Waterborne polyurethane-polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion and water-based polyurethane is applied in the field of water-based polyurethane-polyacrylate emulsion and its preparation. Excellent water resistance and high solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

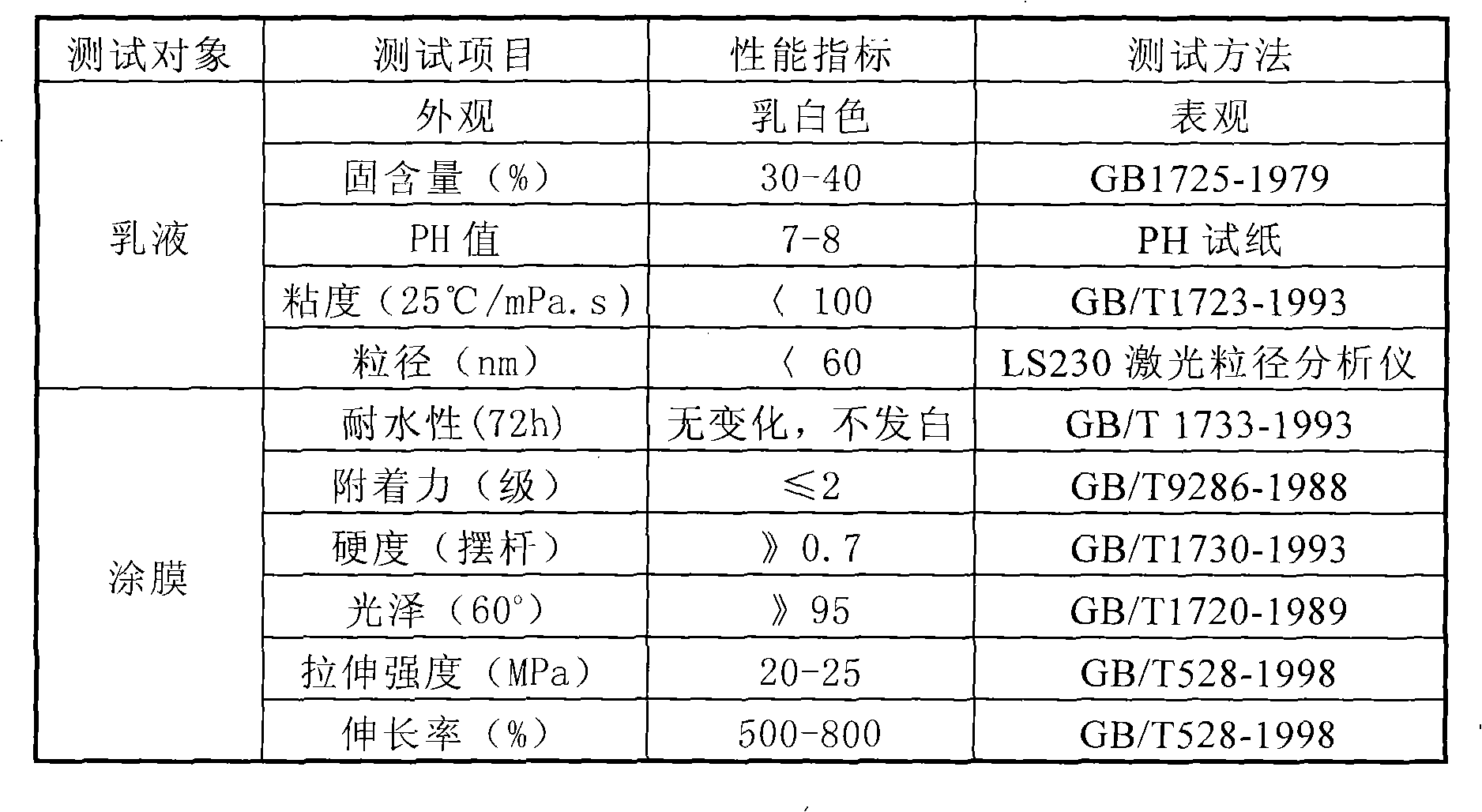

Image

Examples

Embodiment 1

[0042] The composition list of waterborne polyurethane-polyacrylate emulsion formula is as follows:

[0043] Waterborne polyurethane-polyacrylate emulsion formulation 1:

[0044] Toluene diisocyanate (TDI): 41.8g

[0045] Polyether polyol (N210): 30.0g

[0046] p-Hydroxyanisole: 0.002g

[0047] Dibutyltin dilaurate (DBTD): 0.05g

[0048] Hydroxyethyl acrylate: 9.3g

[0049] Dimethylolpropionic acid (DMPA): 8.0g

[0050] Triethylamine (TEA): 6.0g

[0051] 1,4-butanediol (BDO): 3.6g

[0052] Ethylenediamine (EDA): 4.2g

[0053] Methyl methacrylate (MMA): 20.0g

[0054] Butyl acrylate: 12.0g

[0055] Acrylonitrile: 8.0g

[0056] Azobisisobutyronitrile (AIBN); 0.4g

[0057] Deionized water: 220.0g

[0058] In a 500ml three-neck flask equipped with a thermometer and a stirring device, add hydroxyethyl acrylate containing an active group ethylenic monomer and excess toluene diisocyanate (TDI) monomer, the molar ratio of the two is 1:3, add a small amount The polymerizat...

Embodiment 2

[0060] The composition list of waterborne polyurethane-polyacrylate emulsion formula is as follows:

[0061] Waterborne polyurethane-polyacrylate emulsion formulation 2:

[0062] Isophorone dicyanate (IPDI) 44.4g

[0063] Polyether polyol (N210) 35.0g

[0064] p-tert-butylcatechol (TBC) 0.001g

[0065] Dibutyltin dilaurate (DBTD) 0.04g

[0066] N-Methylolacrylamide 5.0g

[0067] Dimethylolpropionic acid (DMPA) 6.0g

[0068] Triethylamine (TEA) 4.5g

[0069] 1,6-butanediol 3.0g

[0070] Ethylenediamine (EDA) 4.8g

[0071] Methyl methacrylate (MMA) 15.0g

[0072] Ethyl acrylate 7.0g

[0073] Acrylonitrile 10.0g

[0074] Azobisisobutyronitrile (AIBN) 0.4g

[0075] Deionized water 230g

[0076] N-methylol acrylamide containing active group ethylenic monomer and excess isophorone dicyanate (IPDI) monomer, the molar ratio of the two is 1:4, adding a small amount of polymerization inhibitor p-tert-butyl o Hydroquinone (TBC), the temperature is controlled at 30°C, heat pr...

Embodiment 3

[0078] The composition list of waterborne polyurethane-polyacrylate emulsion formula is as follows:

[0079] Waterborne polyurethane-polyacrylate emulsion formulation 3:

[0080] Isophorone dicyanate (IPDI): 47.5g

[0081] Polytetrahydrofuran polyol (Mw=1000): 40.0g

[0082] Hydroquinone: 0.001g

[0083] Stannous octoate: 0.04g

[0084] Hydroxypropyl methacrylate: 5.1g

[0085] Dimethylolpropionic acid (DMPA): 7.2g

[0086] Triethylamine (TEA): 4.6g

[0087] 1,6-Butanediol: 3.2g

[0088] Ethylenediamine (EDA): 4.5g

[0089] Methyl methacrylate (MMA): 16.0g

[0090] Butyl acrylate: 7.0g

[0091] Acrylonitrile: 9.0g

[0092] Azobisisobutyronitrile (AIBN): 0.4g

[0093] Deionized water: 250g

[0094] Active group-containing ethylenic monomer hydroxypropyl methacrylate and excess isophorone dicyanate (IPDI) monomer, the molar ratio of the two is 1:6, adding a small amount of inhibitor hydroquinone , the temperature was controlled at 25°C, and the heat preservation rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com