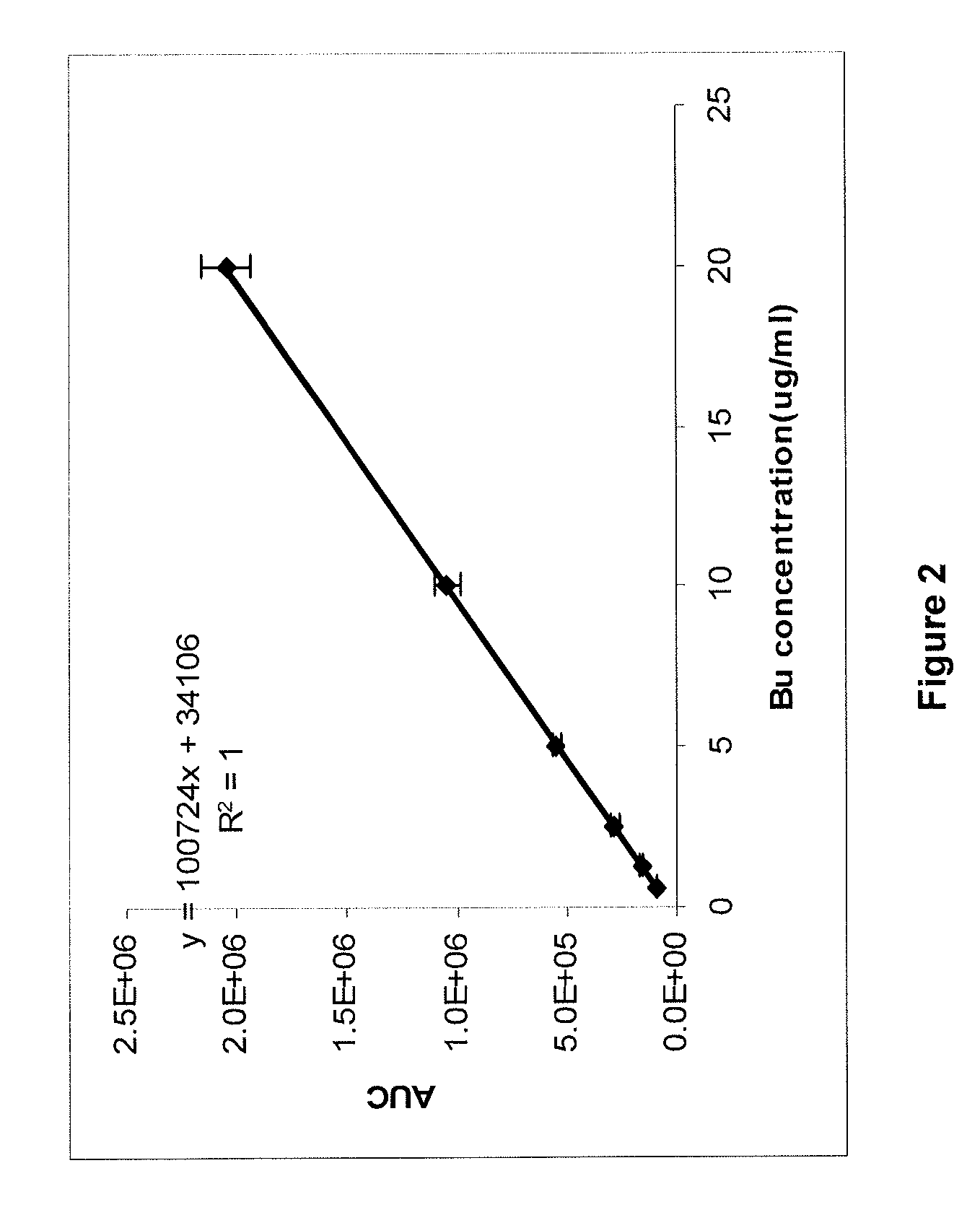

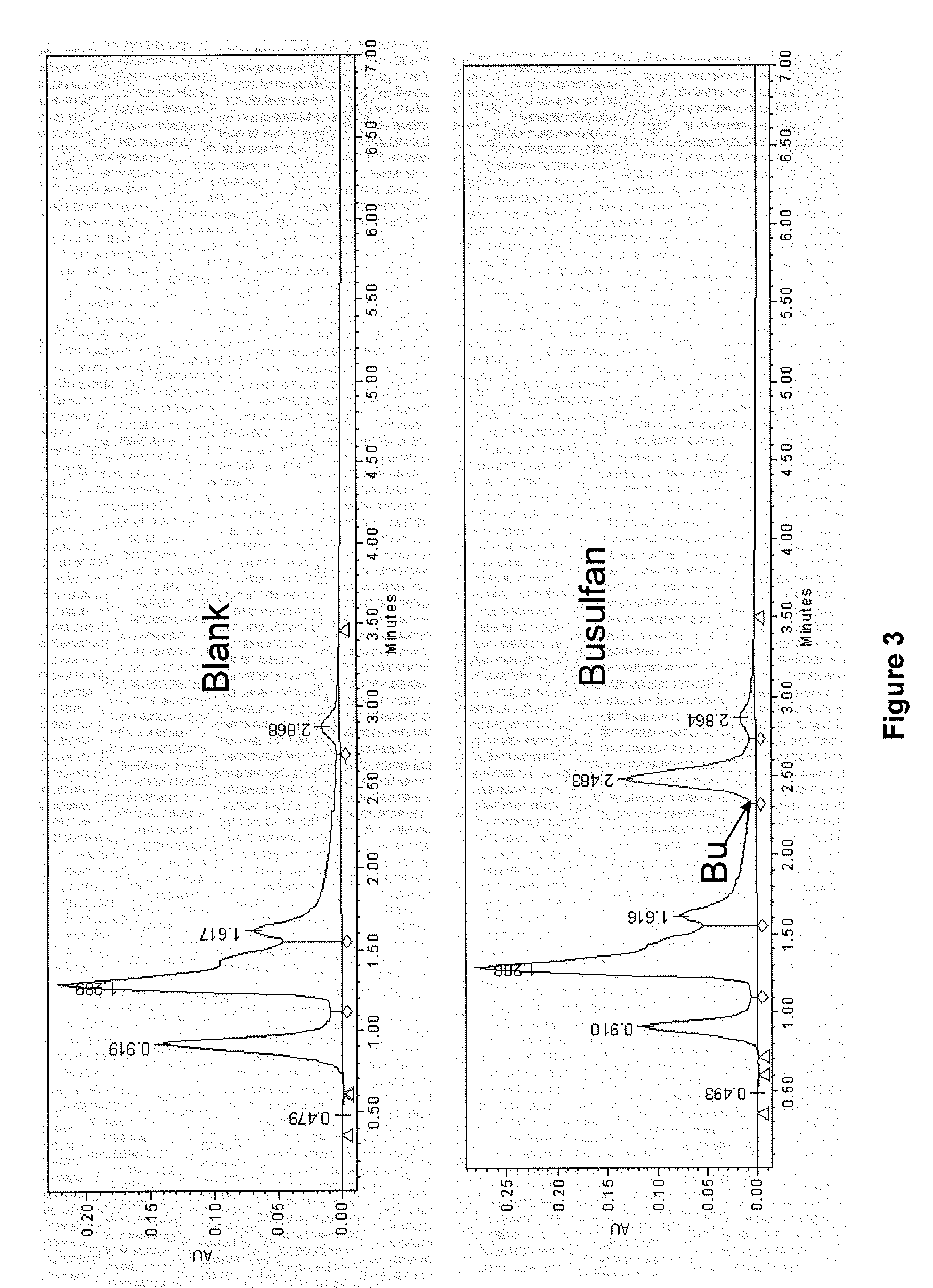

Parenteral formulations of lipophilic pharmaceutical agents and methods for preparing and using the same

ActiveUS20120277249A1Improve solubilityImprove stabilityAntibacterial agentsOrganic active ingredientsOrganic solventAutoimmune disease

There may be provided compositions of lipophilic pharmaceutical agents with improved solubility and stability. For example, there may be provided a non-aqueous composition that comprises a lipophilic pharmaceutical agent, and an amphiphilic polymeric solvent such as PEG400 but essentially free of organic solvents and non-solubilized particles. The composition may be further diluted with a desired aqueous diluent such as an infusion fluid for parenteral administration to a subject such as a human. The compositions may be useful for the treatment for diseases or conditions that are sensitive to lipophilic agents, such as infectious diseases, malignant or autoimmune diseases.

Owner:GREENJAY THERAPEUTICS INC

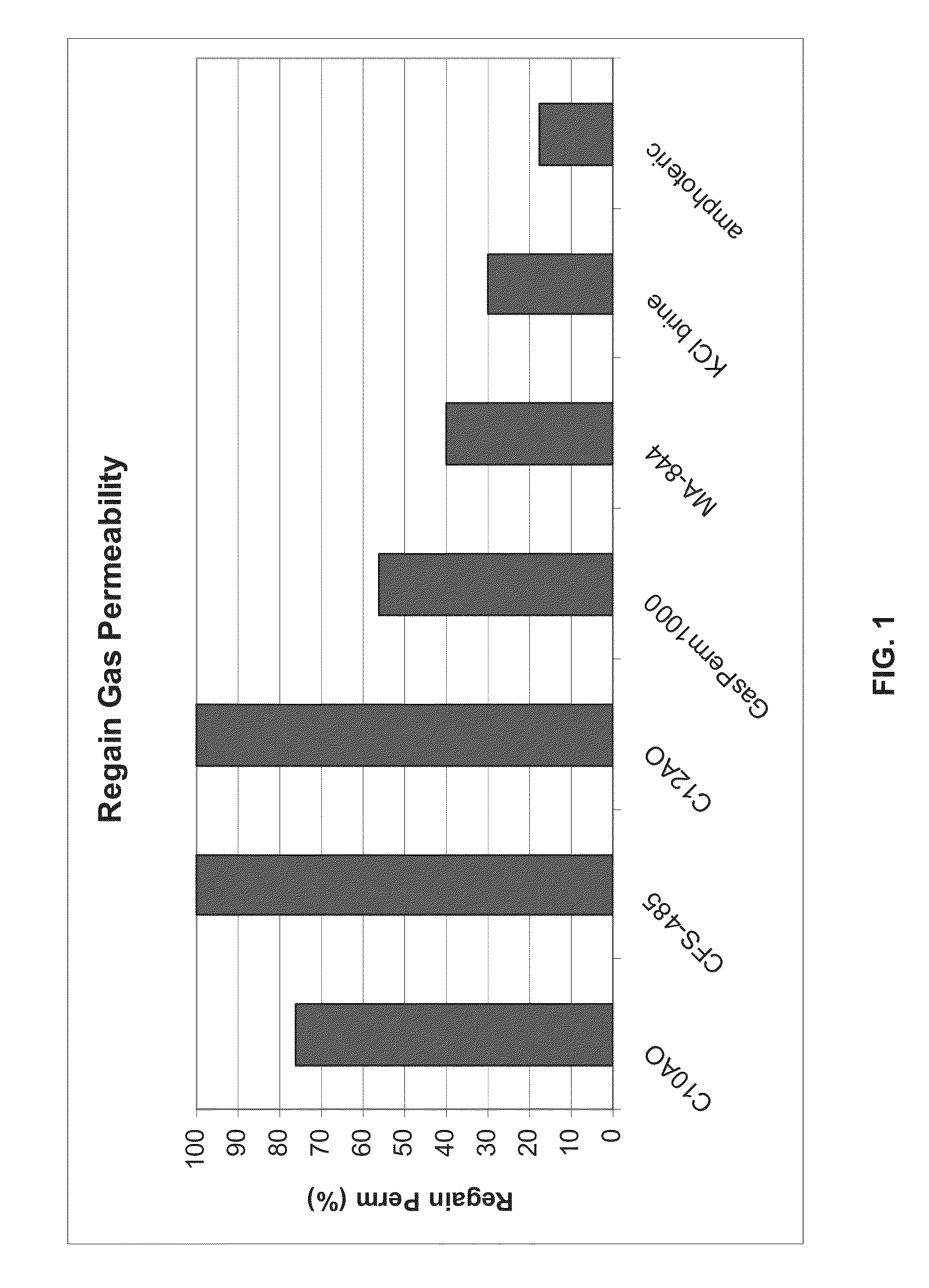

Surfactant Additives for Stimulating Subterranean Formation During Fracturing Operations

The present invention relates to surfactant additives useful for restoring permeability of a subterranean formation and methods of use thereof. One embodiment of the present invention provides a method that includes providing a fracturing fluid having an aqueous fluid, and a microemulsion surfactant, wherein the fracturing fluid is substantially free of an organic solvent; and placing the fracturing fluid into a subterranean formation at a rate sufficient to create or enhance at least one fracture in the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

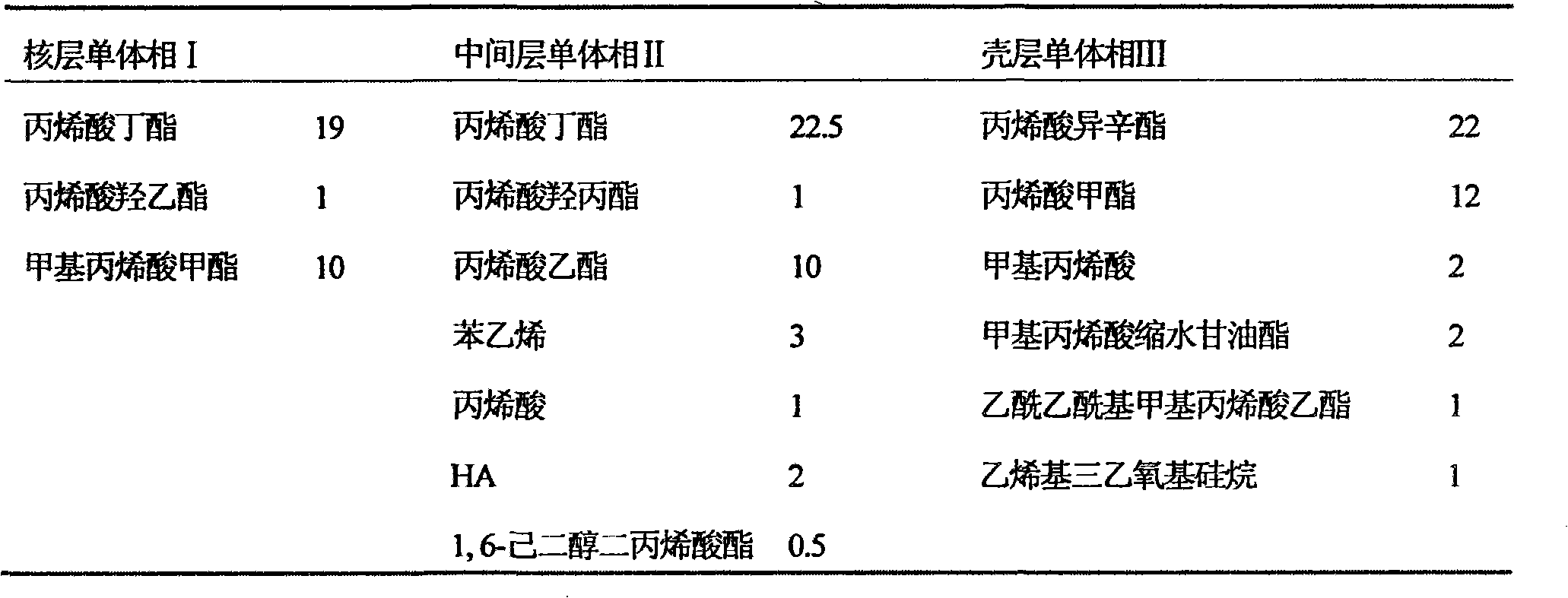

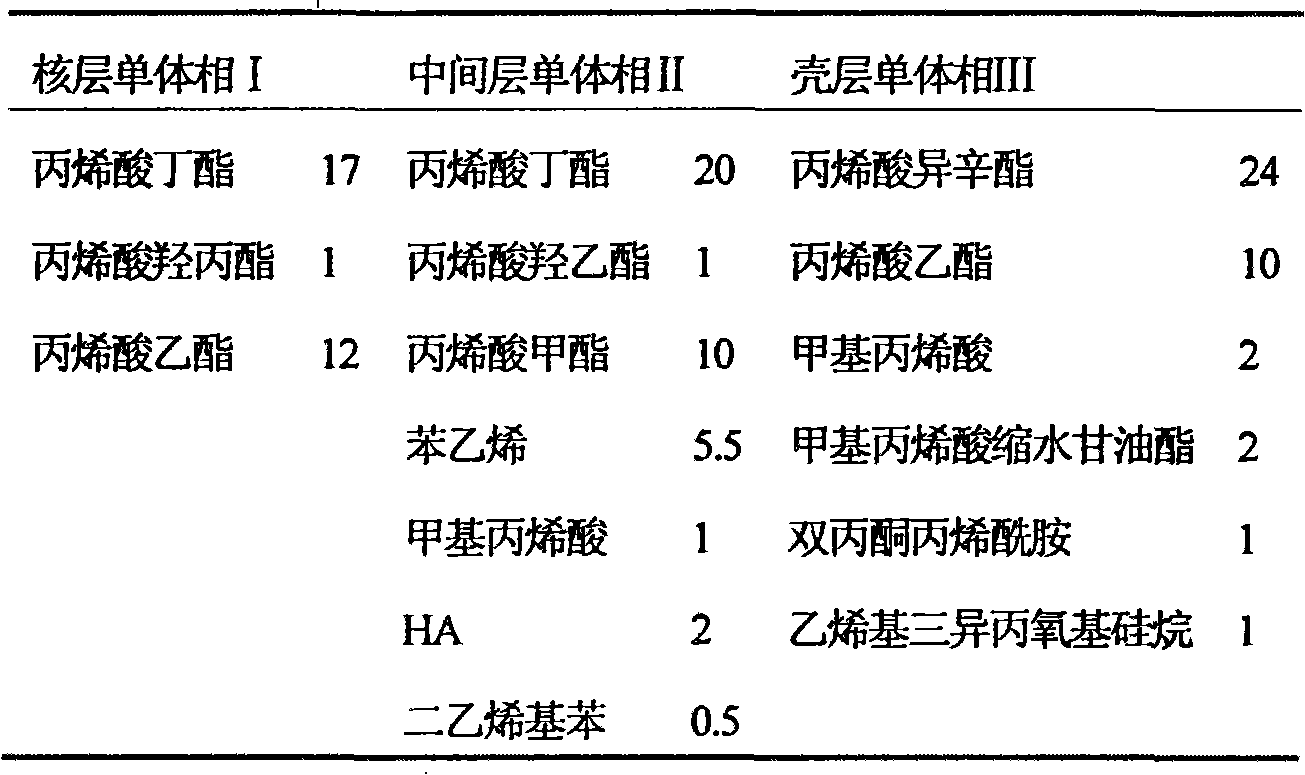

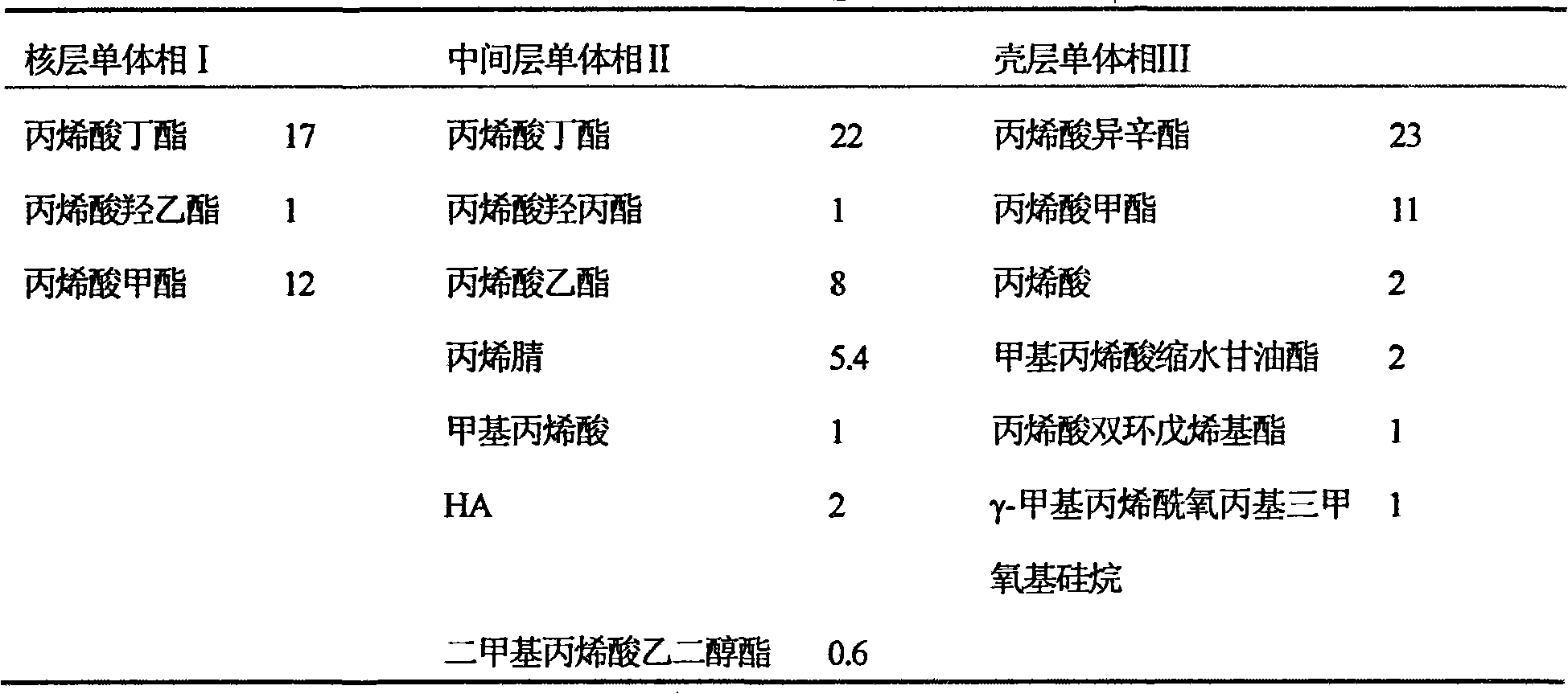

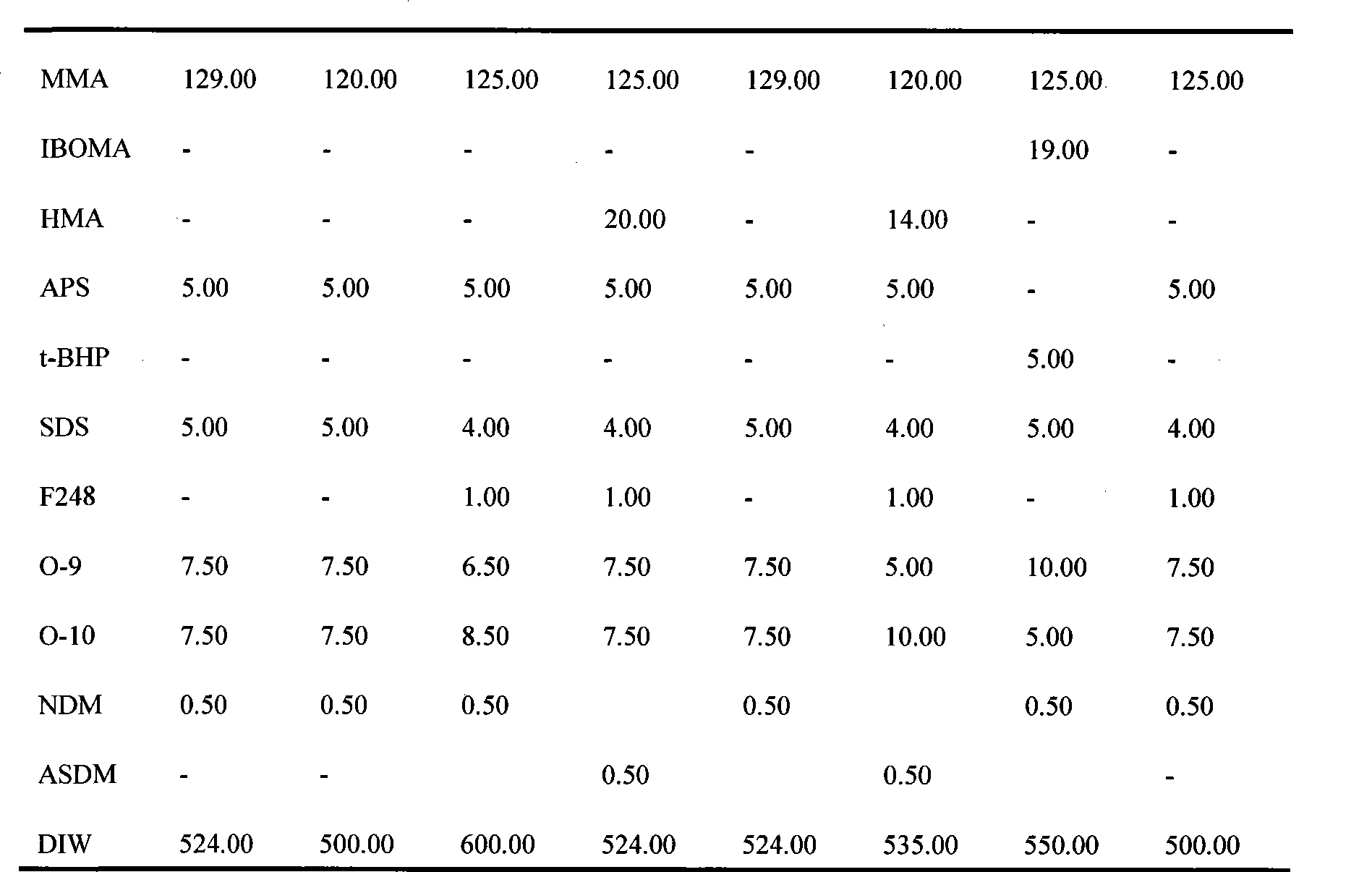

Single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and preparing method thereof

InactiveCN101928534ALess slagHigh affinityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a single-component low temperature self-crossing emulsion adhesive for paper and plastic compounds and a preparing method thereof. The raw materials of the self-crossing emulsion adhesive comprise the following components in part by weight: 100-150 parts of de-ionized water, 0.8-3.0 parts of emulsifier, 20-40 parts of nuclear layer monomer, 30-50 parts of interlayer monomer, 20-40 parts of shell layer monomer, and 0.2-0.6 part of initiator. The invention uses a small amount of anionic emulsifier to prepare nuclear emulsion, uses polymerisable emulsifier to prepare interlayer and shell layer pre-emulsion, and adopts semi-continuous seeded low emulsion polymerization process to prepare emulsion particles that have a three-layer core-shell microstructure to obtain the exquisite and stable emulsion. The product has no organic solvent, and does not release methanal, contains no APEO and no phthalate; the film coating has high transparency, high water resistance and high heat and humidity resistance; and the emulsion adhesive is applied to plastic and paper compounds, has high adhesive strength, peel strength and permanent adhesion, is also compatible to oil and ink and has high oil / ink transferring rate.

Owner:SOUTH CHINA UNIV OF TECH

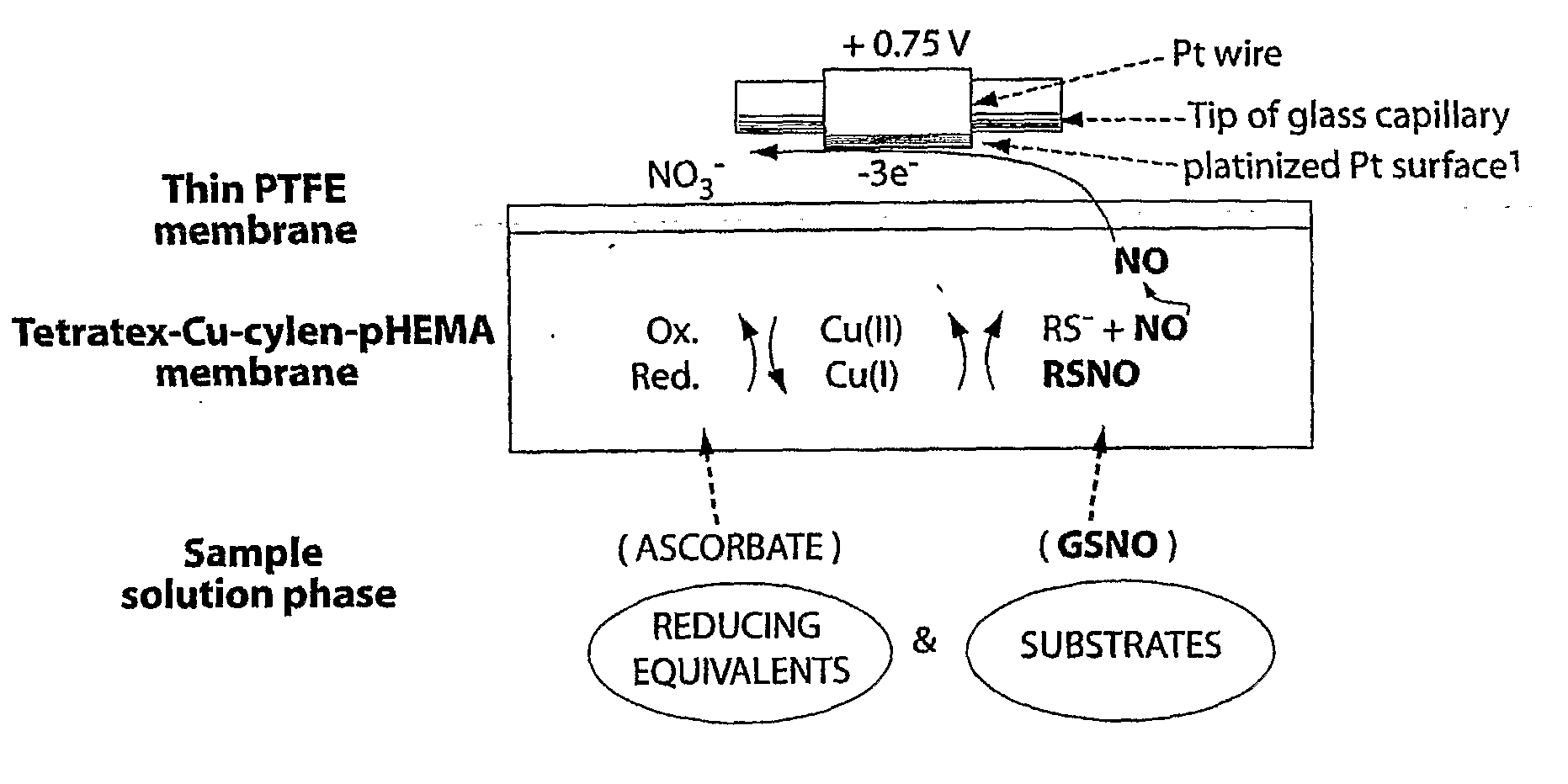

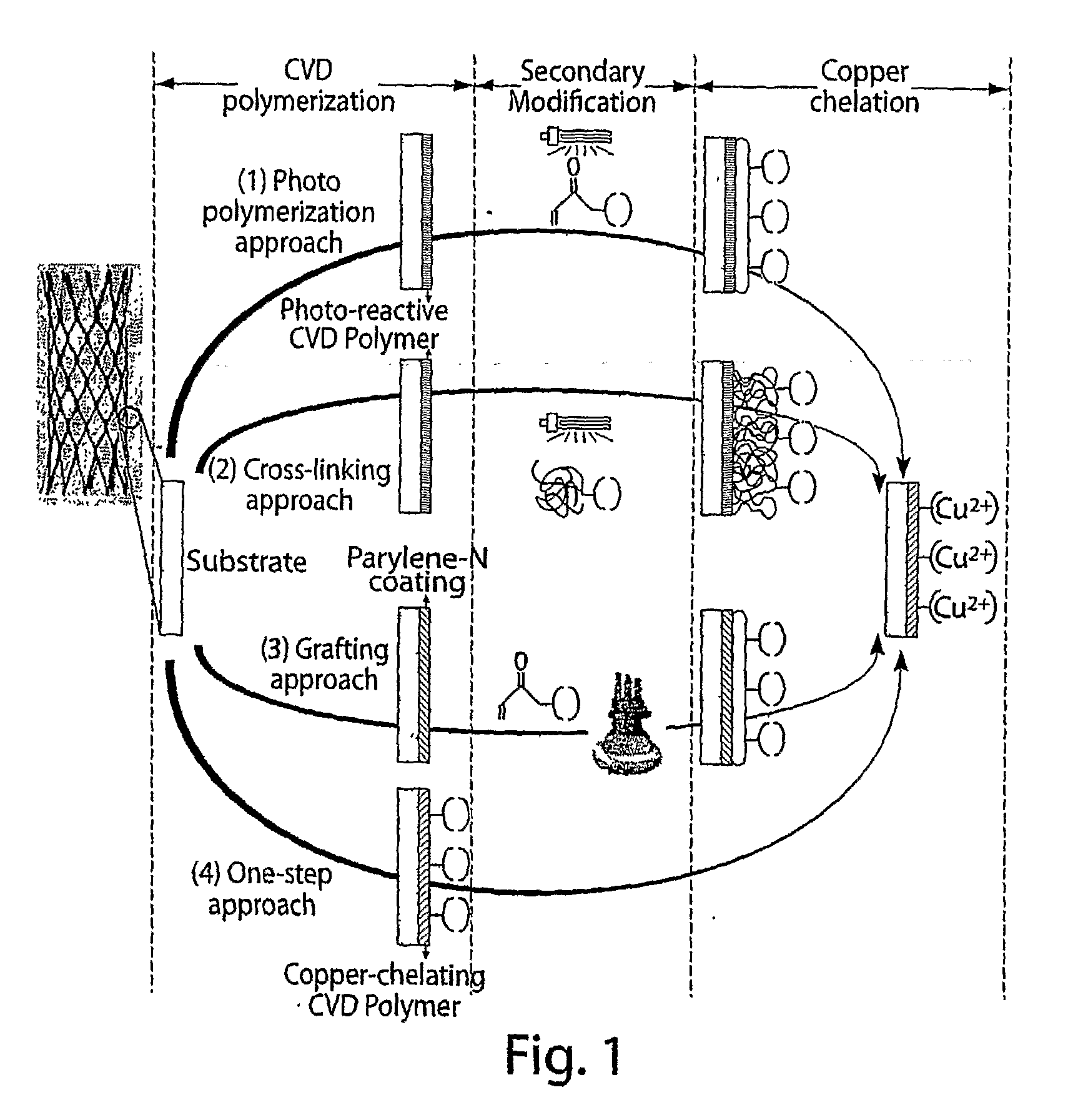

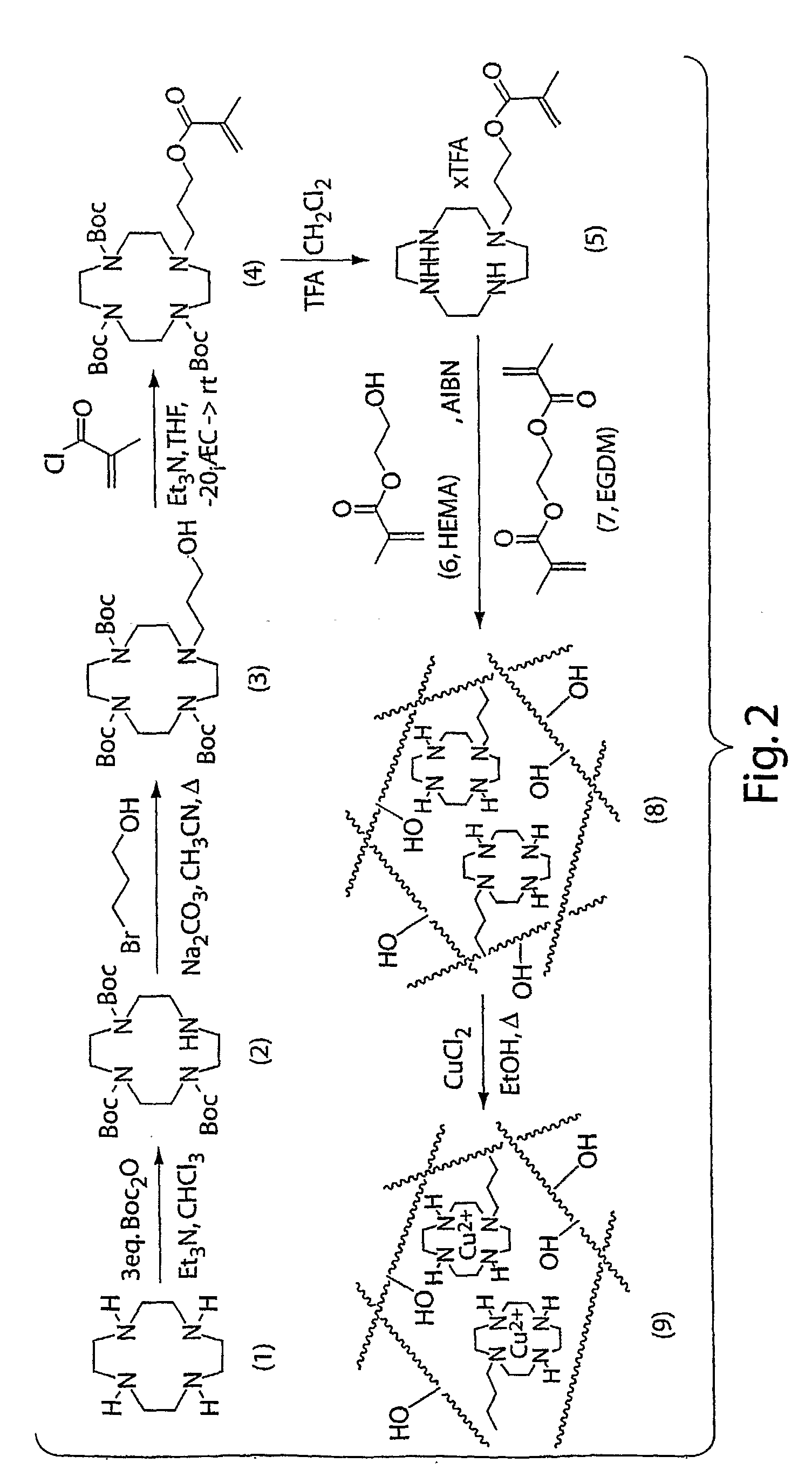

Nitric Oxide Coatings for Medical Devices

InactiveUS20090118819A1Inhibit the inflammatory responseAntipyreticAnalgesicsOrganic solventNitric oxide

The disclosure provides for devices and coatings that are substantially free of organic solvent sand suitable for insertion into a patient, and that comprise a metal layer and a coating with a thickness of about 20 nm to about 2000 nm wherein the coating comprises a biocompatible polymer comprising at least one residue covalently bonded to a nitric oxide generating compound.

Owner:RGT UNIV OF MICHIGAN +1

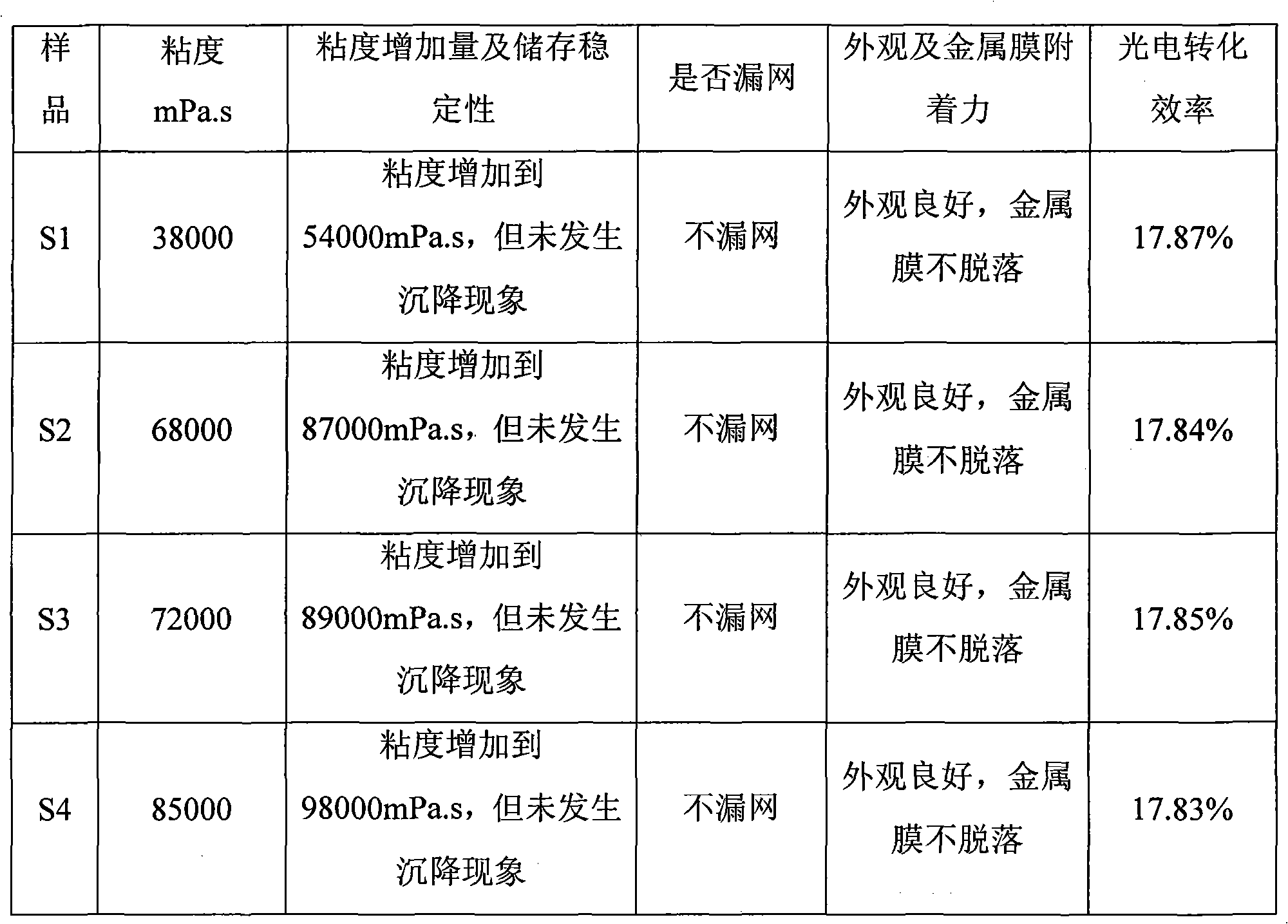

Conductive paste for solar cell and preparation method thereof

InactiveCN102034877AImprove performanceNo sedimentation and caking phenomenonConductive materialInksSilicon matrixSilicon solar cell

The invention provides a conductive paste for a solar cell, comprising the following components based on the total weight: 60-85 percent by weight of conductive metal powder, 0.5-10.0 percent by weight of inorganic binder, 10.0-30.0 percent by weight of water-borne binder and 0.05-5.0 percent by weight of additive, wherein the water-borne binder is a solution formed by dissolving a water-borne polymer into the water. The conductive paste for the solar cell, provided by the invention, has no organic solvent and pollution, is environment-friendly and has low cost of materials; the mesh leakage can be avoided when the conductive paste is stood in a screen mesh; the phenomena of settling and aggregation can be avoided after the conductive paste is stored for a long time; after being subjected to the silk-screen sintering, the conductive paste has firm adhesive force to a silicon matrix and excellent electrical performance; and the average photoelectric conversion efficiency of the produced monocrystal silicon solar cell is more than 17.80 percent.

Owner:BYD CO LTD

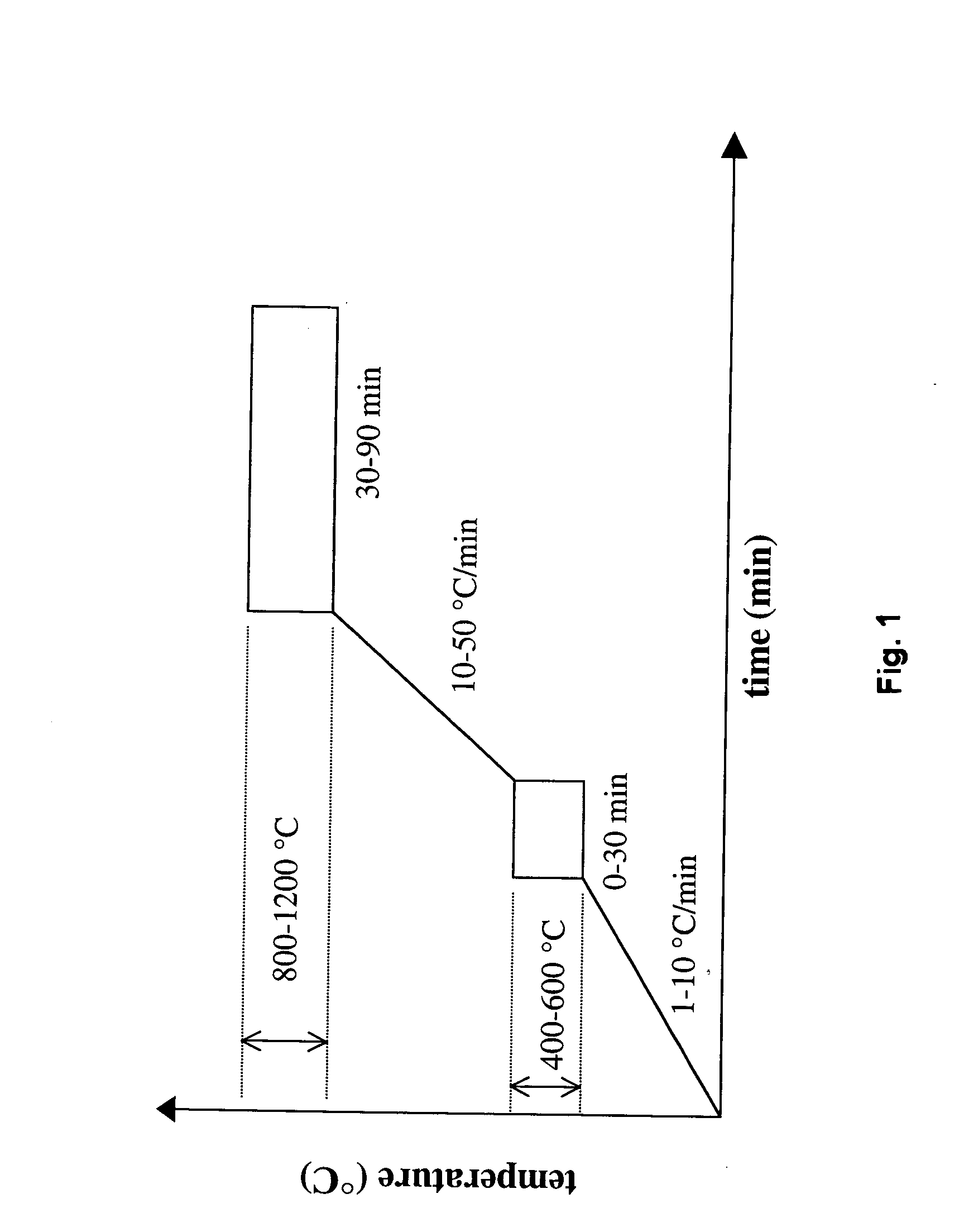

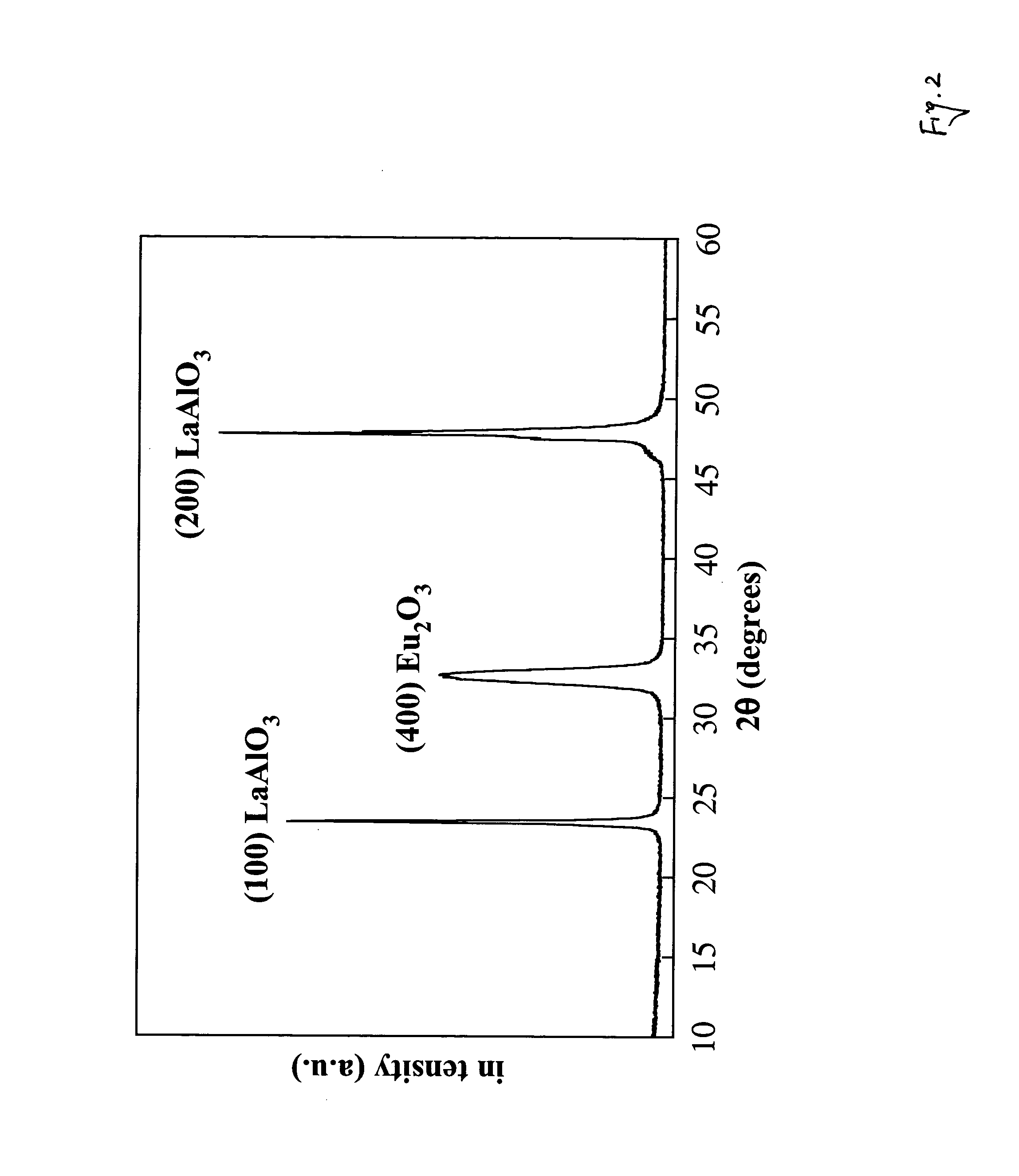

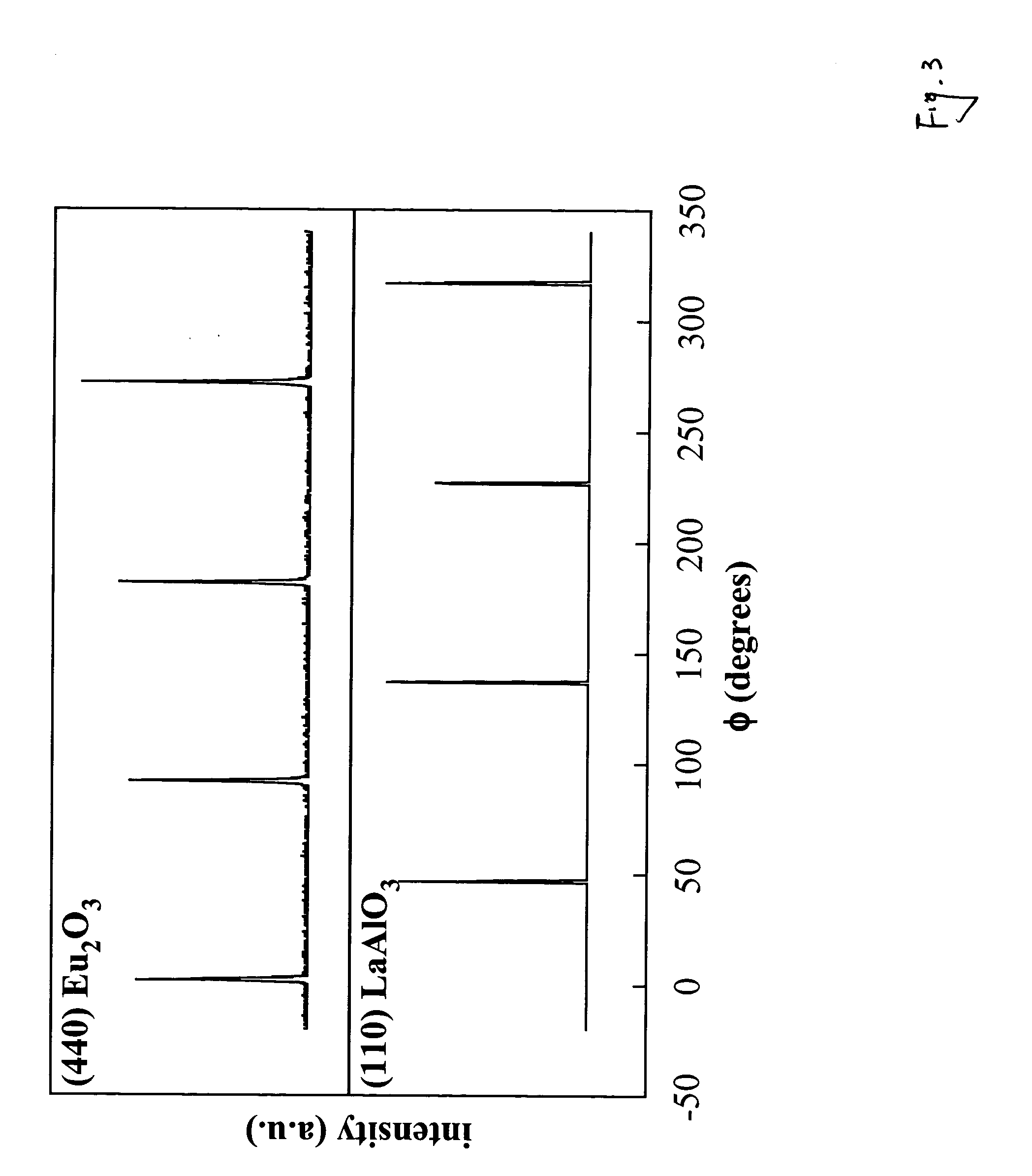

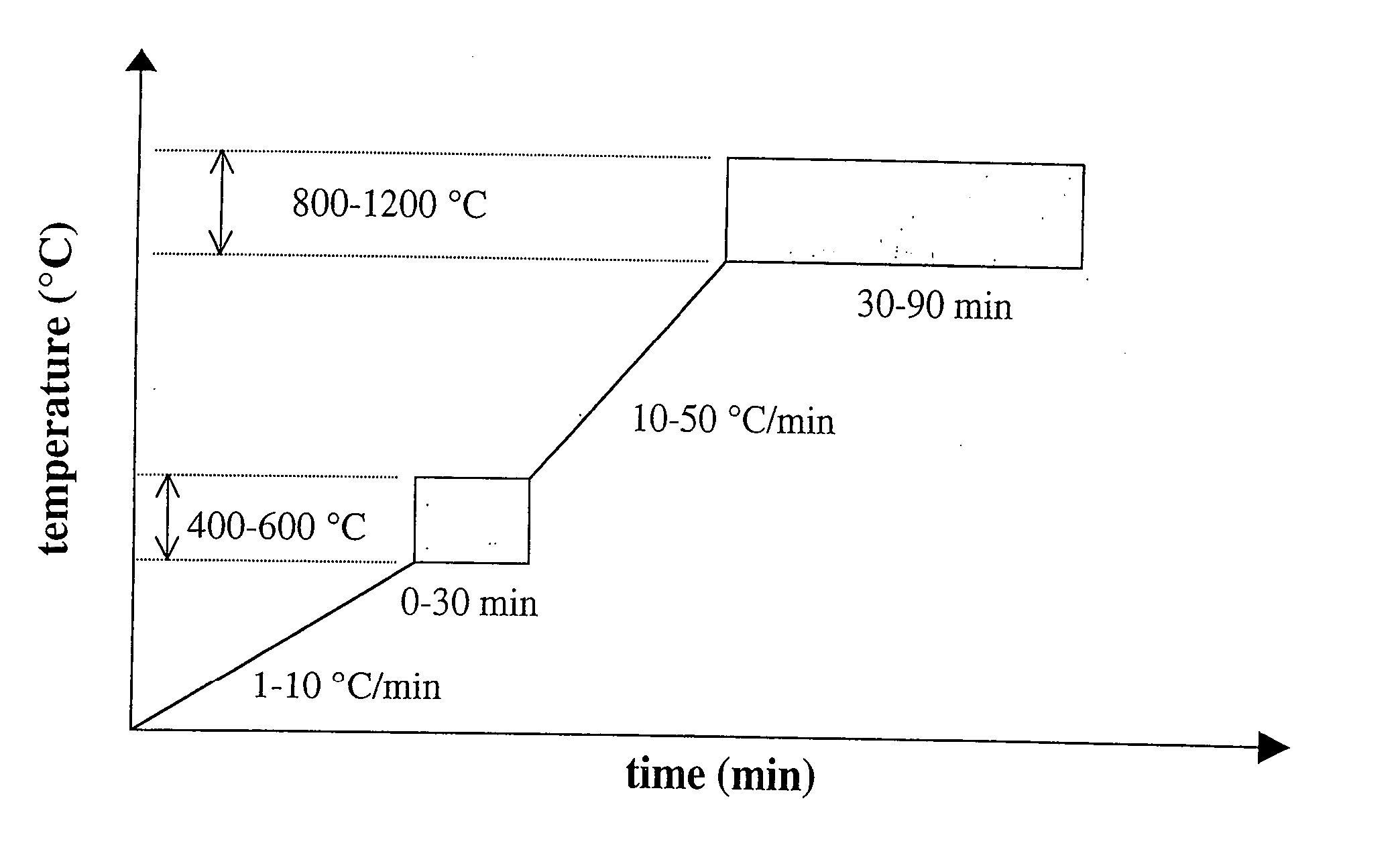

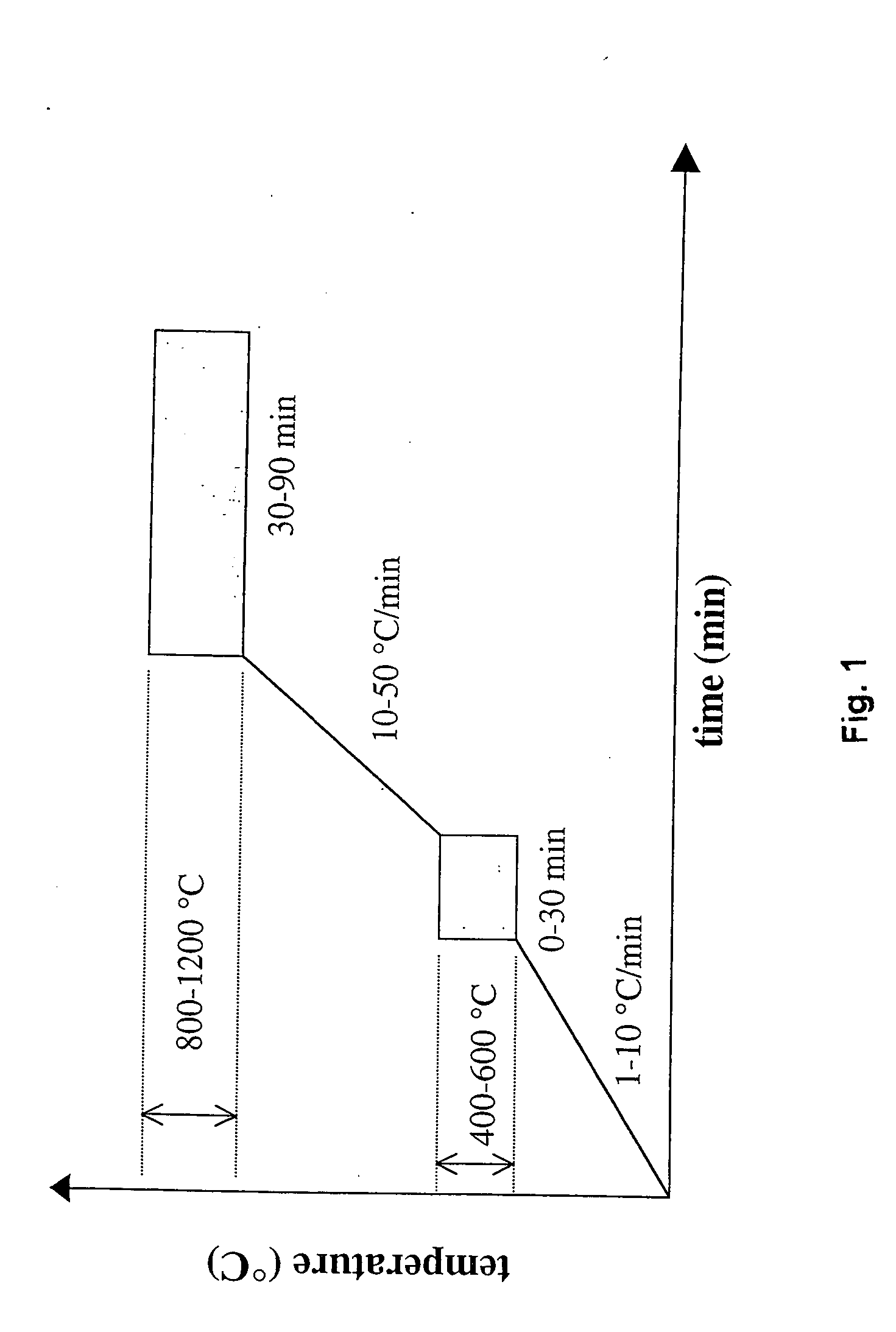

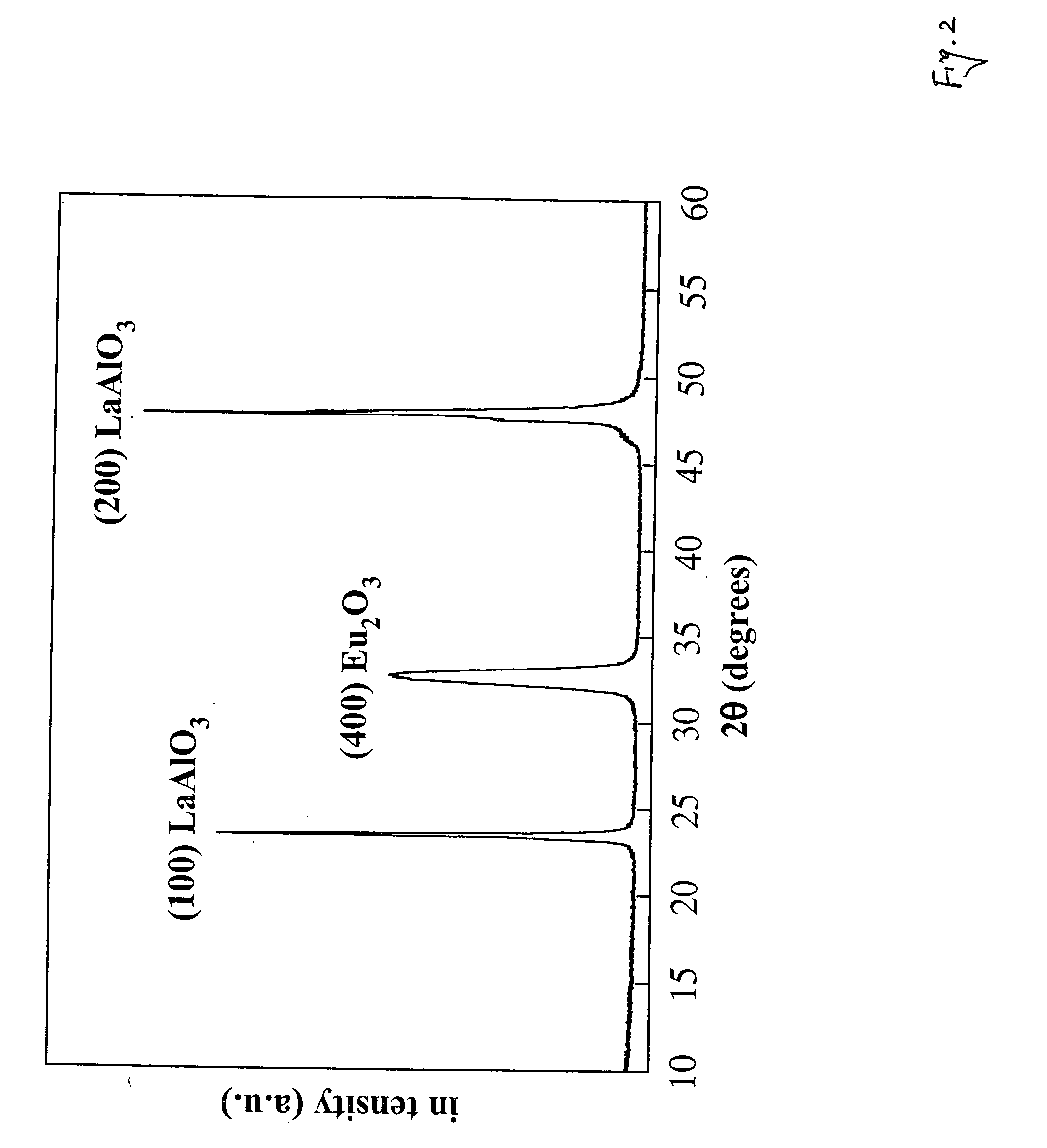

Polymer-assisted deposition of films

InactiveUS20050008777A1Pretreated surfacesSemiconductor/solid-state device manufacturingOrganic solventBound property

A polymer assisted deposition process for deposition of metal oxide films is presented. The process includes solutions of one or more metal precursor and soluble polymers having binding properties for the one or more metal precursor. After a coating operation, the resultant coating is heated at high temperatures to yield metal oxide films. Such films can be epitaxial in structure and can be of optical quality. The process can be organic solvent-free.

Owner:LOS ALAMOS NATIONAL SECURITY

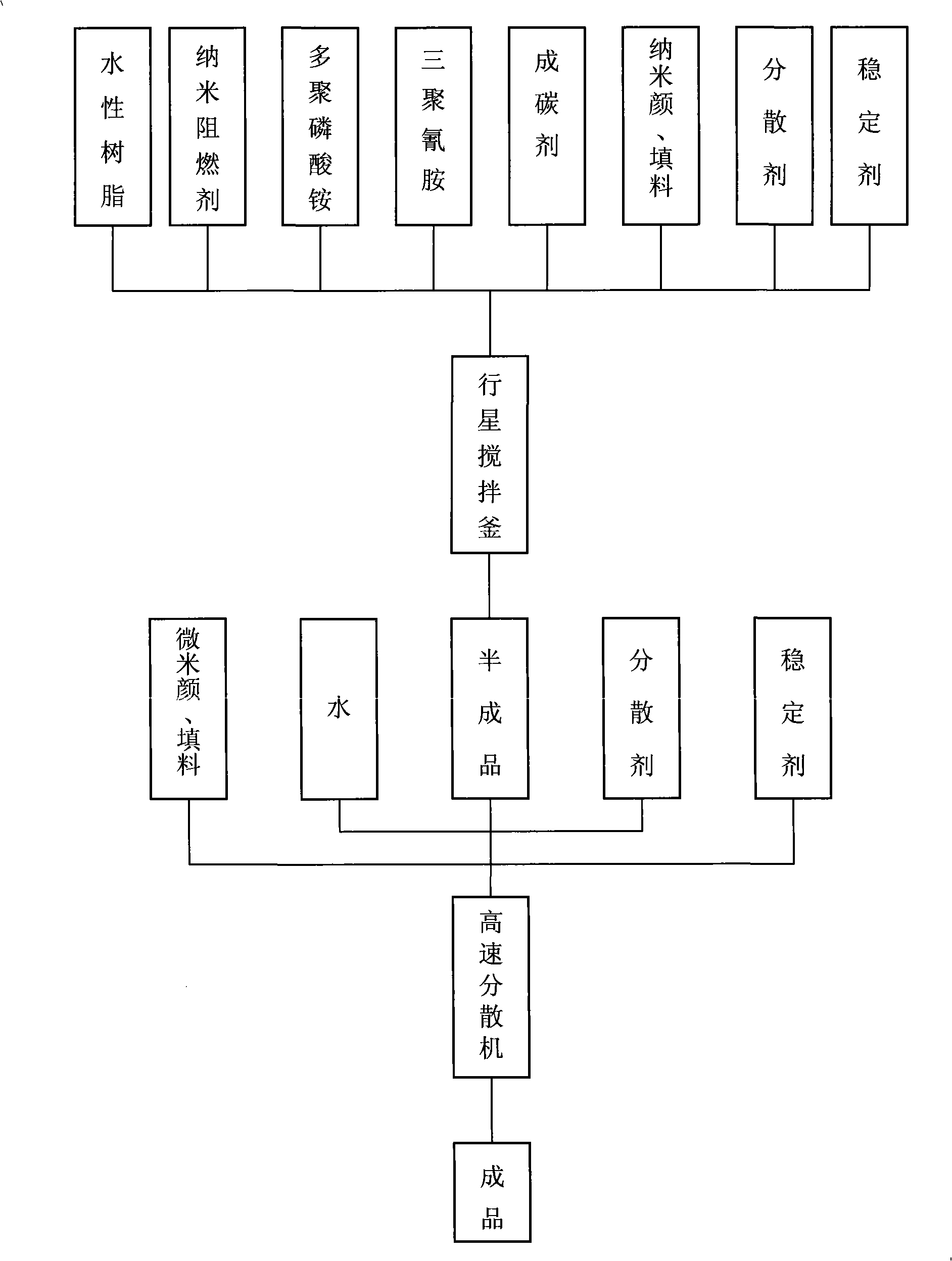

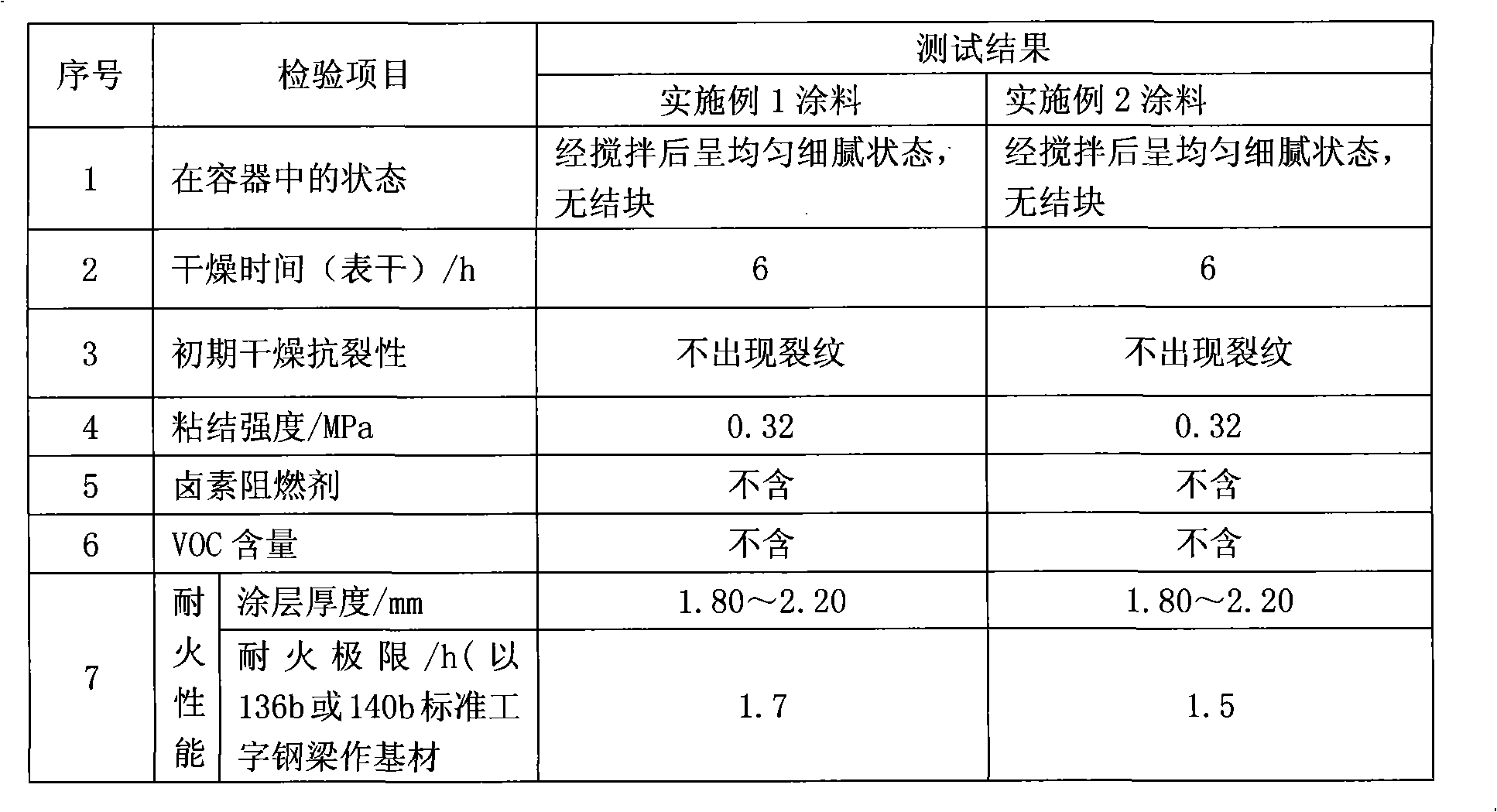

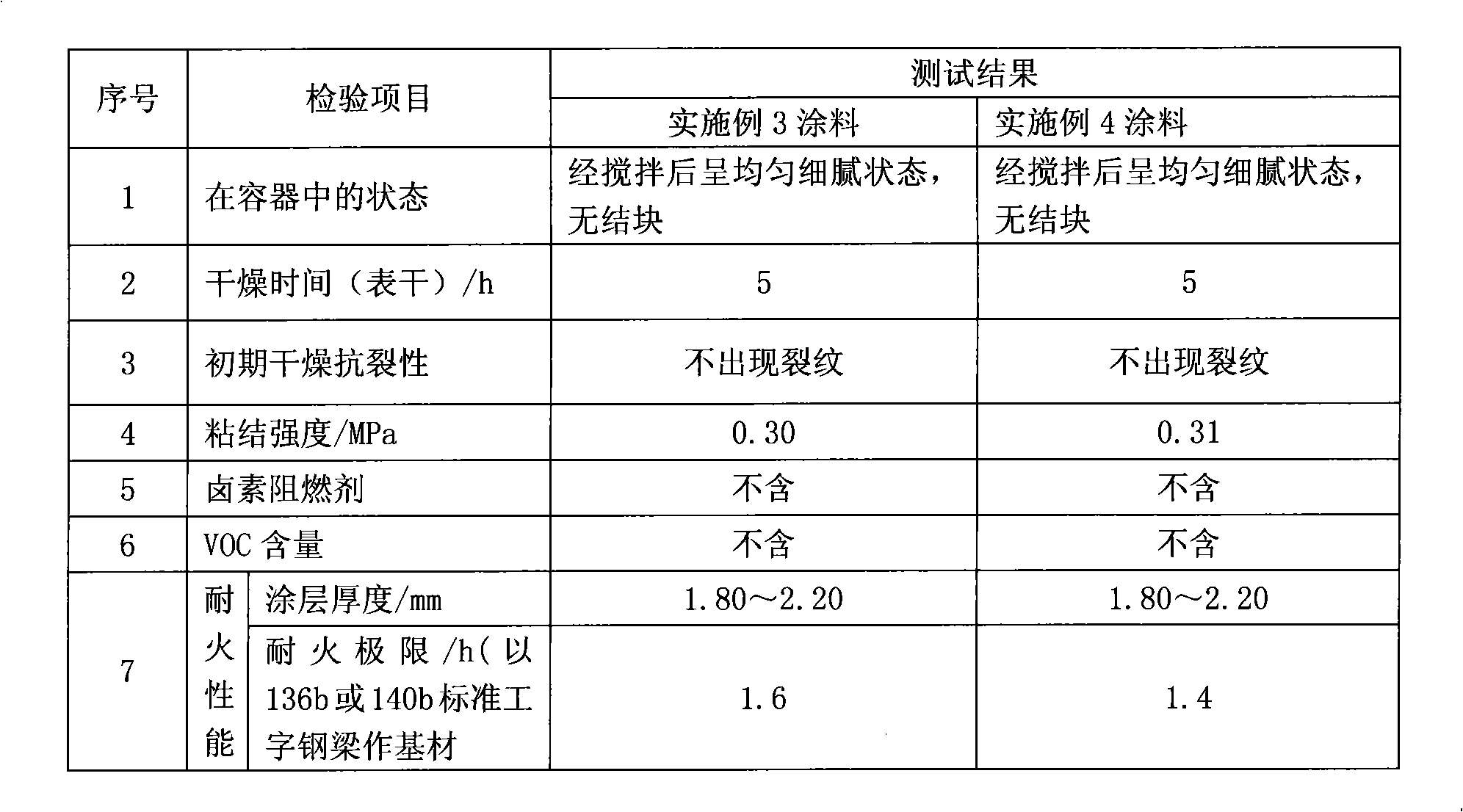

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

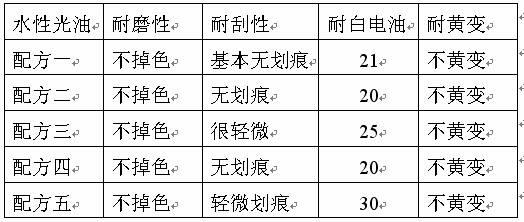

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

Aqueous acrylic modified epoxy ester primer-topcoat integrated anticorrosive baking finish

InactiveCN101864236AHigh hardnessHigh mechanical strengthAnti-corrosive paintsEpoxyWater dispersible

The invention discloses aqueous acrylic modified epoxy ester primer-topcoat integrated anticorrosive baking finish. The baking finish consists of the following components in part by weight: 45 to 65 parts of aqueous acrylic modified epoxy ester resin, 2 to 20 parts of amino resin, 5 to 35 parts of pigment, 0 to 15 parts of filler, 1 to 3 parts of water dispersible dryer, 0.1 to 0.55 part of pH regulator, 5 to 15 parts of softened water, 0.2 to 0.4 part of dispersant, 0.3 to 0.5 part of wetting agent, 0.15 to 0.25 part of flatting agent, 0.3 to 0.5 part of antifoaming agent, and 0.2 to 0.3 part of preservative and mildew preventive. Without organic solvent, the baking finish is safe, energy-saving and free from pollution; the pencil hardness reaches 2H, the coating performance is stable, the film-coating mechanical strength is high, the positive and negative impact resistance can reach 5Kg.cm, and the flexibility can reach 1mm; the baking finish can integrate antirust and anticorrosive functions, can be used as primer or topcoat, reduces the construction process, is simple and quick to operate, can be sprayed or dip-coated, and can be quickly cured; a coated film does not become yellow; and the baking finish meets the development direction of aqueous anticorrosive paint.

Owner:HUNAN XIANGJIANG PAINT GRP

Silicone resin-containing emulsion composition, method for making same, and article having a cured film of same

InactiveUS6114440AGroup 4/14 element organic compoundsPretreated surfacesPolymer scienceOrganic solvent

A silicone resin-containing emulsion composition is prepared by emulsion polymerizing a solution containing a water-insoluble silanol group-bearing silicone resin and a radical polymerizable vinyl monomer and substantially free of an organic solvent. The emulsion may further contain a film-forming assistant having a boiling point of at least 100 DEG C. and soluble or uniformly dispersible in water. The emulsion can be coated and cured into a film having mar resistance, weather resistance, and chemical resistance.

Owner:SHIN ETSU CHEM IND CO LTD

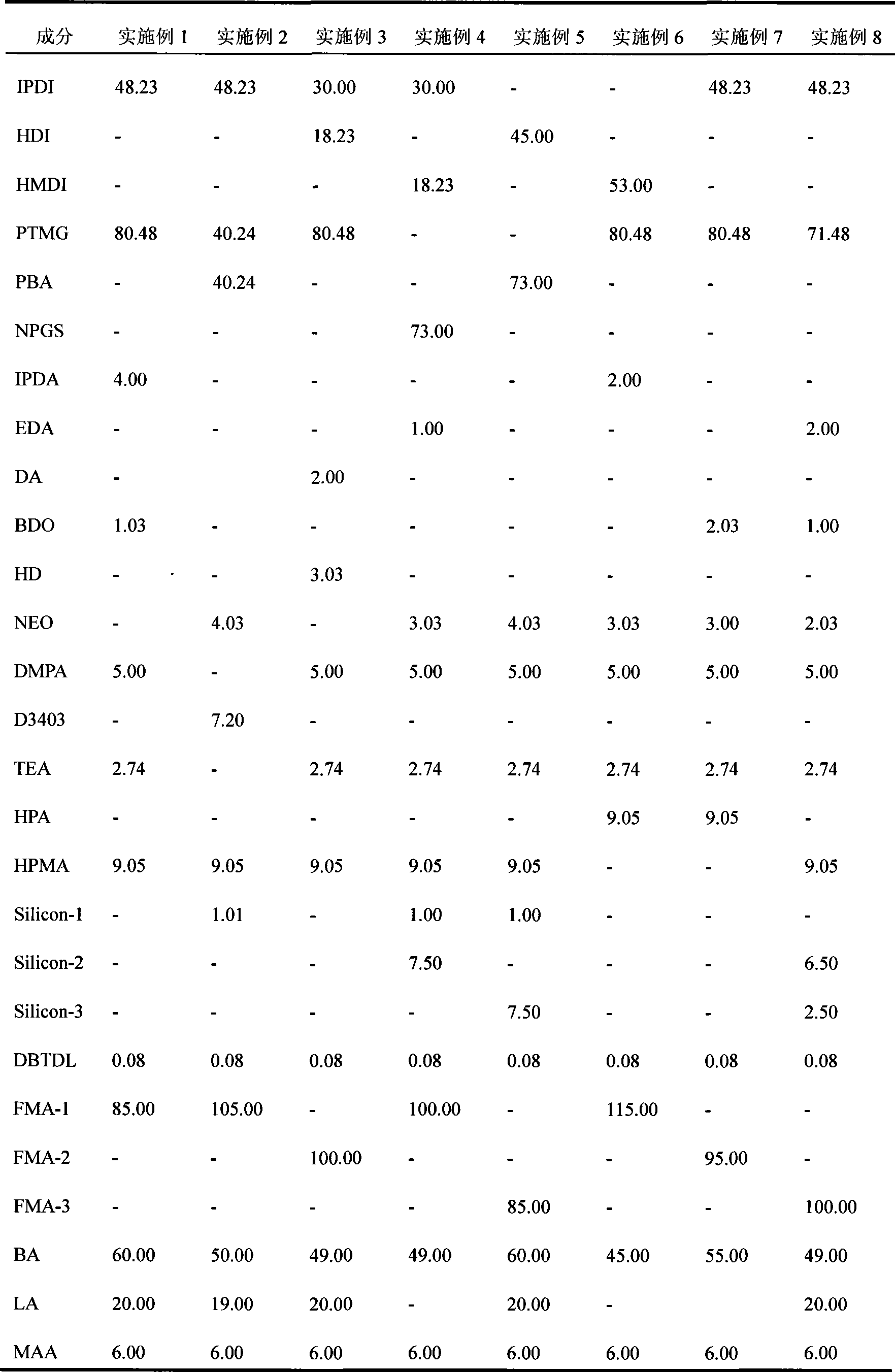

Hybrid polyurethane-polyacrylacid ester dispersion containing fluorine and/or siloxane and preparation method thereof

InactiveCN101362815AGood oil proofImprove waterproof performanceCoatingsDouble bondPhysical property

The invention provides a hybrid polyurethane-polyacrylate dispersoid containing fluorine and siloxane and a preparation method thereof, wherein, an interpenetrating network structure and a nuclear shell structure exist in a dispersoid particle simultaneously. The hybrid polyurethane-polyacrylate dispersoid is polymerizing a polyurethane dispersoid containing double bonds (10-20 percent), a fluorine-containing monomer (5-15 percent), a fluorine-free monomer (10-30 percent), an initiating agent (0.1-2.0 percent), an emulsifying agent (0.5-5 percent), a chain transfer agent (0.01-0.5 percent) and deionized water (50-70 percent) by emulsion. The dispersoid is white lacteal liquid, contains no organic solvent, and has a solid content of 30-50 percent, a molecular weight of 10,000-100,000, a pH value of 7-9, a viscosity of 30-300cp and a stationary phase of more than 1 year. Paint films prepared by the dispersoid have good physical property and relatively low surface energy and can be applied to providing surface coatings with excellent water-proof / antifouling performance.

Owner:大连振邦氟涂料股份有限公司

Polymer-assisted deposition of films

Owner:LOS ALAMOS NATIONAL SECURITY

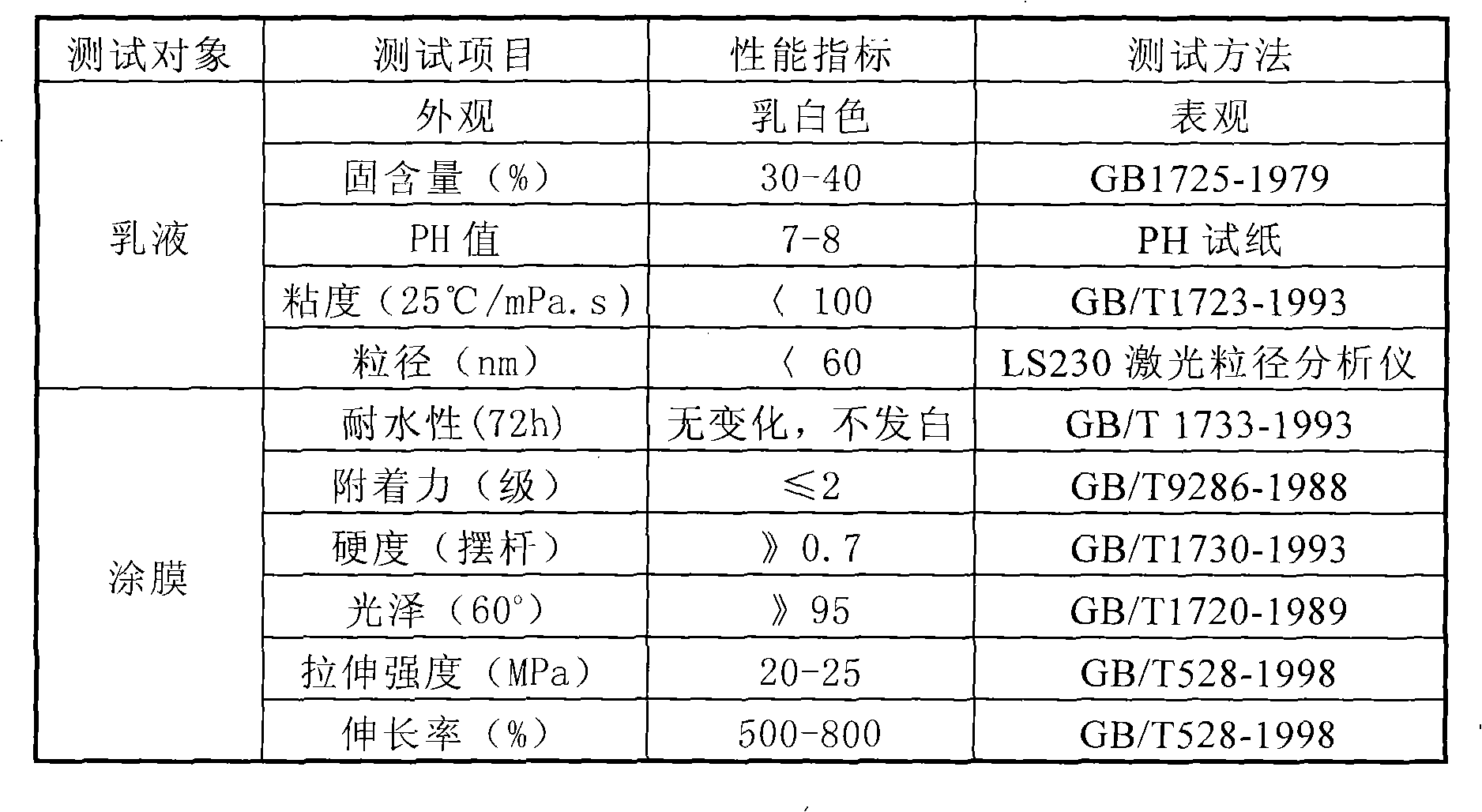

Waterborne polyurethane-polyacrylate emulsion and preparation method thereof

The invention relates to aqueous polyurethane-polyacrylate emulsion and a preparation method thereof. In the preparation method of the aqueous polyurethane-polyacrylate emulsion, vinyl monomers containing reactive groups react with an excess of polyisocyanate under the controlled conditions of a minute amount of a polymerization inhibitor and low temperature to produce partially single terminated vinyl isocyanate; the partially single terminated vinyl isocyanate reacts with a polyhydric alcohol polymer to produce a prepolymer; small amounts of acrylate monomers are added as a thinner; an neutralizer and a small molecule chain extendor are added; the product is dispersed into de-ionized water after reaction; an initiator and remaining acrylate monomers are added, thus getting the stable aqueous polyurethane-polyacrylate emulsion after polymerization. The aqueous polyurethane-polyacrylate emulsion has the characteristics of being free of organic solvent, being friendly to the environment, small and uniform particle size, excellent mechanical property of emulsion film coating, high resistivity against water, high solvent resistance, high hardness and adhesion.

Owner:中国科学院嘉兴应用化学工程中心

Waterborne residual rust antirust coating and preparation method thereof

ActiveCN103897510AExcellent physical and chemical anti-rustFunction increaseAnti-corrosive paintsEpoxy resin coatingsAcrylic resinMechanical equipment

The invention discloses a waterborne residual rust antirust coating and a preparation method thereof. The waterborne residual rust antirust coating is prepared from styrene-acrylic emulsion, water soluble epoxy resin, water soluble acrylic resin, iron oxide red, graphene, zinc oxide, barium sulphate, transforming agents, a transformation accelerator, a levelling agent, a defoaming agent, a dispersing agent, a thickening agent and water. The waterborne residual rust antirust coating contains no organic solvent, is environment-friendly and pollution-free, has the characteristic that bottom and surface are combined and has an excellent physical and chemical antirust and rust transforming function, is applicable to rust protection of the surface of steel with rust, a hard oxidation skin layer or an oil paint film and is also applicable to rust protection of the surface of rust-free steel, the preparation method is simple, construction is easy, two transforming agents are complexed in the waterborne residual rust antirust coating, so that a binding force between the waterborne residual rust antirust coating and rust is increased, the waterborne residual rust antirust coating can be directly brushed and coated on the surface of rusty steel and is applicable to multiple construction ways such as spraying, brushing and showering, the coating cost is low, and the rust protection requirements of urban road facilities, bridges, oil and gas pipelines, engineering mechanical equipment, ships and the like can be met.

Owner:重庆南方漆业有限公司

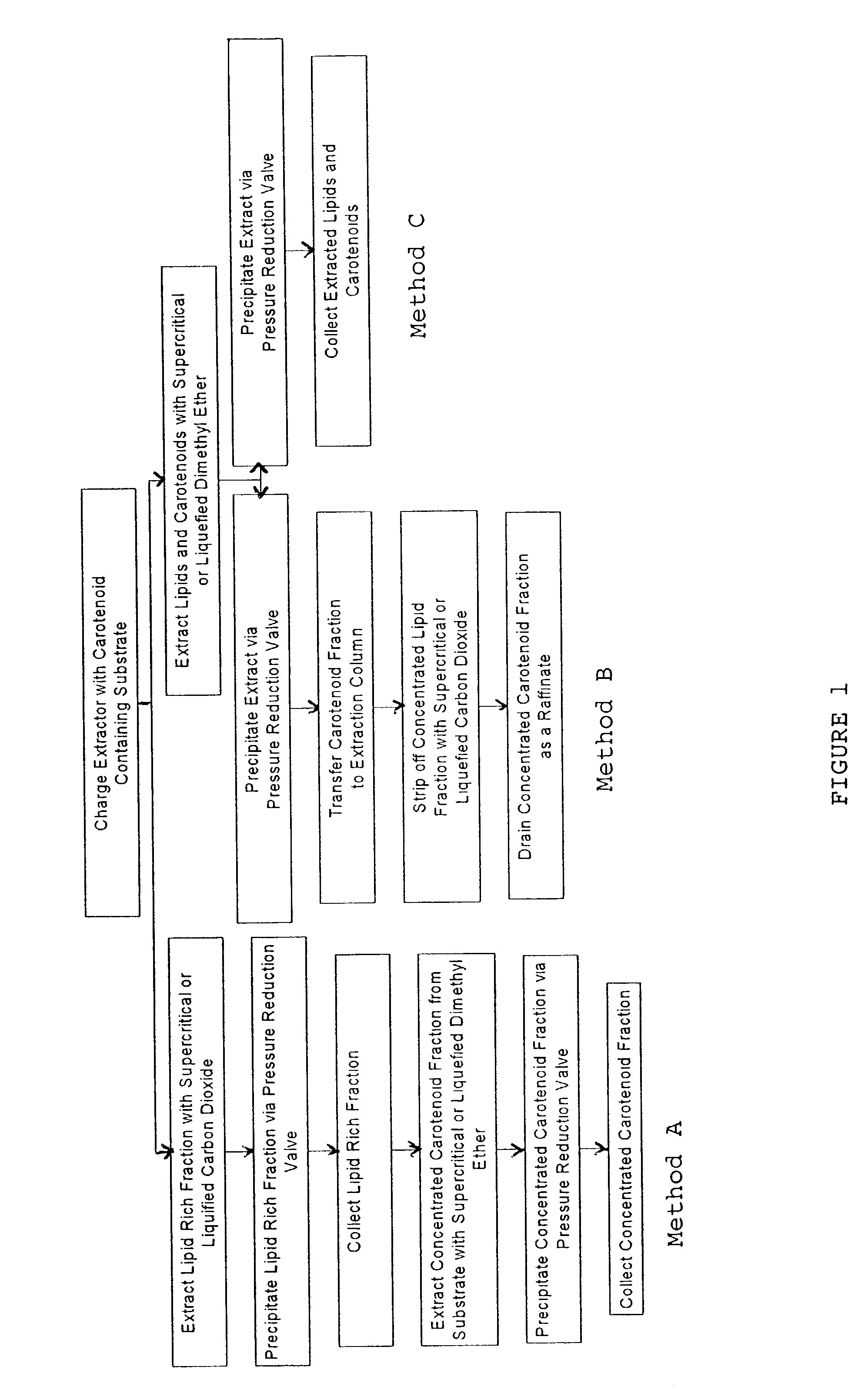

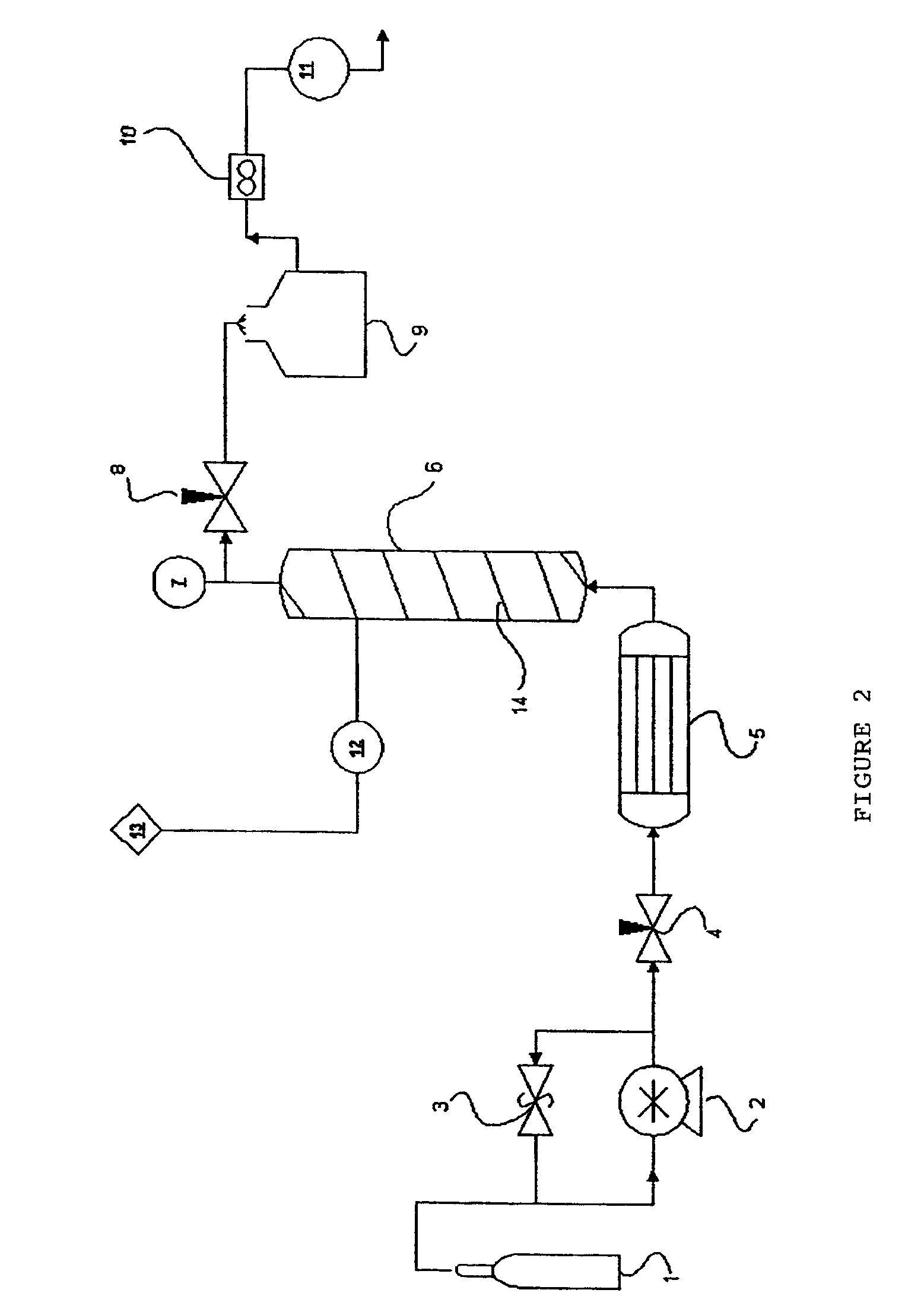

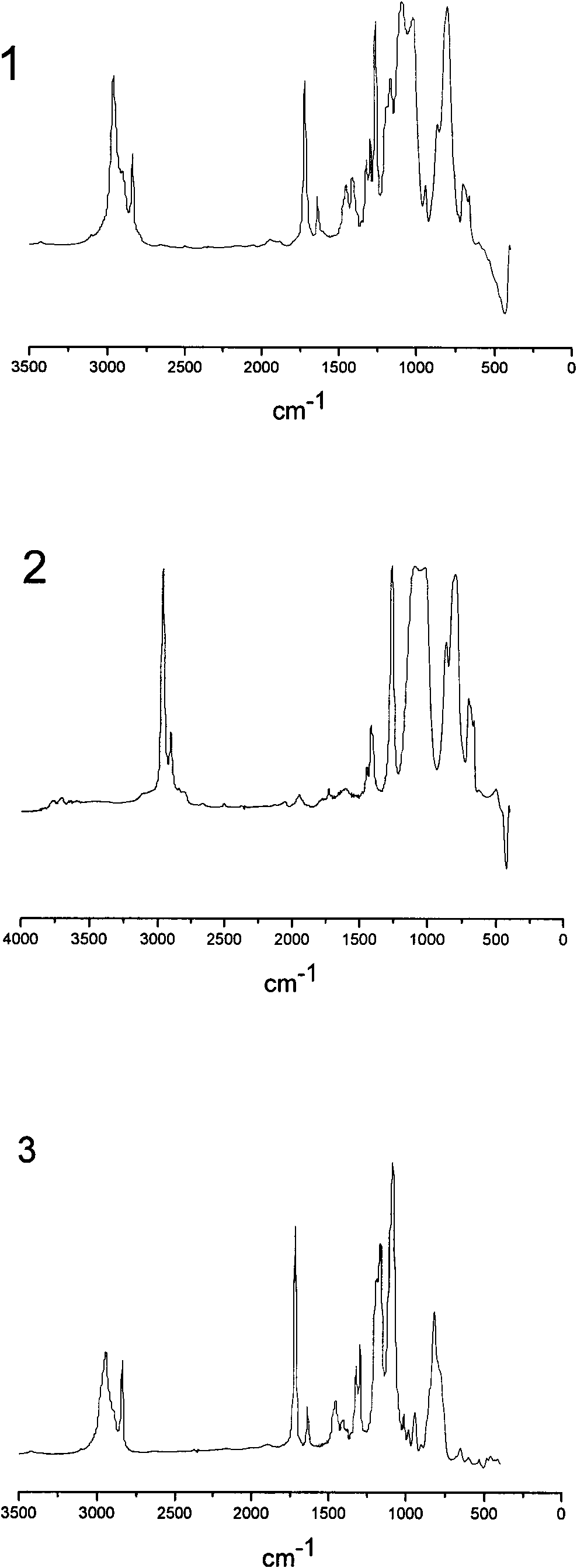

Method for extraction and concentration of carotenoids using supercritical fluids

ActiveUS7329789B1Hydrocarbon purification/separationWater/sewage treatment bu osmosis/dialysisLipid formationOrganic solvent

Carotenoids are extracted and / or enriched from a mixture containing such compounds. The extraction / enrichment process involves the use of liquefied or supercritical solvents to extract lipids and carotenoids from carotenoid-containing substrates. The extraction process can also be performed in two steps in which lipids and carotenoids are first removed from a carotenoid-containing substrate with a liquefied or supercritical solvent, and subsequently a liquefied or supercritical gas is used to separate the lipids from the carotenoids. The two step process can be reversed to first extract lipids with the liquefied or supercritical gas, and subsequently use the solvent to extract the carotenoids. The process is also applicable to yield an organic solvent-free product from a carotenoid-containing source that was first extracted using an organic solvent.

Owner:GREEN RECOVERY TECH

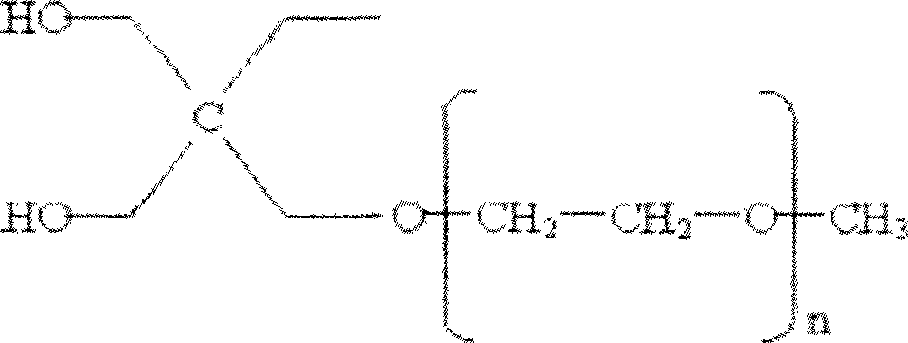

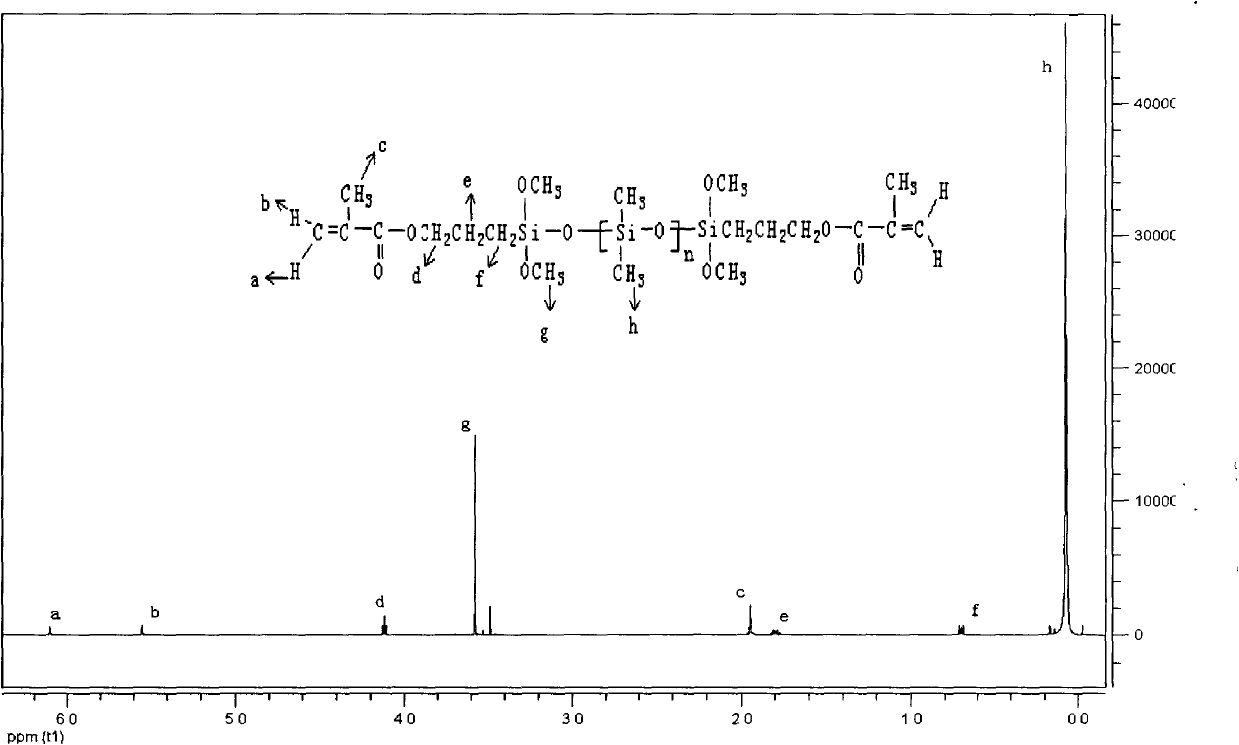

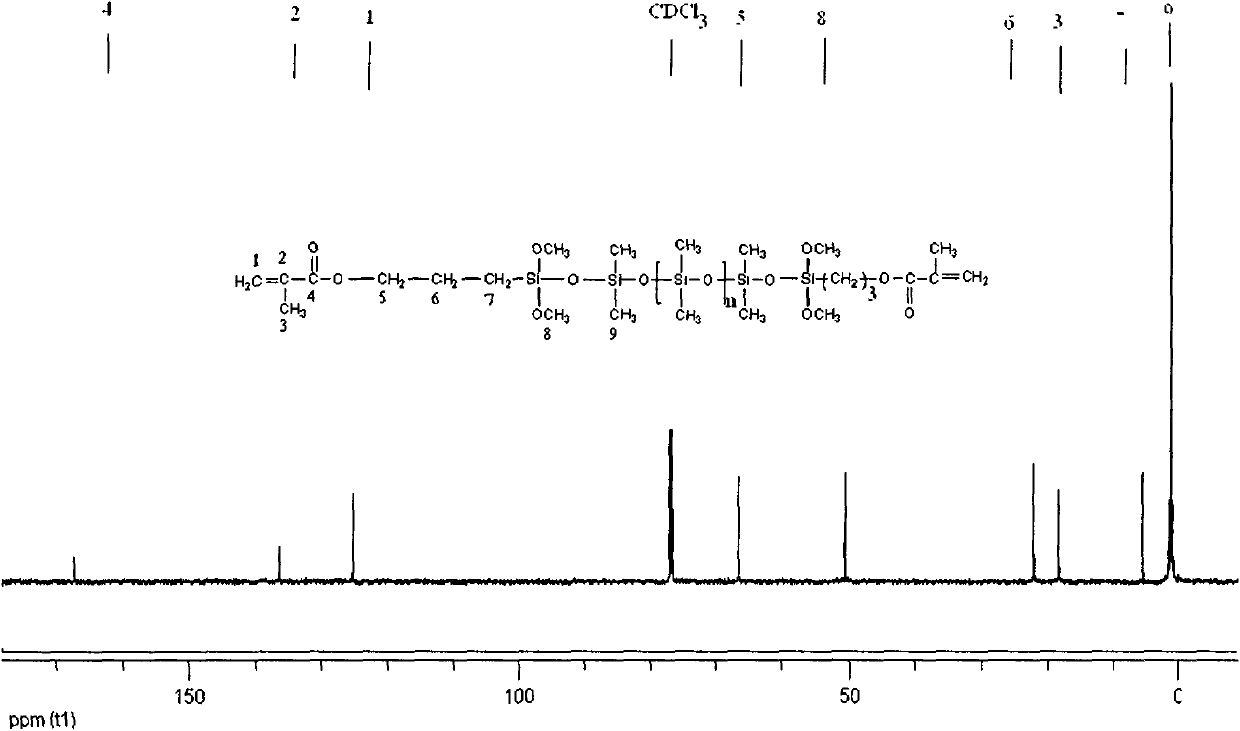

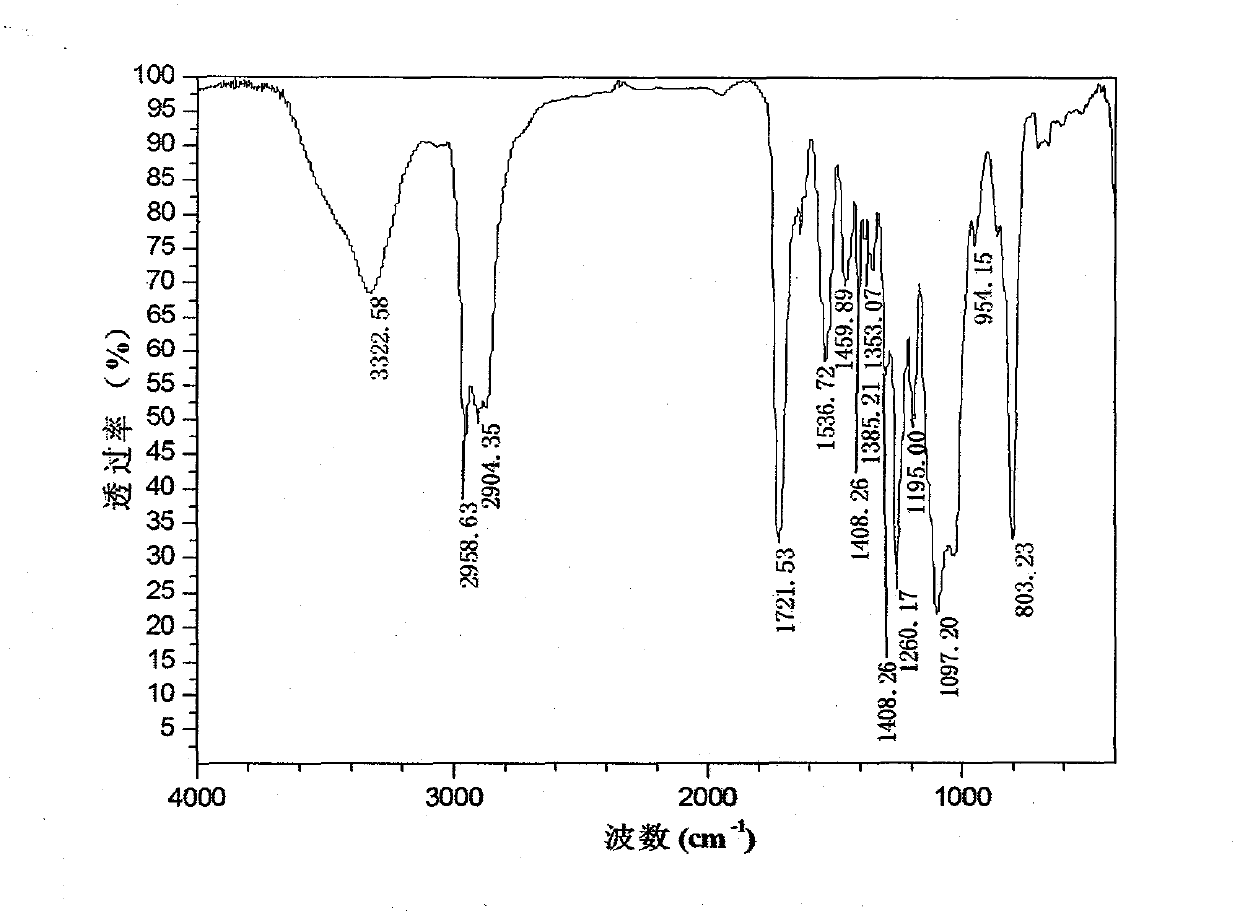

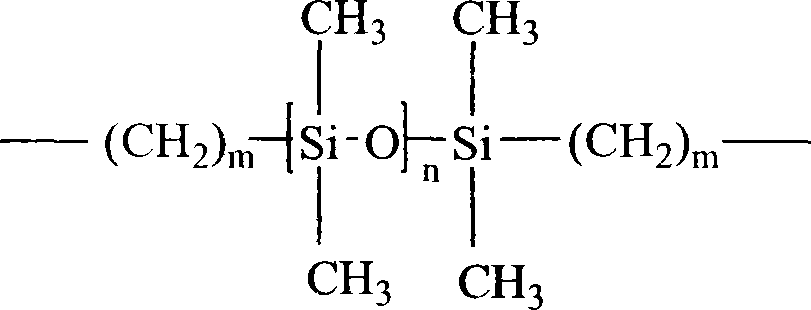

Dual-curable polysiloxane acrylate resin and preparation method thereof

ActiveCN102408569AGood storage stabilityEasy to prepareOther chemical processesAdhesivesSilanesUltraviolet lights

The invention discloses dual-curable polysiloxane acrylate resin and a preparation method thereof, belonging to the technical field of ultraviolet light / moisture dual-curing of organosilicone. The dual-curable polysiloxane acrylate resin has a structural formula (shown as a drawing), wherein R1 is a formula (shown as a drawing), and R2 is OCH3. The preparation method comprises the following stepsof: under the protection of N2, mixing terminal hydroxyl polydimethylsiloxane with methacryloxy propyl trimethoxy silane, adding a solvent and a catalyst, and carrying out an ester exchange reaction to obtain a preproduct; carrying out rotary steaming to remove the solvent, and obtaining a mixture; and at room temperature, extracting by using anhydrous methanol, carrying out centrifugation, further, removing a solvent, and obtaining the dual-curable polysiloxane acrylate resin. The resin is clear and transparent and has good stability for reserving at normal temperature; and the preparation method is simple, short in cycle, and low in cost, and the resin per se does not contain an organic solvent.

Owner:BEIJING UNIV OF CHEM TECH

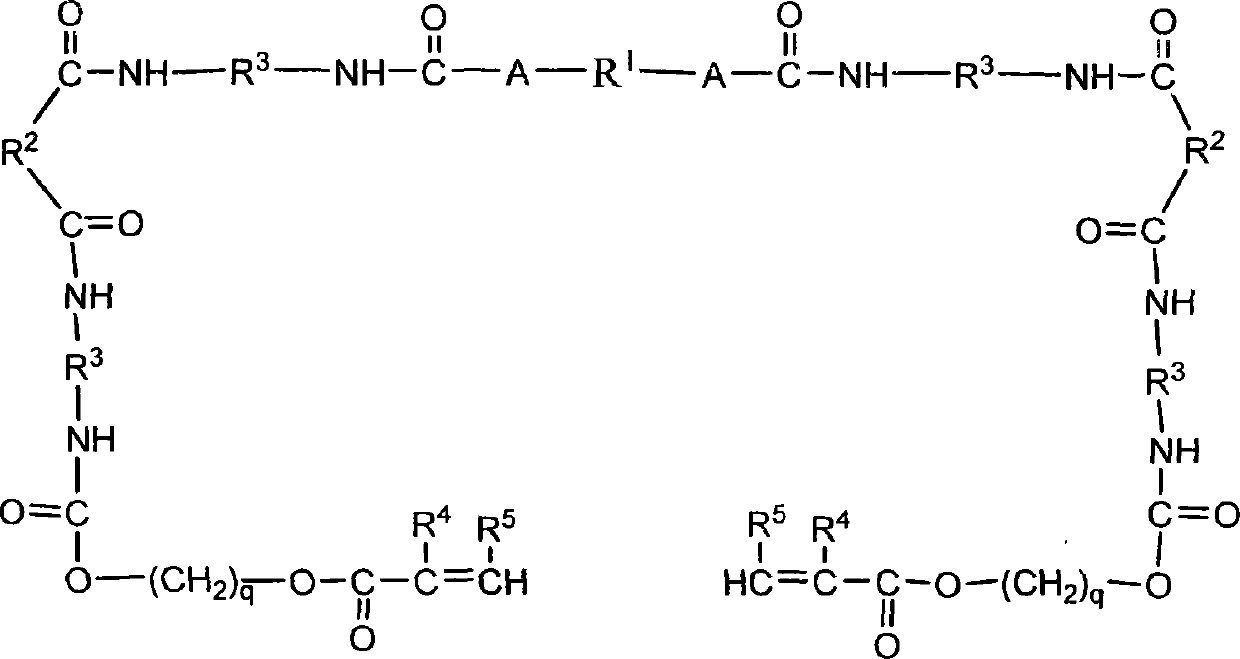

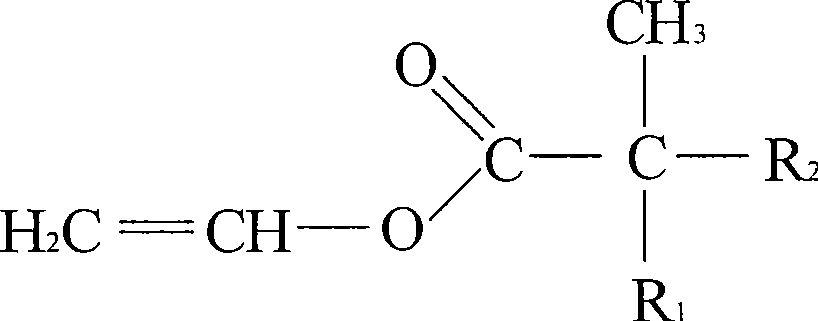

Photosensitive fluorosilicone segmented urethane acrylate oligomer and preparation method thereof

ActiveCN102993404AIncrease photosensitivityGood high resistanceFibre treatmentCoatingsOrganic solventOligomer

The invention relates to a photosensitive fluorosilicone segmented urethane acrylate oligomer and a preparation method of the photosensitive fluorosilicone segmented urethane acrylate oligomer. The preparation method comprises the steps of: (1) adding a fluorinated acrylate monomer and dialkylol amine into a reactor for reaction for 2-6hours at 20-50 DEG C; (2) adding organic silicon, polyisocyanate and a catalyst into the reactor for reaction for 0.25-2hours at 30-60 DEG C; (3) adding a second step product, a first step product, polyisocyanate and the catalyst into the reactor for reaction for 0.25-1hour at 30-60 DEG C; (4) carrying out reaction of a third step product, olefine acid-hydroxyl ester compounds, a polymerization inhibitor and the catalyst for 2-6hours at 30-80 DEG C; and (5) reducing the temperature and cooling to room temperature, discharging, and keeping in a dark place for later use. The invention has the beneficial effects that (1) the synthesized oligomer has the characteristics of better photosensitiveness, high and low temperature resistance, chemical medium resistance, resistance to pollution, flexibility and the like; (2) a ultraviolet cured leather finishing agent prepared by the oligomer has better adhesive force and low temperature hard fold resistance, does not contain organic solvents, is pollution-free and belongs to an environment-friendly material; and (3) the oligomer is simple in synthetic method, mild in reaction condition and easy to operate.

Owner:BEIJING UNIV OF CHEM TECH +1

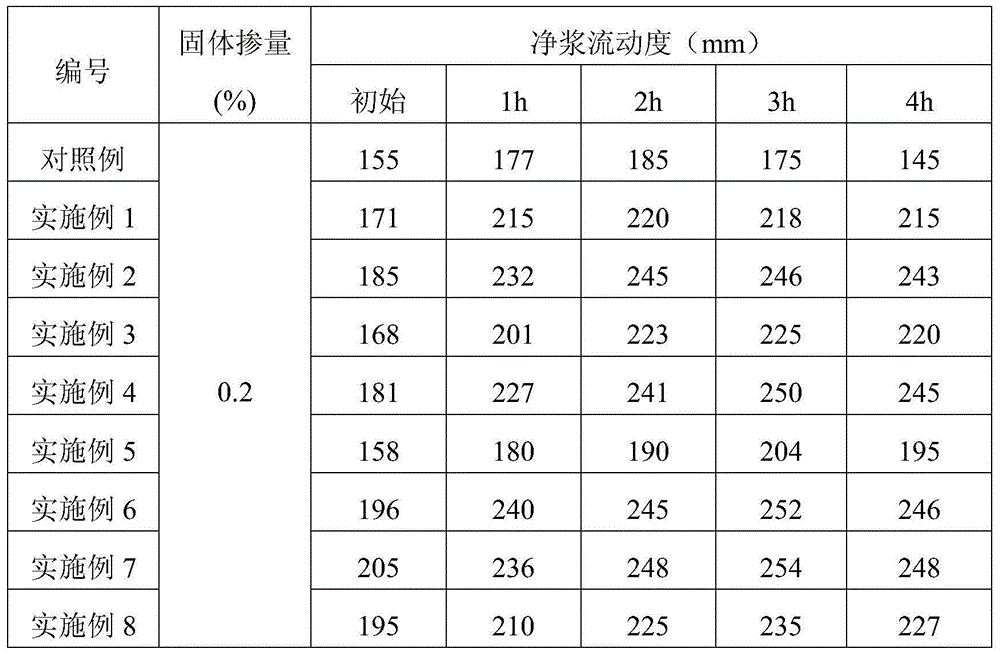

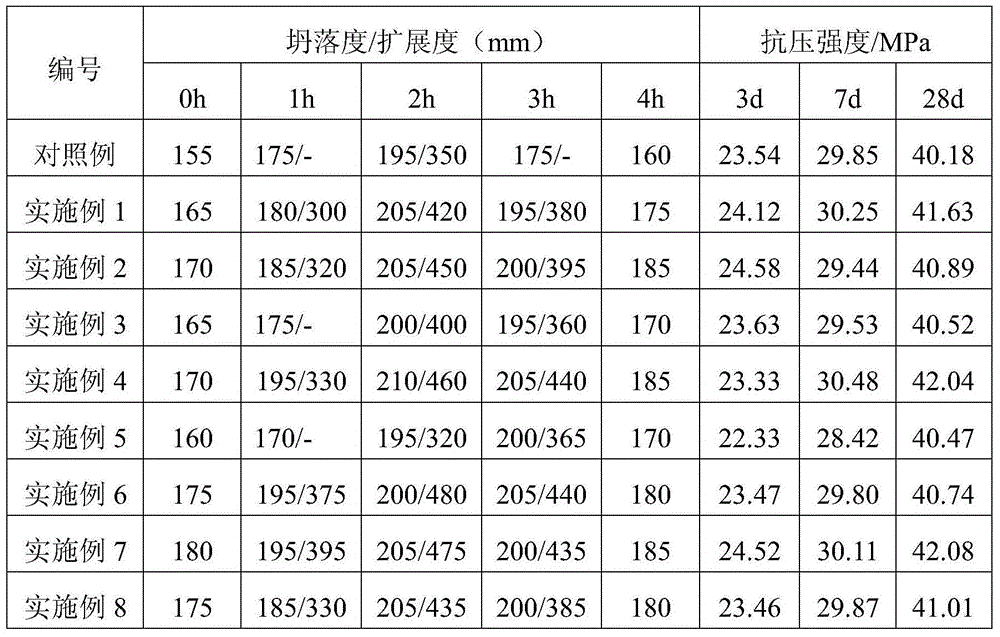

Preparation method of slow-release solid polycarboxylic acid water reducing agent

The invention relates to a preparation method of a slow-release solid polycarboxylic acid water reducing agent, which comprises the following steps: pretreating carboxylic acid small monomer containing unsaturated double bond by using amine organic small molecule; and after heating to melt the pretreated unsaturated acrylic small monomer and unsaturated polyethenoxy ether big monomer, dropwisely adding unsaturated ester small monomer to perform mass polymerization reaction under the action of an initiator and a chain-transfer agent in a water-free organic-solvent-free environment. The slow-release solid polycarboxylic acid water reducing agent prepared by the mass polymerization process in the water-free solvent-free environment has the advantages of simple and controllable technique, transportation cost saving, environment friendliness, no pollution and the like, achieves the goal of slow release and keeping the slump for 3-4 hours without loss in concrete, and has wide market application prospects.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

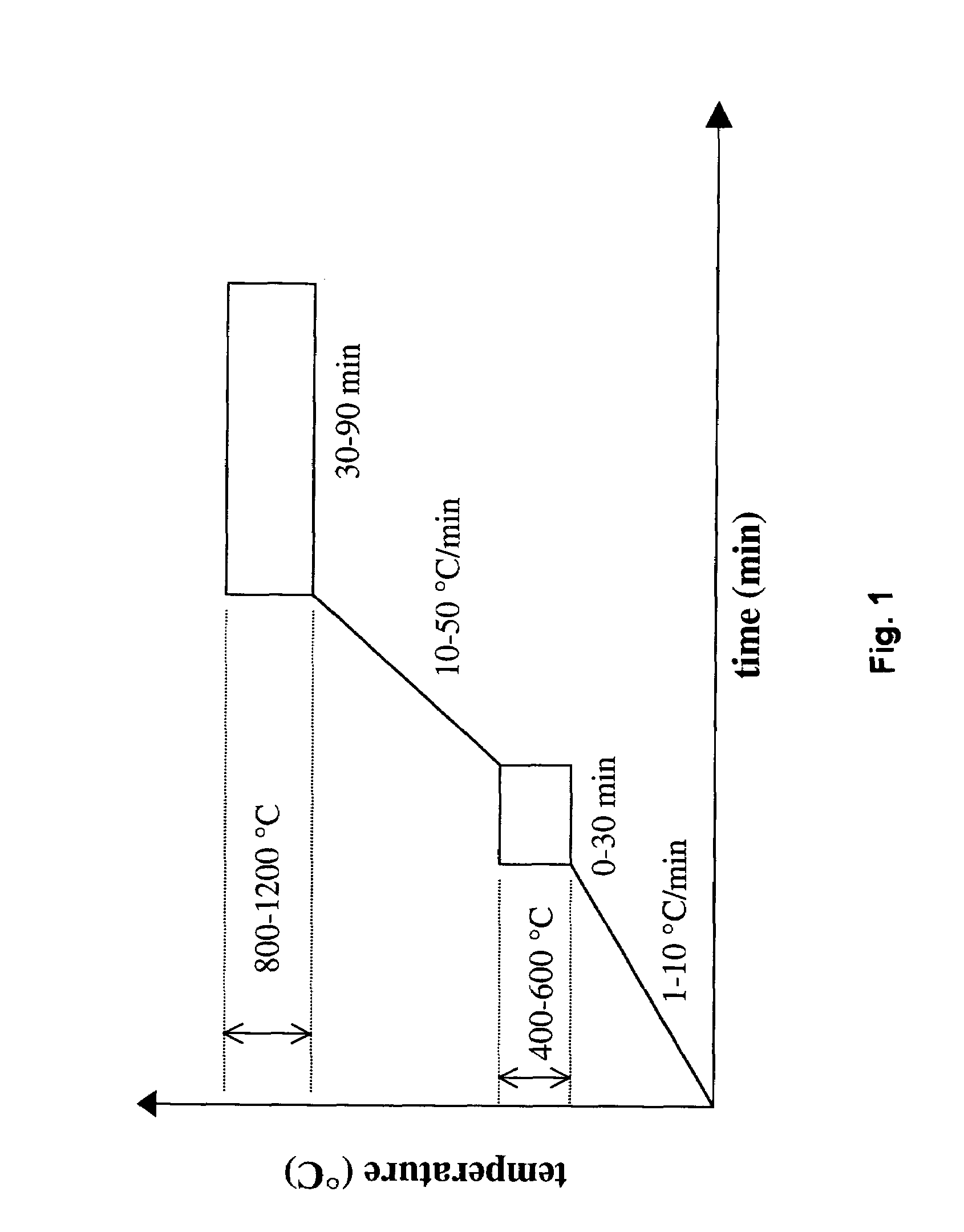

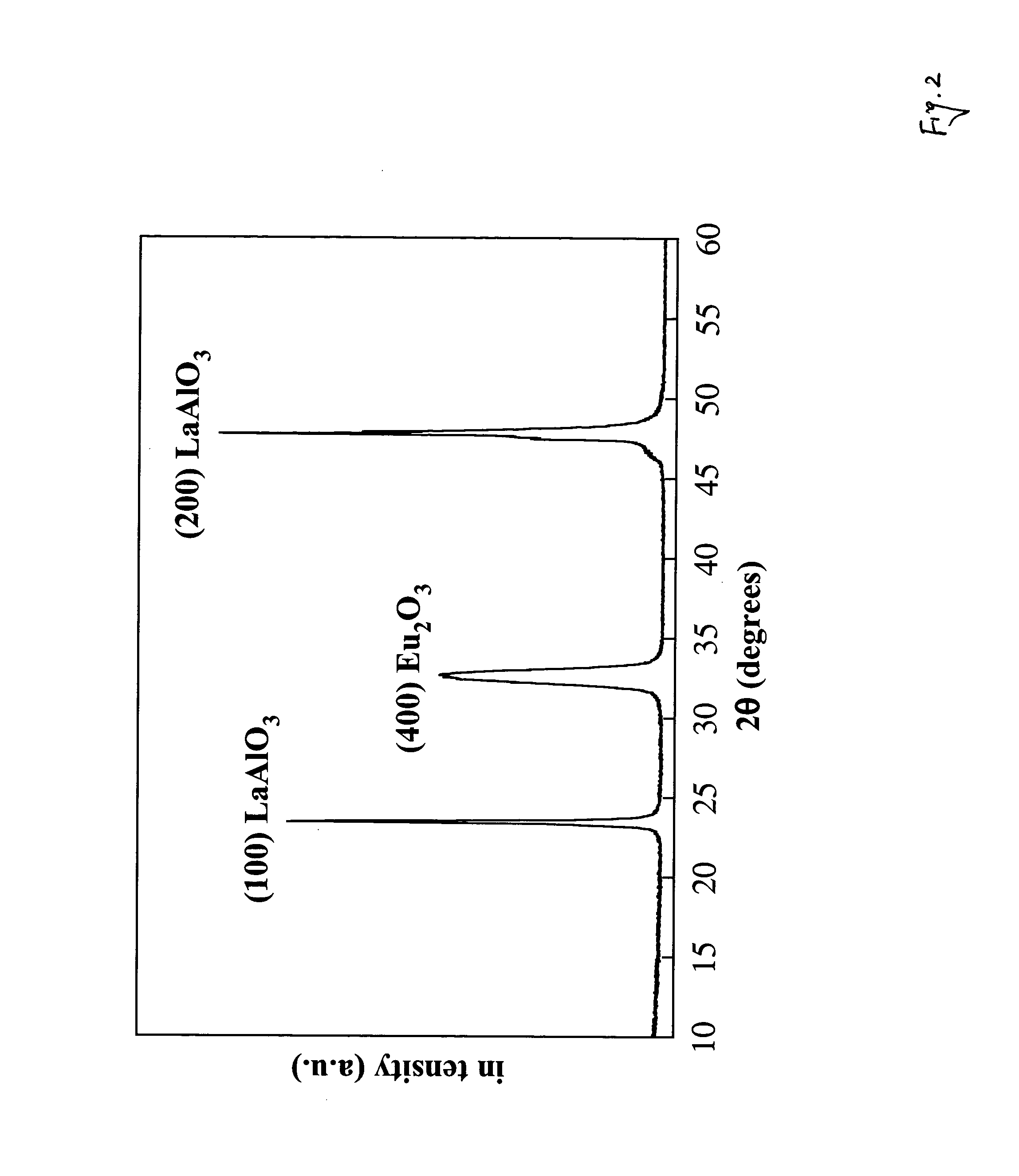

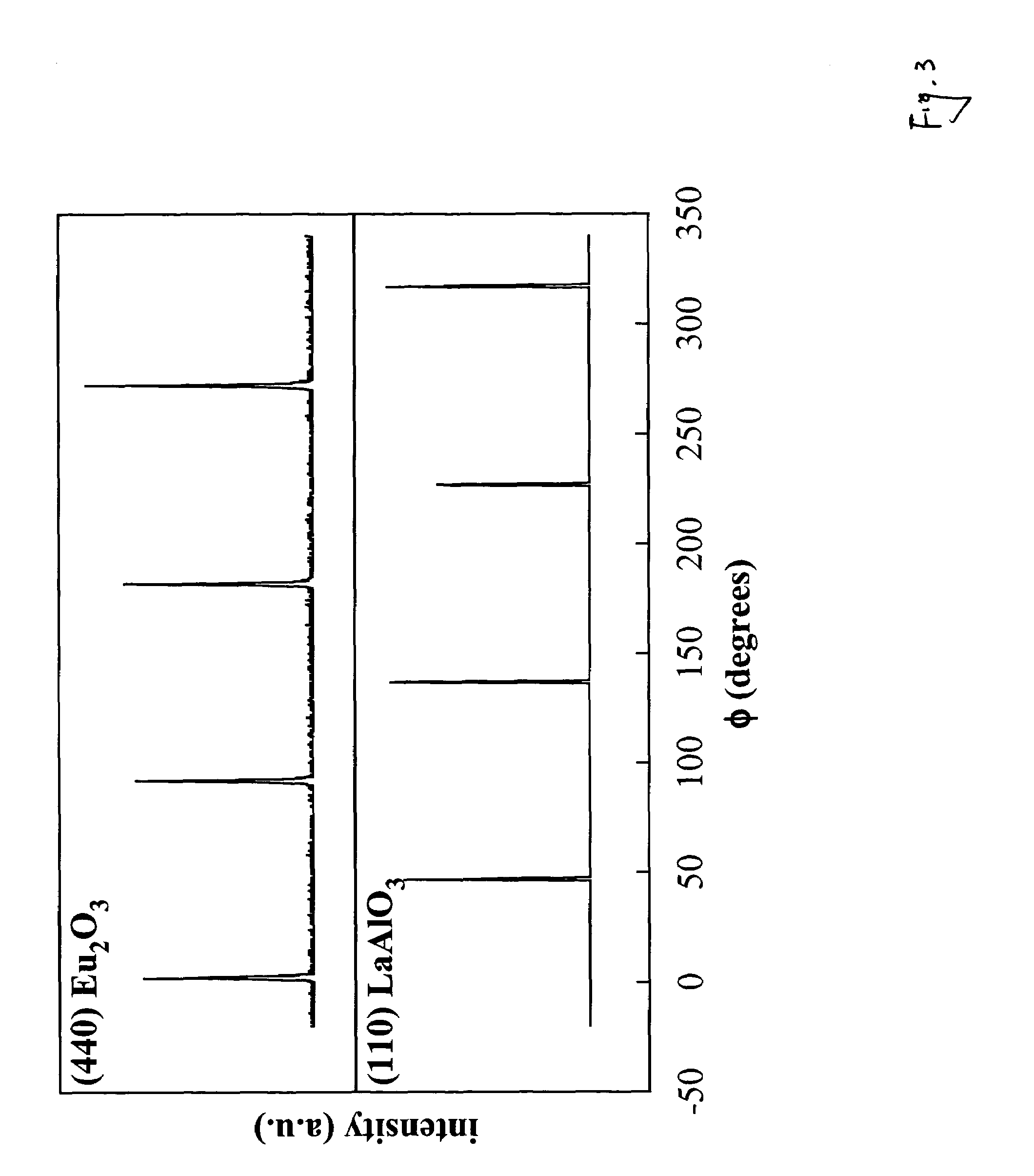

Polymer-assisted deposition of films

A polymer assisted deposition process for deposition of metal oxide films and the like is presented. The process includes solutions of one or more metal precursor and soluble polymers having binding properties for the one or more metal precursor. After a coating operation, the resultant coating is heated at high temperatures to yield metal oxide films and the like. Such films can be epitaxial in structure and can be of optical quality. The process can be organic solvent-free.

Owner:TRIAD NAT SECURITY LLC

Strong virgin's emulsoid

InactiveCN1456628AImprove frost resistanceImprove water resistanceUnsaturated alcohol polymer adhesivesHigh resistanceEmulsion

A strong while emulsion is prepared from polyvinyl alcohol, sodium hydroxide, starch, hydrochloric acid, formaldehyde, urea and water. Its advantages are high resistance to freeze and water, high stability and adhesion, no irritative odor, and low cost.

Owner:长春市泰发实业(集团)有限责任公司

Water-soluble acroleic-acid modified epoxy ester anti-rast paint

InactiveCN1640968AImprove the protective effectImprove the decorative effectAnti-corrosive paintsEpoxy resin coatingsChromium CompoundsEpoxy

The present invention relates to one kind of water soluble acrylic acid modified antirust epoxy resin paint. The modified antirust epoxy resin paint includes water soluble acrylic acid modified epoxy resin 45.0-62.0 wt%, water soluble amino resin 3.0-6.0 wt%, coloring pigment 5.0-15.0 wt%, antirust pigment 6.0-10.0 wt% and stuffing 5.0-10.0 wt%, and it contains also neutralizing agent, co-solvent, dispersant, defoaming agent, thickener, corrosion inhibitor, drying promoter and deionized water. The modified antirust epoxy resin paint contains no organic solvent and harmful lead and chromium compound, has no hazard of burning, explosion, poisoning and polluting environment, and has excellent protecting performance and decoration effect.

Owner:重庆亿隆涂料股份有限公司

Organosilicon modified tert-fluoro emulsion and preparation of luminescent coating with the emulsion as base material

InactiveCN101463108ATake advantage ofNo pollution in the processLuminescent paintsCarboxylic acidSolvent

The invention discloses an organosilicon modified tert-fluoro emulsion and a preparation method of a luminescent coating which takes the emulsion as a base material. The emulsion takes vinyl ester of tertary carboxylic acid, an organosilicon monomer, an organic fluorine monomer and an acrylic monomer to perform graft copolymerization, the prepared emulsion takes water as a solvent, does not contain organic solvent and is an environment-friendly product, and emulsion particles are of a core-shell structure. The production method of the luminescent coating comprises the following steps: mixing and blending the emulsion with super-efficiency afterglow luminescent powder and other coating additives, the prepared luminescent coating has corrosion prevention and self-cleaning functions, and can be applied to the fields such as building decoration, advertisement signs, factory instruments, airfield runways, road rails, handicraft articles and the like. The coating has the advantages of excellent cost performance ratio, convenient production and construction and easy implementation and popularization.

Owner:NORTHWEST NORMAL UNIVERSITY

Aqueous Systems For The Preparation Of Lipid Based Pharmaceutical Compounds; Compositions, Methods, And Uses Thereof

InactiveUS20100068251A1Simple and rapid and to produceSimple and rapid inspectionBiocidePowder deliveryDiseaseOrganic solvent

The present invention relates to a methods of preparing active compounds complexed with lipids using aqueous systems that are free of organic solvents, and methods of using the complexes, e.g., in treating a disease in a subject. In some embodiments, the present invention comprises a composition comprising a complex comprising at least one active compound, e.g., a polyene antibiotic, an immunosuppressant agent such as tacrolimus or a taxane or taxane derivative, and one or more lipids. In some embodiments, the present invention provides a method comprising preparing a composition comprising a lipid complex comprising at least one active compound and at least one lipid and administering the composition to a subject. In certain embodiments the subject is a mammal. In certain preferred embodiments, the subject is human.

Owner:JINA PHARMA

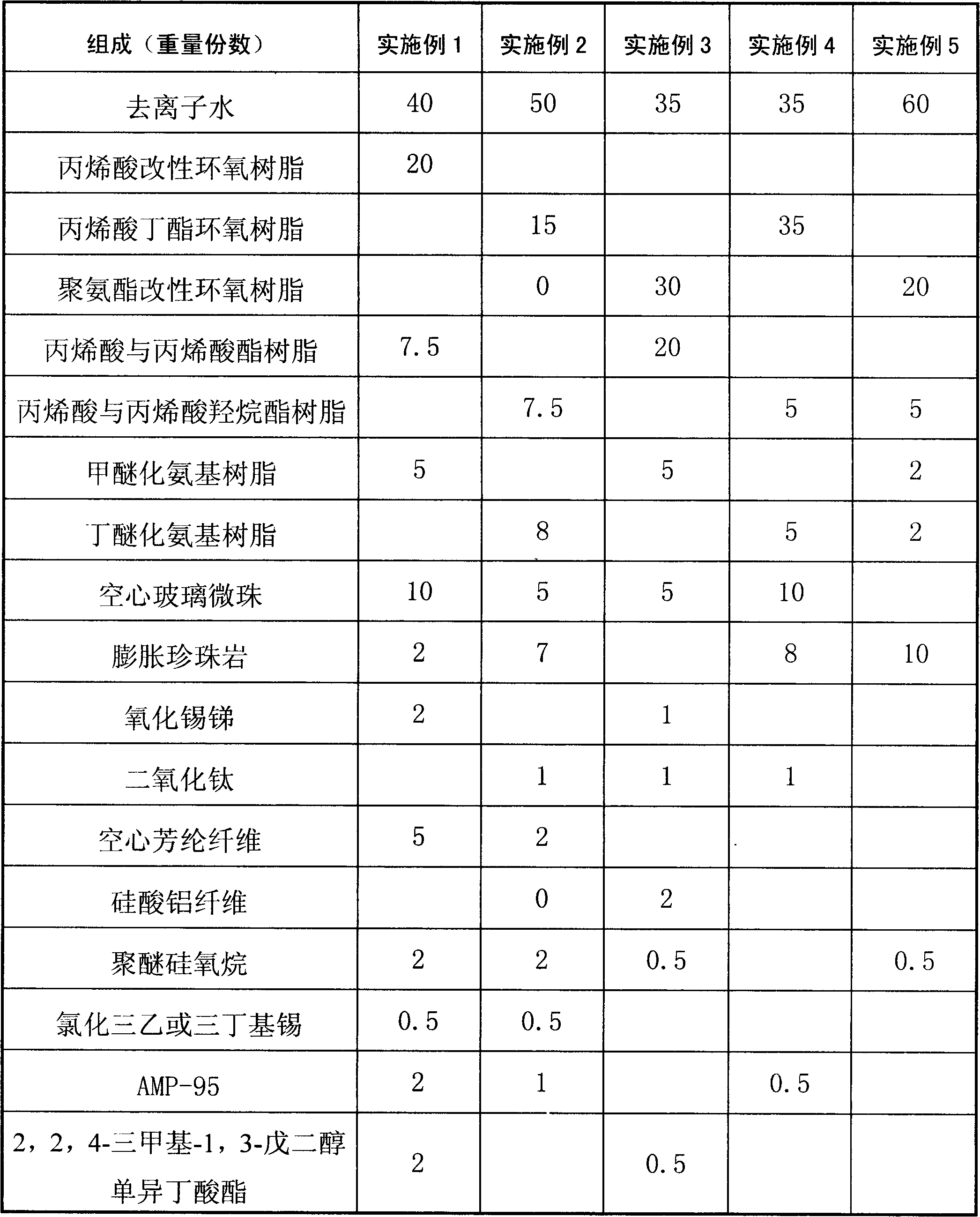

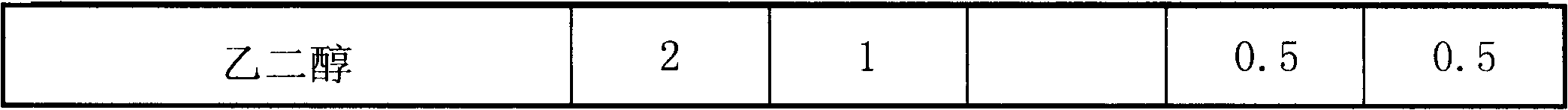

Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

InactiveCN103450773AStrong adhesionHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to a kind of heat insulation paint with a high anticorrosion performance and a preparation method thereof. The anticorrosion heat insulation paint is composed of following components in percentage by weight: 35 to 60% of deionized water, 20 to 40% of modified epoxy resin, 5 to 30% of modified acrylic resin, 1 to 8% of amino resin, 10 to 25% of heat insulation materials, 0 to 8% of strengthening materials, and 1 to 10% of auxiliary agent. The preparation method comprises following steps: orderly adding deionized water, modified epoxy resin, modified acrylic resin, and amino resin into a reactor, starting the stirrer, evenly mixing the materials, adjusting the pH value of the system to a range of 7 to 9, then orderly adding the auxiliary agent, the heat insulation materials, and the strengthening materials, stirring for 1 to 3 hours in a high speed, and evenly mixing so as to obtain the anticorrosion heat insulation paint. The preparation method has the advantages of simple technology, high production efficiency, and low energy consumption. The prepared paint does not contain any organic solvent, so no solvent will volatilize during the coating solidification process, so no pollution is generated to the environment. The paint has the advantages of excellent mechanical properties of bonding strength, hardness, scratch resistance, wear resistance, and water resistance, and good properties of anticorrosion, salt smog resistance, forming ability, heat resistance, and deflection resistance.

Owner:BOYIFEI EQUIP INST FOR NEW MATERIALS

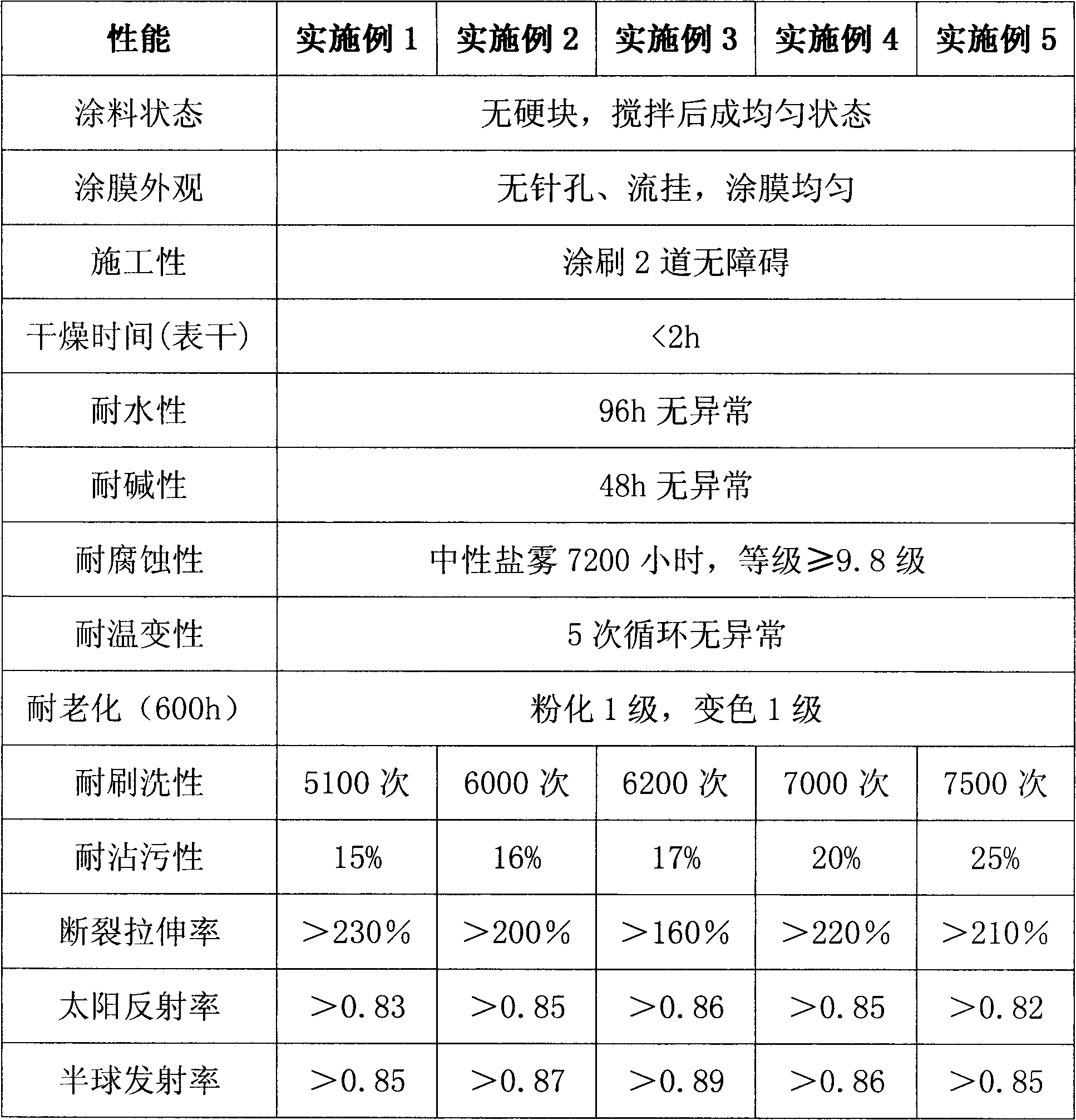

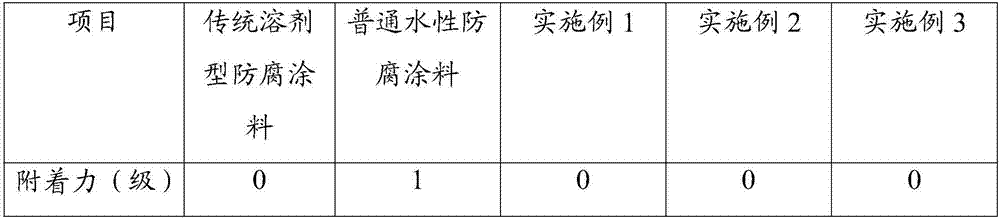

Waterborne graphene anticorrosive paint and preparation method thereof

InactiveCN107266999AImprove water resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsFoaming agentHydrogen

The invention belongs to the field of chemical paint and in particular relates to waterborne graphene anticorrosive paint and a preparation method thereof. The waterborne graphene anticorrosive paint is prepared from the following components in parts by weight: polymer waterborne resin, a wet dispersant, a de-foaming agent, a pH (Potential of Hydrogen) regulator, graphene filling slurry, pigment slurry, a flatting agent, a thickener, de-ionized water, a curing agent and an adhesion promoter. The waterborne graphene anticorrosive paint provided by the invention takes water as a diluting agent, does not contain an organic solvent and has no pungent odor so that the waterborne graphene anticorrosive paint does not pollute the environment and has no harms to human bodies. Graphene is added so that the wearing resistance, rigidity and anticorrosive performance of a whole paint surface are improved.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Ultraviolet cured printing ink for digital flat ink jet printer and method for making same

Disclosed are components of a ultraviolet ray solidified printing ink for digital spraying machine and its preparing method. The UV solidified printing ink comprises of prepolymer, active monomer, color, photoinitiator, dispersant and surface active agent, which are mixed by a certain ratio, through grinded ( instantaneously ) and stirring to produce the product. The printing ink doesn't contain organic solvent, for environmental protection, it can be solidified in grinded ( instantaneously ) under the ultraviolet ray for satisfying high speed requirement, as well as print on glass steel,PE and PP film, eramic tile and film and other material, with wide application and bright future.

Owner:DONGHUA UNIV

Process for making biodiesel from crude tall oil

InactiveUS20070130820A1Improve overall utilizationIncrease productionBiofuelsLiquid carbonaceous fuelsBiodieselOrganic solvent

A process of making biodiesel from crude tall oil by reacting crude tall oil with a C1-C6 alkanol in the presence of an acid catalyst or by reacting crude tall oil with an acyl halide in the presence of a C1-C6 alkanol. The reaction product of either of these reactions is separated into a suspension liquid by the addition of a polar liquid. The biodiesel product is recovered from the suspension liquid by addition of an organic solvent which produces a polar liquid phase and an organic liquid phase. The biodiesel is recovered from the organic liquid phase by evaporating the organic solvent, which is recovered for use in subsequent separation processes, and vacuum distilling off the product biodiesel from the organic solvent-free organic liquid phase.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Antimicrobial silver halide composition

InactiveUS20060068024A1Improve antibacterial propertiesIncreased durabilityBiocideInorganic active ingredientsOrganic solventHydrophilic polymers

This invention relates to a composition comprising at least 50% water, silver halide particles and a hydrophilic polymer, wherein the composition does not substantially gel or solidify at 25 degrees C.; is substantially free of organic solvents; and exhibits antimicrobial activity upon drying. The composition may further comprise a hydrophobic binder or a crosslinker for the hydrophilic polymer.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com