Surfactant Additives for Stimulating Subterranean Formation During Fracturing Operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

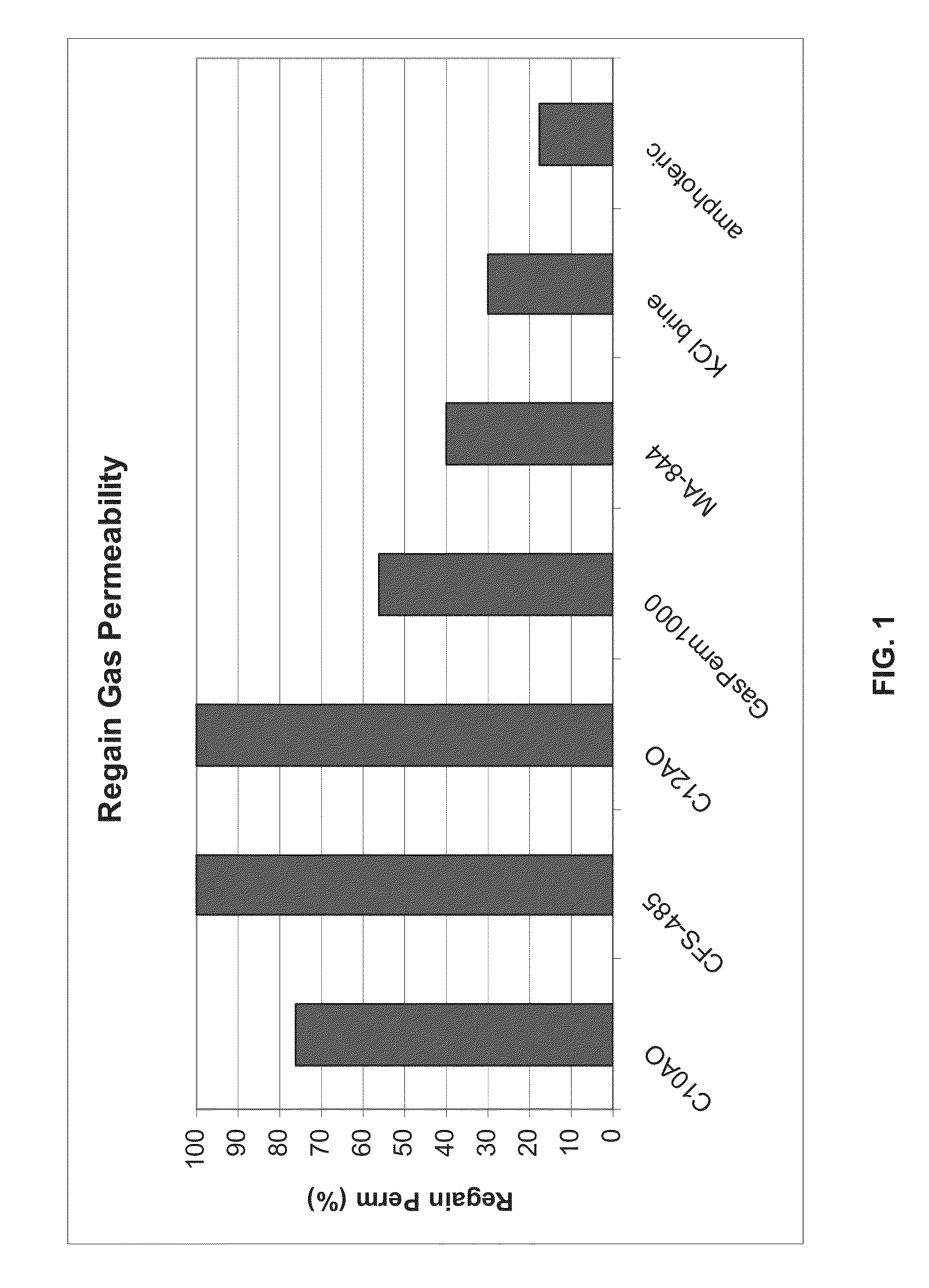

[0040]Regain permeability tests were performed for various surfactants using a 150 μD Crab Orchard Sandstone core to simulate a tight gas formation. Table 1 summarizes the composition of the surfactants including decyl amine oxide (C10AO), cocoamidopropyl betaine (CFS-485), dodecyl amine oxide (C12AO), microemulsion surfactant / solvent additive (commercially available as GASPERM 1000™ from Halliburton Energy Services, Inc.), microemulsion additive (commercially available as MA-844 from CESI Chemical), KCl brine, and amphoteric surfactant. Some of the samples also include a cosurfactant (pyrrolidin commercially available as SURFADONE® from ISP Performance Chemicals or butanol). The tests were performed according to the following description.

TABLE 1RegainPerme-SurfactantCosurfactantRatioability (%)decyl amine oxide (C10AO)pyrrolidin ring1:276(Surfadone ®)cocoamidopropyl betaine (CFS-485)butanol1:5100dodecyl amine oxide (C12AO)butanol1:4100microemulsion surfactant / solvent56additive (Gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com