Patents

Literature

158 results about "Fracture face" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for deliberate fluid removal by capillary imbibition

InactiveUS6283212B1Increase the lengthRateFluid removalDrilling compositionCapillary pressureWell stimulation

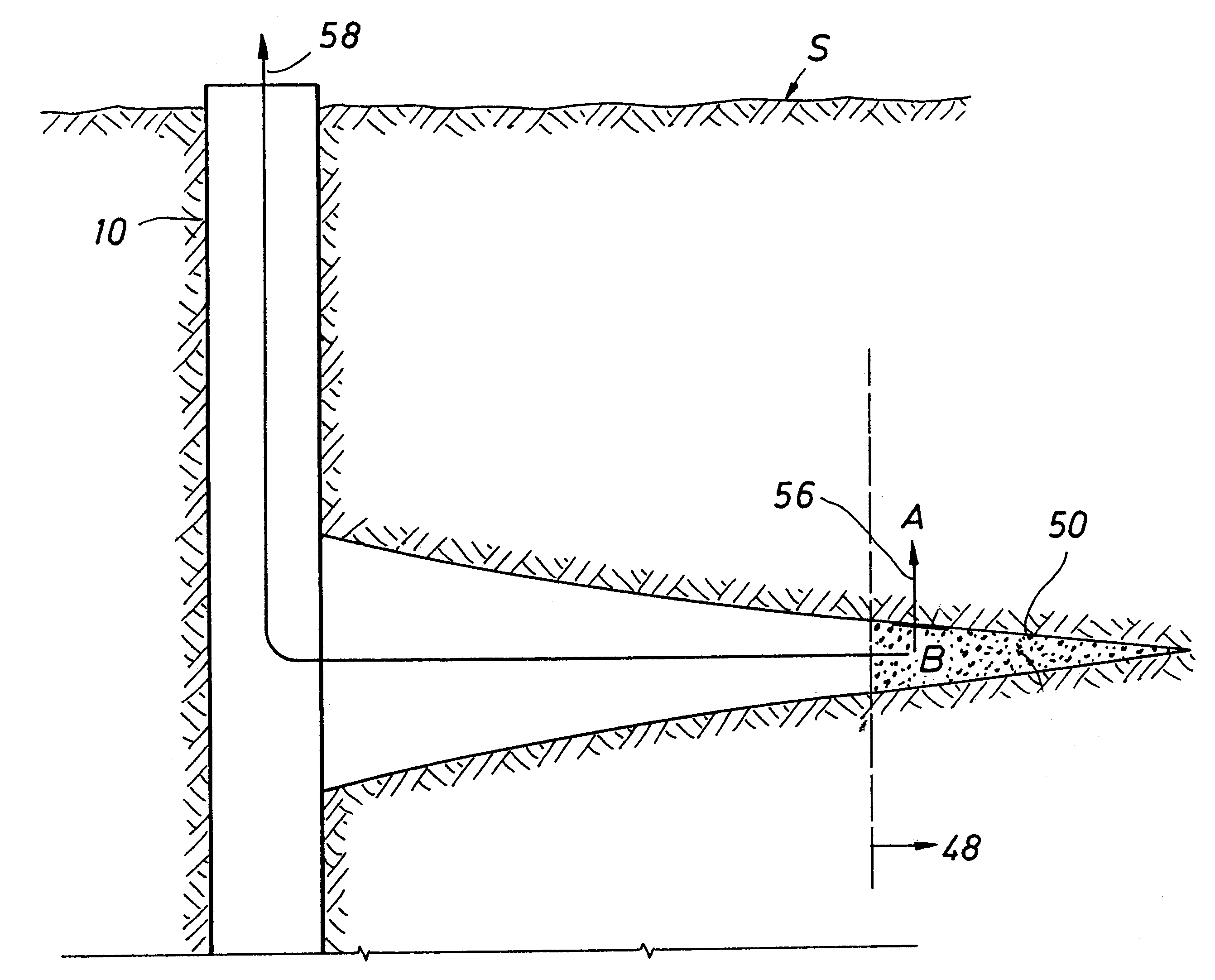

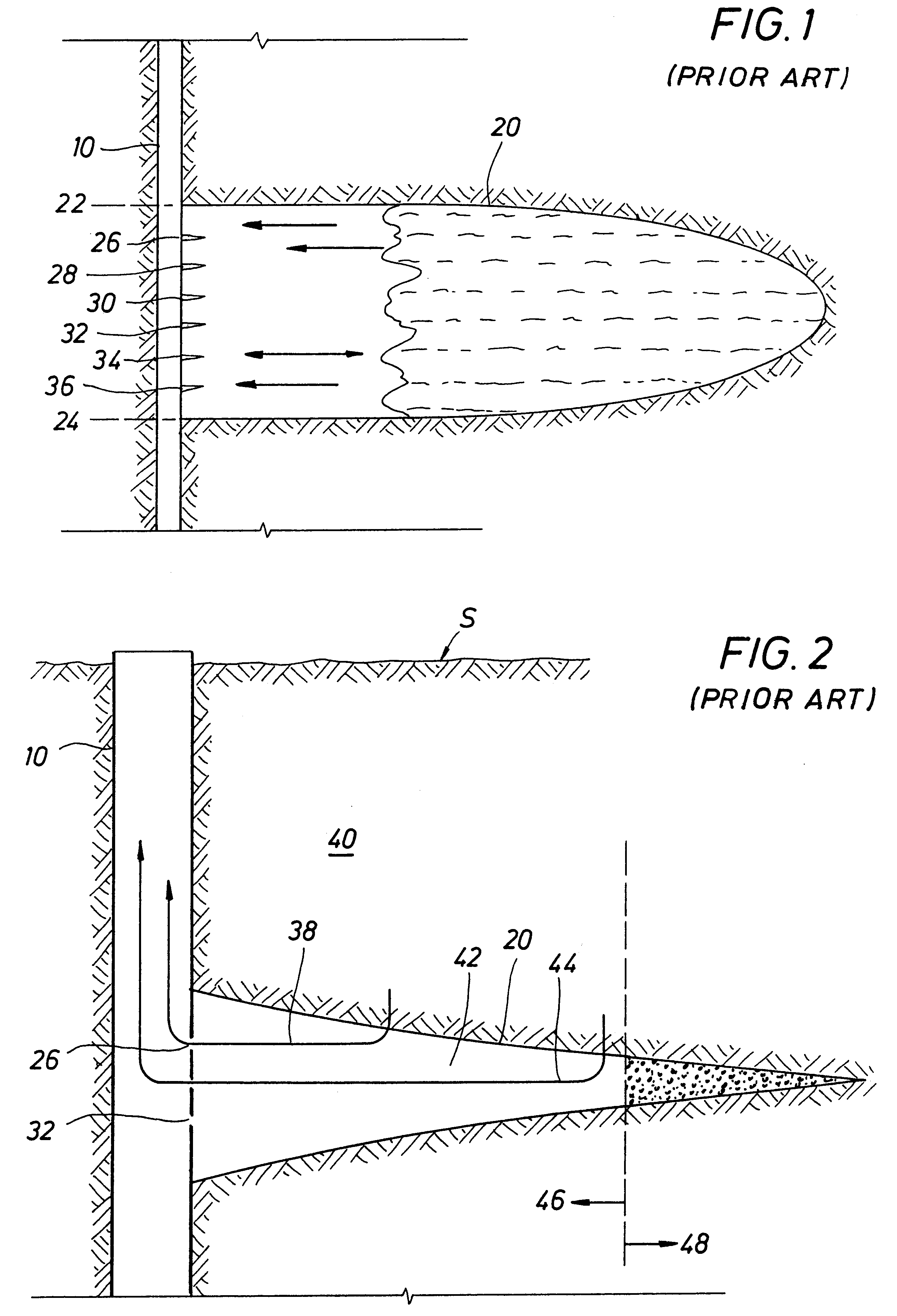

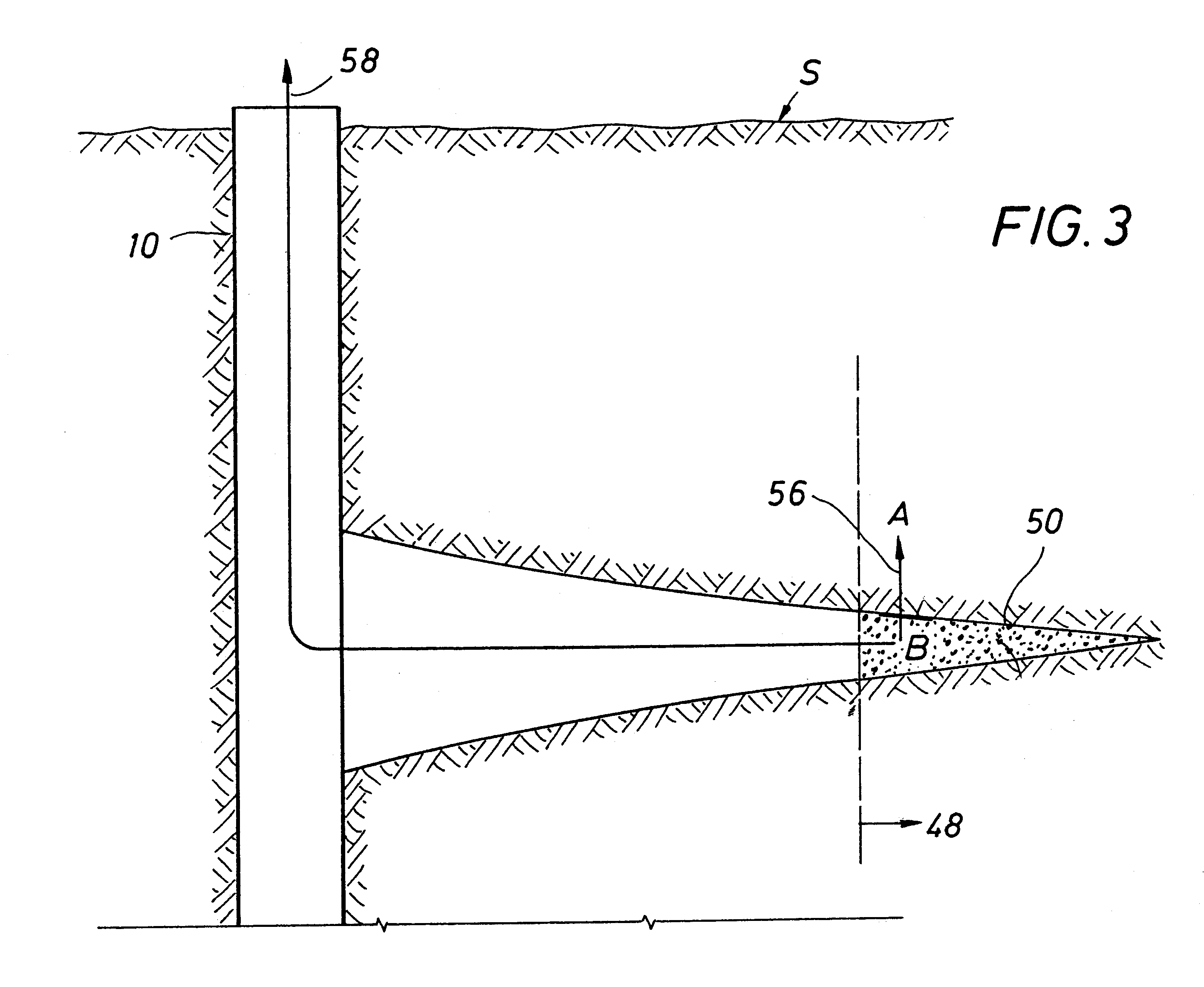

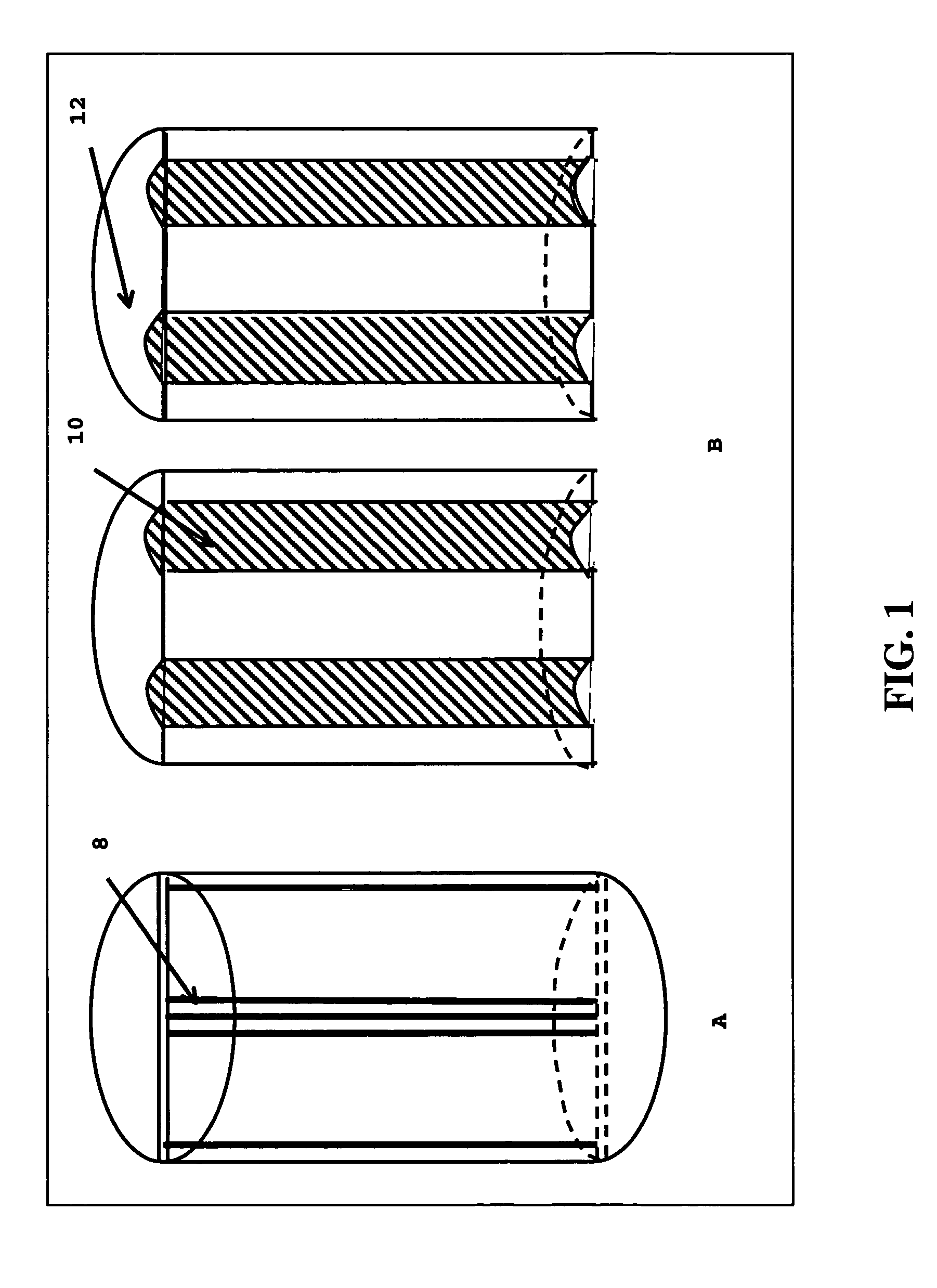

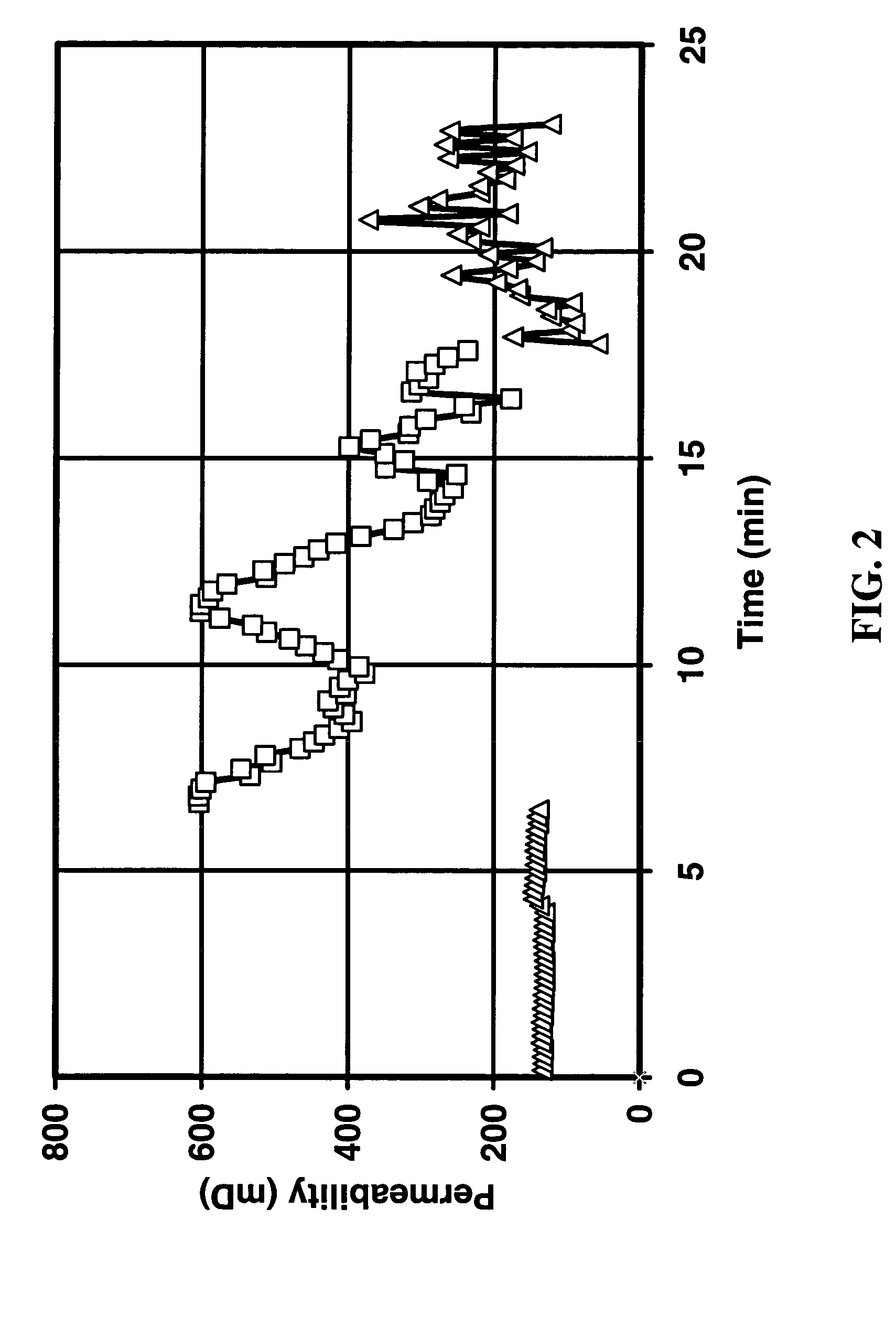

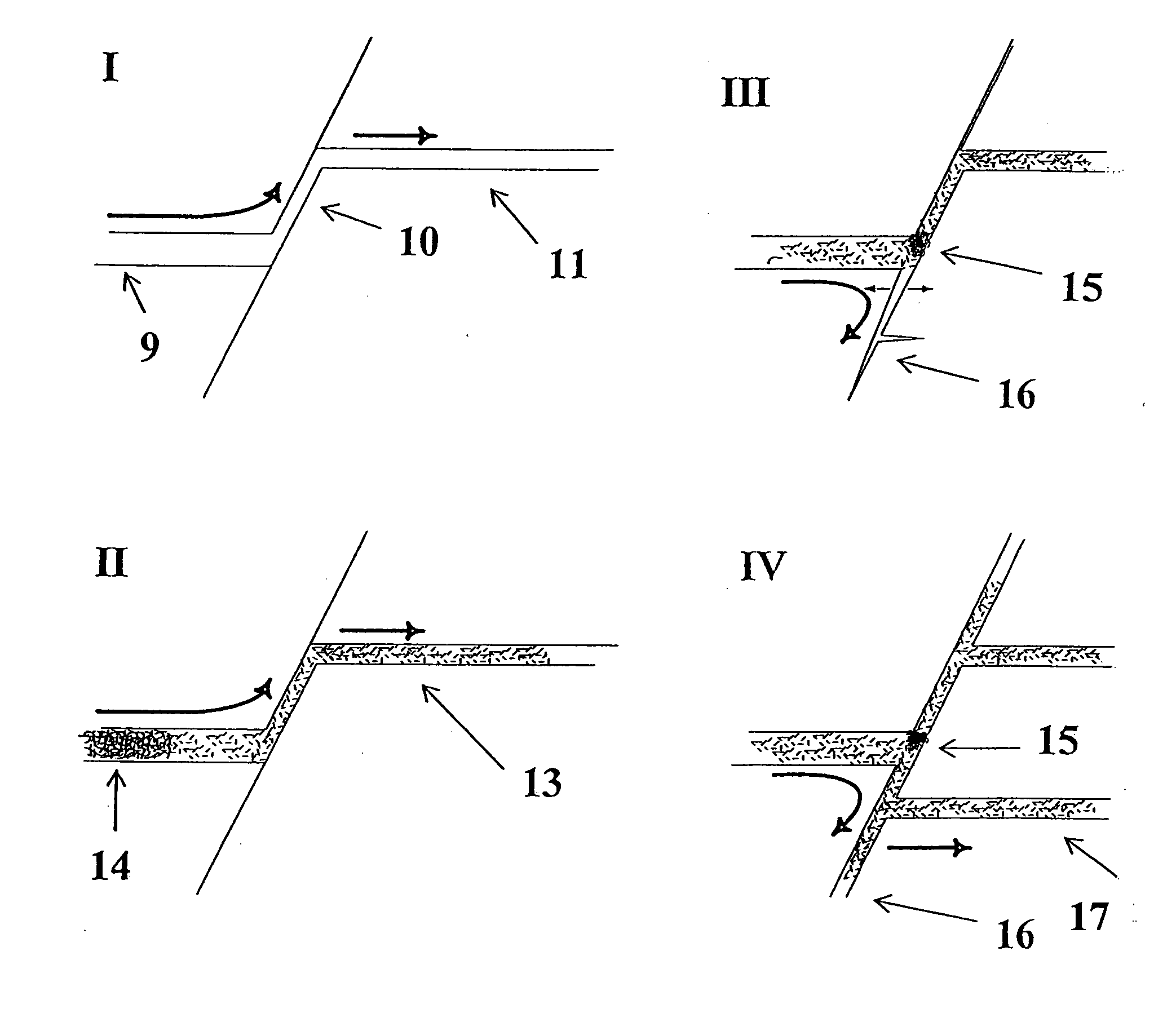

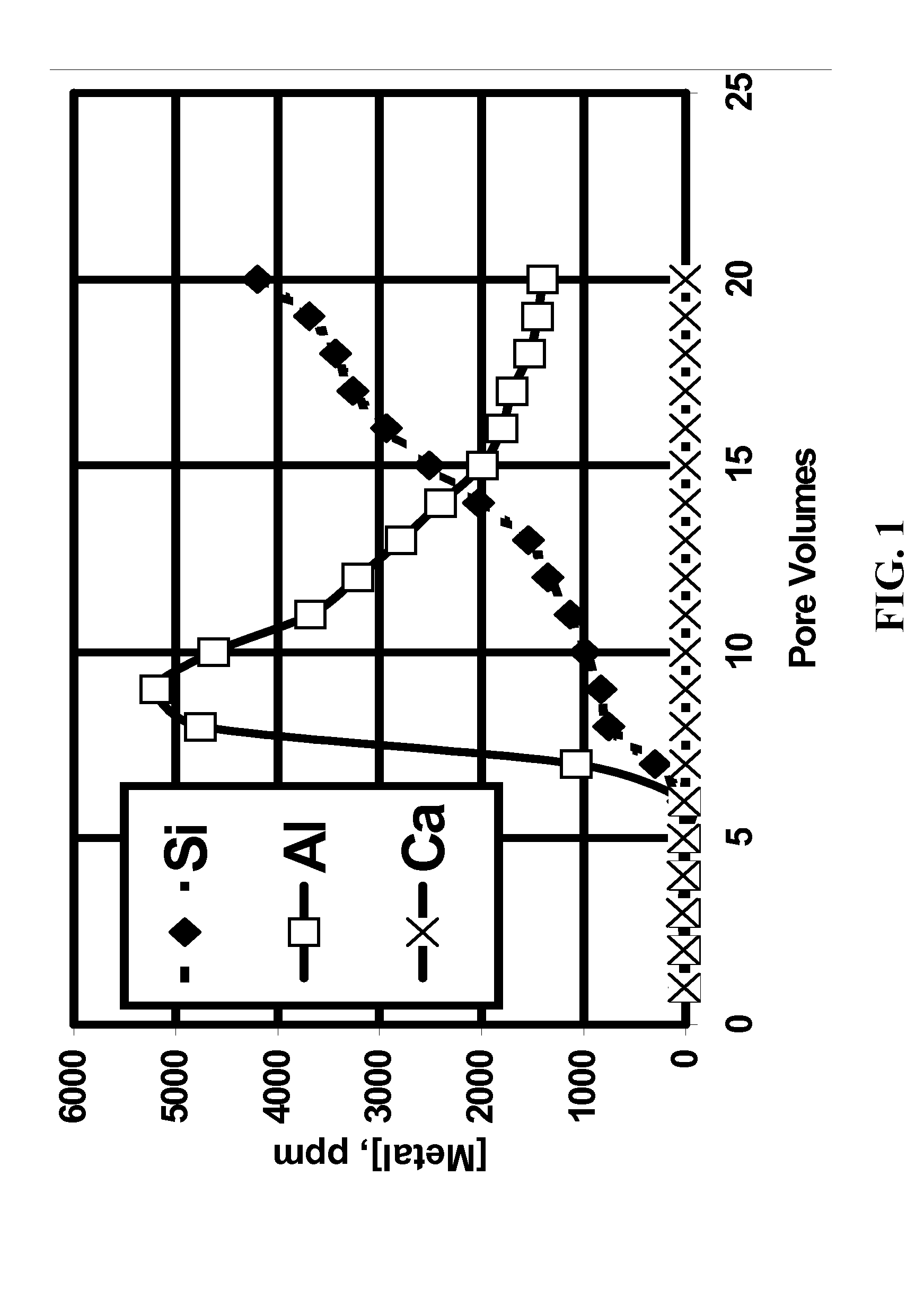

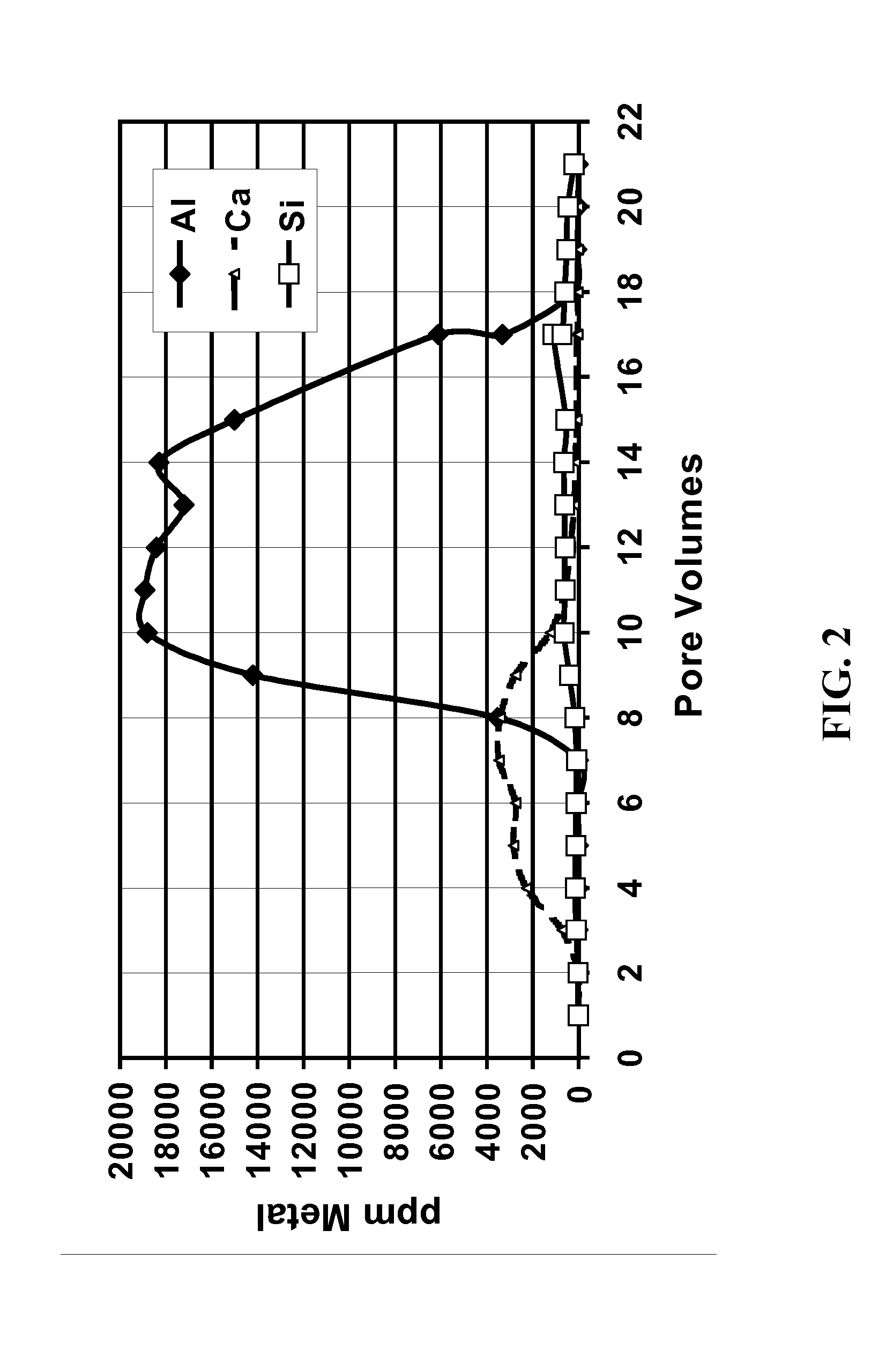

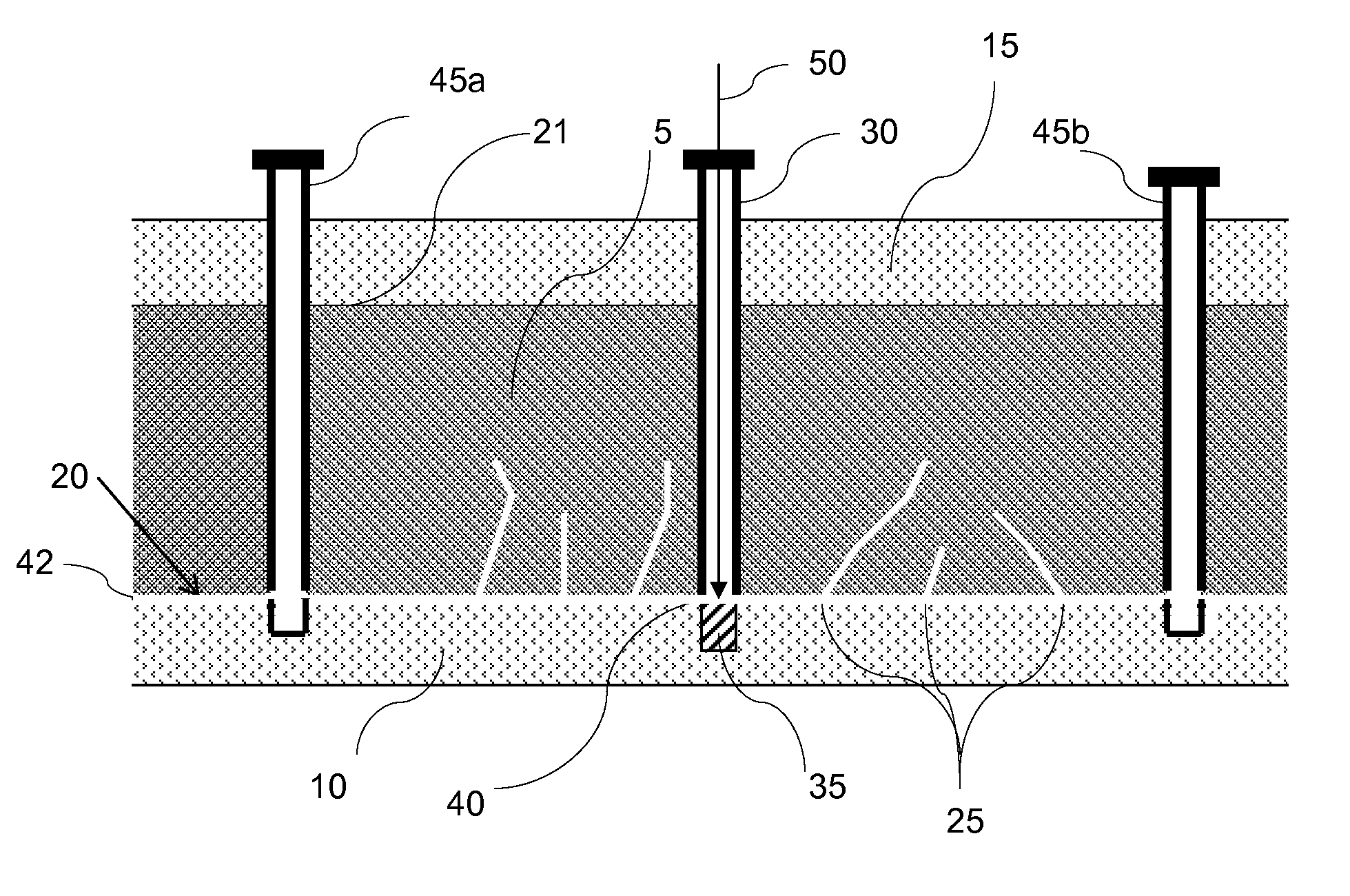

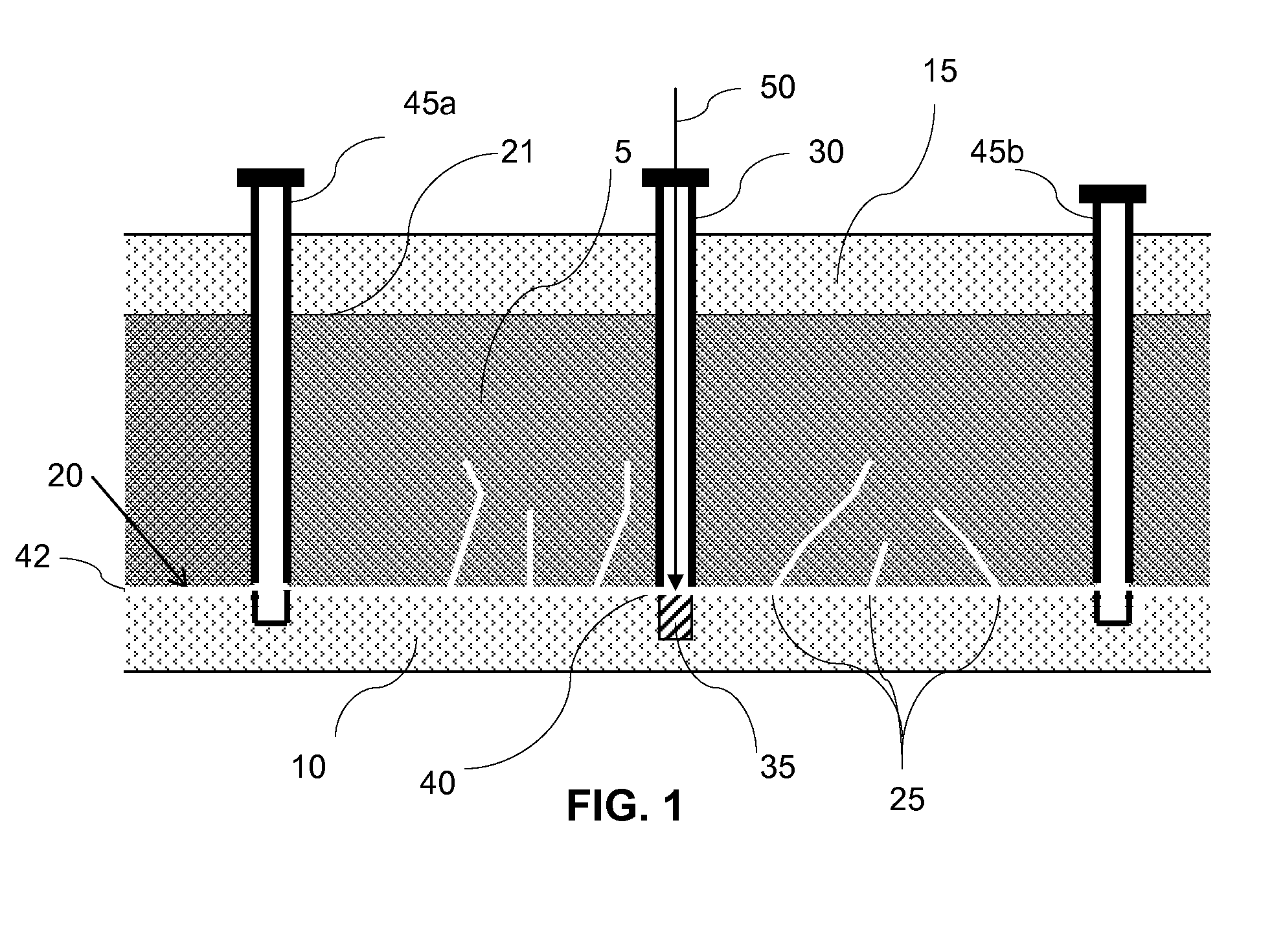

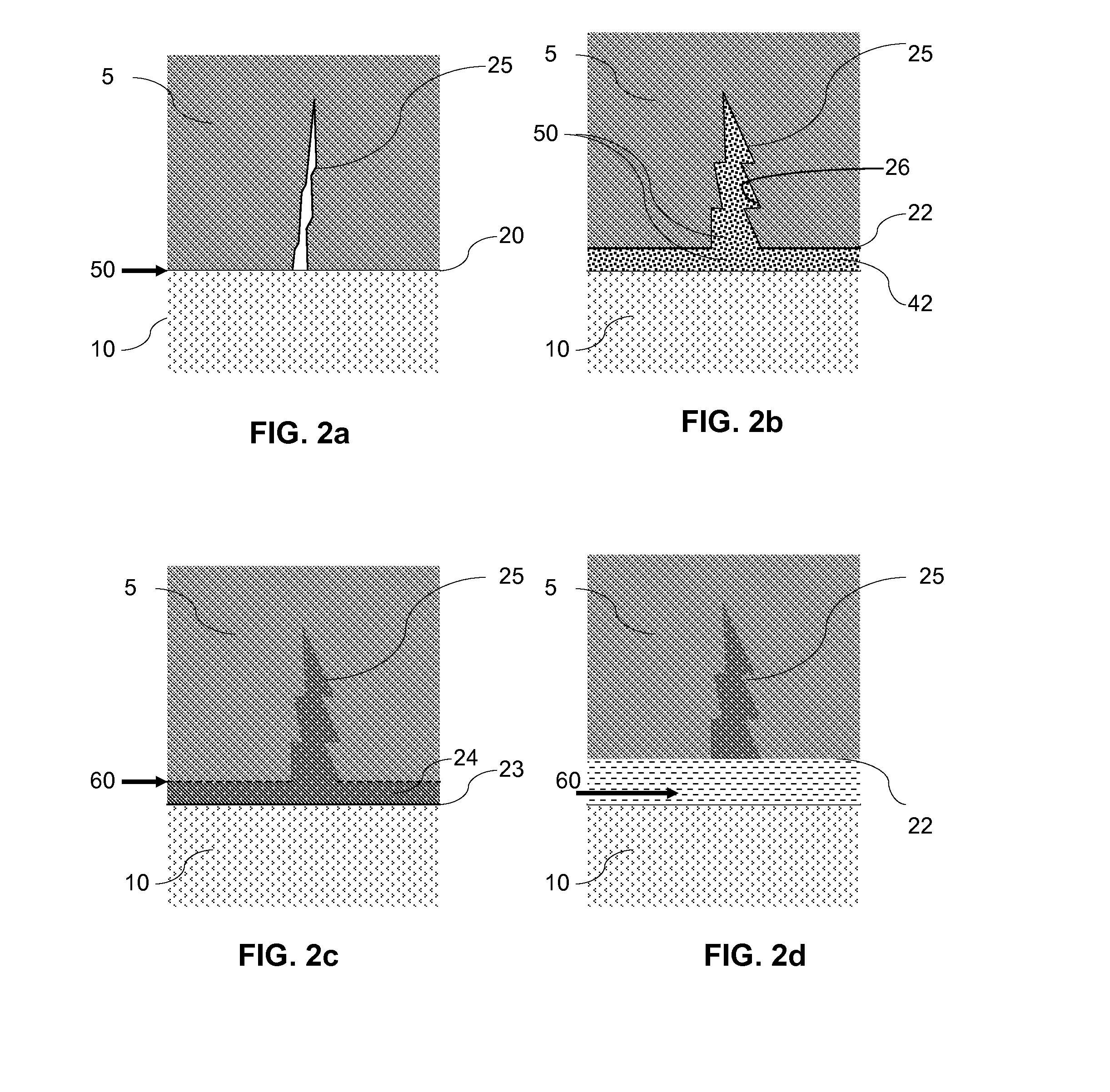

The present Invention relates to hydrocarbon well stimulation, and more particularly to methods and compositions to remove (or more generally to transfer) fluid introduced into the subsurface. For instance, preferred methods involve creating then exploiting a capillary pressure gradient at the fracture face to induce fluid flow from the fracture into the formation thereby increasing effective fracture length, and then improving fracture conductivity.

Owner:SCHLUMBERGER TECH CORP

Selective fracture face dissolution

A method is given for acid fracturing a subterranean formation for improving the flow of fluids. The principal source, optionally the sole source, of the acid is a solid acid-precursor, optionally injected with an additional solid that is inert and that masks a portion of the newly created fracture faces so that the fracture face etching by the acid is not uniform. The method ensures a good flow path for fluids between the fracture tip and the wellbore.

Owner:SCHLUMBERGER TECH CORP

Methods and compositions for stabilizing the surface of a subterranean formation

The present invention relates to stabilizing surfaces within a subterranean formation using particulates coated with a consolidating liquid. One embodiment of the present invention provides a method of fracturing a subterranean formation, comprising providing a fracturing fluid comprising proppant particulates at least partially coated with a hardenable resin composition that comprises a hardenable resin component and a hardening agent component, wherein the hardenable resin component comprises a hardenable resin and wherein the hardening agent component comprises a hardening agent, a silane coupling agent, and a surfactant; introducing the fracturing fluid into at least one fracture within the subterranean formation; depositing at least a portion of the proppant particulates in the fracture; allowing at least a portion of the proppant particulates in the fracture to form a proppant pack; and, allowing at least a portion of the hardenable resin composition to migrate from the proppant particulates to a fracture face.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and compositions for stabilizing the surface of a subterranean formation

Methods comprising providing a fracturing fluid comprising proppant particulates at least partially coated with a hardenable resin composition that comprises a hardenable resin component and a hardening agent component, wherein the hardenable resin component comprises a hardenable resin and wherein the hardening agent component comprises a hardening agent, a silane coupling agent, and a surfactant; introducing the fracturing fluid into at least one fracture within the subterranean formation; depositing at least a portion of the proppant particulates in the fracture; allowing at least a portion of the proppant particulates in the fracture to form a proppant pack; and, allowing at least a portion of the hardenable resin composition to migrate from the proppant particulates to a fracture face.

Owner:HALLIBURTON ENERGY SERVICES INC

Differential etching in acid fracturing

A method for fracturing a subterranean formation is provided in which inert masking material particles are injected into the formation with a dissolution agent so that the masking material inhibits dissolution where it contacts a portion of one or both fracture faces. The undissolved regions provide support to keep the fracture open after the treatment and the dissolved regions provide a conductive pathway for flow of fluid to or from the wellbore.

Owner:SCHLUMBERGER TECH CORP

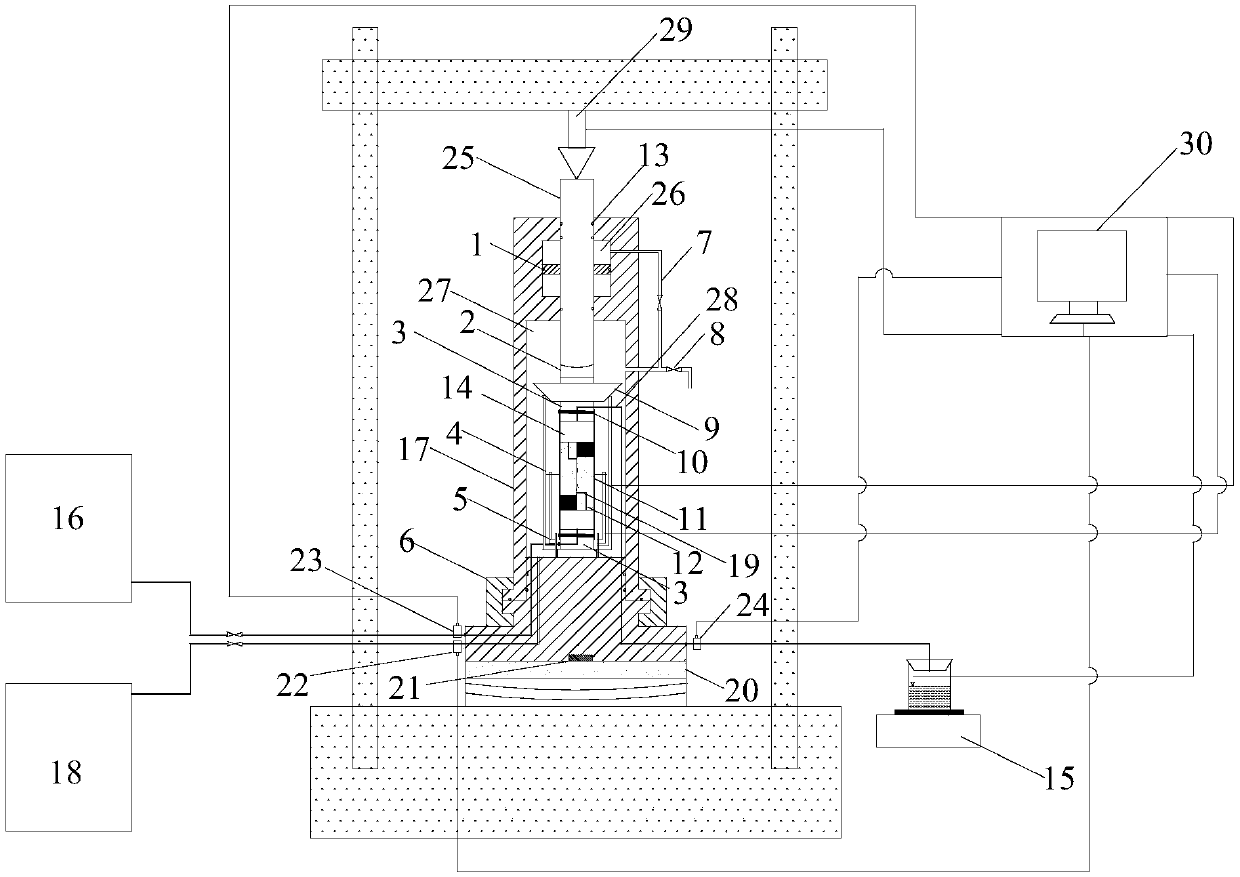

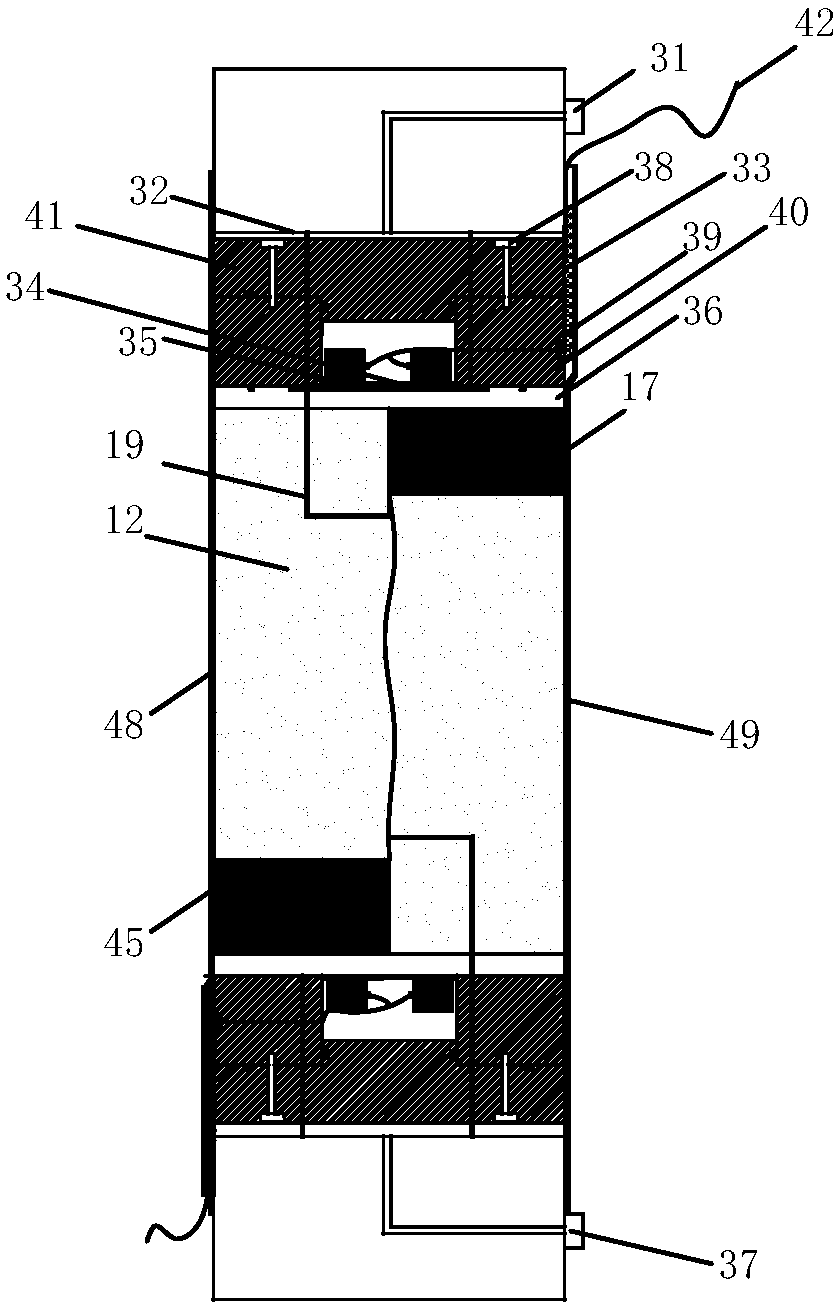

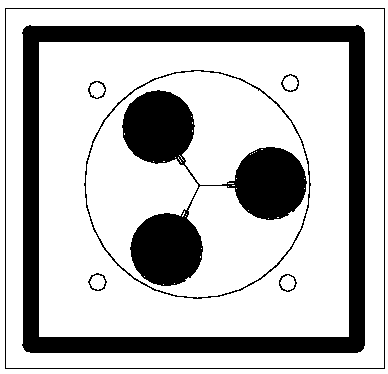

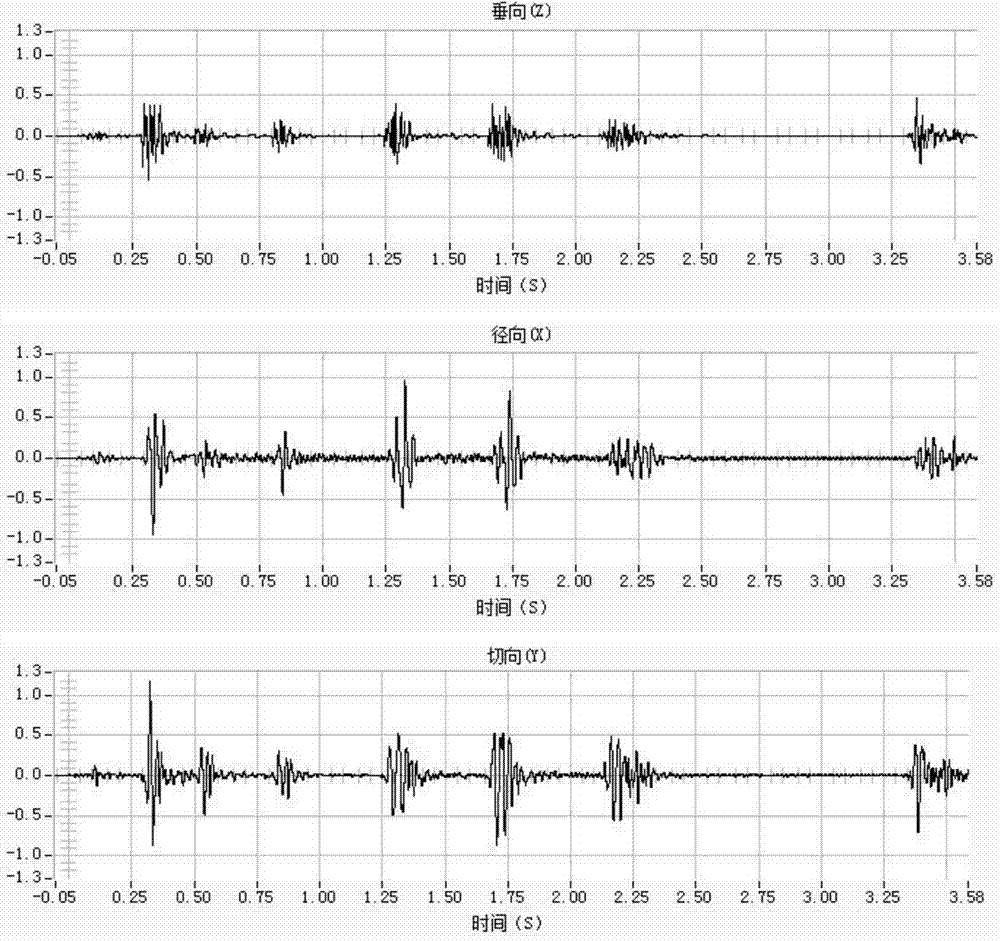

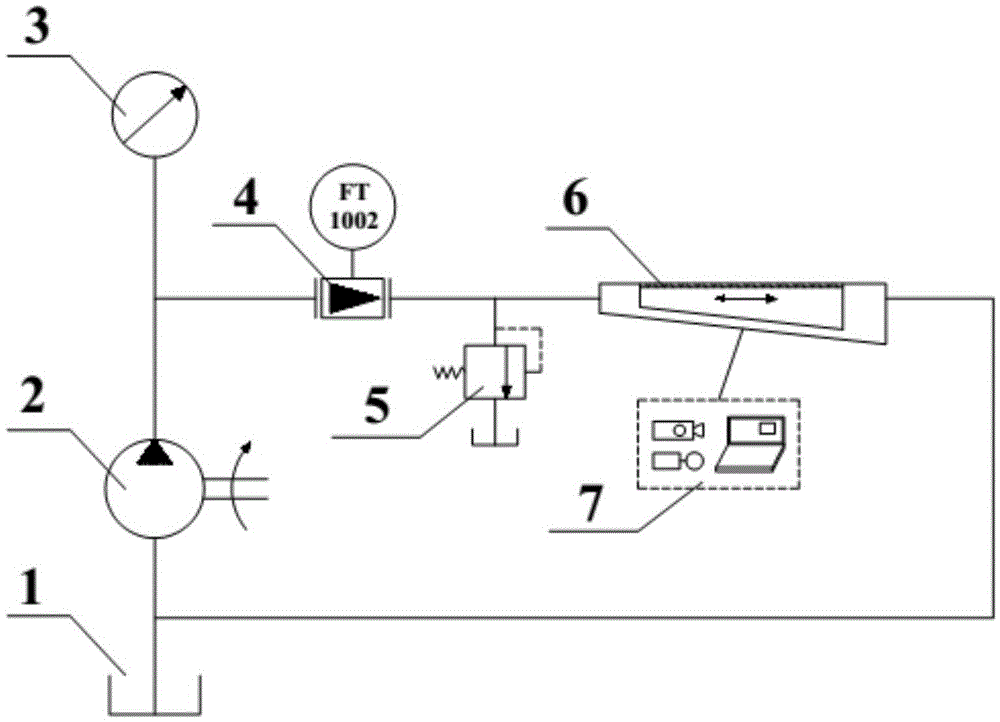

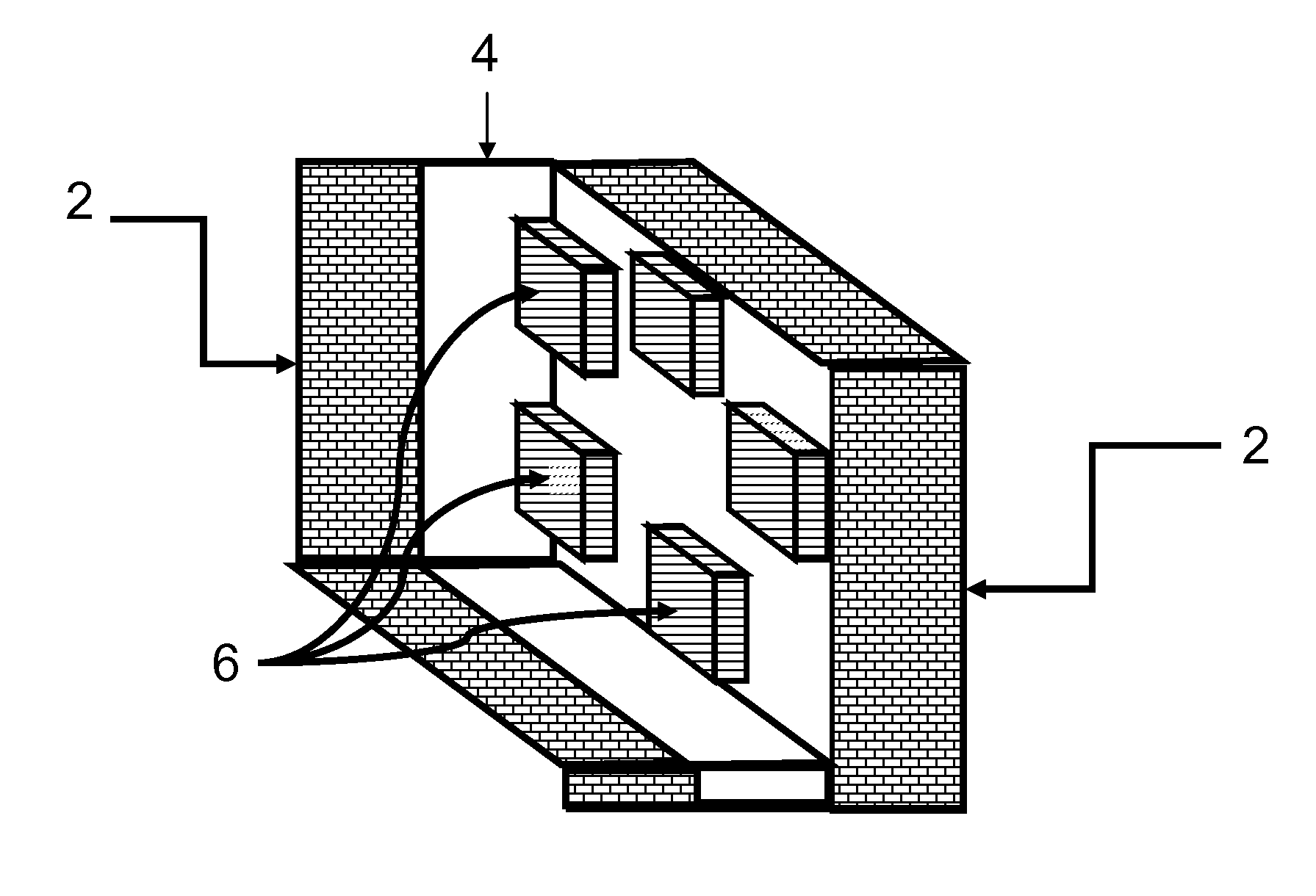

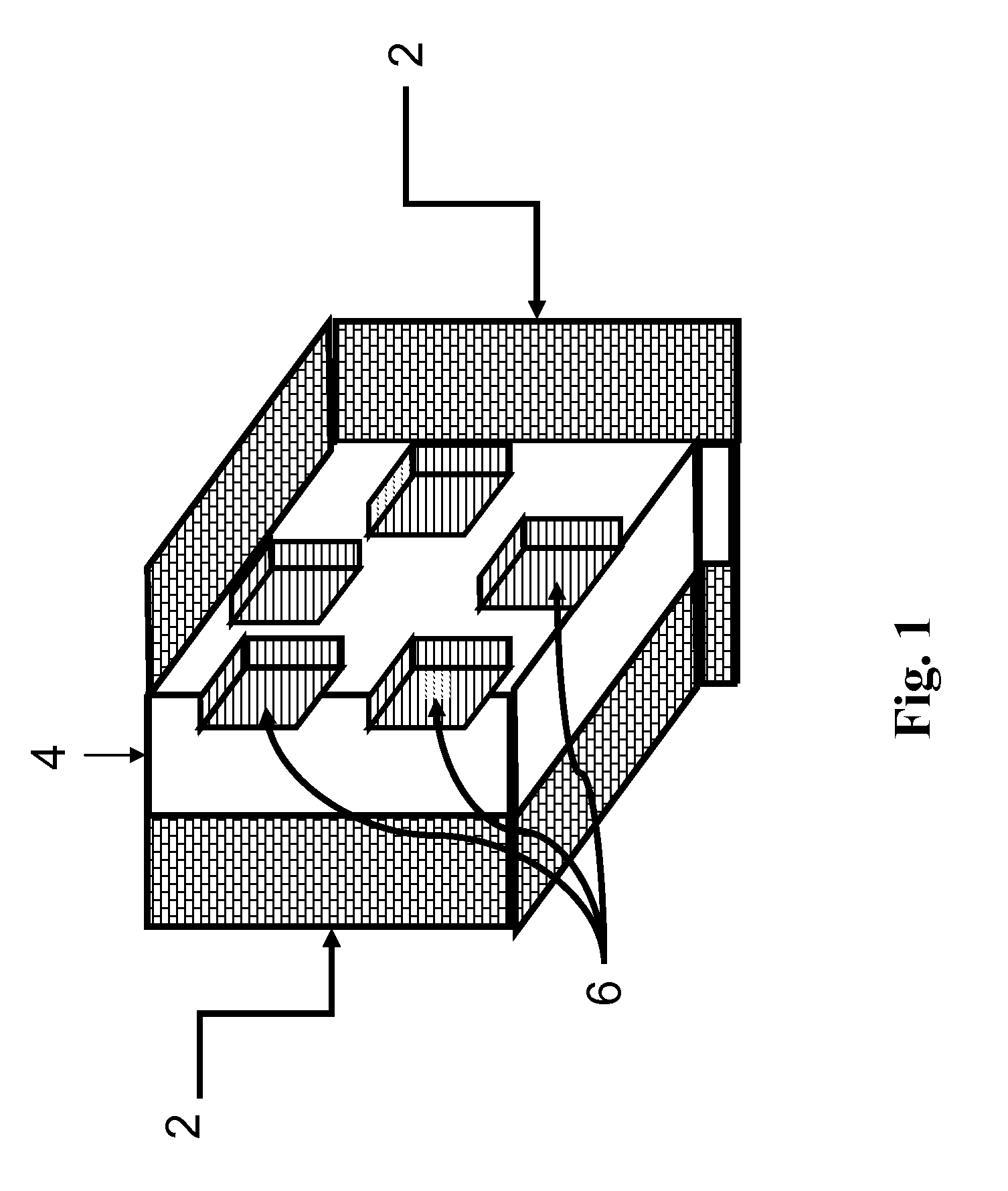

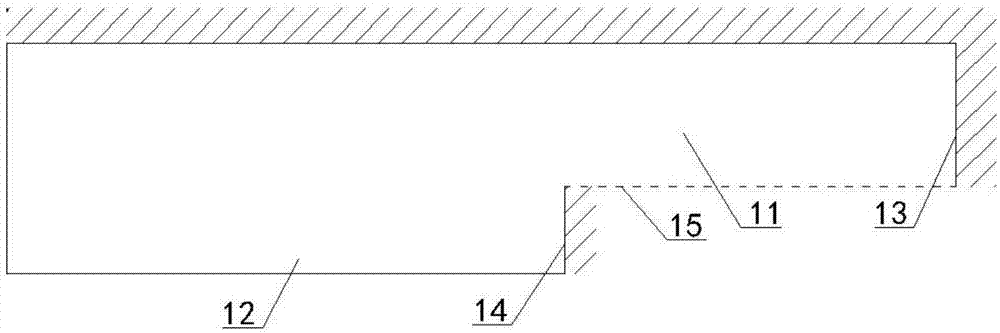

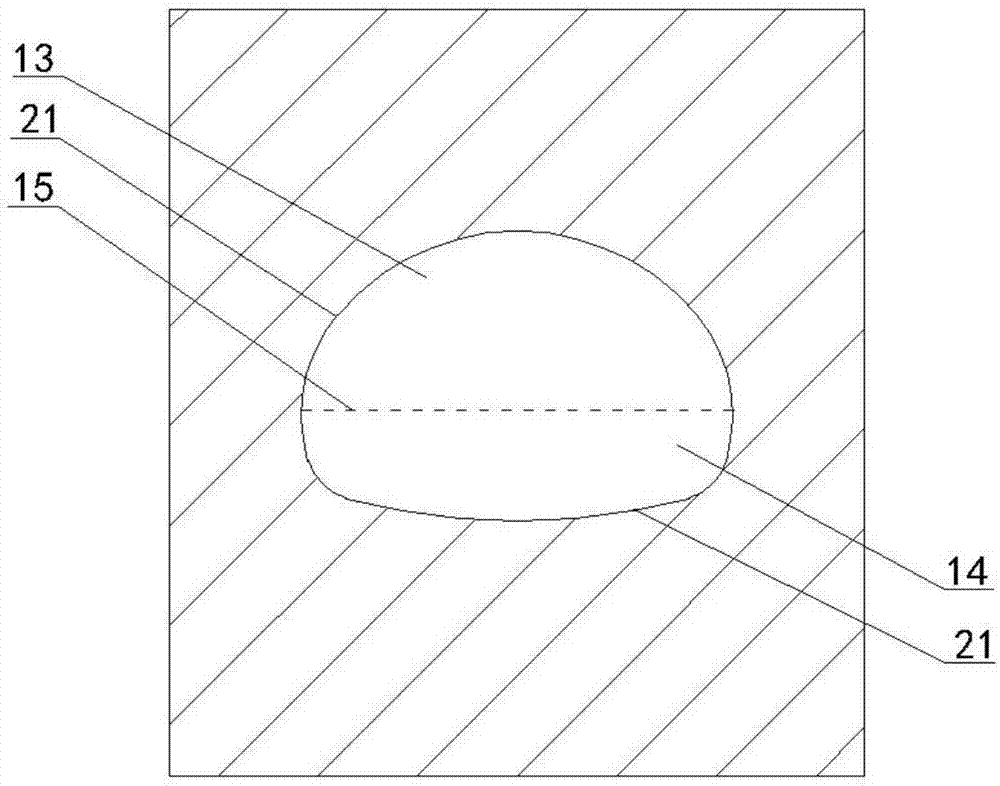

Direct shear-seepage test device and test method for single fracture rock specimen under hydrostatic pressure condition

ActiveCN107782628ARealize integrationAchieving tightnessMaterial strength using tensile/compressive forcesData acquisitionInstability

The invention belongs to the field of rocks and rock mass mechanics and discloses a direct shear-seepage test device and test method for a single fracture rock specimen under a hydrostatic pressure condition. The device is characterized by comprising a loading system, an acoustic emission monitoring system, a seal system, a data acquisition system and a rock specimen pre-treatment system. By the direct shear-seepage test device and the test method, hydrostatic pressure packaging and direct shear-seepage testing of the single fracture rock specimen under high shear displacement and high seepagepressure conditions can be realized, friction fracture changes of a fracture face in a shearing process can be monitored in real time through the acoustic emission monitoring system, fracture face changes of the single fracture rock specimen before and after direct shear-seepage testing can be analyzed through a fracture face data processing system, deeply analyzing a direct shear-seepage mechanism and exploring main factors having effects on direct shear-seepage characteristics of single fracture rock can be realized, and a theoretical foundation and a test basis are provided for a shear-seepage instability mechanism of mining-induced fracture rock under the action of underground water.

Owner:TAIYUAN UNIV OF TECH

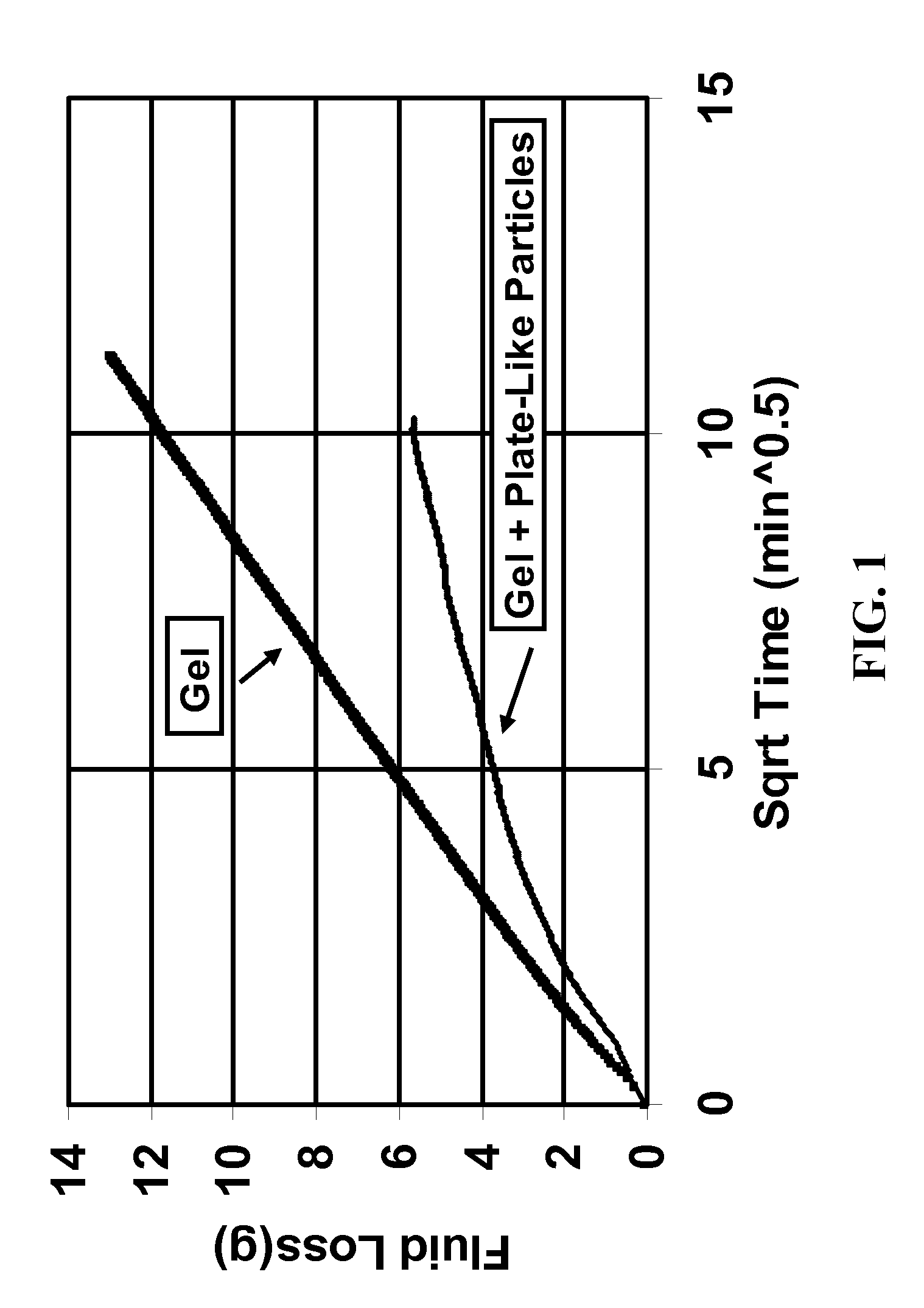

Hydraulic Fracturing Proppants

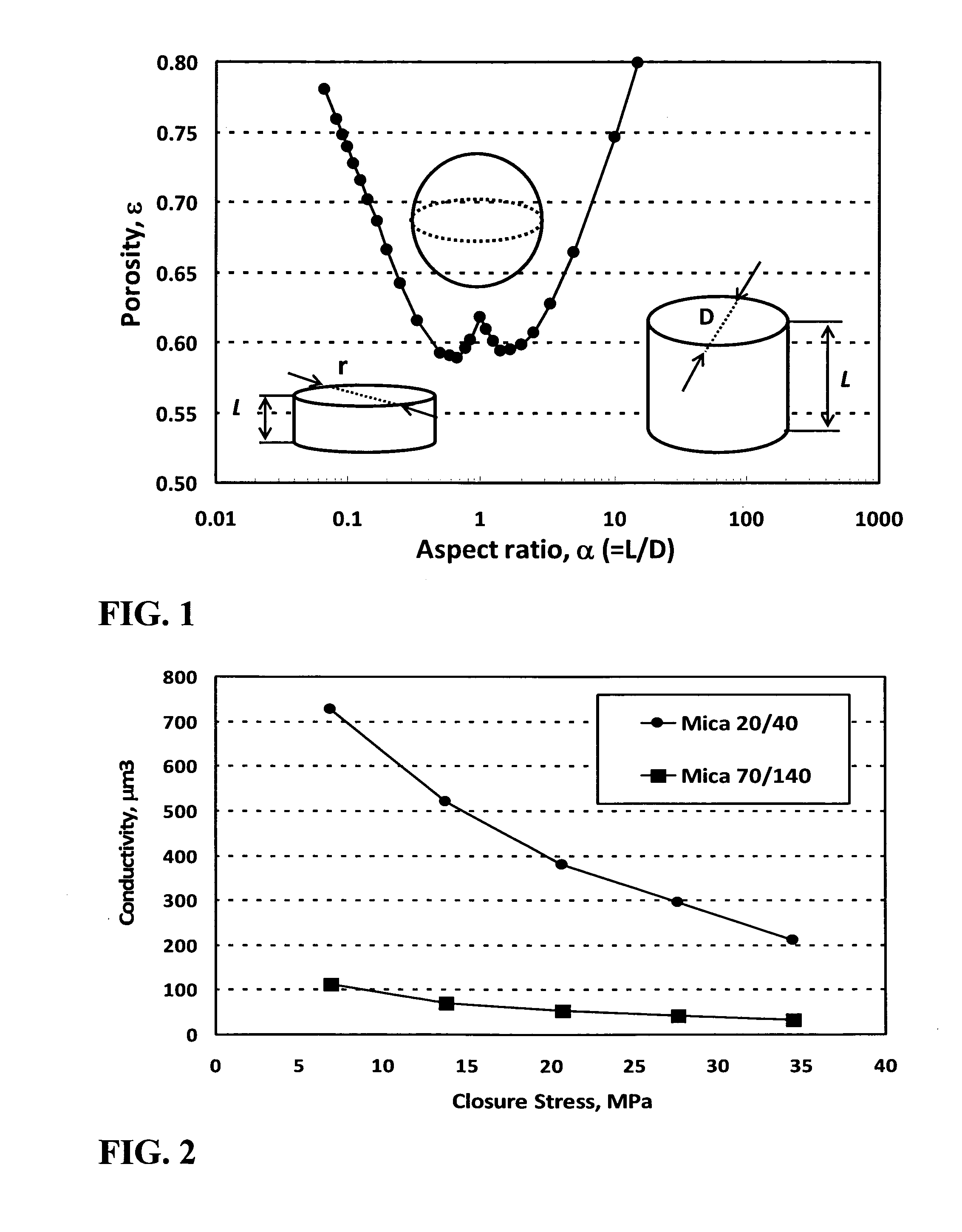

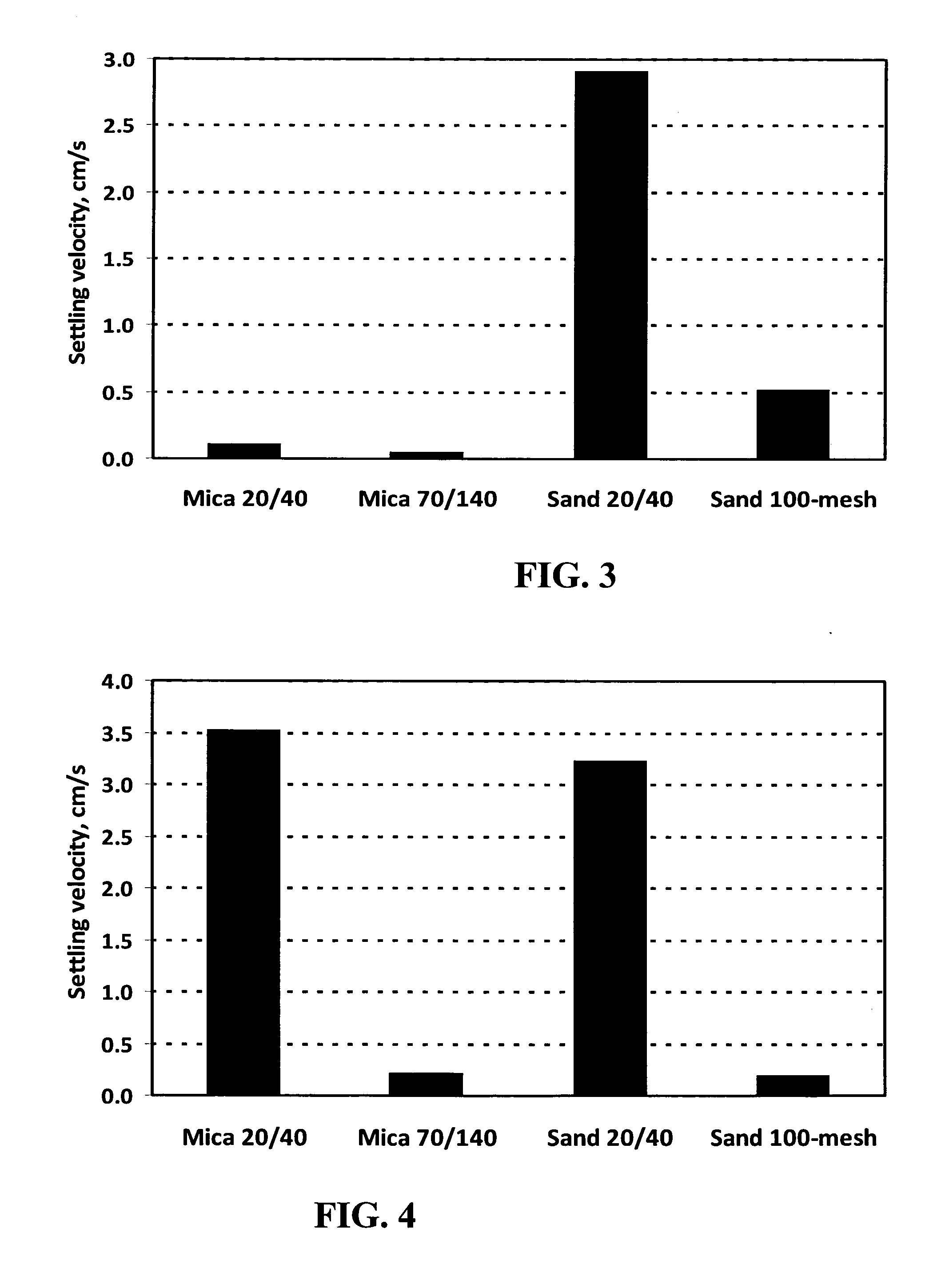

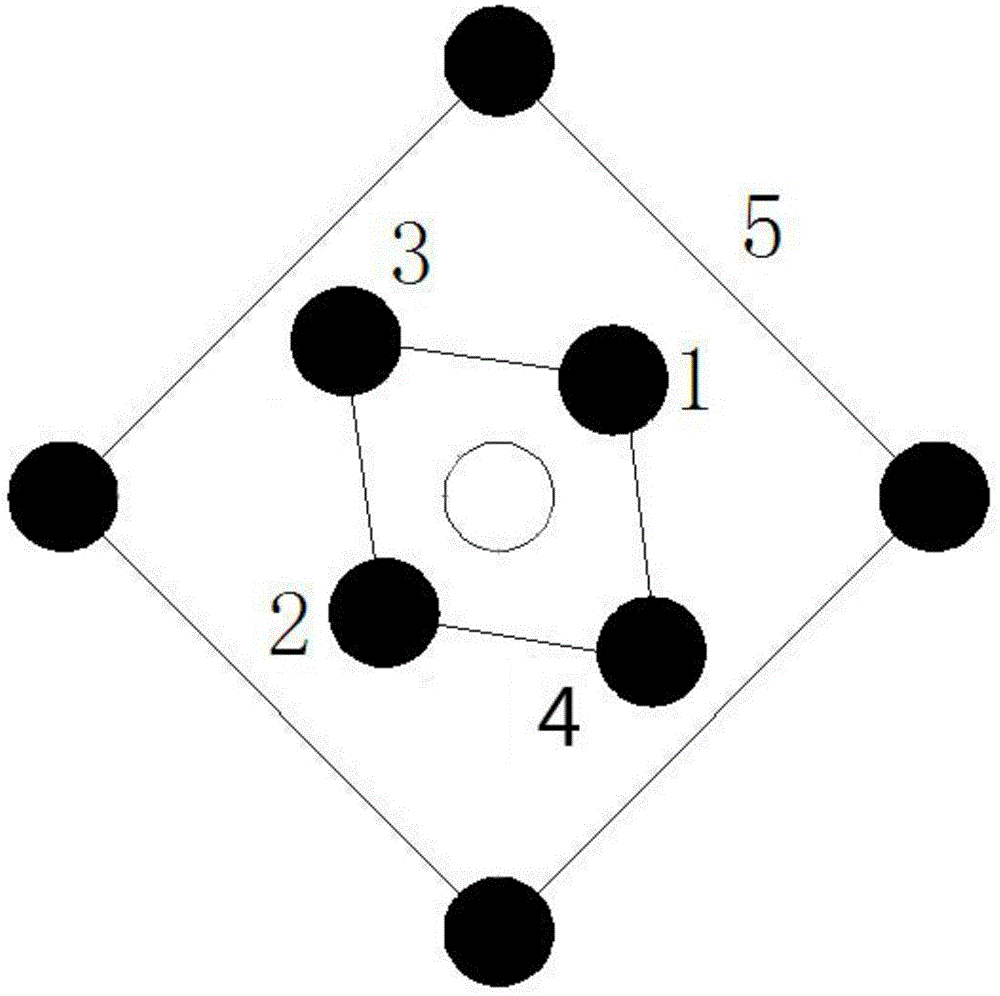

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

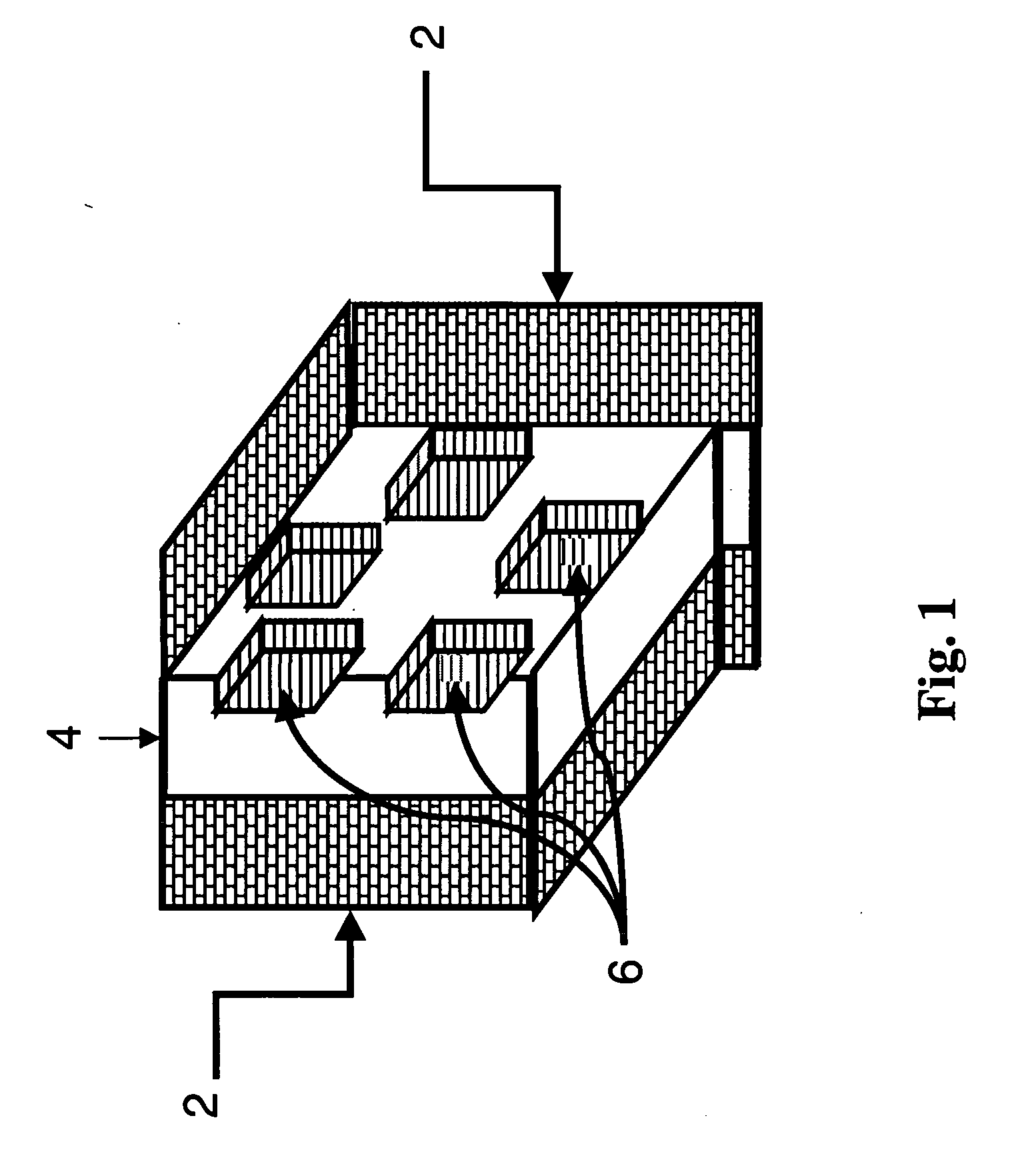

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

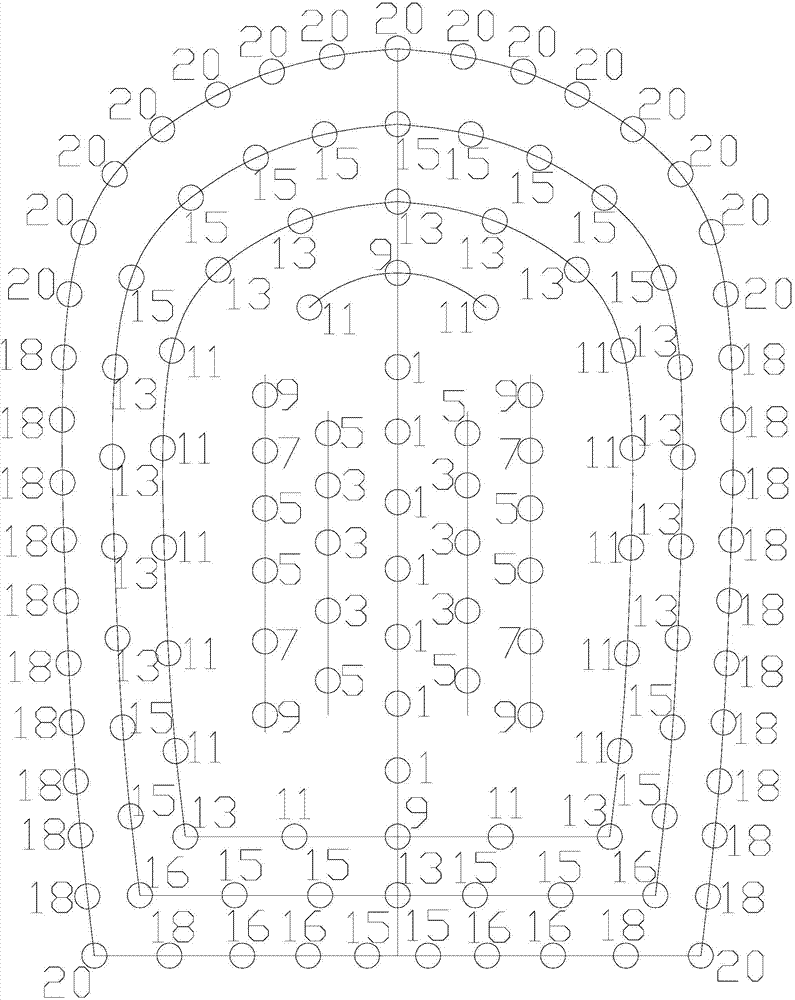

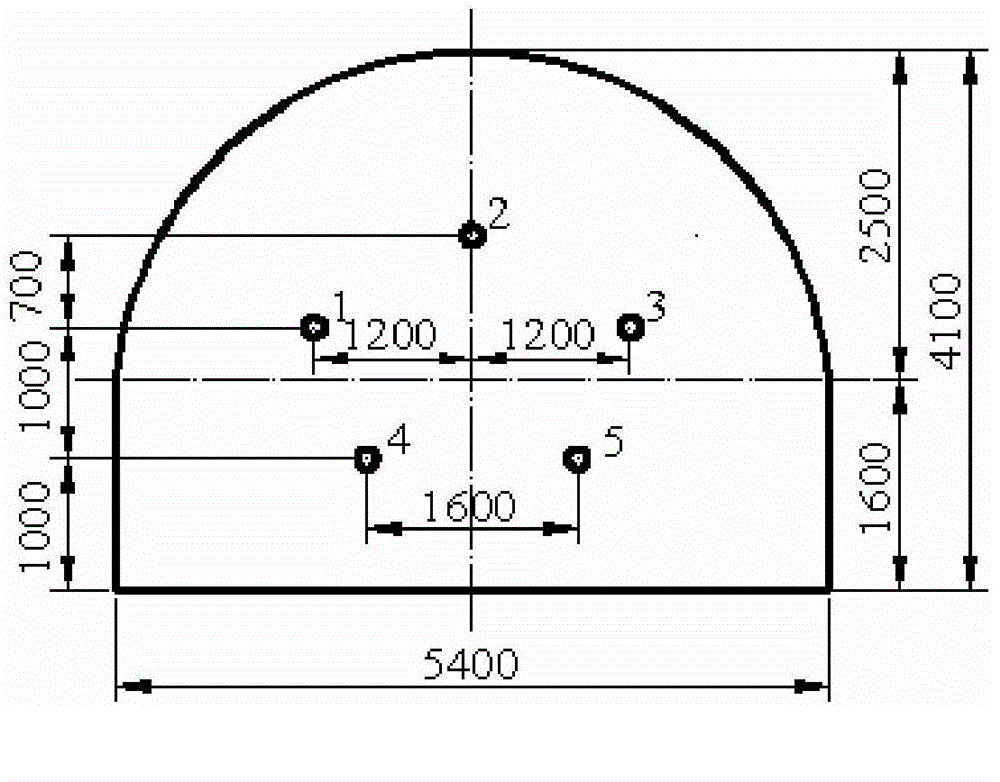

Tunnel smooth blasting method

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

Method for blasting shallow section of modernization railway tunnel

The invention relates to the field of tunnel blasting, in particular to a method for blasting a shallow section of a modernization railway tunnel. The method includes the steps that houses around a blasting position are firstly assessed; arrangement positions of shot holes are then determined, and a full fracture surface is divided into a left blasting area and a right blasting area; charge structures of all the shot holes are determined; time for delay initiation, shot hole charge quantity and explosive kinds are determined; an underholing method, the distance between periphery holes and the least resistance line of the periphery holes are selected according to the characteristics of surrounding rock on site, the various shot holes are machined on the full fracture face according to the data determined in the step two, and explosive is installed according to the data determined in the step three; blasting is performed according to the blasting area partition sequence of cutholes-satellite holes-periphery holes-bottom plate holes, the satellite holes perform layer-by-layer blasting from inside to outside, and same-section millisecond blasting caps are adopted for initiation of the periphery holes. The purpose is to provide the method for blasting the shallow section of the modernization railway tunnel, wherein blasting influence can be reduced stably when the shallow section of the tunnel is blasted.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

Leak-Off Control Agent

A method of controlling leak-off and reducing the concentration of polymers (and / or other materials) in filter cakes formed when oilfield treatment fluids flow through subterranean formation faces involves adding large plate-like degradable and / or non-degradable, particles to polymer or VES-viscosified oilfield treatment fluids, at concentrations of such particles that are less than that required to cover the contacted formation face with a monolayer of such particles. When these large plate-like degradable and / or non-degradable particles are included in the fluid, polymer concentrates to form filter cake only in regions on the formation face (for example fracture faces) not shielded by the large plate-like particles, and the remaining formation face is not covered by concentrated polymer. As a result, the damage due to concentration of polymer and / or other materials in the filter cake during leak-off is reduced, and subsequent clean-up of the filter cake is easier.

Owner:SCHLUMBERGER TECH CORP

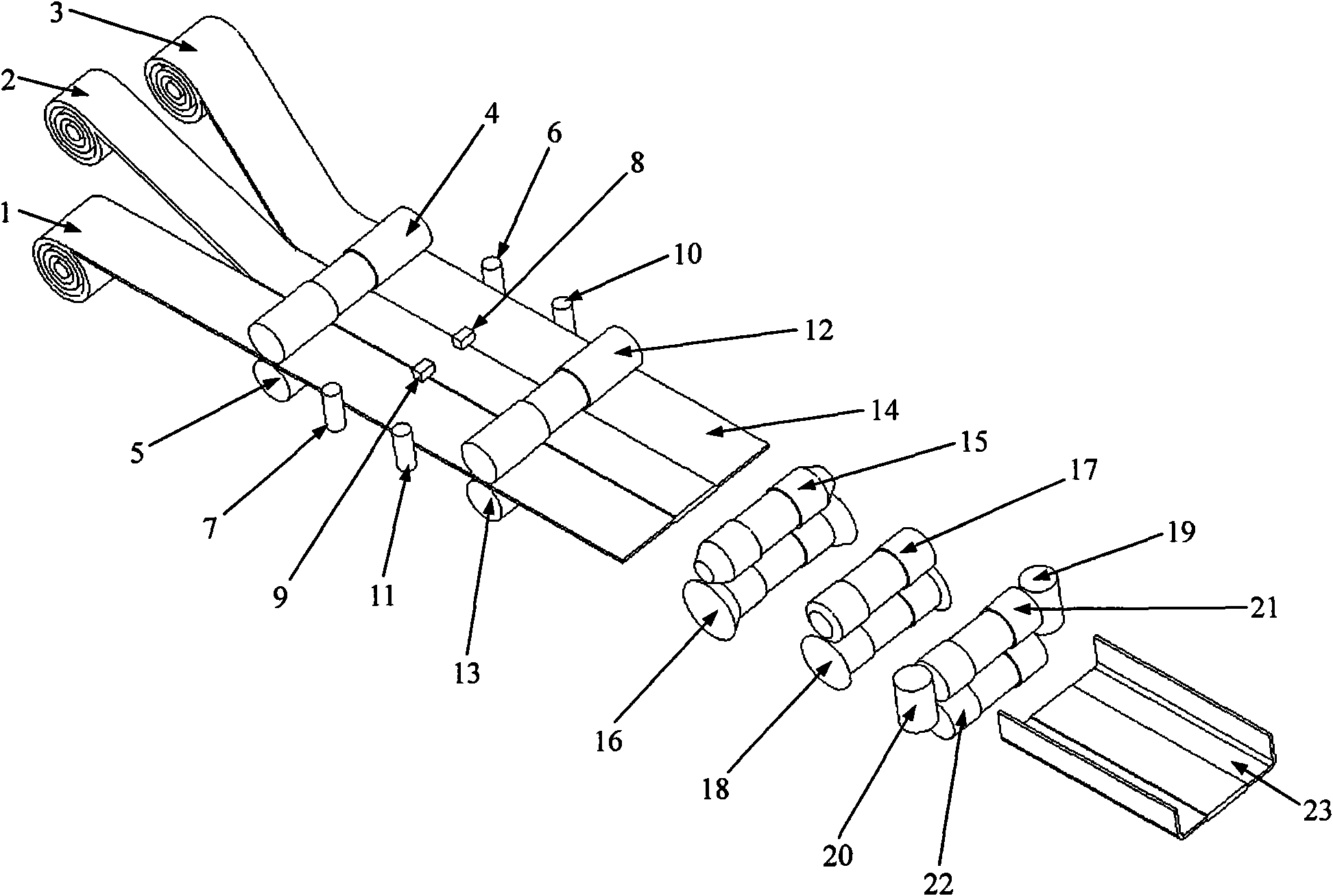

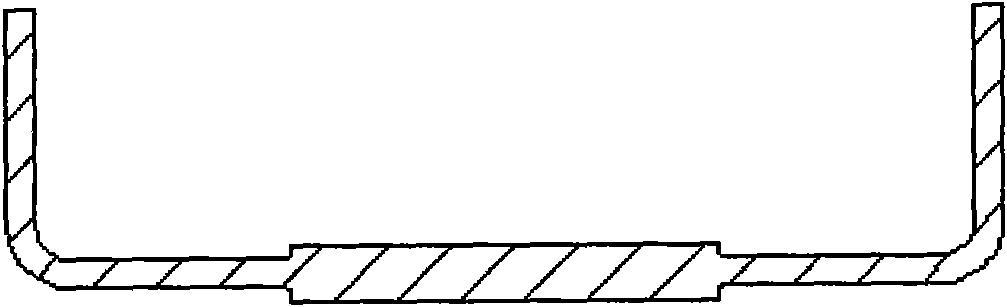

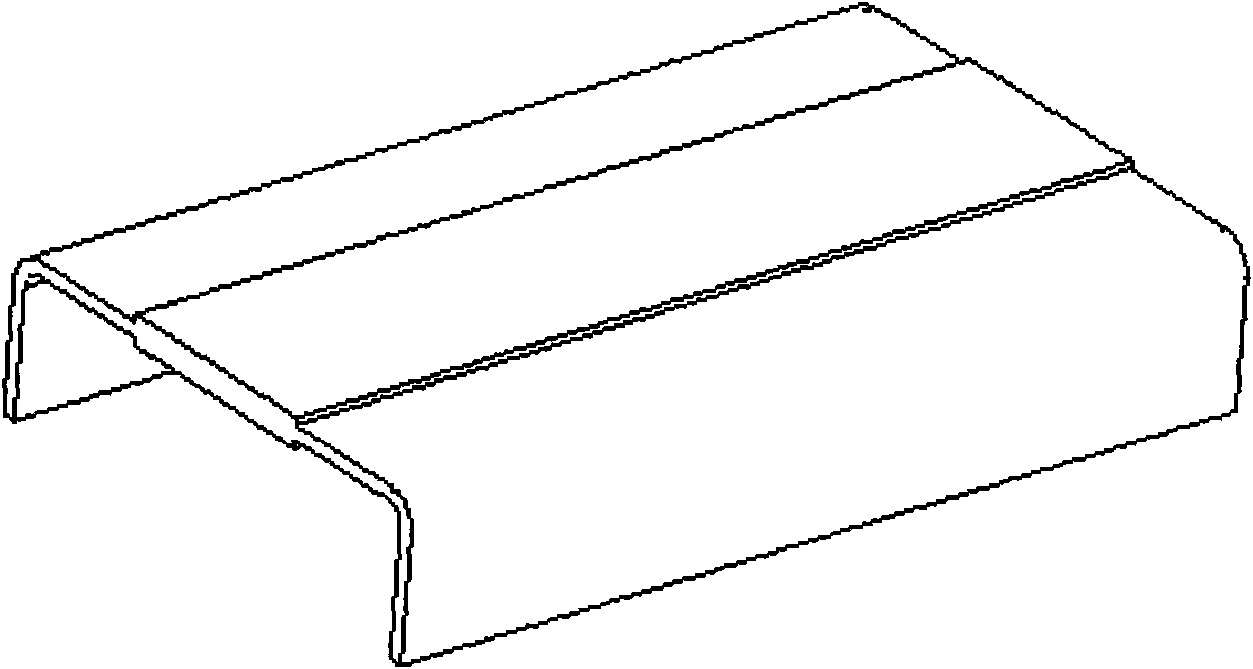

Tailor-welded blank roll bending formation device and method thereof

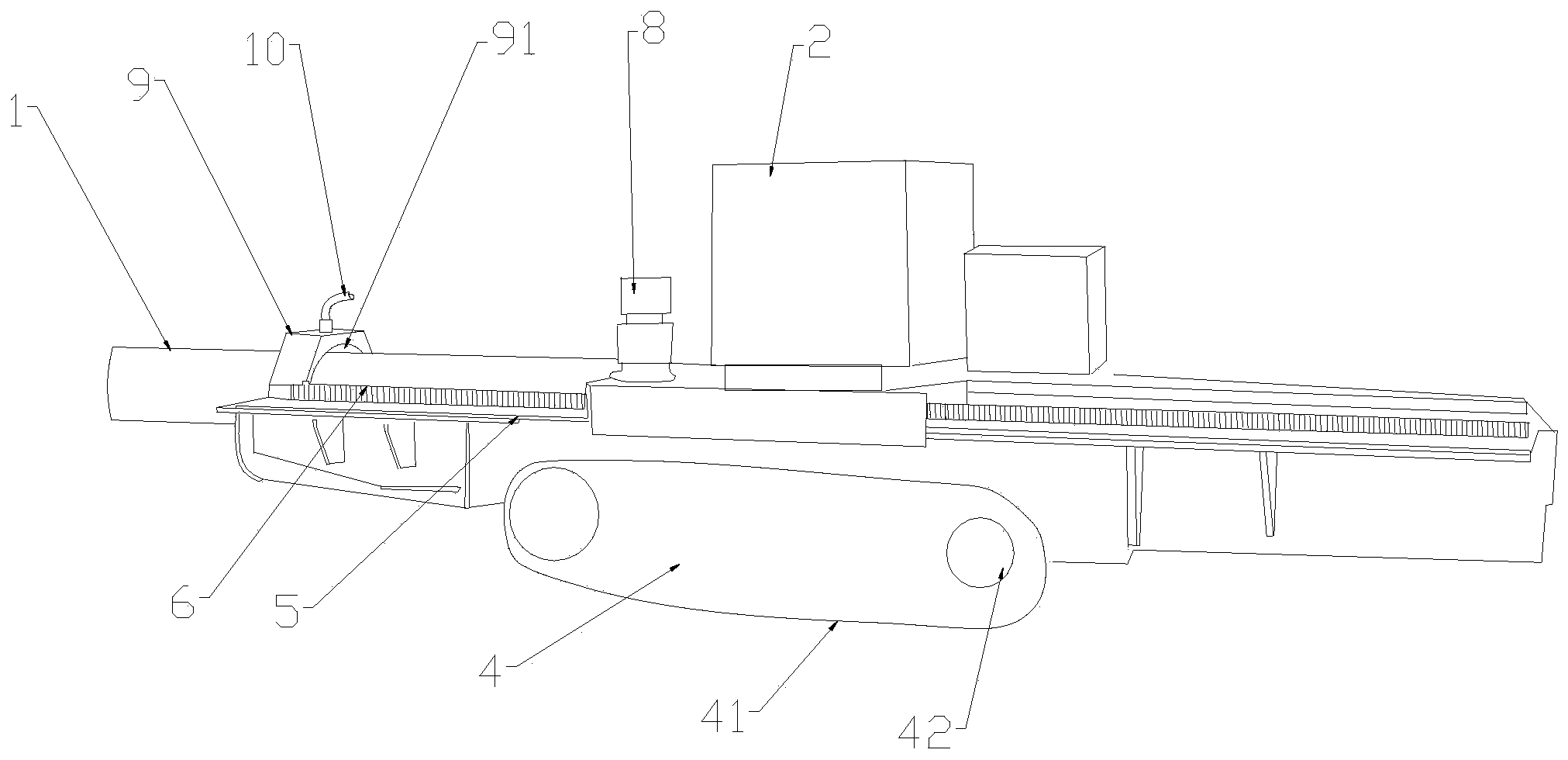

InactiveCN101664879ARealize online continuous productionIncrease productivityMetal-working feeding devicesWelding/cutting auxillary devicesPunchingEngineering

The invention relates to a tailor-welded blank roll bending formation device and a method thereof, belonging to the roll bending formation technology and equipment field. The tailor-welded blank rollbending formation device comprises before-welding upper and lower locating rollers, before-welding left and right locating rollers, after-welding welding device, after-welding left and right locatingrollers, after-welding upper and lower locating rollers and a formation roller bank. By adopting the device, two or more than blanks with different thickness, performance, material and surface coatingare welded together by the before-welding upper and lower locating rollers, the before-welding left and right locating rollers and the welding device, and then carry out roller bending formation through the after-welding left and right locating rollers, after-welding upper and lower locating rollers and the formation roller bank. Compared with the existing punching technology, the device can continuously produce tailor-welded blanks with any cross section in a high-efficiency and high-quality way.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

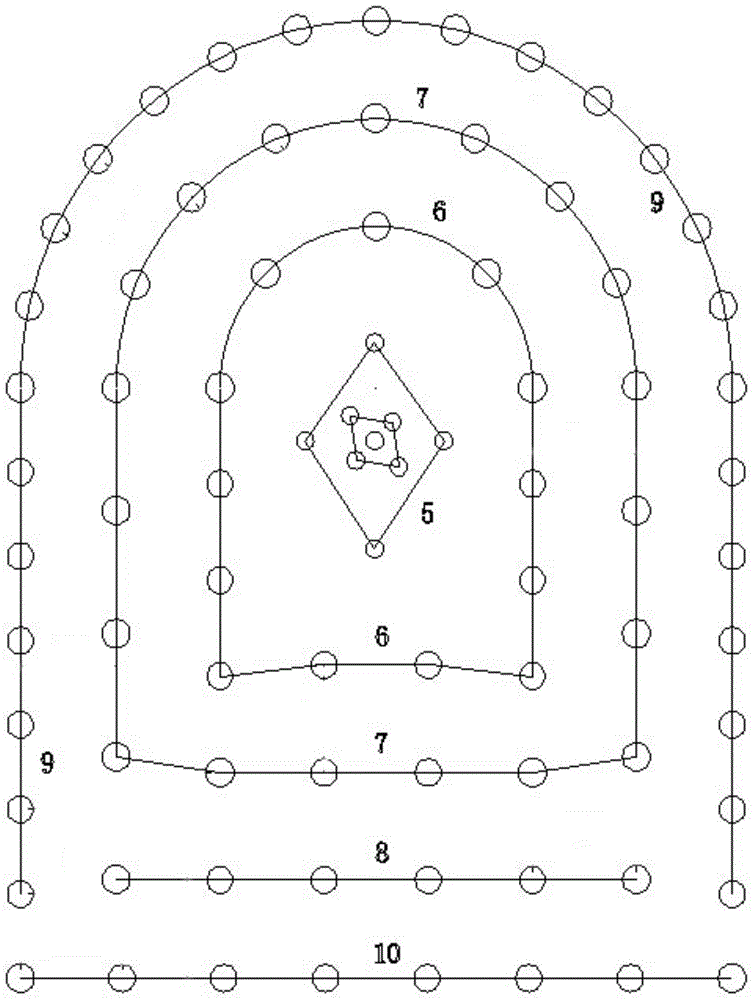

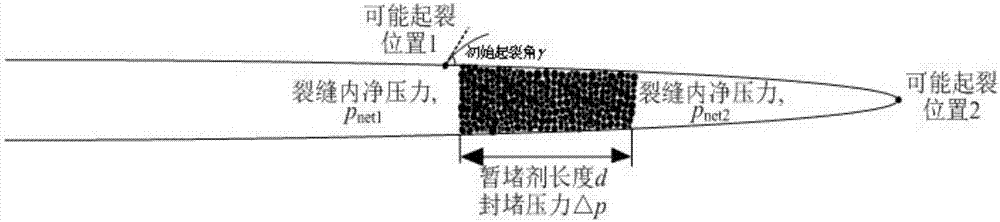

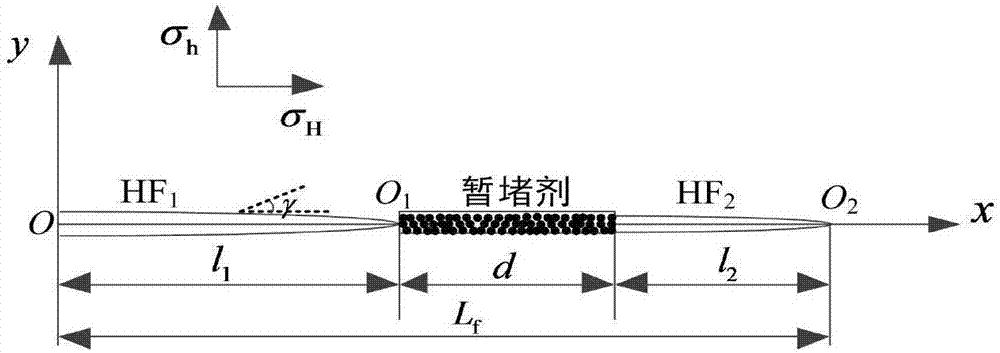

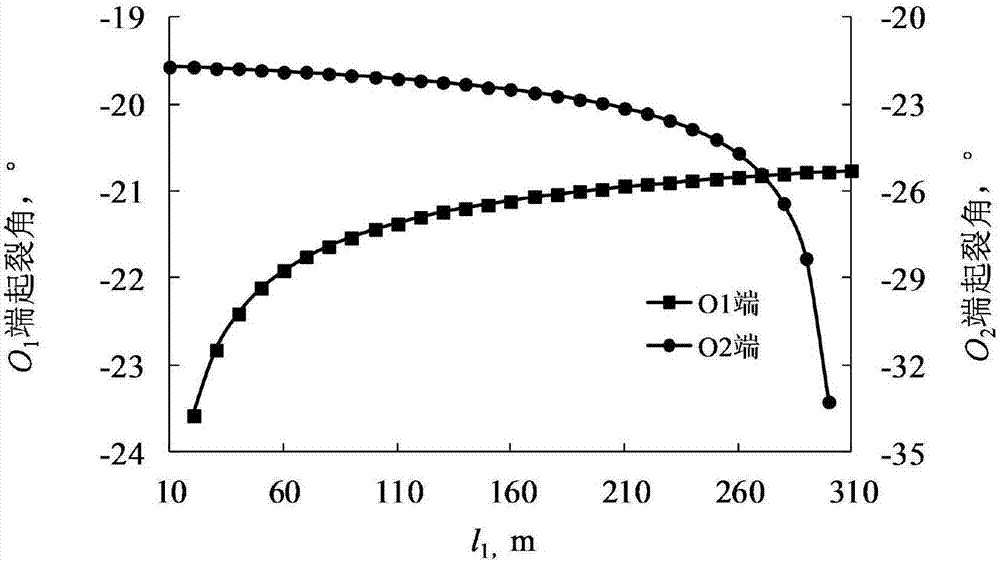

Method for judging temporary plugging and fracture initiation in repeated fracturing well crack

ActiveCN106869892AImproving the effect of refracturing temporary plugging and diversionFluid removalRepeated fracturesForce analysis

The invention discloses a method for judging temporary plugging and fracture initiation in a repeated fracturing well crack. The method specifically comprises the following steps that basic parameters are collected; a hydraulic fracture filled with temporary plugging agents is divided into two hydraulic fractures, and the stress of all points on the fracture face is calculated; a judging criterion of the temporary plugging, fracture initiation and diversion the fracture wall face after the temporary plugging agents are added into the hydraulic fractures is established by the force analysis of the fracture wall face; and the effects of different fracture length, net fluid pressure in the fracture, the temporary plugging agents, the pressure and the sealing blocking length of the temporary plugging agents on the temporary plugging and fracture initiation of the fracture wall face are analyzed quantitatively. According to the method for judging temporary plugging and fracture initiation in the repeated fracturing well crack, the organic combination of the parameters of induced stress fields produced by the extension of the hydraulic fractures and pressure changing of stratum hole fluid, the performance parameters of the temporary plugging agents, the sealing blocking length of the temporary plugging agents and the like is fully considered, the location and orientation of the fracture initiation of the temporary plugging fracture in the repeated fracturing well fracture can be effectively predicted, and the effect of repeated fracturing temporary plugging diversion transforming can be effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

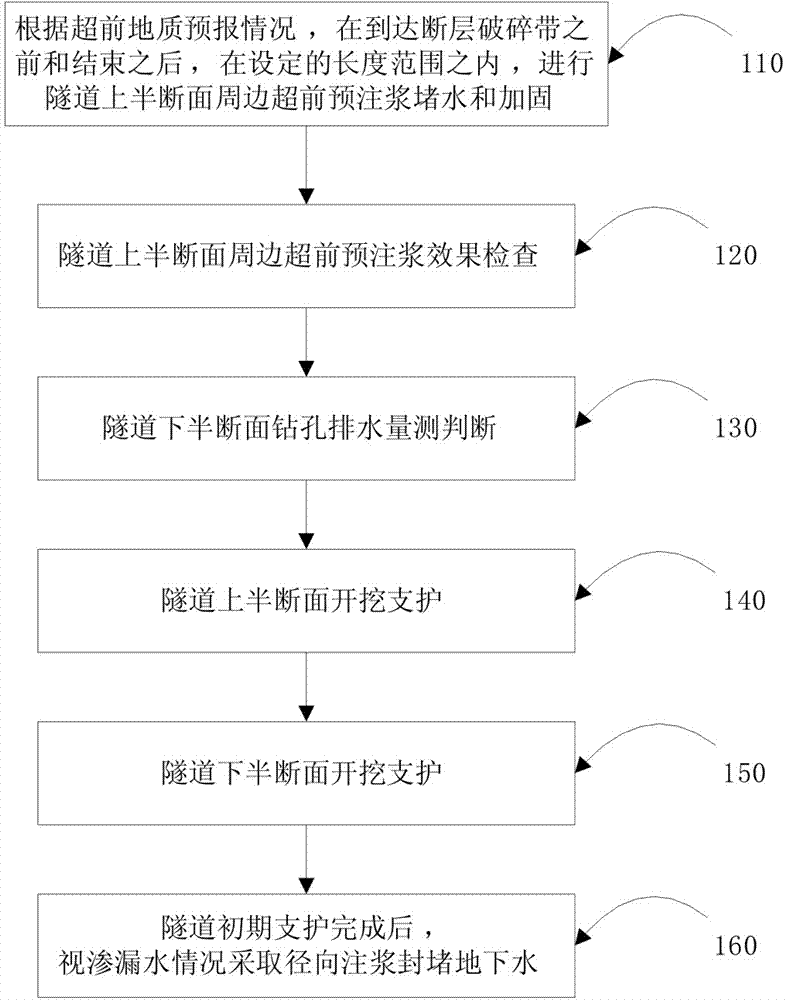

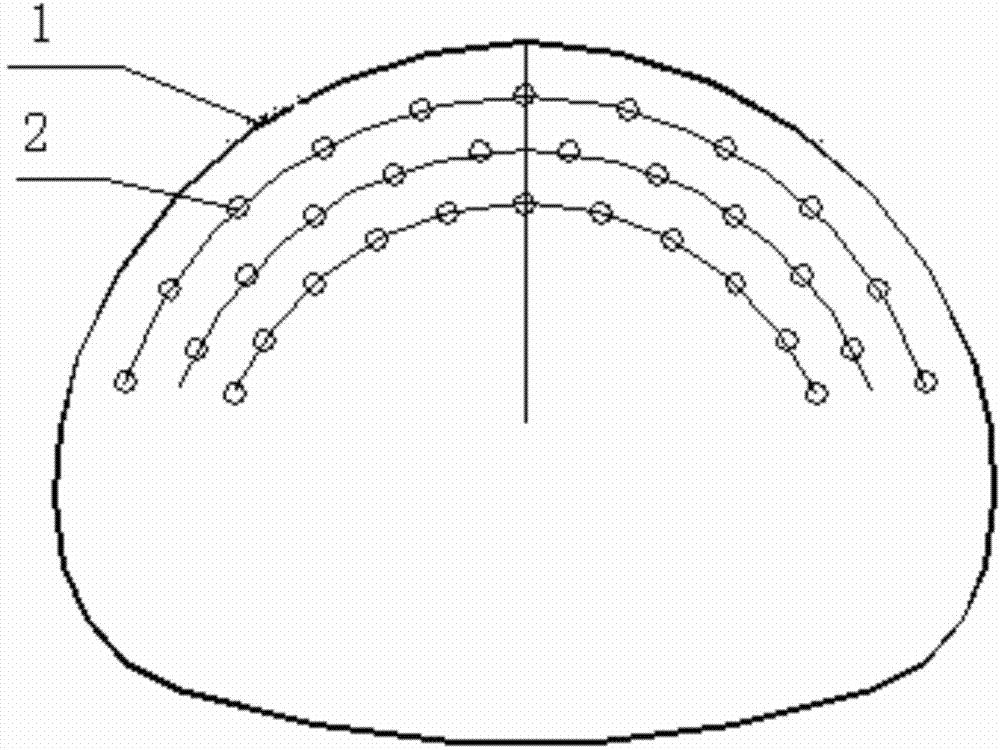

Upper-blocking and lower-draining construction method for undersea tunnel fault fracture zone

ActiveCN102787846AEnsure excavation safetyImprove construction efficiencyUnderground chambersTunnel liningFracture zoneStructural engineering

The invention relates to the technical field of underground engineering construction, and discloses an upper-blocking and lower-draining construction method for an undersea tunnel fault fracture zone. The method comprises the following steps of: rapidly grouting the upper half section of a tunnel for reinforcing, forming inspection holes according to 3-5 percent of number of grouting holes, drilling drainage inspection holes on the lower half section of the tunnel, and excavating and supporting on the upper half section of the tunnel when the maximum water inflow of a single inspection hole is lower than a predetermined standard; and rapidly excavating on the lower half section of the tunnel, and enclosing the initial support of the tunnel into a ring in time to safely and smoothly pass through the fault fracture zone and ensure that the tunnel is free from leakage basically. The construction method is suitable for an undersea tunnel fault fracture zone or a broken rock stratum developed from a water-rich crack; and construction is performed in an enclosed structure, so that the safety of tunnel excavation construction is ensured, the work amount of drilling, grouting, reinforcing and blocking water is reduced, and the requirement of drainage prevention is met. The construction method has the advantages of high construction efficiency, low cost and contributes to saving investment and time for successful building of the tunnel.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

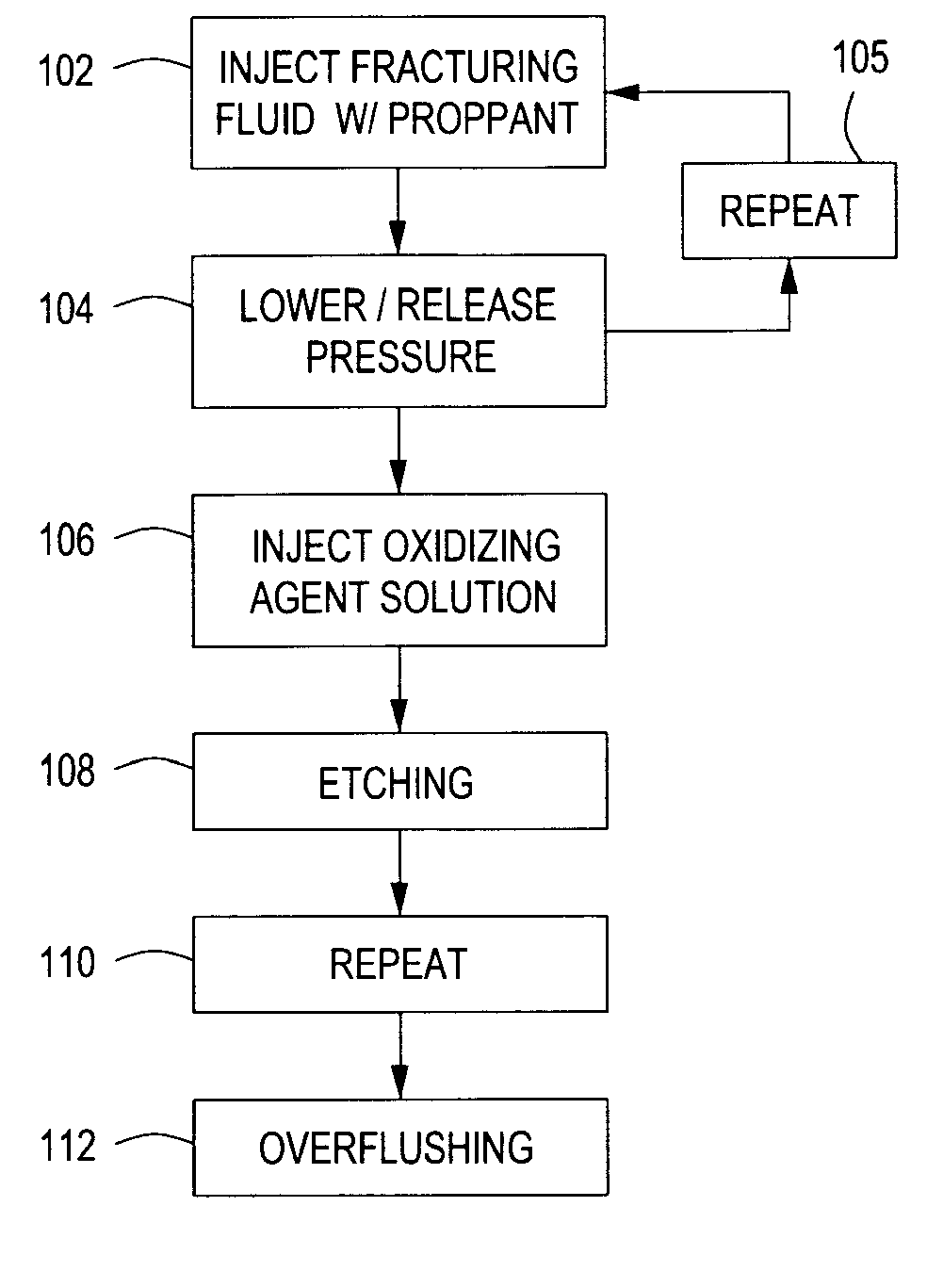

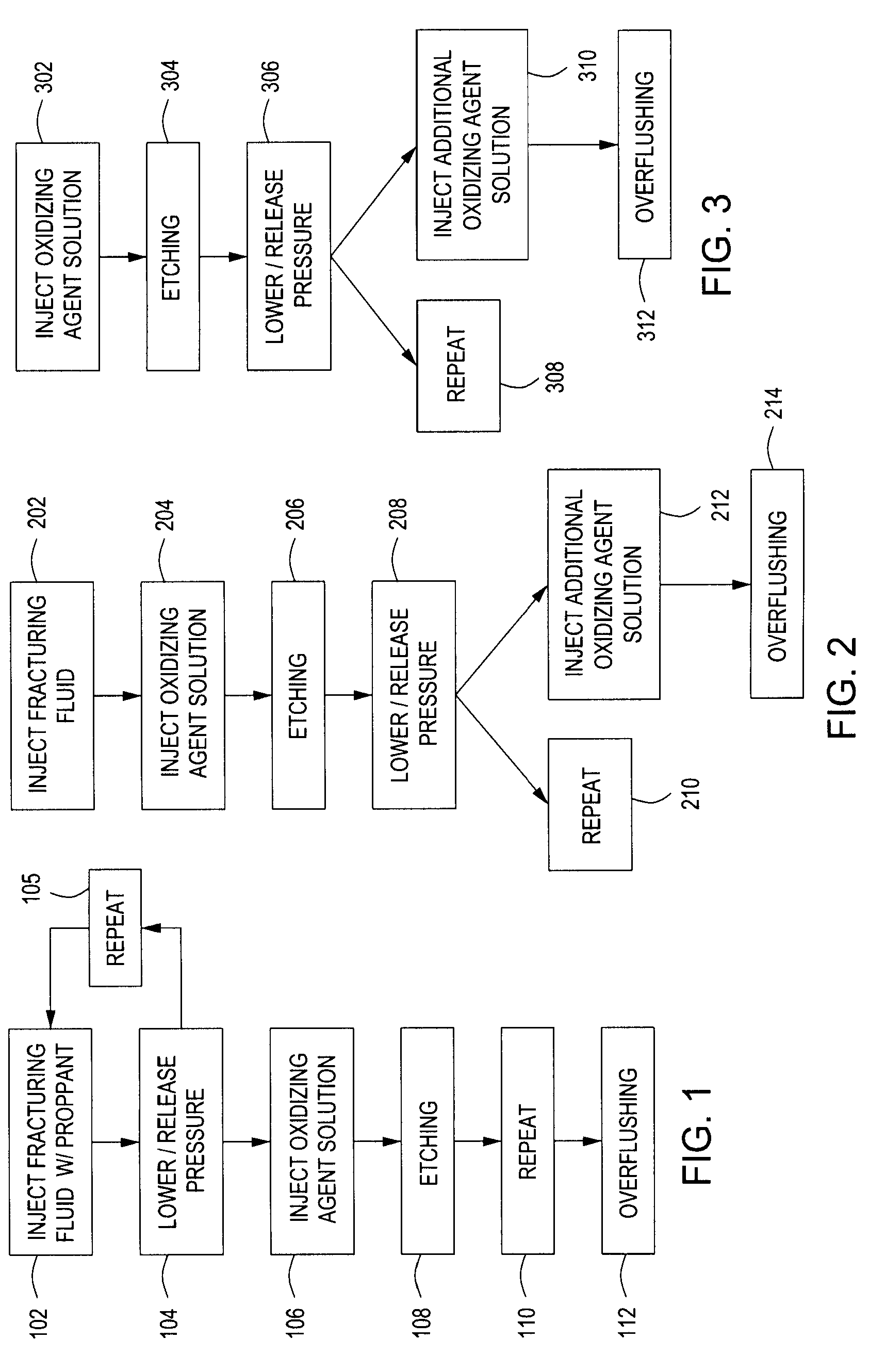

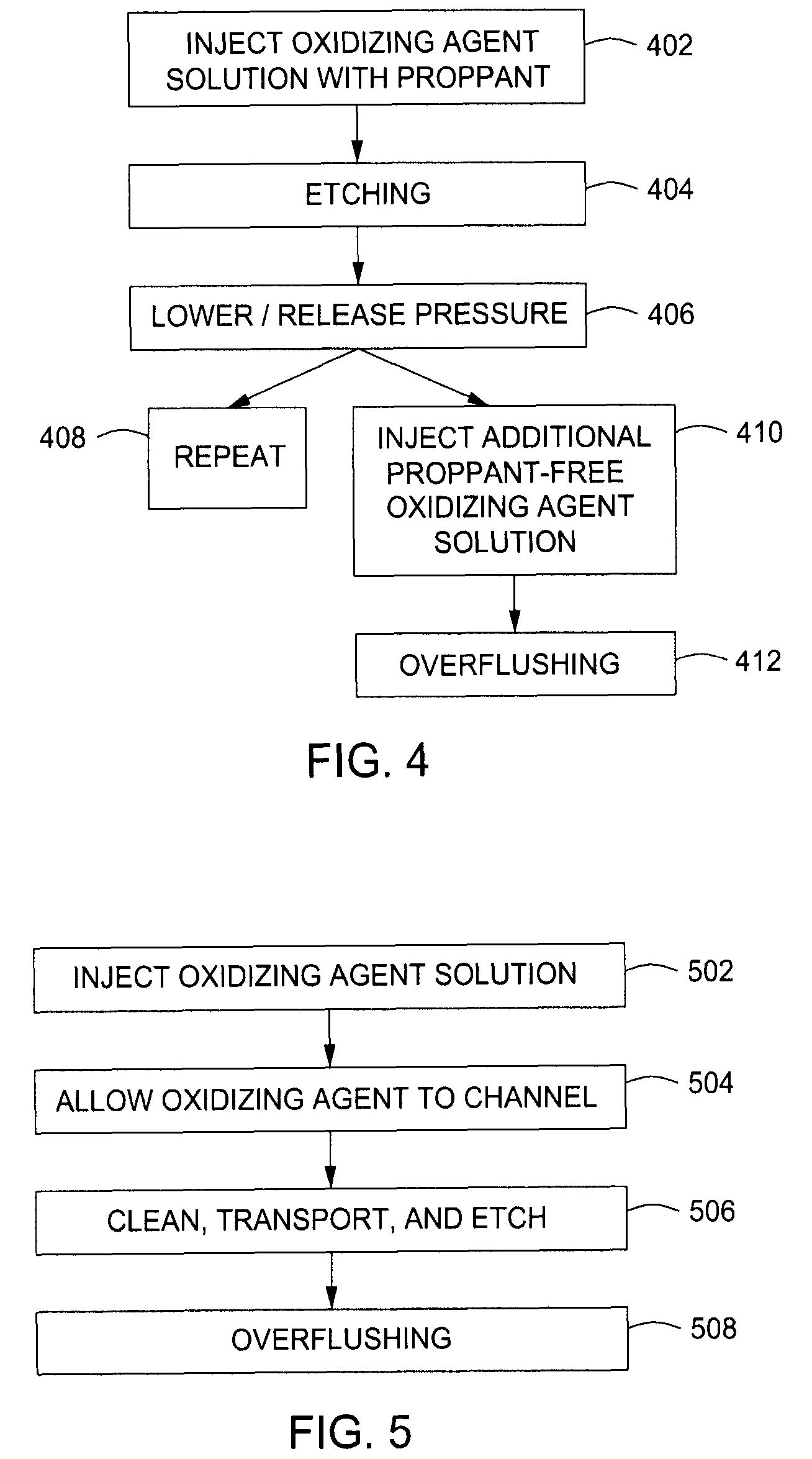

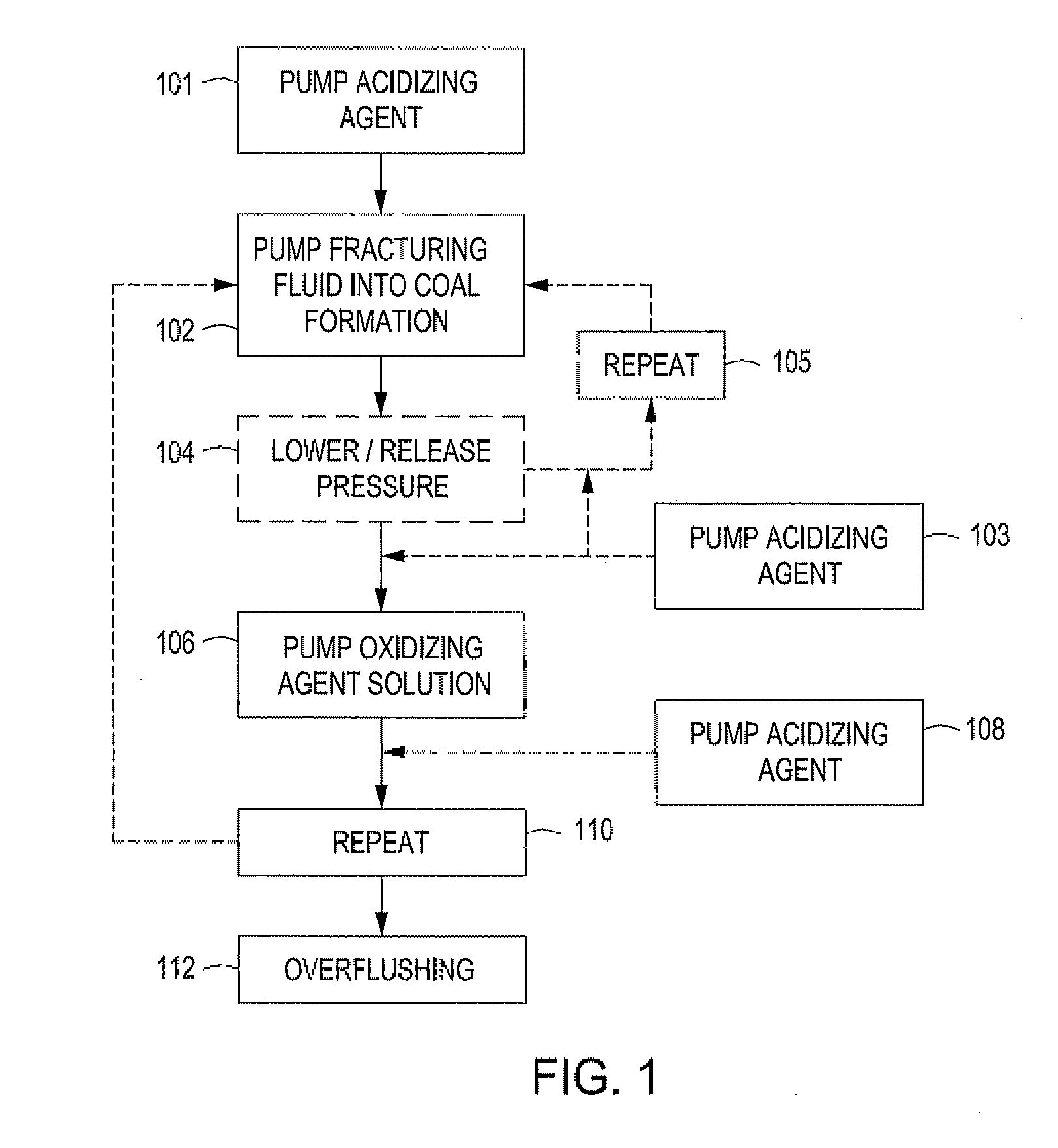

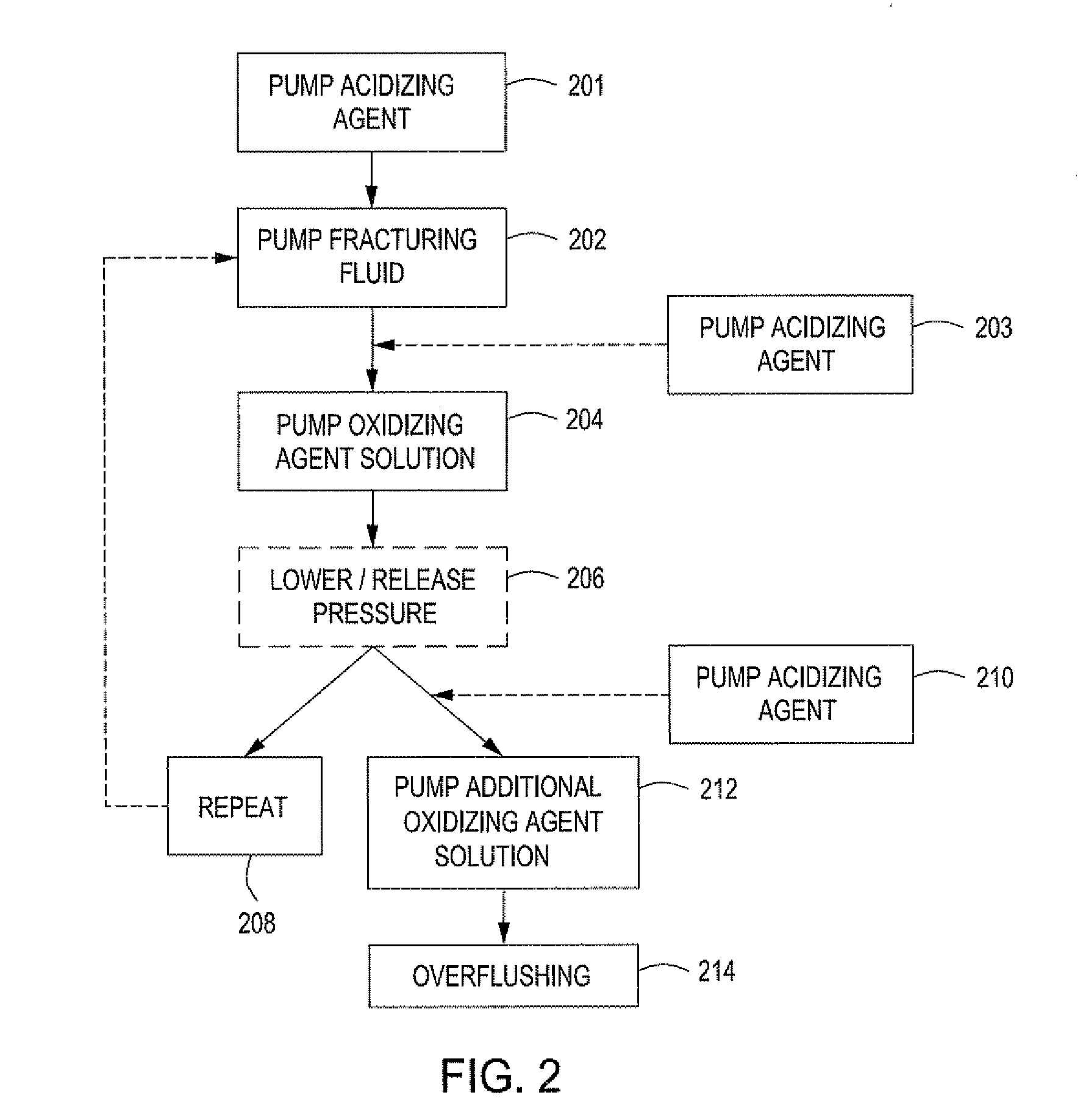

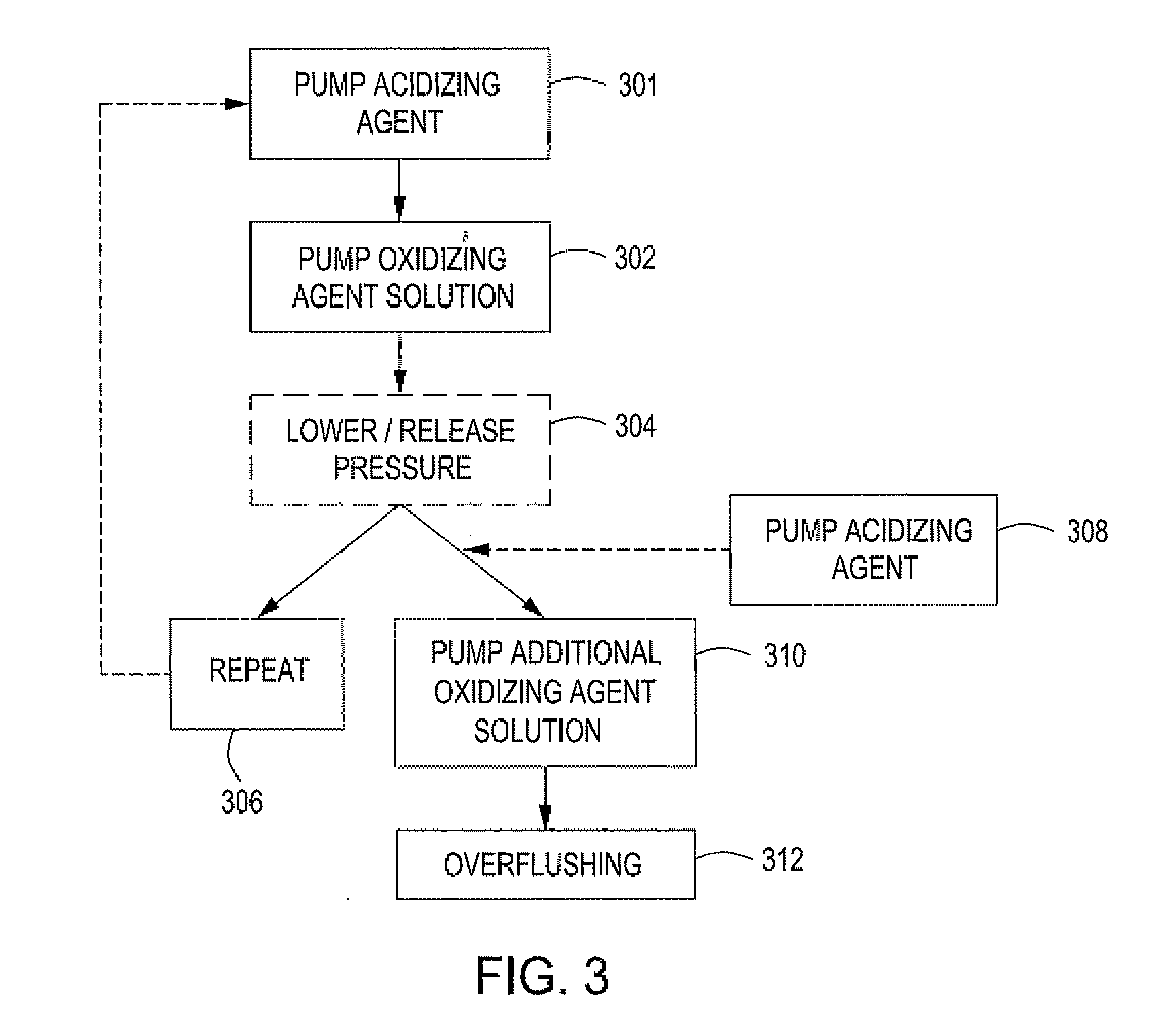

Hydraulic fracturing of subterranean formations

InactiveUS7770647B2Improve conductivityUniform widthFluid removalFracturing fluidHydraulic fracturing

Methods of hydraulically fracturing subterranean coal seams and formations resulting in improved permeability to stimulate Coalbed Methane. In one method, the coal seam is fractured using a proppant-containing fracturing fluid in alternating stages with an aqueous base solution that etches the fracture faces of the coal thereby creating channels for fluid flow. In another method, the coal seam is fractured using a fracturing fluid without propping agents in alternating stages with an aqueous base solution that is pumped at a pressure sufficient to maintain the fractures in an open position thereby etching the fracture faces to create channels for fluid flow. In yet another embodiment, a base solution is injected into the formation at a pressure sufficient to create fractures therein and simultaneously etch the faces of the open fractures to thereby form channels in the faces for increased fluid flow.

Owner:ACT OPERATING

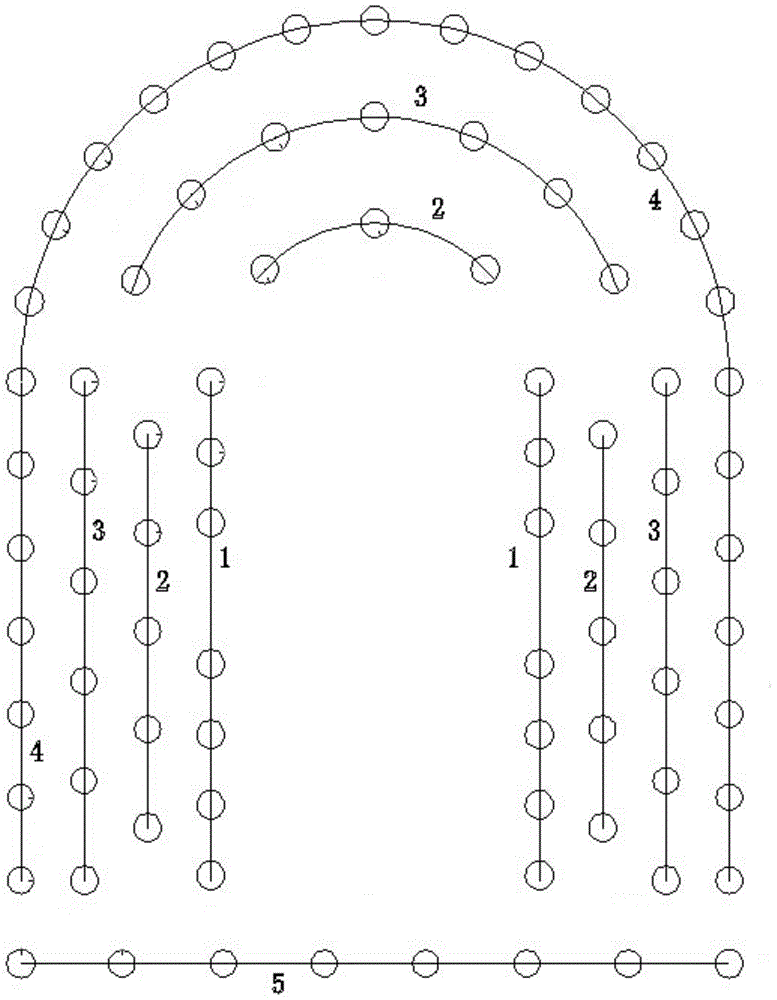

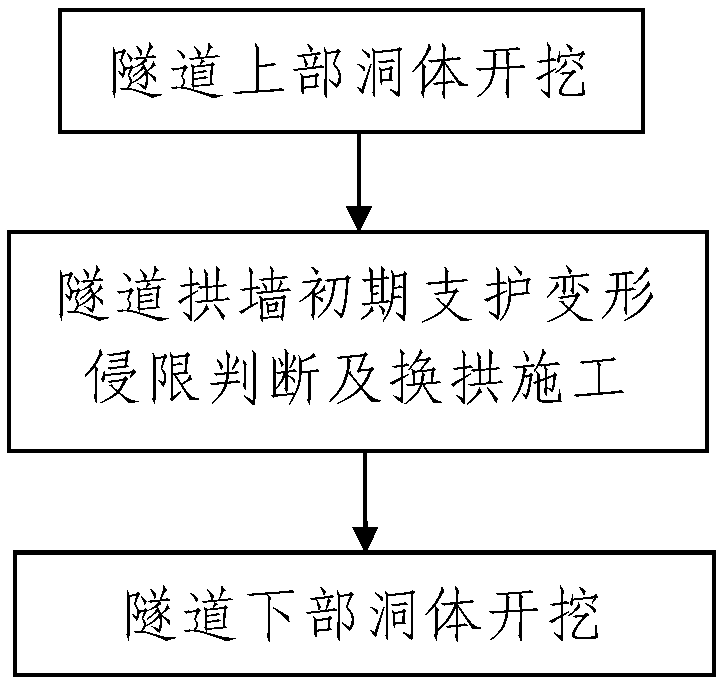

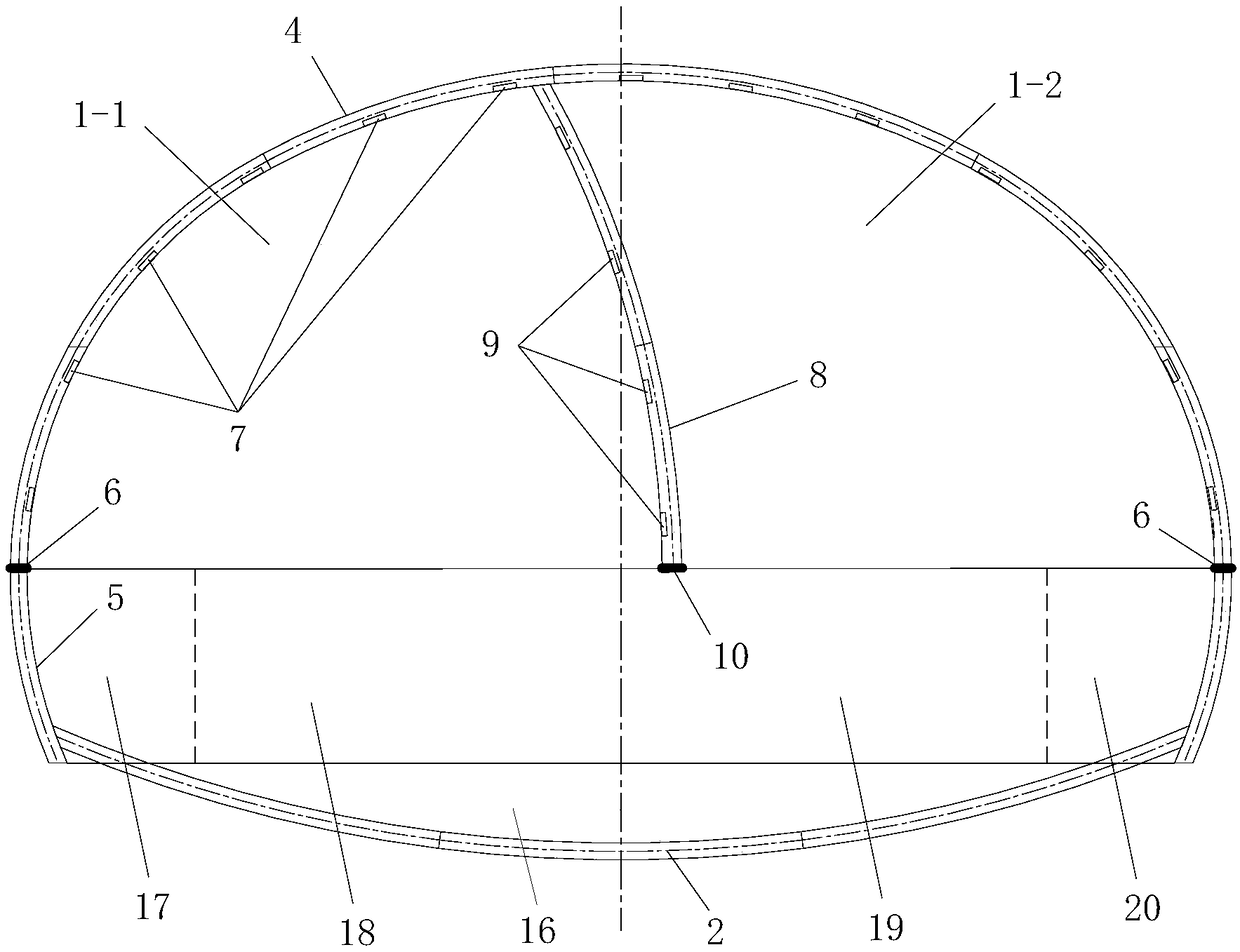

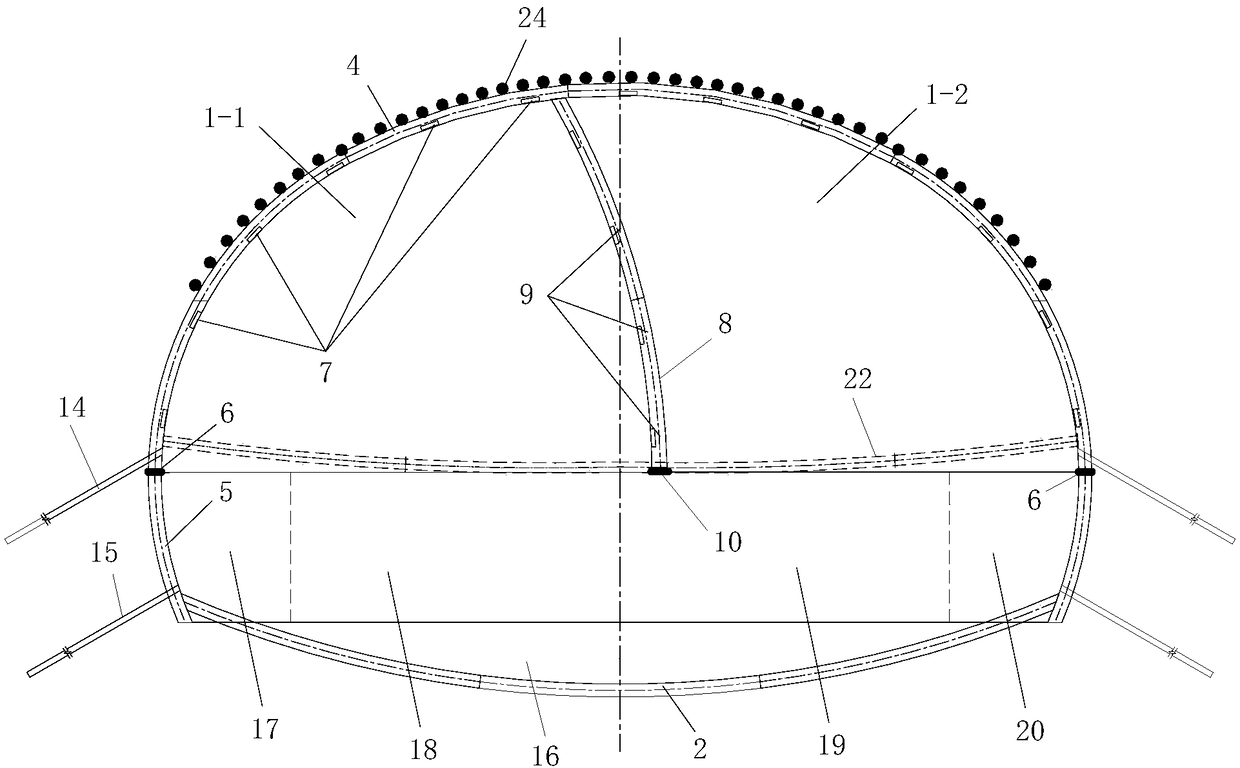

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

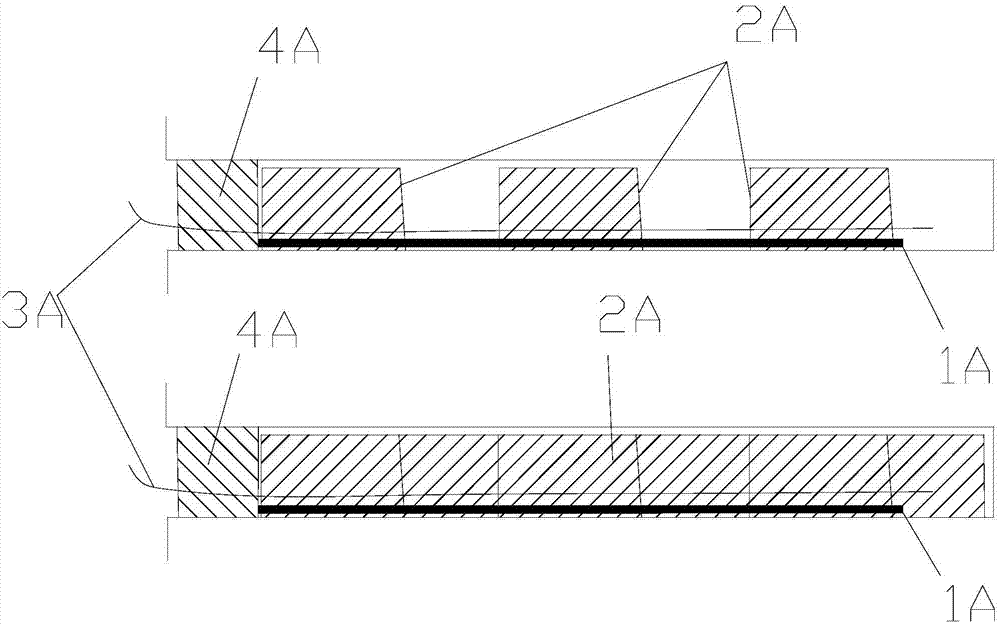

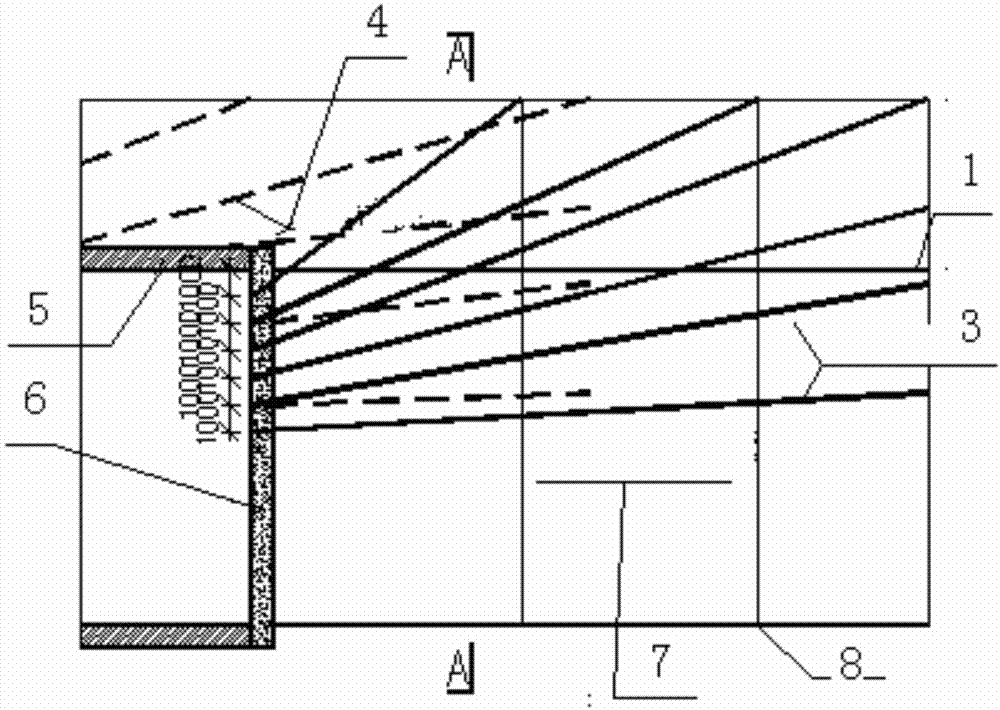

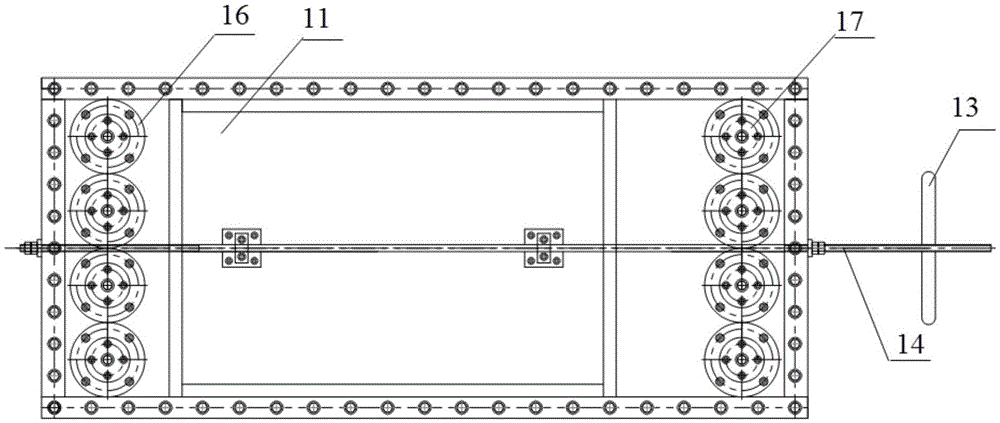

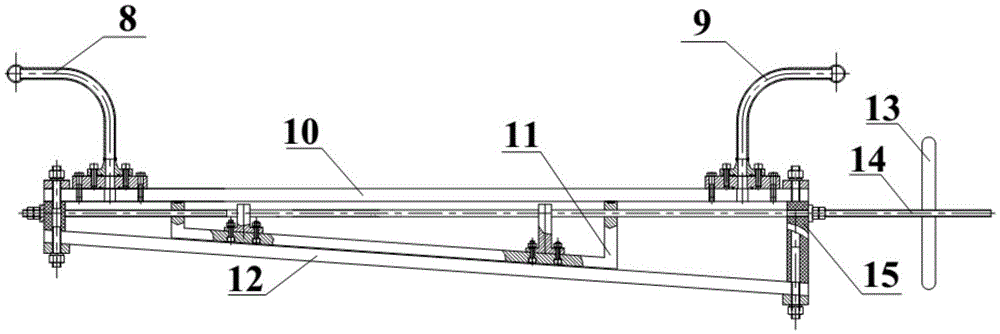

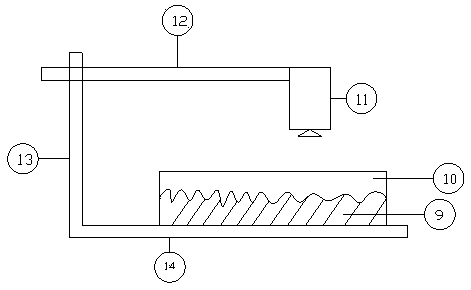

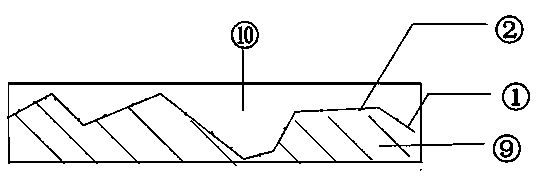

Fracturing fluid rheological proppant transport simulation method and stepless adjustable fracture width test device

ActiveCN105569651ASimple structureOvercome limitationsSurveyConstructionsThermodynamicsFracturing fluid

The invention provides a fracturing fluid rheological proppant transport simulation method and a stepless adjustable fracture width test device. The device comprises a transparent observation window, a back panel, a screw rod and a wedge-shaped sliding block, wherein input holes are longitudinally formed in the input side of the back panel and output holes are longitudinally formed in the output side of the back panel; and an observation cavity is communicated with a material supply device through a first multi-pass pipe arranged on the input side and a second multi-pass pipe arranged on the output side. According to the method and the device, the simulation of a large-section crack is realized through the movable sliding block, the change of the crack can be subjected to stepless regulation, the liquid-solid flow state change in the crack in a fracturing environment can be effectively simulated, and more direct reference data is provided for fracturing fluid formula optimization and proppant selection, so that a fracturing fluid and a proppant can be optimized; and for the flow change of coal bed gas and shale gas fracturing fluids in the crack and the sanding effect monitoring, measurement data can reflect a fracture forming effect of the fracturing fluid and a coal bed gas and shale gas fracturing process is optimized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Selective fracture face dissolution

A method is given for acid fracturing a subterranean formation for improving the flow of fluids. The principal source, optionally the sole source, of the acid is a solid acid-precursor, optionally injected with an additional solid that is inert and that masks a portion of the newly created fracture faces so that the fracture face etching by the acid is not uniform. The method ensures a good flow path for fluids between the fracture tip and the wellbore.

Owner:BROWN J ERNEST +1

Solid Sandstone Dissolver

Owner:SCHLUMBERGER TECH CORP

Method for determining a grid cell size in geomechanical modeling of fractured reservoirs

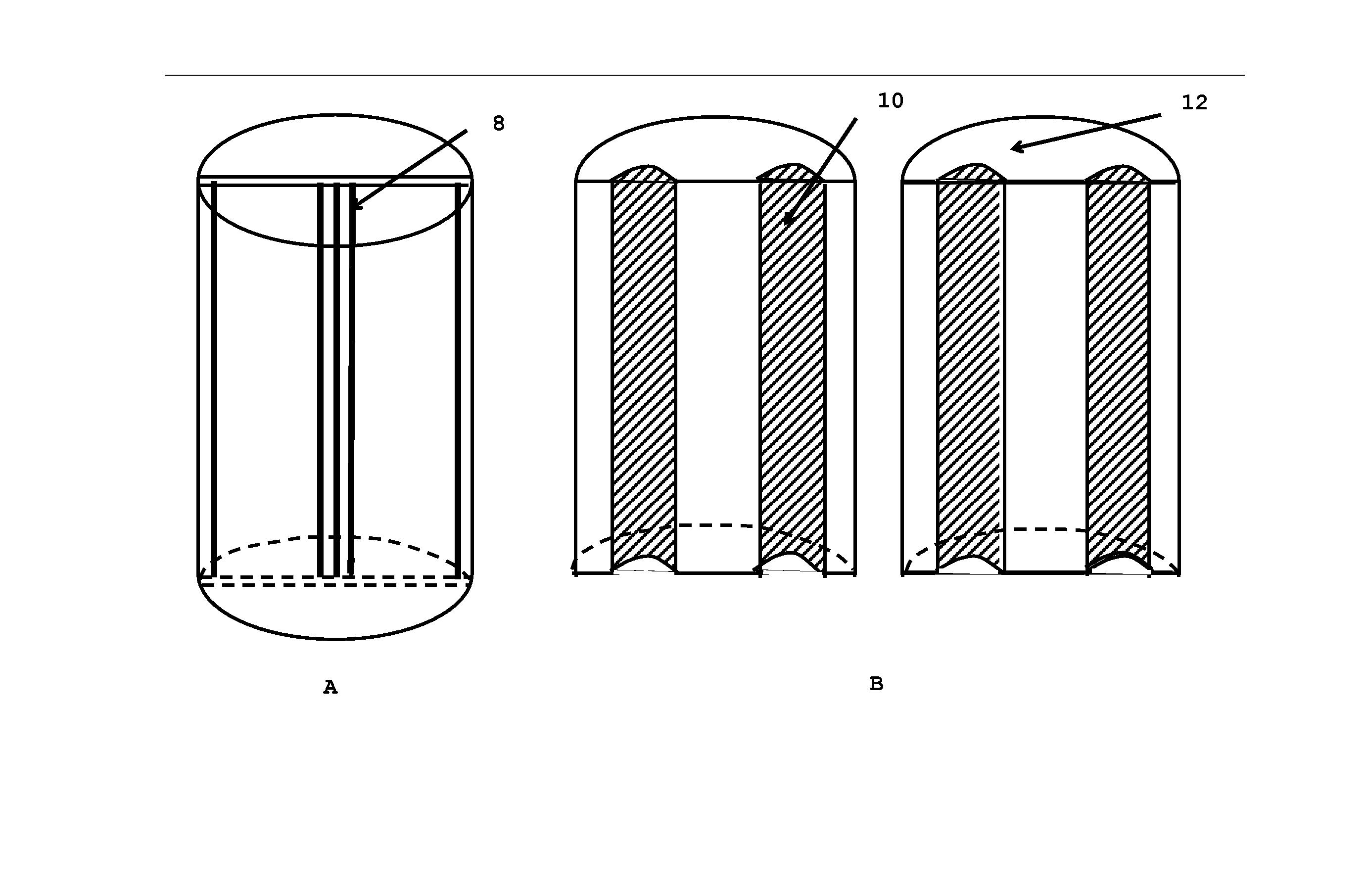

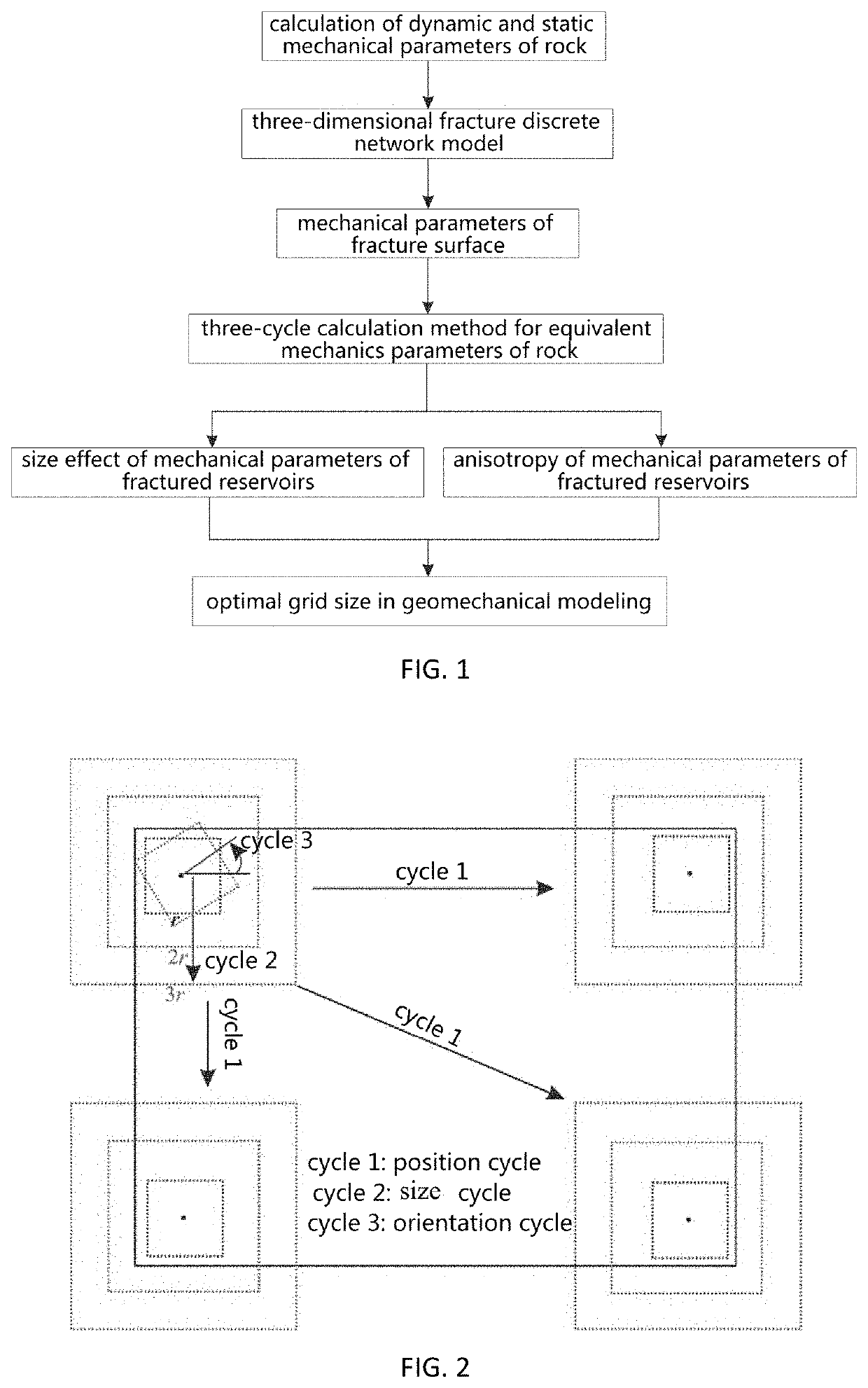

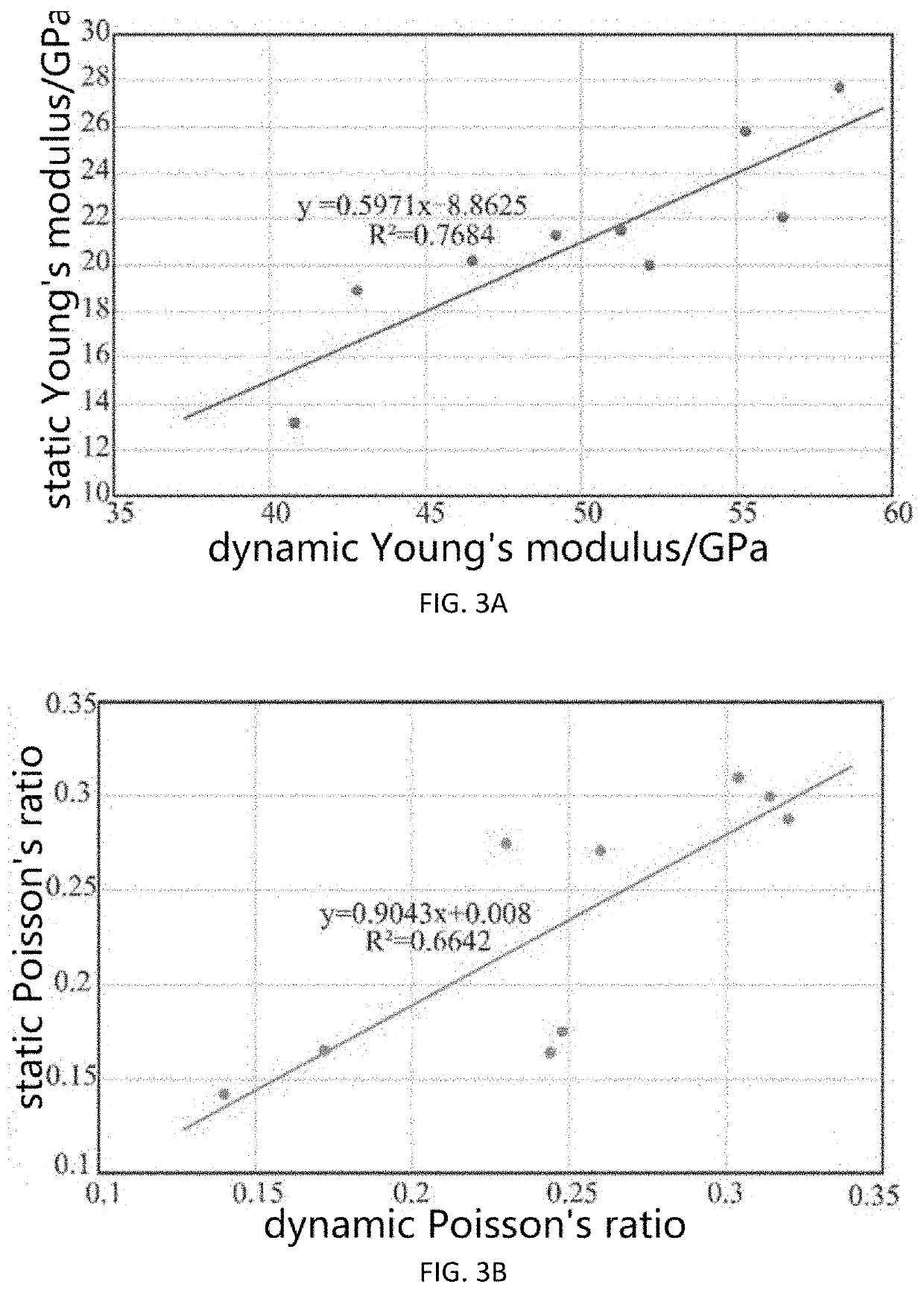

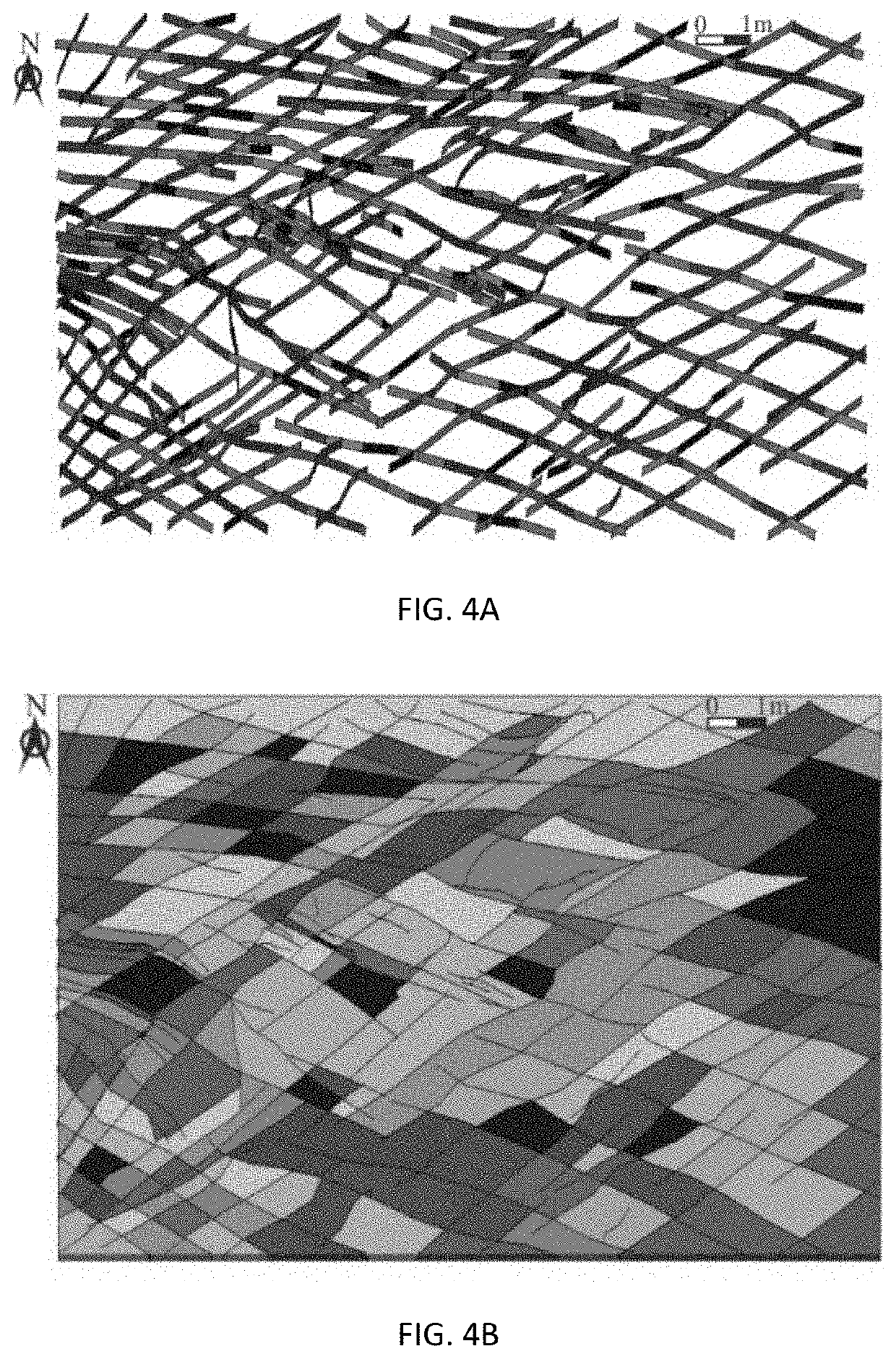

InactiveUS20210132246A1High practical valueEasy to operateMaterial strength using tensile/compressive forcesGeomodellingNetwork modelGrid cell

A method for determining grid cell size in geomechanical modeling of fractured reservoirs including a variation range of mechanical parameters of the reservoir is determined. A three-dimensional fracture discrete network model is established. Mechanical parameters of fracture surface are determined on the basis of fracture surface mechanical test. Equivalent mechanical parameters of models with different sizes are researched by three-cycle method, and size effect and the anisotropy of the mechanical parameters of the fractured reservoir are calculated respectively, and an optimal grid cell size in geomechanical modeling is determined.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

In situ method for sealing undesirable transverse fractures under hydraulic pressure during lithological displacement of an evaporite deposit

Methods for sealing undesirable transverse fractures enlarged and / or created during lithological displacement of an underground water-soluble evaporite stratum by hydraulic pressure greater than overburden pressure at an evaporite / non-evaporite strata interface, comprising injecting and maintaining a sealing agent into these undesirable fractures to form a solidified matter in situ and ultimately seal them, while forming a main free surface at the interface suitable for initiating solution mining of the evaporite stratum. The solidified matter may be crystallized, precipitated, compacted, agglomerated, cross-linked, coagulated, water-swollen, and / or cemented matter, or may include a wall-building matter with the mineral on fracture faces. The sealing agent may comprise at least one component of the mineral and / or the non-evaporite. The evaporite stratum is preferably a trona stratum overlying an oil shale stratum. The sealing agent may comprise dissolved and / or solid trona, trona tailings particles, and / or water-swelling particles.

Owner:SOLVAY SA

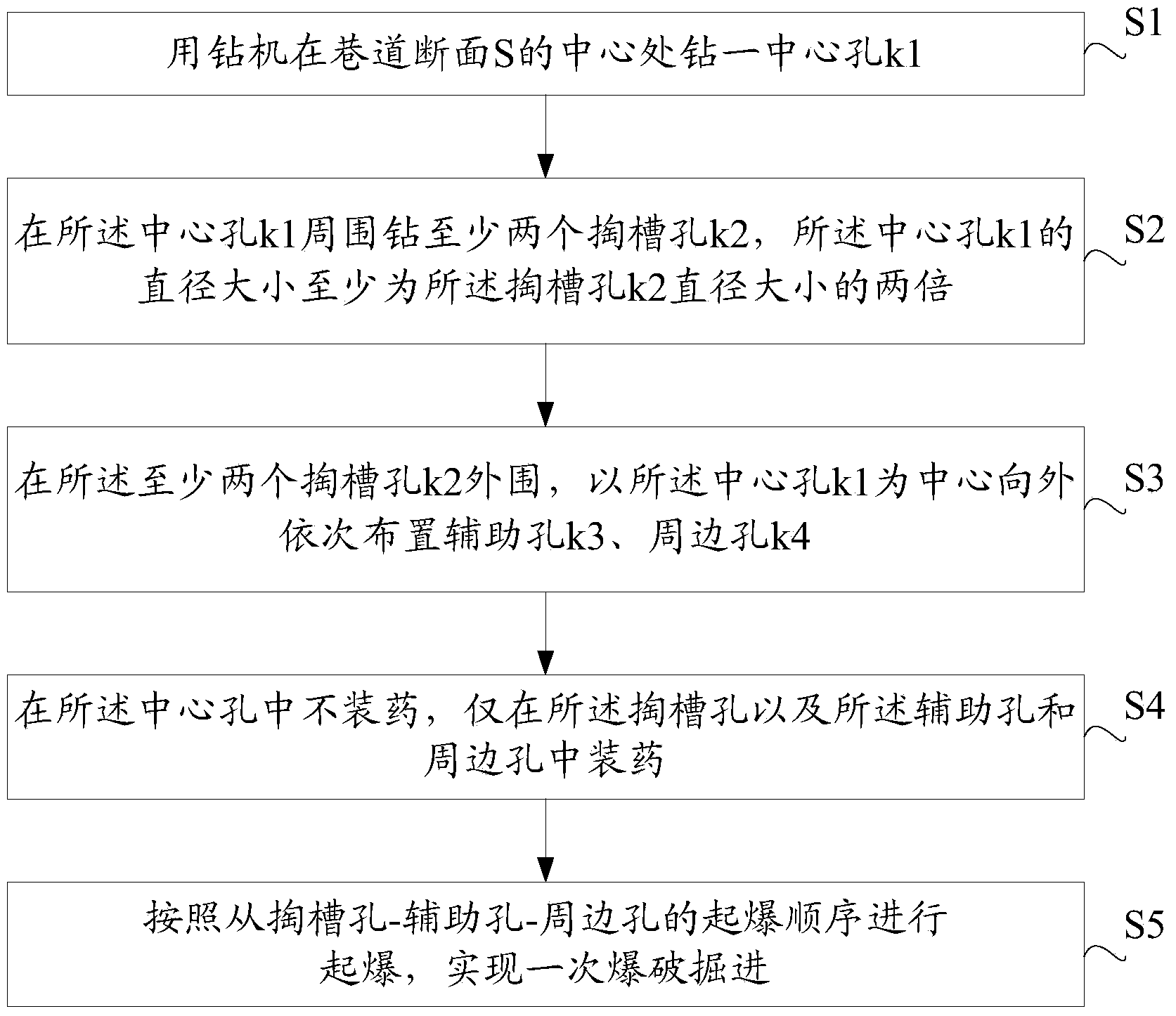

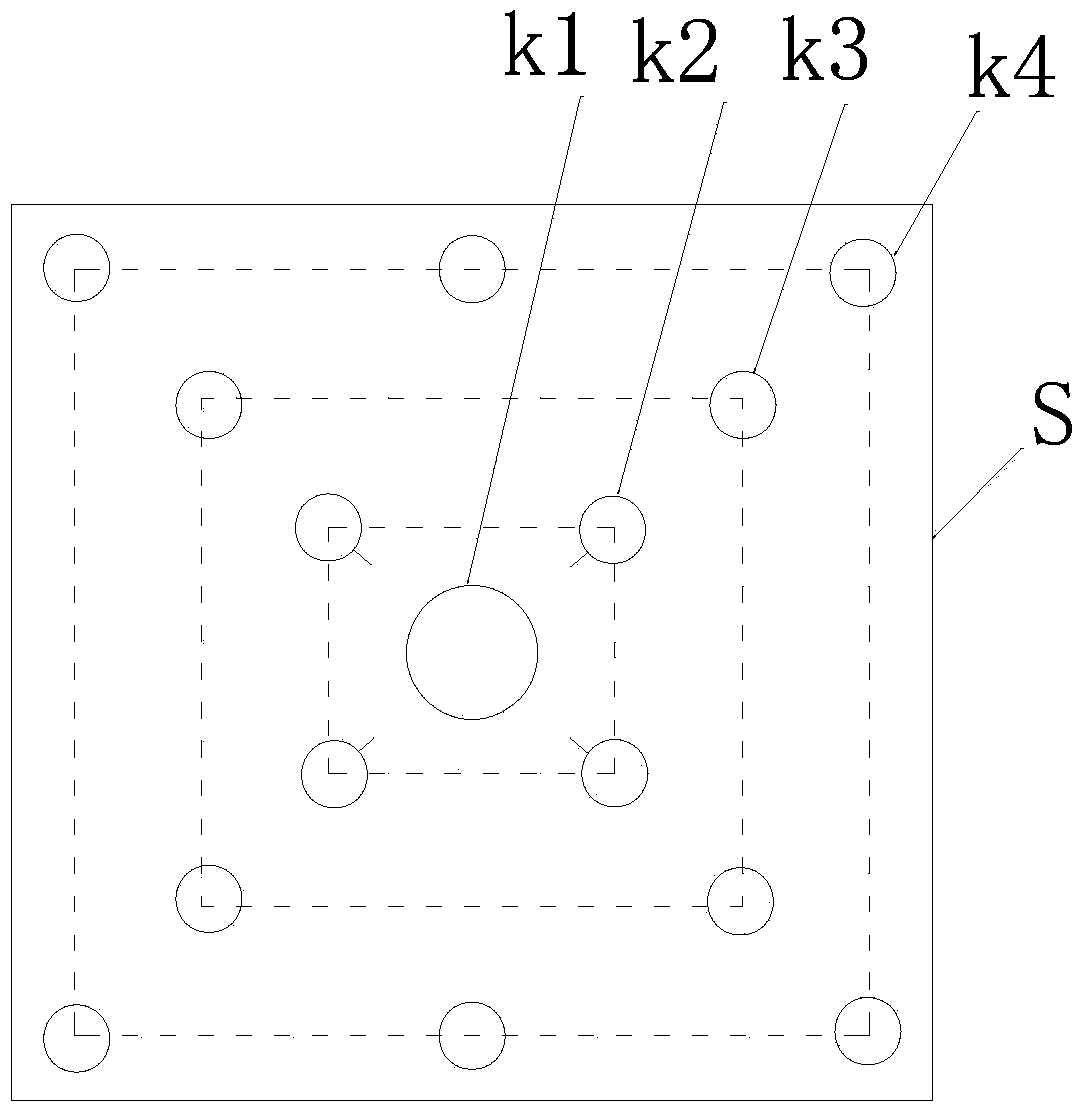

Medium-hard rock deep-hole cut blasting method

The invention discloses a medium-hard rock deep-hole cut blasting method, which relates to the field of shaft and drift cut blasting and can reduce the affection of blasting noise and vibration on surrounding environments. The method includes the following steps: a special drilling machine is used for drilling a big central hole at the center of the section of a roadway; cut holes are arranged around the central hole for rock breaking; supplementary holes and surrounding holes are then sequentially outwardly arranged around the cut holes with the central hole as a center; charges are loaded into the cut holes, the supplementary holes and the surrounding holes; blasting is carried out according to a cut hole-supplementary hole-surrounding hole blasting sequence, and thereby one-step blast excavation is realized. The medium-hard rock deep-hole cut blasting method is applicable to medium-hard rock deep-hole cut blasting in underground roadways.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Hydraulic fracturing of subterranean formations

InactiveUS20100282471A1Improved methane extractionReduce pressureFluid removalFracturing fluidHydraulic fracturing

Methods of hydraulically fracturing subterranean coal seams and formations resulting in improved permeability to stimulate Coalbed Methane. In one method, the coal seam is fractured using a proppant-containing fracturing fluid in alternating stages with an aqueous base solution that etches the fracture faces of the coal thereby creating channels for fluid flow. In another method, the coal seam is fractured using a fracturing fluid without propping agents in alternating stages with an aqueous oxidizing solution that is pumped at a pressure sufficient to maintain the fractures in an open position thereby etching the fracture faces to create channels for fluid flow. In yet another embodiment, the aqueous oxidizing agent solution is pumped into the formation at a pressure sufficient to create fractures therein and simultaneously etch the faces of the open fractures to thereby form channels in the faces for increased fluid flow.

Owner:ACT OPERATING

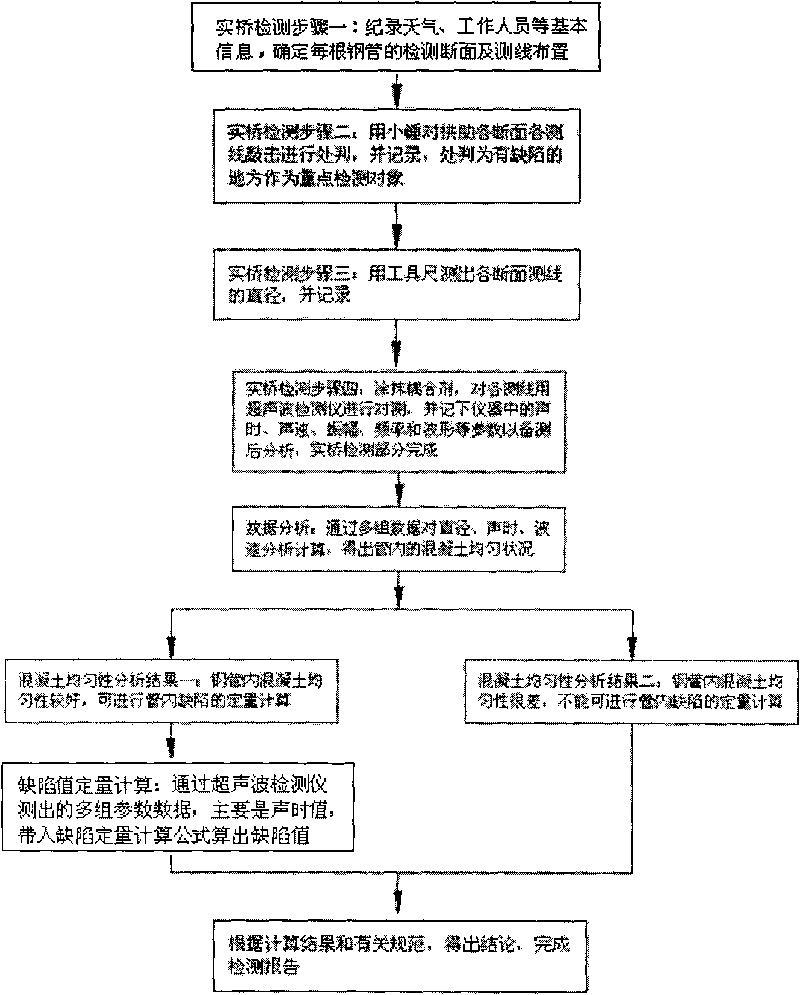

Ultrasonic testing method for steel pipe void

InactiveCN101710101AReduce uniformitySave human effortAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPipe

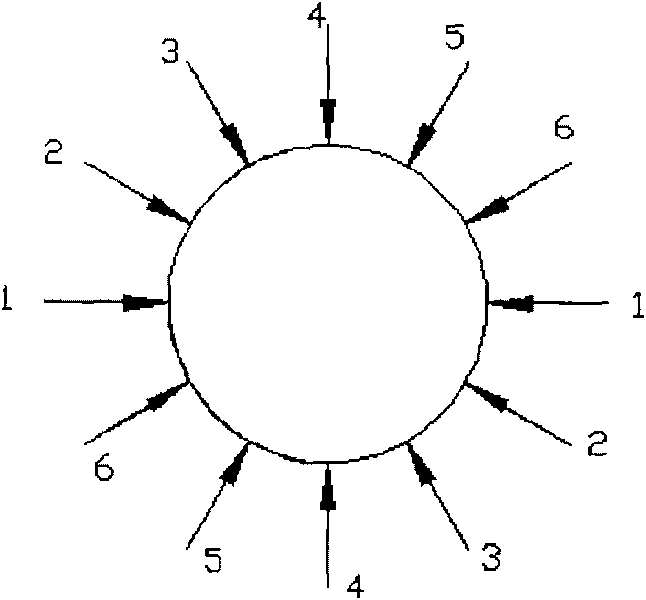

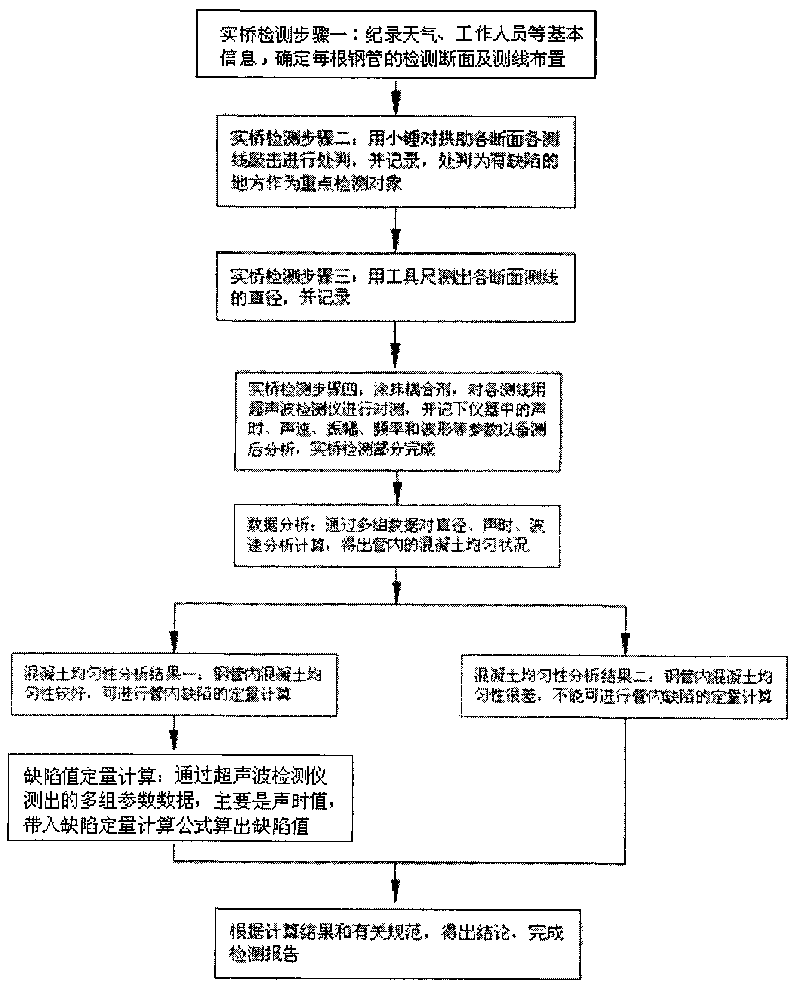

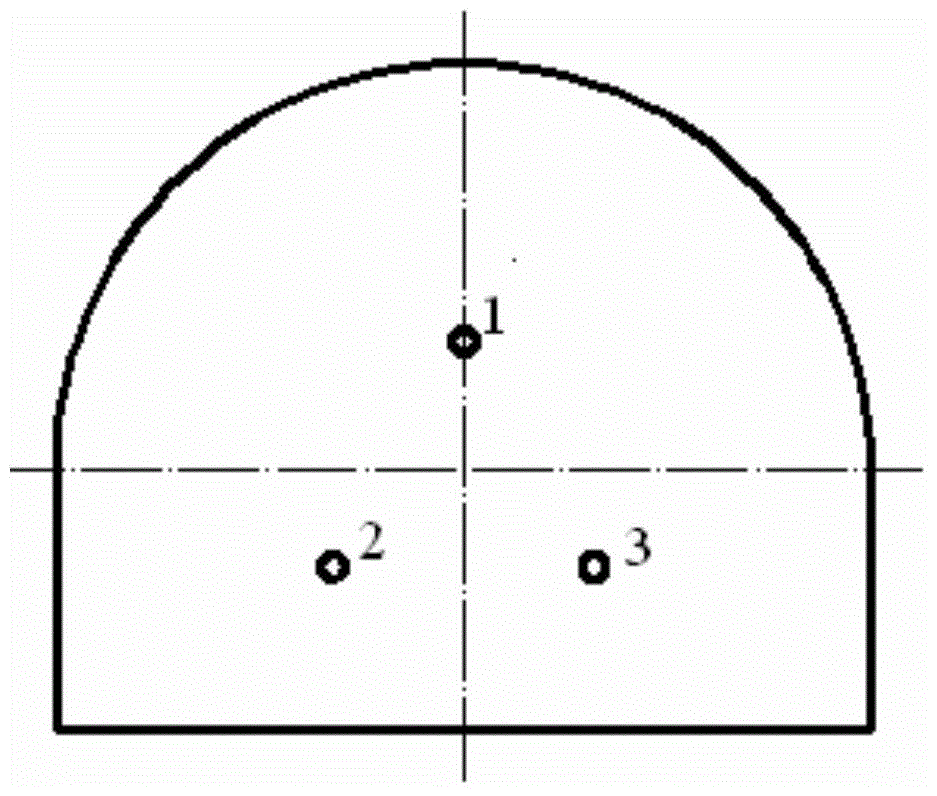

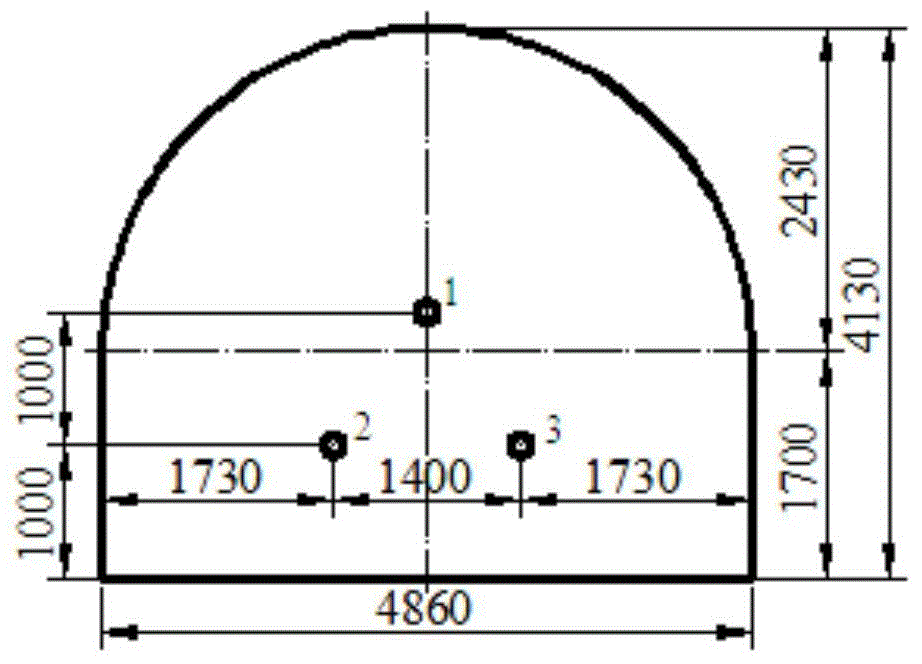

The invention relates to an ultrasonic testing method for steel pipe void, which comprises the following steps of: confirming a tested fracture surface of each steel pipe and arranging a plurality of survey lines on the surface of each steel pipe in a uniform distribution way; knocking each survey line on each fracture surface of arch ribs by a small hammer, preliminarily judging the compaction rate of concretes inside the steel pipe according to the knock, and recording judging results; measuring diameters of the survey lines on each fracture surface by using a tooling scale and recording; coating a coupling agent on the surface of each steel pipe, detecting each survey line by using an ultrasonic detector, and recording parameters of sound time, sound velocity, amplitude and wave form which are displayed in the detector; analyzing and calculating the recorded multi-group data to obtain the uniformity state of the concretes inside the steel pipes; if the uniformity state is favorable, then carrying out a quantitative calculation on inner pipe defects, and working out an inner pipe defect value of each fracture surface through a sound time value detected by the ultrasonic detector; and if the uniformity state is unfavorable, then obtaining a detection conclusion.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

Fully mechanized excavation construction method for rock roadway

The invention discloses a fully mechanized excavation construction method for a rock roadway. The method comprises the following steps of arranging blast holes parallel to the trend of the roadway on a roadway excavation tunnel face by using a loose split blasting technology; Filling an explosive in the blast holes; then detonating; increasing a fracture in to-be-excavated rock through the blasting to damage the rock around the blast holes; finally cutting the rock by using a fully mechanized excavation machine. The construction of the fully mechanized excavation machine is combined with the deep hole loose split blasting, so the fracture and the damage range in the rock are increased, the integrity of the rock is reduced, the efficiency of cutting the rock by the fully mechanized excavation machine is improved, the construction cost is saved, and the field operation environment is improved. The method is suitable for constructing various hard rock roadways by the fully mechanized excavation machine, particularly suitable for large-section inclined shafts and levels with a section area of being greater than 18m<2>.

Owner:ANHUI UNIV OF SCI & TECH

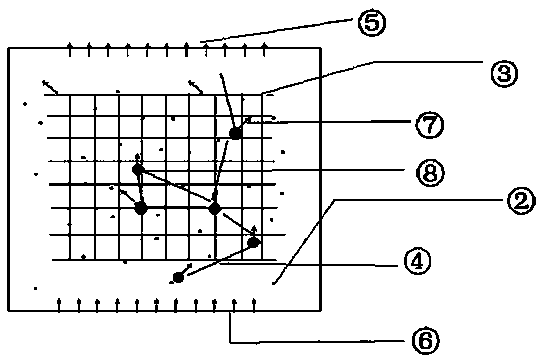

Method for measuring flow vector of seepage liquid

ActiveCN105372167ARealize measurementImprove discriminationPermeability/surface area analysisGeomorphologyMinimum time

Provided is a method for measuring the flow vector of seepage liquid. The method includes the following steps that 1, rock is selected; 2, observation points are selected; 3, pigment is arranged on the observation points; 4, a transparent opposite face model of a rock fracture face is made; 5, the transparent opposite face model is arranged on the rock fracture face; 6, transparent sulfuric acid grid paper is placed on the upper surface of the transparent opposite face model; 7, a camera device is installed; 8, water injection is performed till seepage occurs; 9, multiple flow path lines with colors appear; 10, flow conditions are recorded; 11, a shot image is analyzed, the seepage speed of any point at the minimum time difference is calculated, and then the seepage vector of any point of the fracture face at any micro time period is measured. By means of the method for measuring the flow vector of the seepage liquid, the problem that it is impossible to trace the seepage direction of any point and calculate the seepage speed can be solved, the instant flow speed of liquid at any point in a fracture joint face can be measured, and measurement precision is high.

Owner:泰州市海通资产管理有限公司

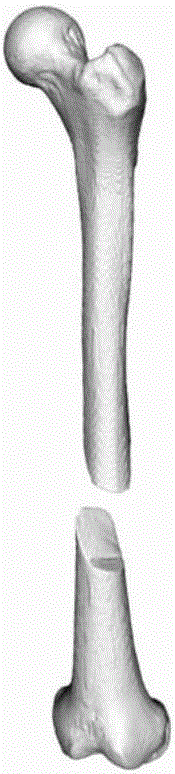

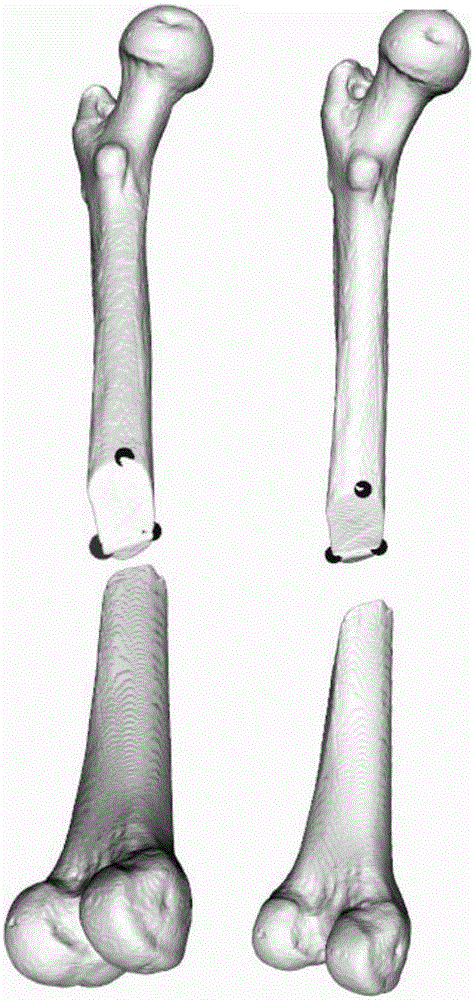

Computer-assisted fracture restitution degree measurement method

InactiveCN107174342AReal-timeRealize the display effectSurgical navigation systemsComputer-aided planning/modellingImaging processingComputer-aided

The invention belongs to the field of three-dimensional medical image processing and in particular relates to a computer-assisted fracture restitution degree measurement method. The computer-assisted fracture restitution degree measurement method comprises the following steps: scanning a fracture part by using medical imaging equipment, acquiring a medical image, and carrying out three-dimensional reconstruction on the fracture part, so that a surface model of a broken bone is obtained; and manually selecting a characteristic point on a fracture face of the reconstructed model, namely taking one broken bone as a target bone, setting the broken bone to be fixed and immobile, manually selecting n points with obvious characteristics on the fracture face of the target bone as a target characteristic point set, and similarly selecting n characteristic points in one-to-one correspondence with the target characteristic point set on the fracture face of an another broken bone as a source characteristic point set. The computer-assisted fracture restitution degree measurement method has the advantages that estimation of the best fracture setting position before an operation is realized, and the best fracture setting distance is calculated; real-time calculation and display of the distance between the two broken bones in a fracture restitution operation are realized; and a restitution operation course is accurately monitored, and a digital restitution progress enables a doctor to be clear at a glance on an operation course.

Owner:HARBIN ENG UNIV

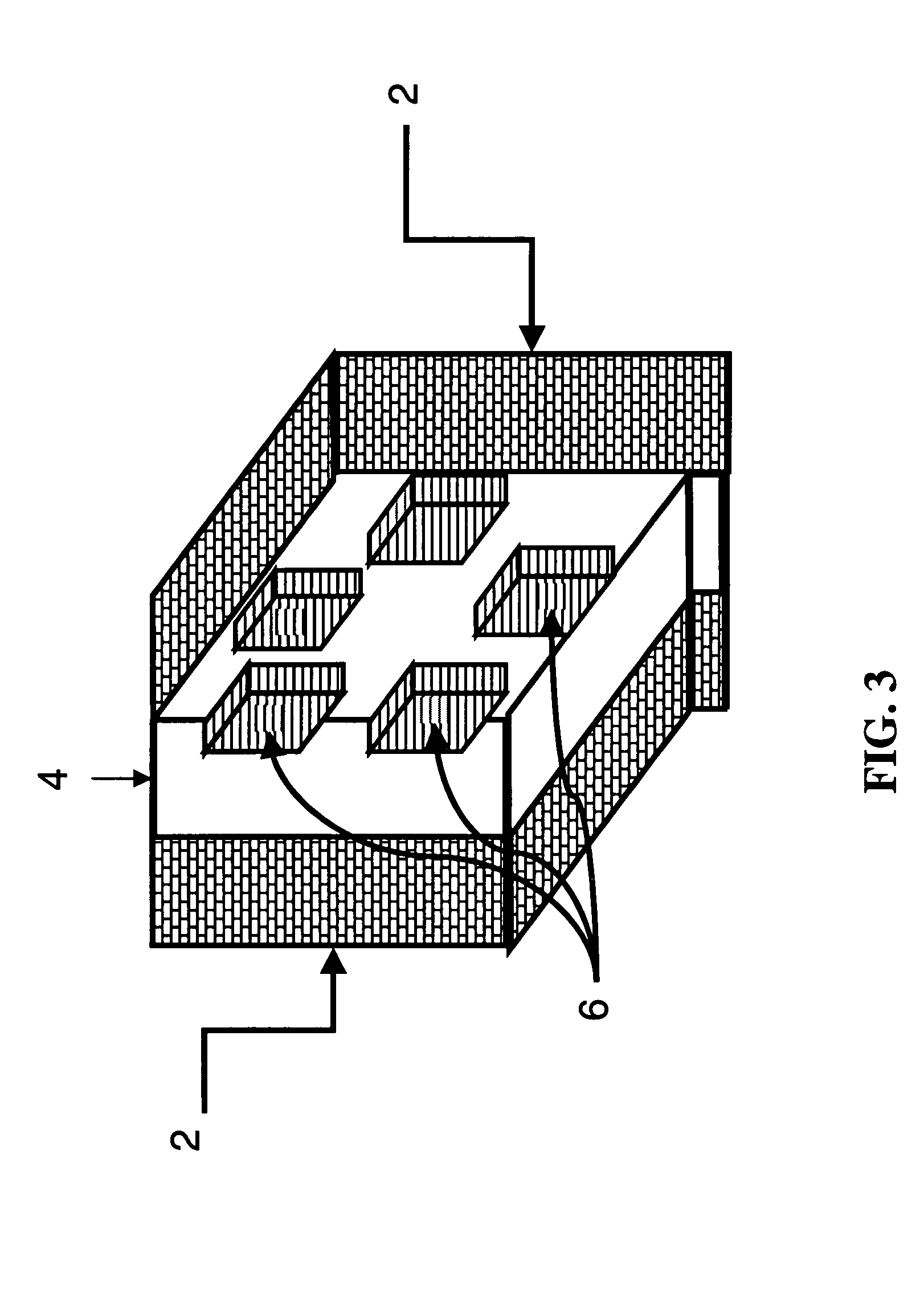

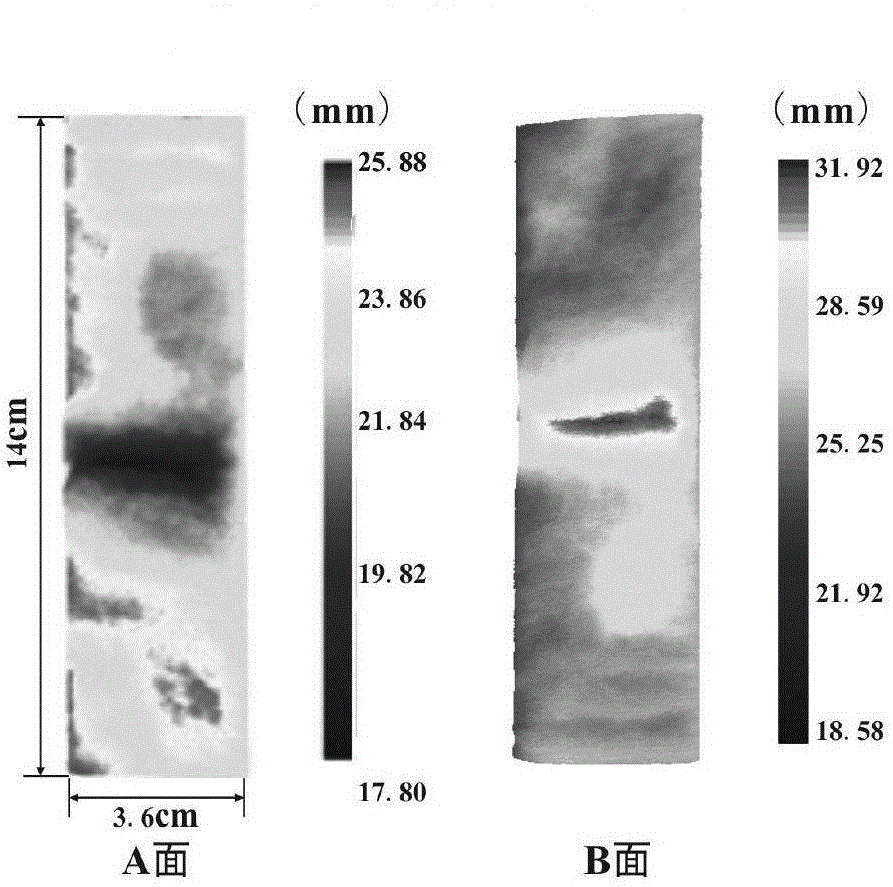

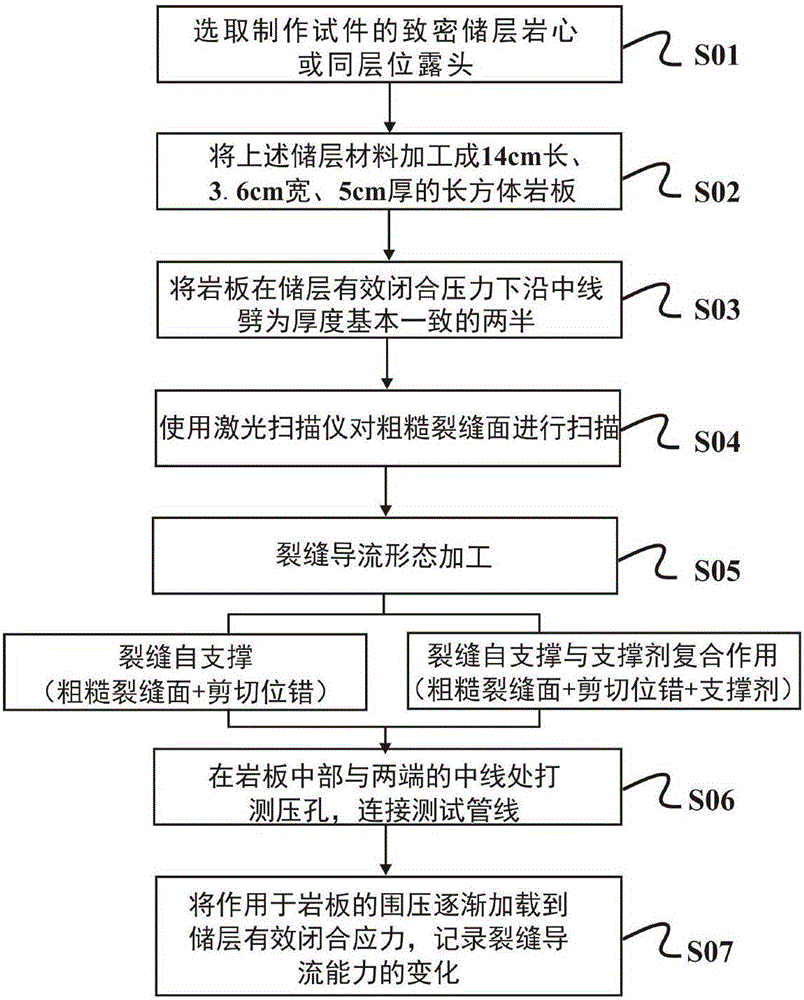

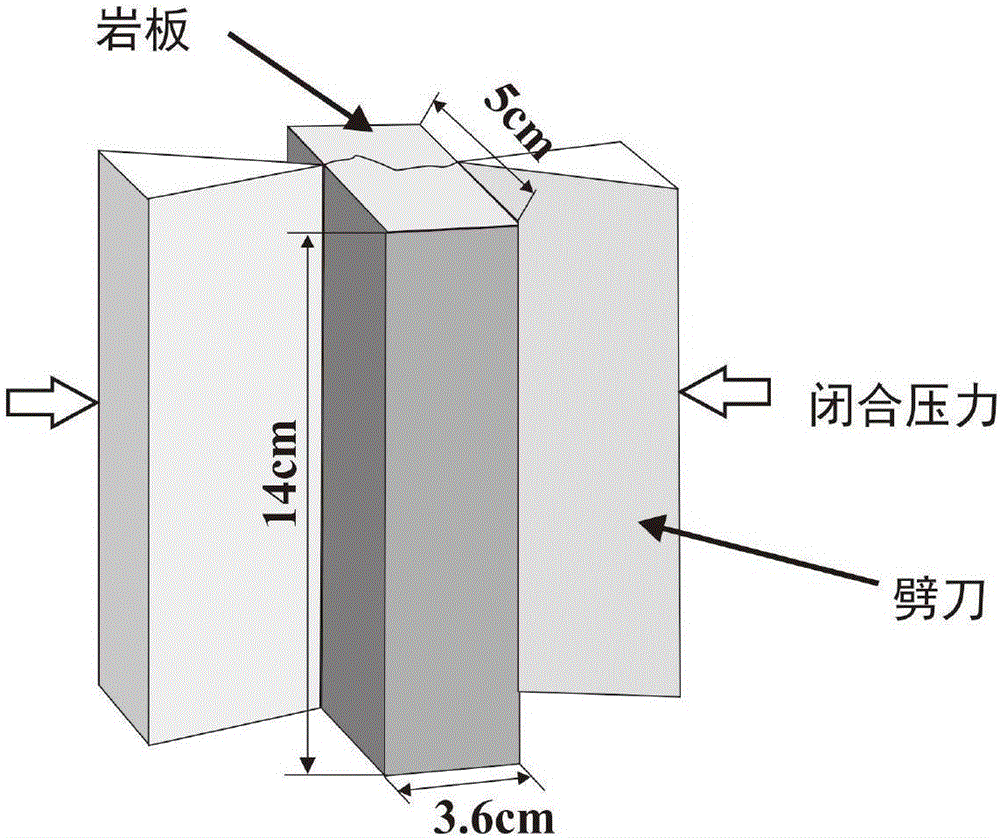

Test method for compact reservoir volume fracture conductivity

ActiveCN106593429AReal simulation of diversion capacityBorehole/well accessoriesGeomorphologyCoupling

The invention discloses a test method for compact reservoir volume fracture conductivity. The test method comprises the following steps that compact reservoir materials used for making a test piece are selected and prepared into a cuboid rock board; the rock board in the first step is divided in half under reservoir closed pressure, a rough fracture face is scanned through a laser scanner, and a scanning fractal result is output; the rock board divided in half is subjected to conducting form processing; a pressure measuring hole, a fluid inlet and a fluid outlet are correspondingly drilled in the positions of the central lines of the middle and the two ends of the rock board, and the rock board is placed in a conducting room; and the confining pressure of the conducting room is increased to reservoir effective closed pressure, and compact reservoir volume fracture conductivity data are obtained and combined with the measured roughness of the fracture face in the second step to conduct analysis. According to the test method, on the one hand, quantitative analysis of the roughness of the fracture coupling face is achieved to enable the roughness of the fracture coupling face to be compared and analyzed with other factors which influence flow conductivity, on the other hand, the fracture conductivity of the rough fracture face in different shear dislocations and different paved-sand concentrations can be simulated more truly.

Owner:SOUTHWEST PETROLEUM UNIV

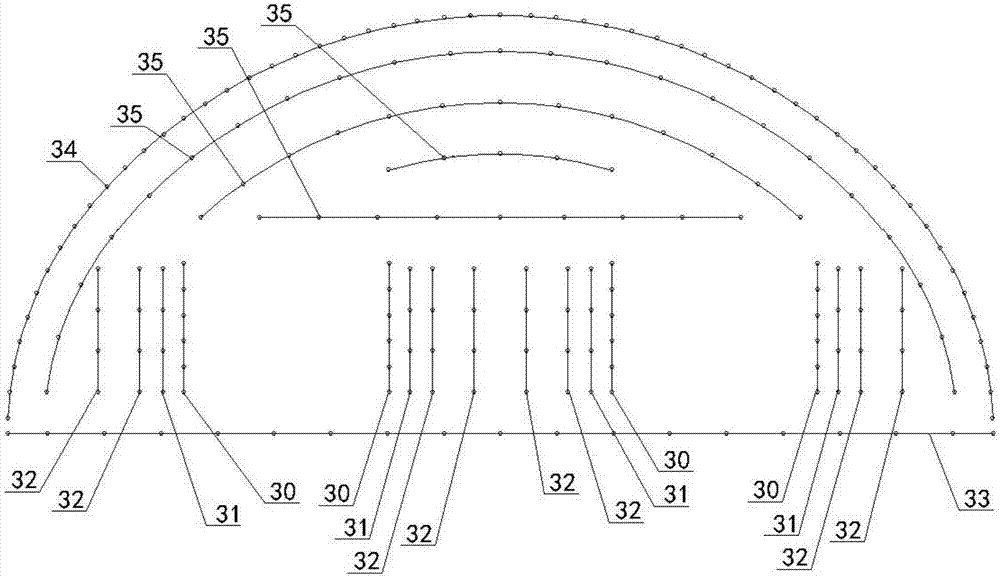

Double-side wedge-shaped cutting, tunneling and detonating method of especially-big fracture surface tunnel

PendingCN107289827AImprove construction efficiencyImprove integrityBlastingEngineeringMechanical engineering

The invention discloses a double-side wedge-shaped cutting, tunneling and detonating method of an especially-big fracture surface tunnel. The to-be-excavated especially-big fracture surface tunnel is divided into an upper step and a lower step to be constructed; as for a to-be-excavated rock mass of the upper step of the tunnel, the double-side wedge-shaped cutting and subsection millisecond delay detonating method is used for excavation; according to double-side wedge-shaped cutting, double-side cutting zones are symmetrically distributed at the lower middle portions of the two sides of a face center line of the upper step, the cutting zones are vertical columnar zones with the plane shapes being wedge shapes, and groove cavities formed by cutting and detonating can provide sufficient smashing expansion space for detonating of various types of shot holes; and according to subsection millisecond delay, millisecond delay detonating is carried out at the positions between rows, detonating of various types of shot holes is carried out, the using rate of various types of shot holes is effectively improved, and the design footage is guaranteed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Composite acidizing and fracturing liquid and preparation method thereof

The invention relates to composite acidizing and fracturing liquid and a preparation method thereof. The fracturing liquid disclosed by the invention is prepared through adding thickened acidizing fluid and additives based on water-based fracturing base liquid and foamed fracturing base liquid and crosslinking by a crosslinker, wherein the water-based fracturing base liquid comprises carboxymethyl cellulose, chromium sulfate and polyacrylamide; the foamed fracturing base liquid comprises urea and a surfactant; the additives comprise a clay stabilizer, a microbicide and a discharge aiding agent; the thickened acidizing fluid is 12% hydrochloric acid, and a mixed solution of polyacrylamide and konjac glucomannan is added into the thickened acidizing fluid, so that the viscosity of the acidizing fluid is improved, the fracture face diffusion capacity of the acidizing fluid is lowered, and meanwhile, a colloidal reticular structure is formed to prevent hydrogen ions from moving, thus a retarding effect is exerted; in addition, the acidizing and fracturing liquid further comprises the crosslinker and the balance of water. The composite acidizing and fracturing liquid has the characteristics of relatively good high-temperature resistance and shear resistance and low damage.

Owner:CHANGZHOU UNIV +1

Mechanical matched construction method for full fracture surfaces and micro steps of IV and V stage weak surrounding rocks of tunnel

ActiveCN111997622AFast constructionImprove working accuracyUnderground chambersHydro energy generationTremieFracture (geology)

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com