Tailor-welded blank roll bending formation device and method thereof

A technology of tailor-welded blanks and welding devices, which is applied in the field of tailor-welded blank roll forming method and its devices, and can solve the problems of plate springback and insufficient continuous production, high manufacturing cost of stamping dies, and offline time of punches, etc. , to achieve the effect of flexible organization and production, improved carrying capacity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

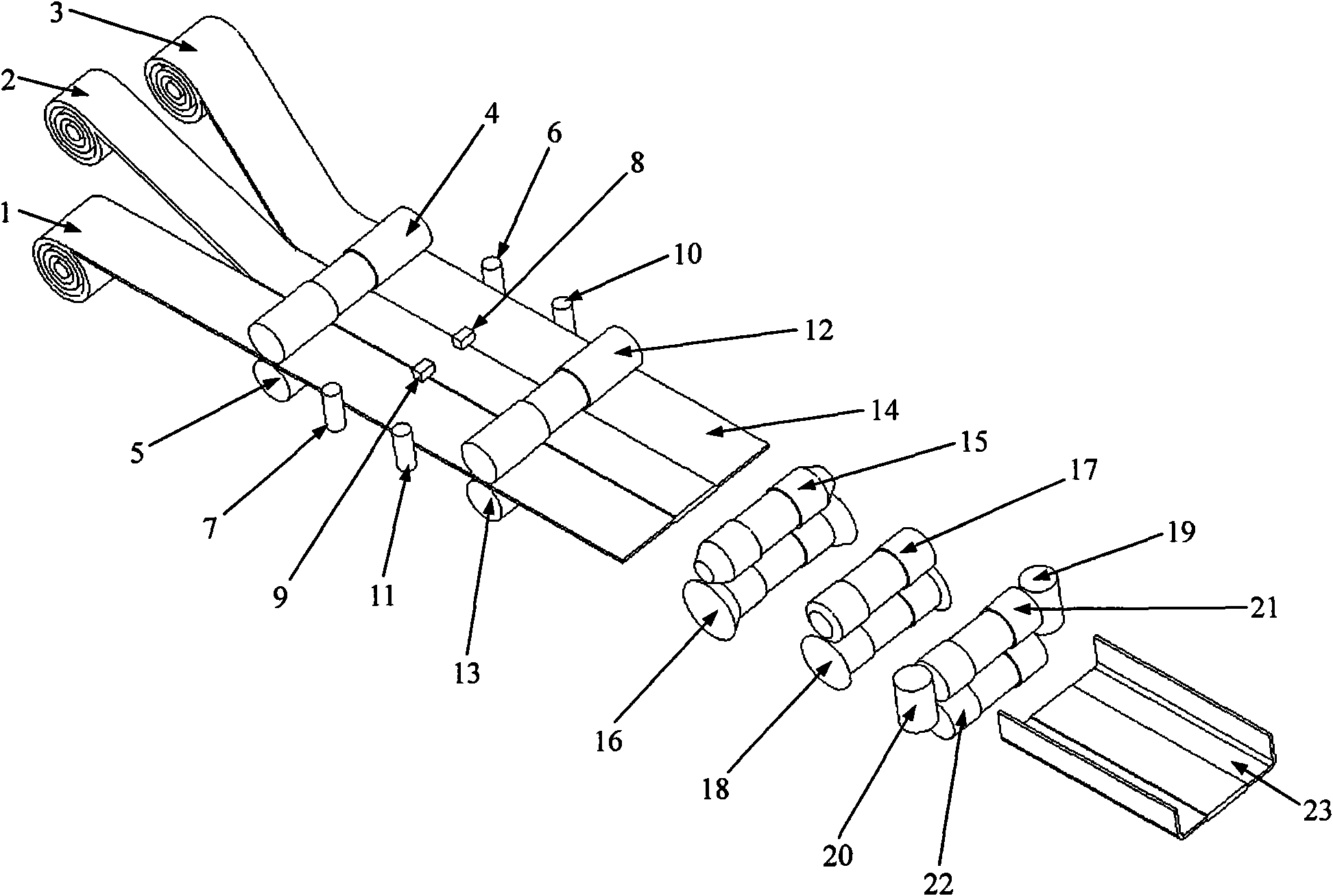

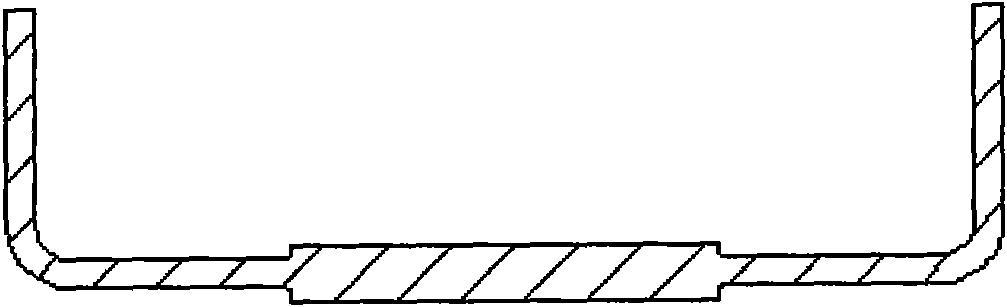

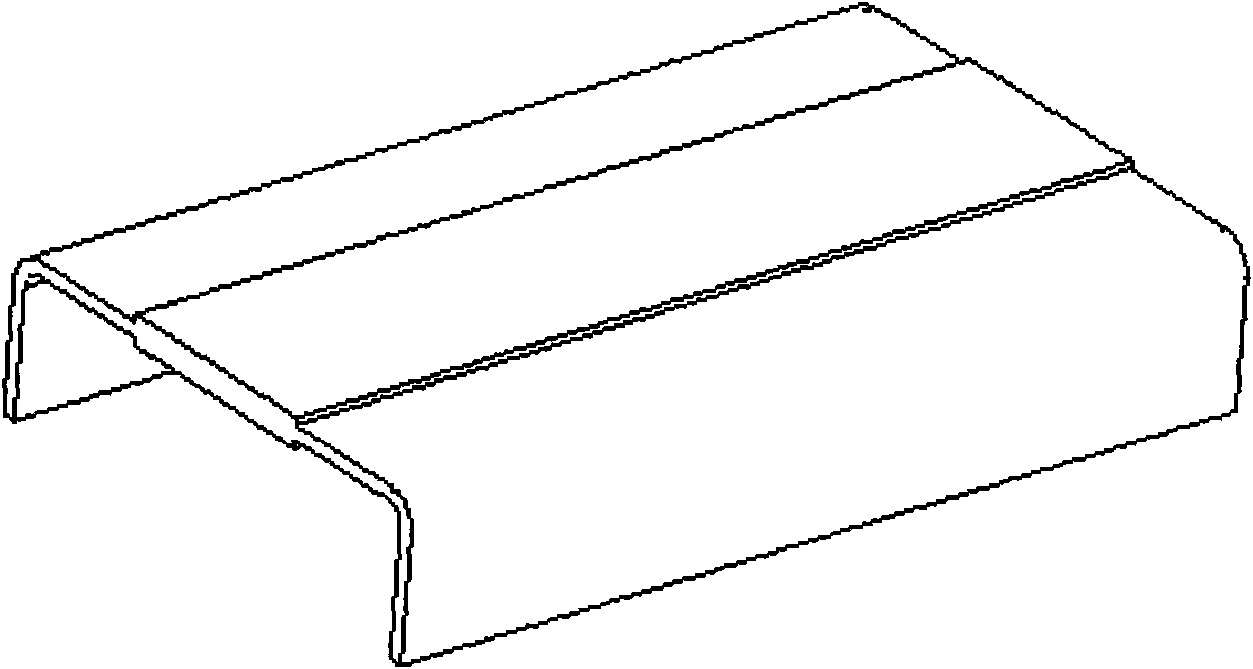

[0026] Plate 1 is high-strength stainless steel ZG10Cr13 with a thickness of 0.8mm and an initial size of 1100mm in length and 40mm in width; plate 2 is Q235 with a thickness of 2mm and an initial size of 1100mm in length and 60mm in width; plate 3 is high-strength stainless steel ZG10Cr13 with a thickness of 0.8mm, the initial size is 1100mm in length and 40mm in width, and it is formed into a U-shaped cross-section profile with a 90-degree angle between the vertical side and the web, such as Figure 2A , Figure 2B shown.

[0027] In the tailor welded blank roll forming device, the welding device uses a neodymium: yttrium aluminum garnet laser, the wavelength of the neodymium: yttrium aluminum garnet laser is 1064nm, and two welding devices 8 and 9 are arranged laterally. Adjust the roller gap between the upper and lower positioning rolls 4 and 5 before welding and the upper and lower positioning rolls 12 and 13 after welding to 2 mm in the middle part and 0.8 mm in both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com