Patents

Literature

40results about How to "Realize online continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

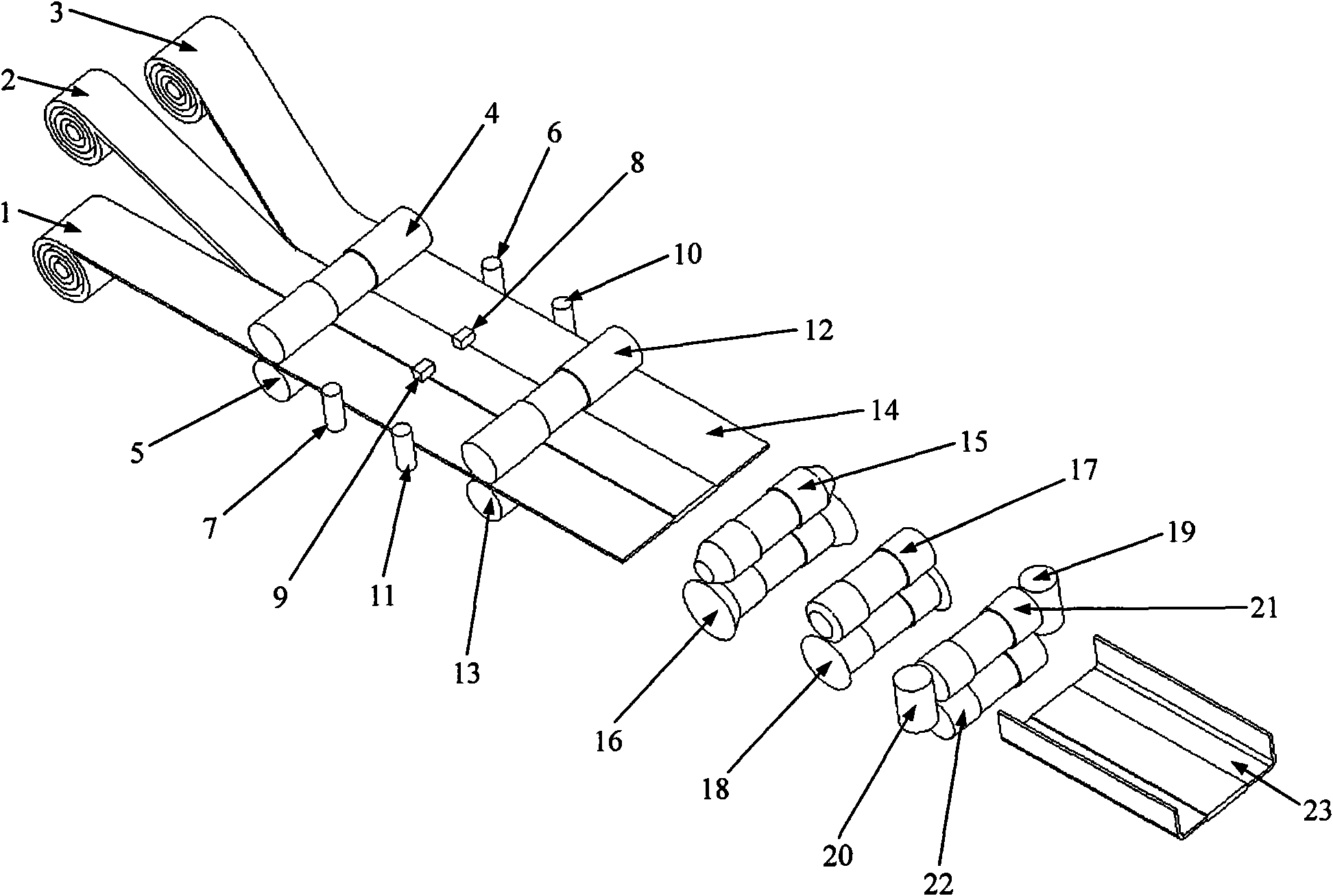

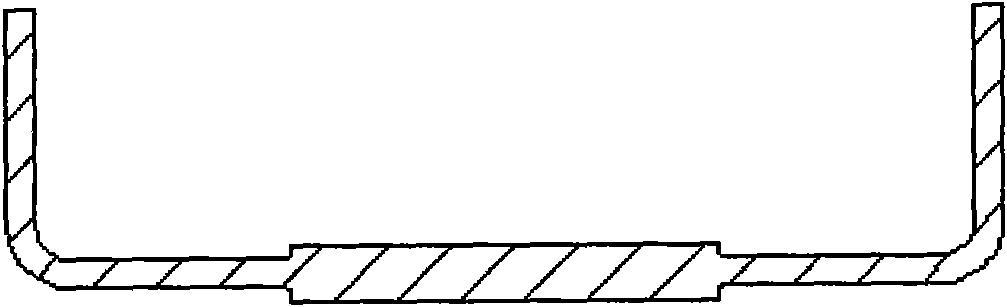

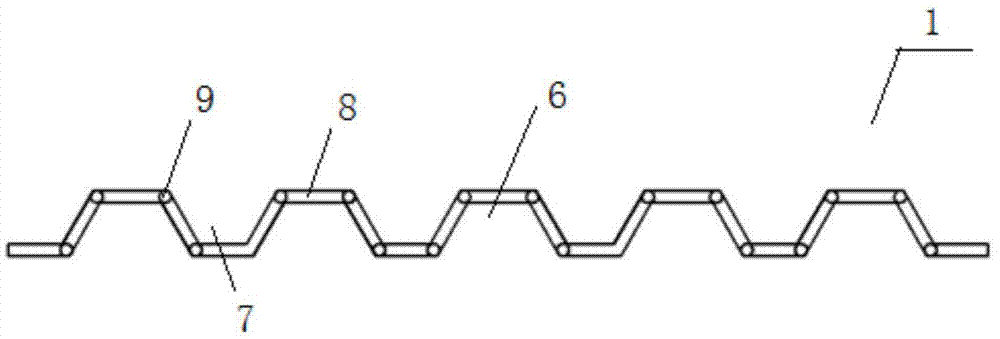

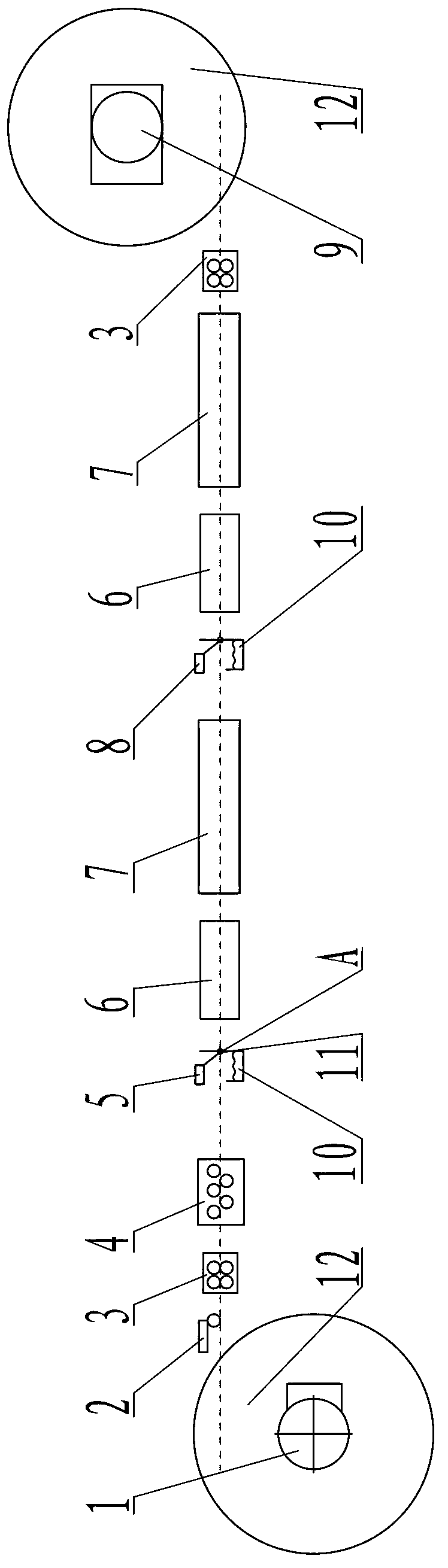

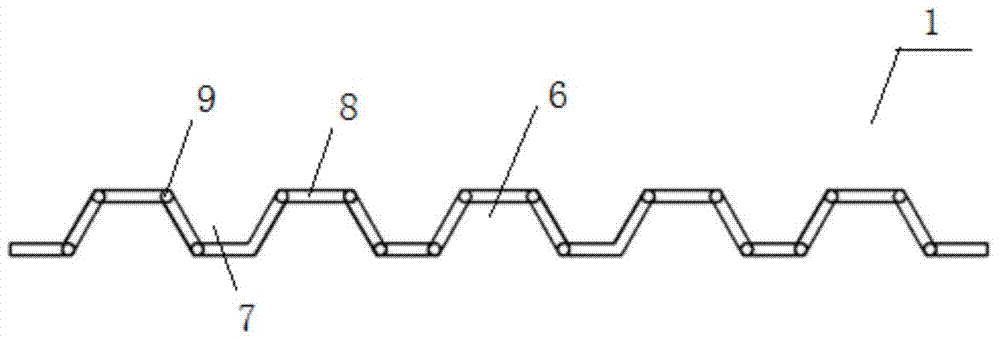

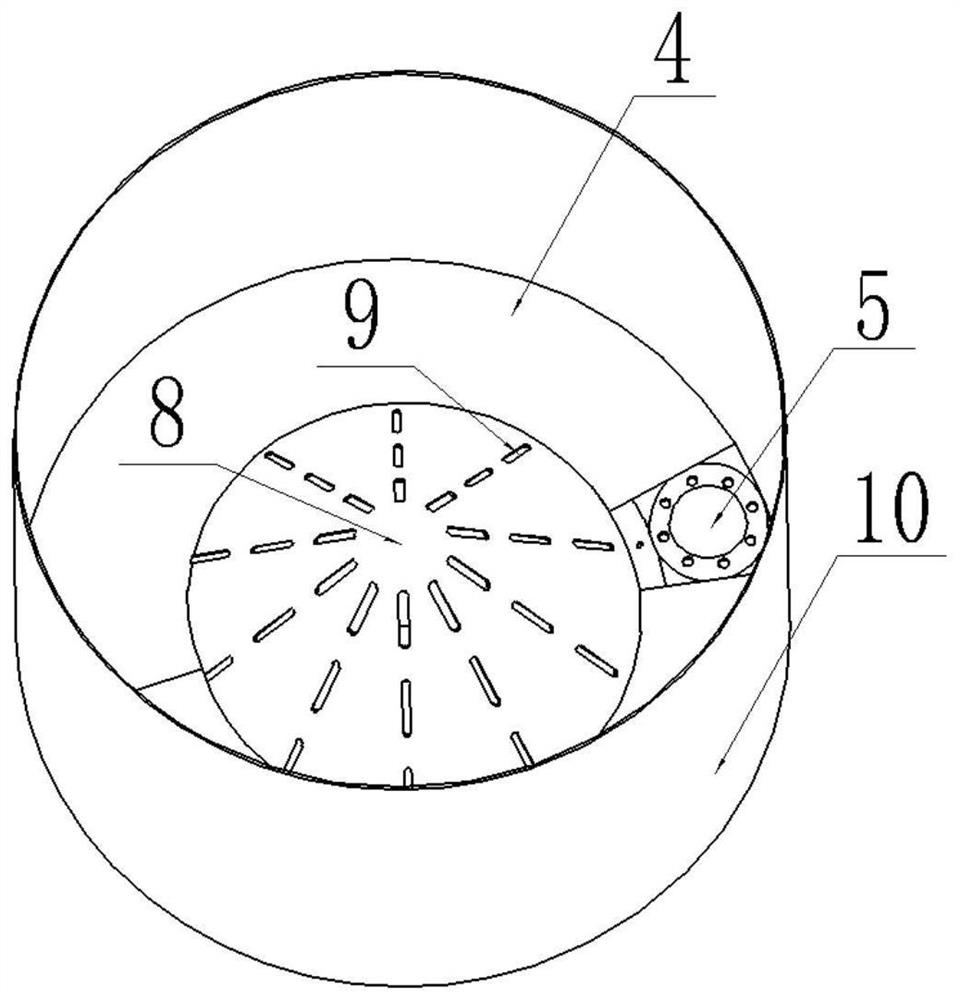

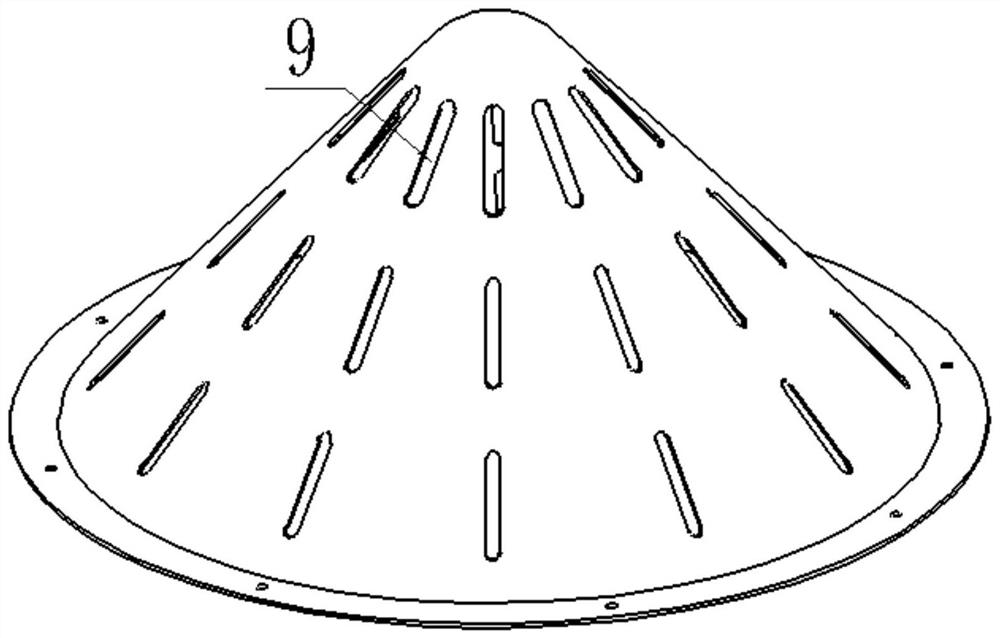

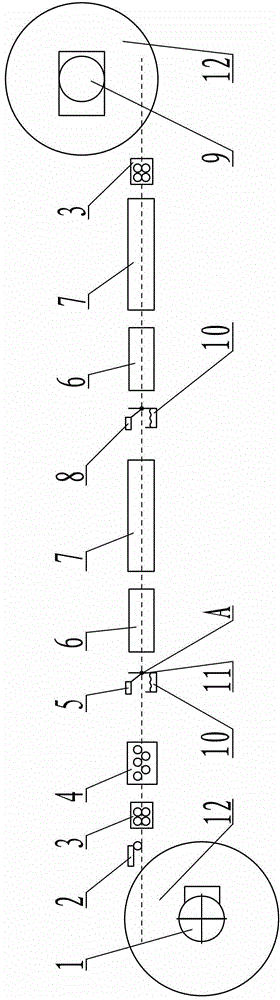

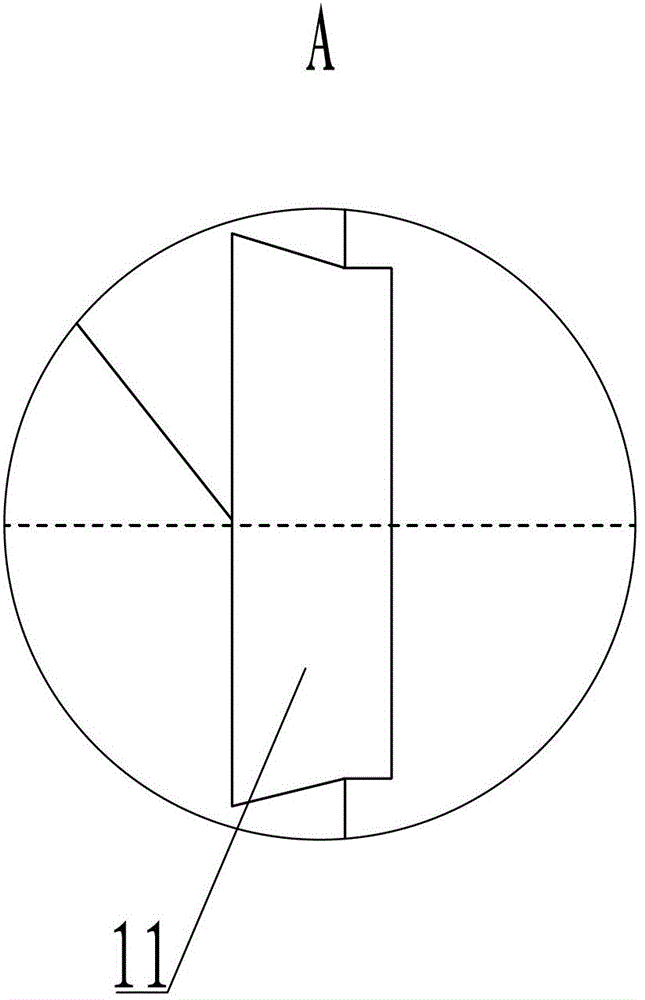

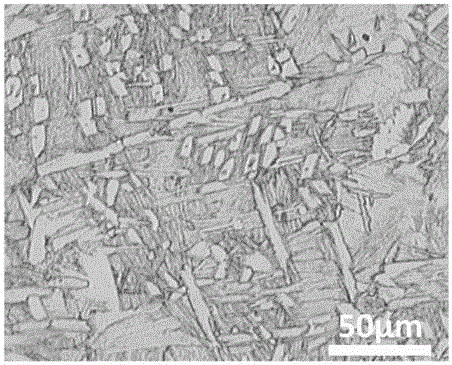

Tailor-welded blank roll bending formation device and method thereof

InactiveCN101664879ARealize online continuous productionIncrease productivityMetal-working feeding devicesWelding/cutting auxillary devicesPunchingEngineering

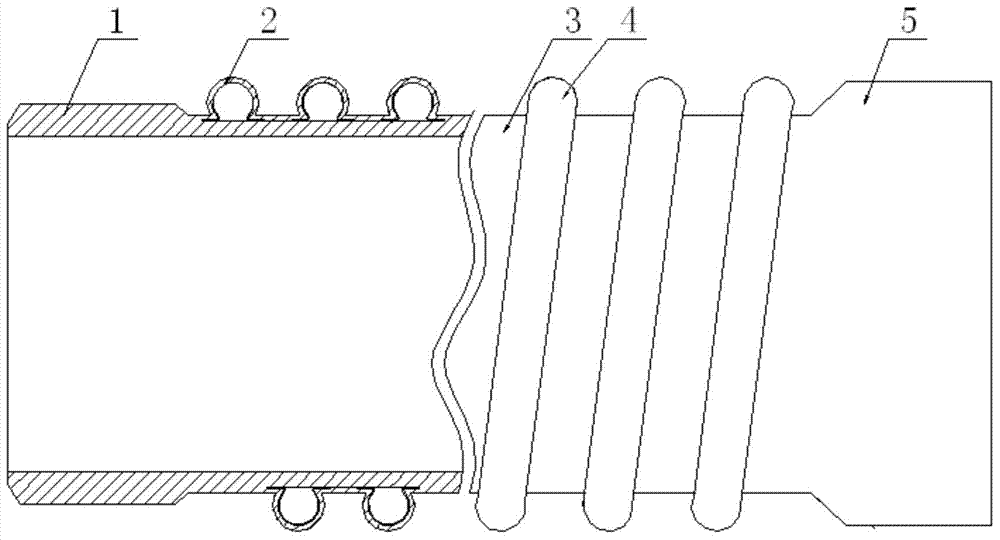

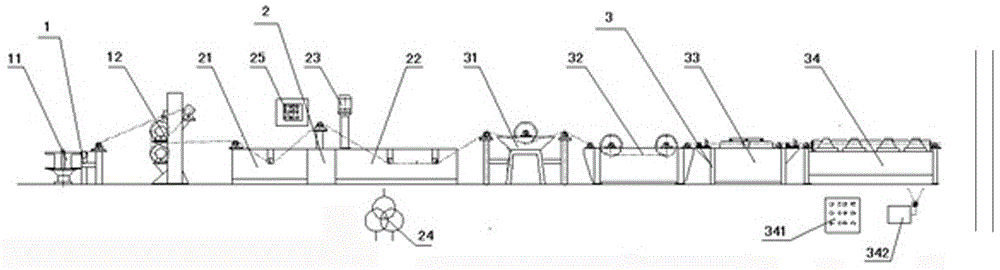

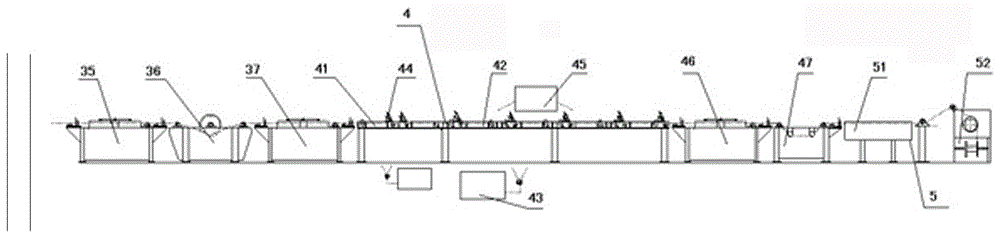

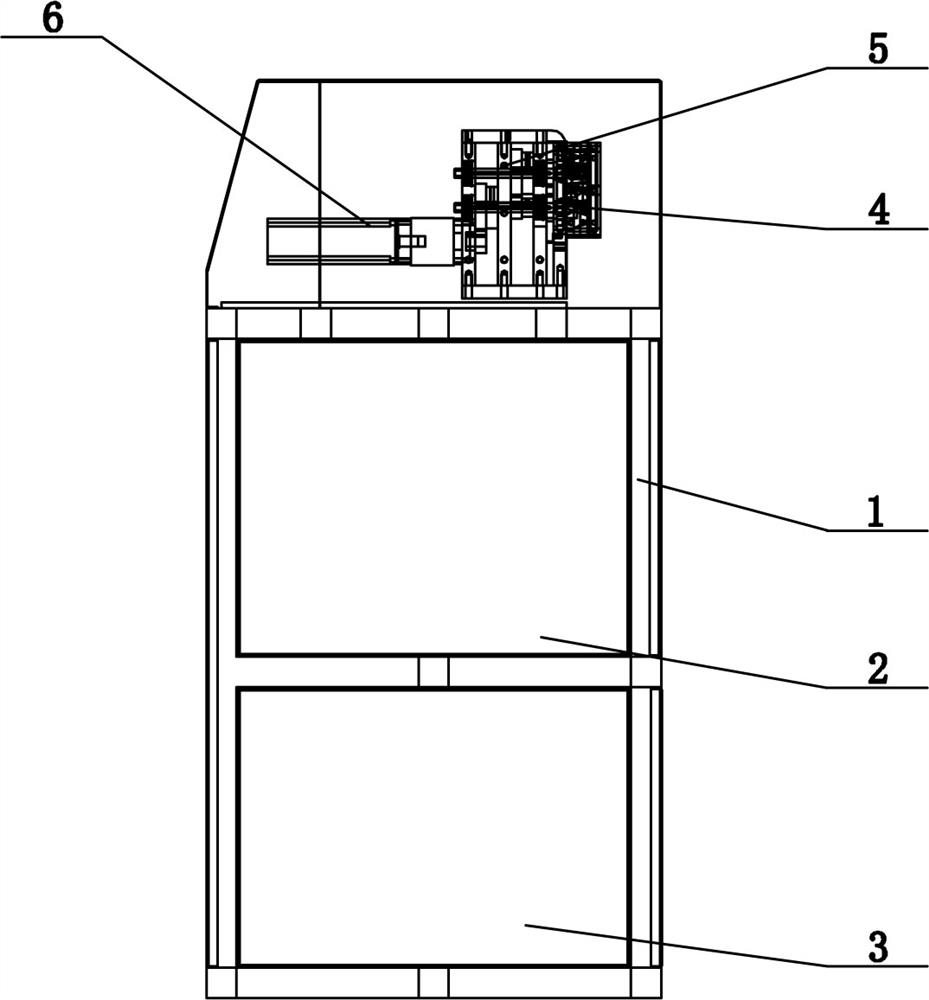

The invention relates to a tailor-welded blank roll bending formation device and a method thereof, belonging to the roll bending formation technology and equipment field. The tailor-welded blank rollbending formation device comprises before-welding upper and lower locating rollers, before-welding left and right locating rollers, after-welding welding device, after-welding left and right locatingrollers, after-welding upper and lower locating rollers and a formation roller bank. By adopting the device, two or more than blanks with different thickness, performance, material and surface coatingare welded together by the before-welding upper and lower locating rollers, the before-welding left and right locating rollers and the welding device, and then carry out roller bending formation through the after-welding left and right locating rollers, after-welding upper and lower locating rollers and the formation roller bank. Compared with the existing punching technology, the device can continuously produce tailor-welded blanks with any cross section in a high-efficiency and high-quality way.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

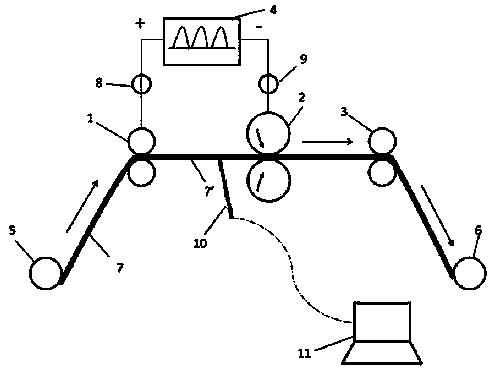

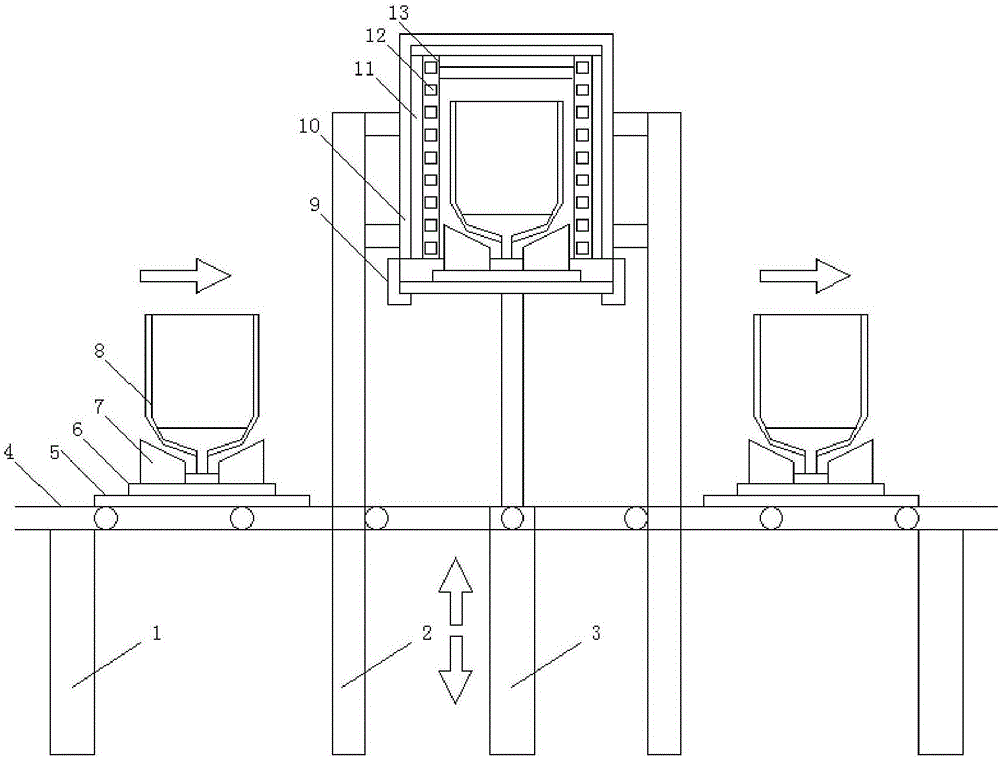

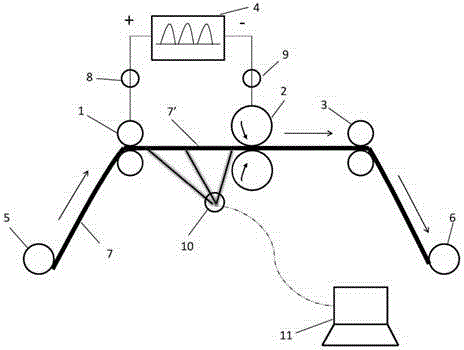

Method for promoting phase change strengthening and toughening of two-phase titanium alloy strip by using pulse current and strip

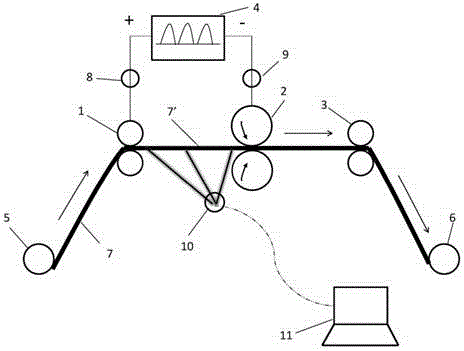

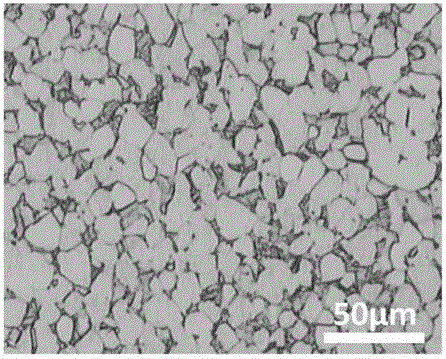

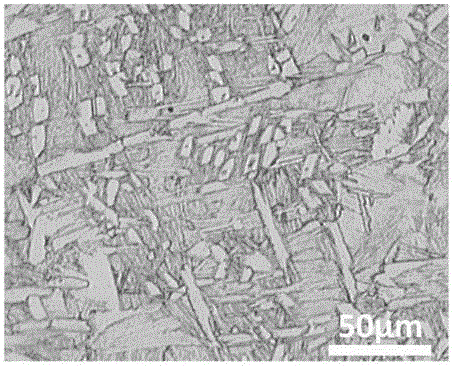

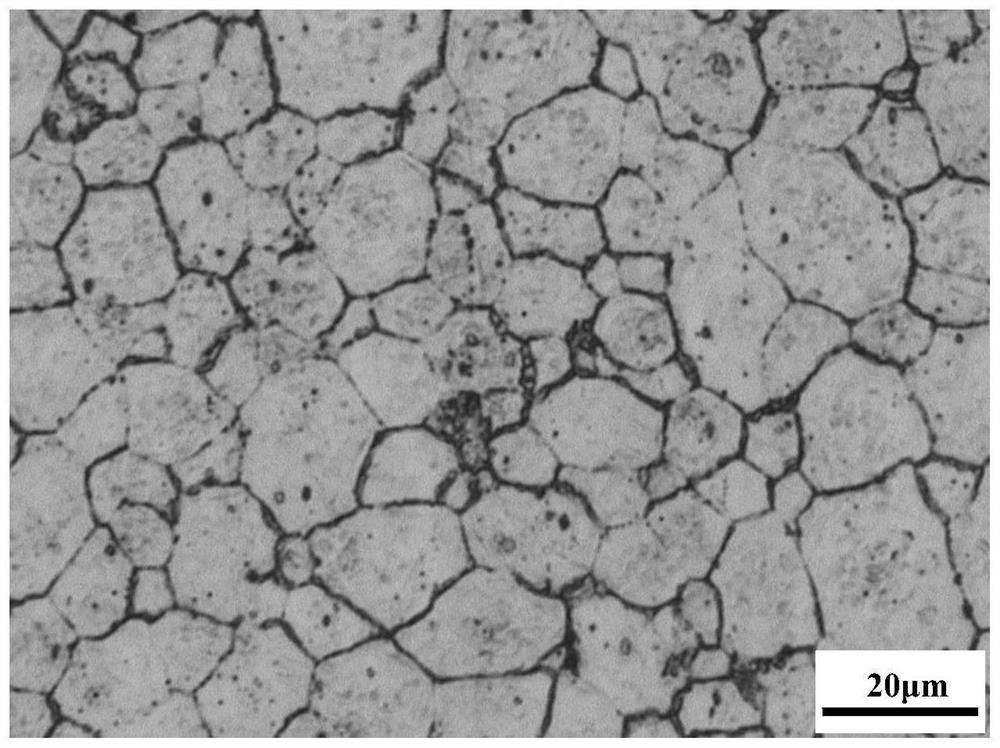

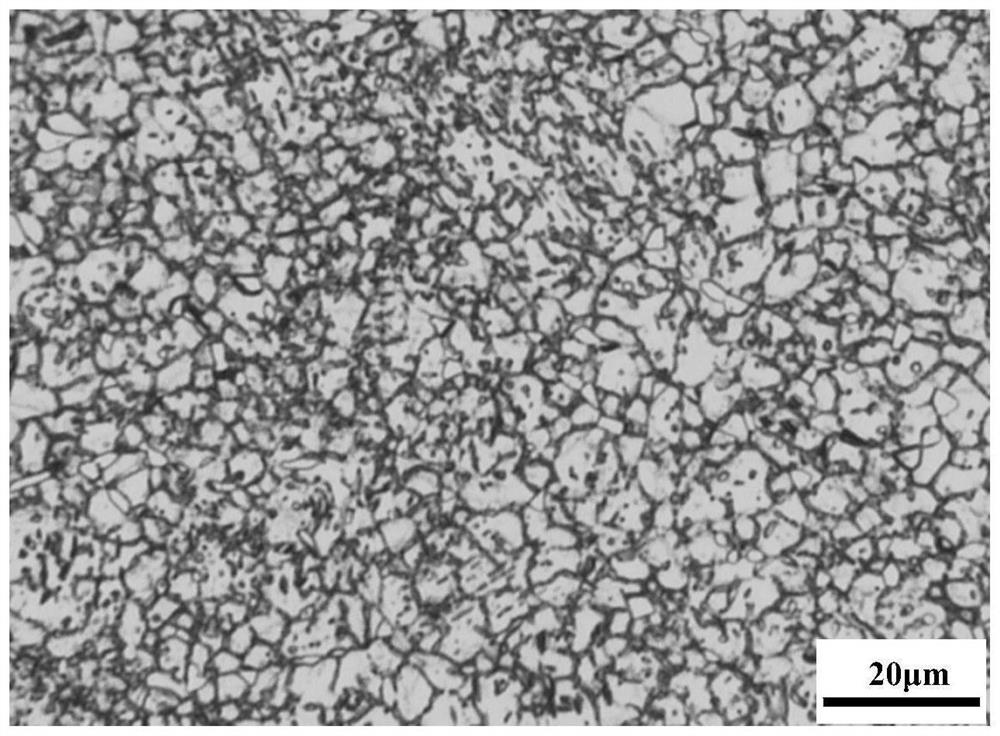

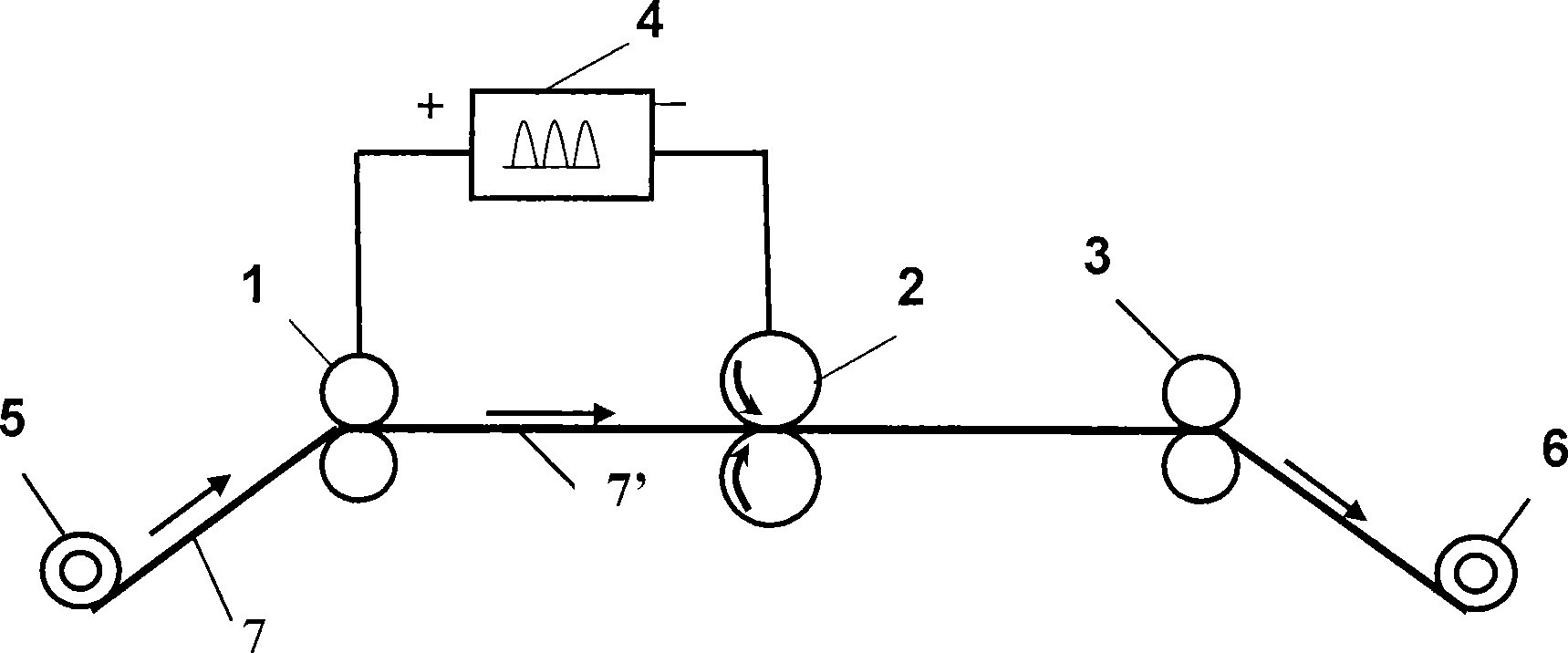

The invention discloses a method for promoting phase change strengthening and toughening of a two-phase titanium alloy strip by using pulse current. The method comprises the following steps: tensioning a TC4 titanium alloy strip through a decoiling device, a winding device, a roller and a support roller of a rolling mill, so that the strip is in tightly elastic contact with the roller; driving the strip to transmit at the speed of 150-800mm / min through friction force by virtue of the roller; inputting the pulse current into a power-up area section of the strip through the roller, the support roller and the like, wherein the pulse current generates a joule heating effect and a non-thermal effect in the power-up area section of the strip within 12-18 seconds, so that the internal microstructure of the strip turns into a two-phase long-axis structure or a two-phase dual-state structure from an original quasi-single phase thick equiaxed structure; and then cooling by natural air at room temperature. Through adjustment of parameters of the pulse current, the TC4 strip with the two-phase long-axis structure and the two-phase dual-state structure can be quickly obtained, thus the ductility is increased; the treatment temperature is far lower than 960 DEG C of a traditional thermal treatment process; the processing process of the titanium alloy strip can be finished without a short period of time at relatively low temperature without an oxidation phenomenon; and therefore, the method is energy-saving, environmentally friendly, safe and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

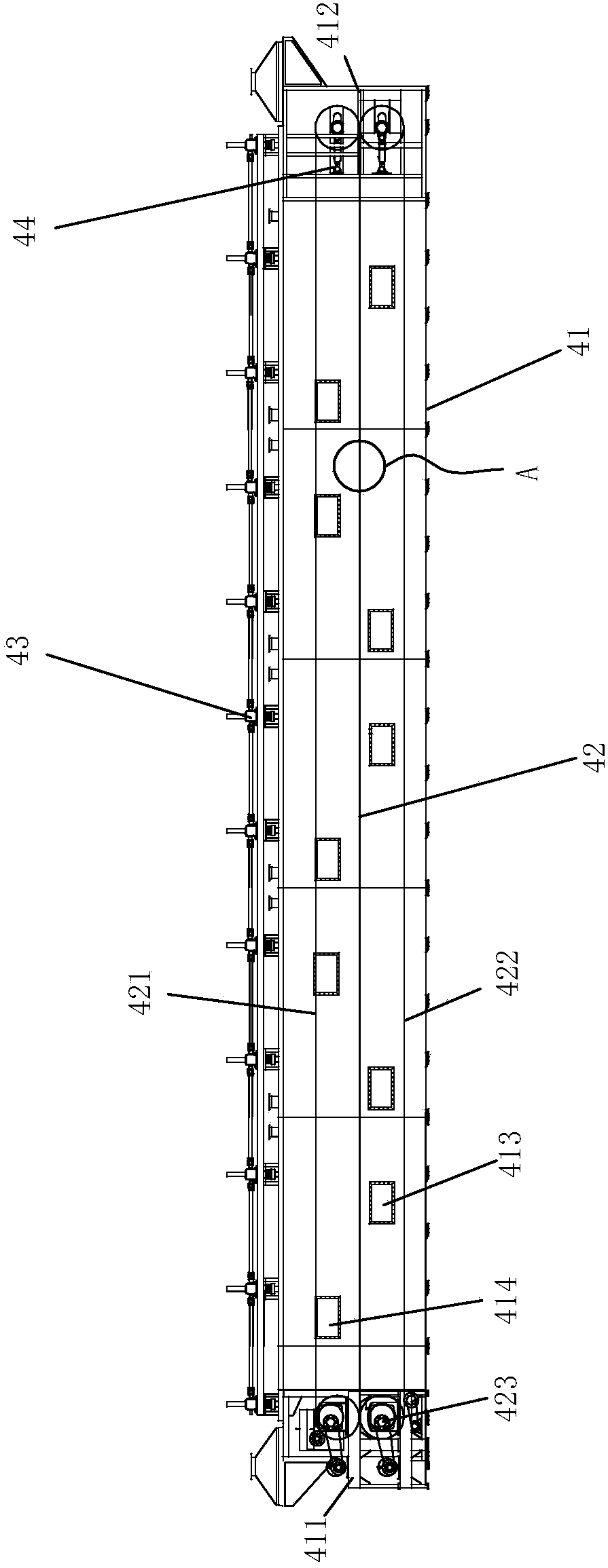

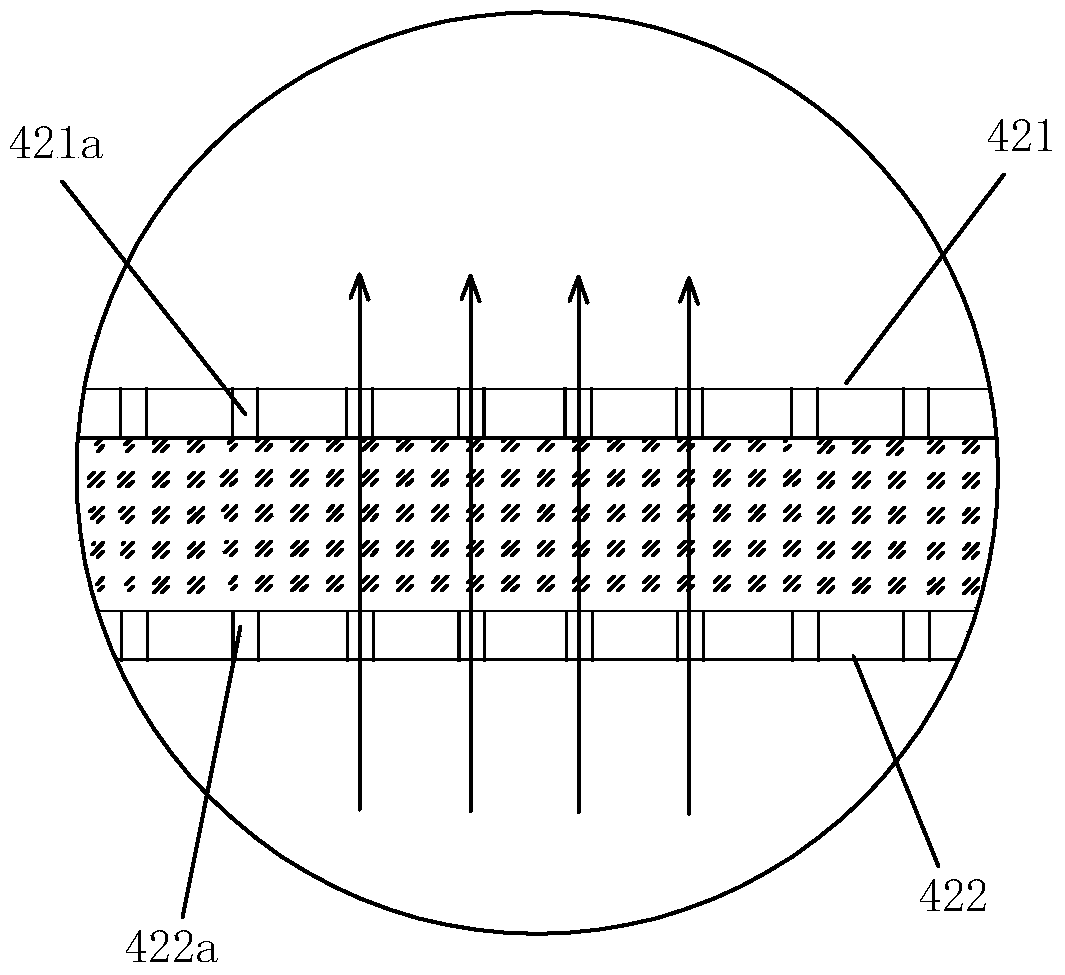

Online dry method glass wool vacuum insulated panel core material production system and method

ActiveCN106149196ARealize online continuous productionIncrease productivityNon-woven fabricsState of artEngineering

The invention discloses an on-line dry-process glass wool vacuum insulation board core material production system, which includes a melting furnace, a centrifuge, a cotton collector and a hot-pressing setting device. The hot-press setting device adopts the upper and lower chain plates to form a pressing gap, and the glass wool is pressed in the pressing gap, and can be continuously hot-pressed during the transmission process. The present invention also provides a production method based on the above production system. Compared with the prior art, the invention realizes on-line continuous production, has high production efficiency, and the prepared glass wool core material has stable structure and good heat insulation effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

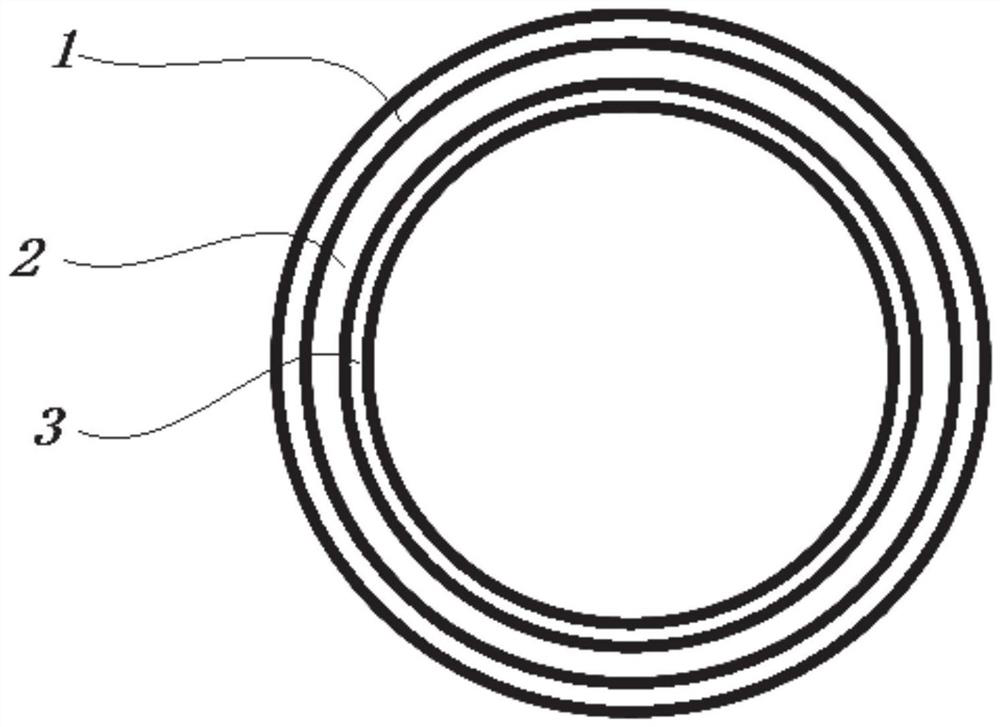

Polyethylene wound structured wall pipe with steel framework and method for manufacturing polyethylene wound structured wall pipe

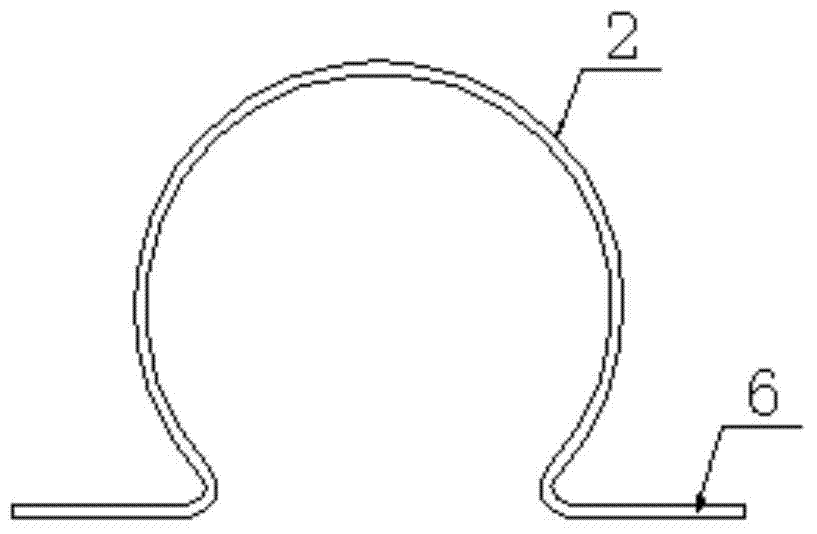

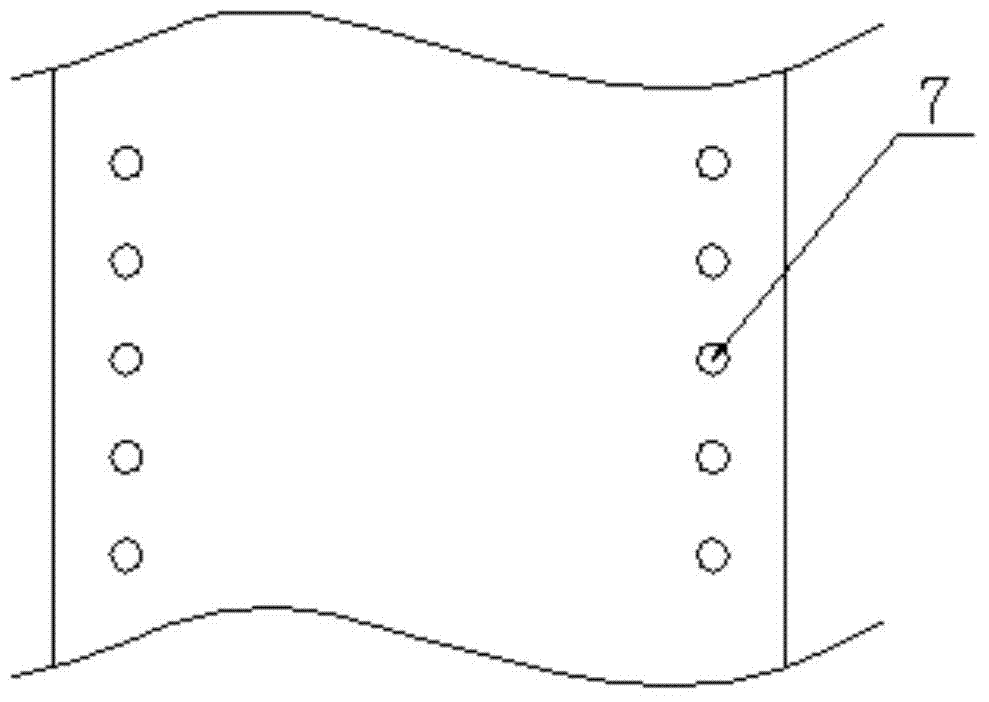

InactiveCN103925427AReduce weightImprove rigidityRigid pipesTubular articlesEngineeringContinuous production

The invention relates to a polyethylene wound structured wall pipe with a steel framework. The polyethylene wound structured wall pipe comprises an inner wall layer and an outer wall layer. The inner wall layer is a continuous solid wall pipe, platy polyethylene strips are spirally wound on drum molds, and the edges of the various adjacent strips are sequentially overlapped on one another and are combined with one another to form the continuous solid wall pipe. The polyethylene wound structured wall pipe is characterized in that the framework of the outer wall layer is made of steel strips, omega-shaped sections of the steel pipes are set by means of bending, the polyethylene strips cover the outer surfaces of the steel strips and are spirally wound on convex reinforcing ribs formed on the outer surface of the inner wall layer, and the convex reinforcing ribs spirally cross overlapped combined gaps among the edges of the various adjacent platy polyethylene strips of the inner wall layer. The polyethylene wound structured wall pipe with the steel framework and the method for manufacturing the polyethylene wound structured wall pipe have the advantages of low raw material consumption, short machining time, light product weight, low cost, high rigidity, efficiency and quality and capability of implementing online continuous production.

Owner:天津业和科技有限公司

Functional gradient titanium alloy strip and preparation method thereof

InactiveCN104630679ASimple preparation processLow costMetal rolling arrangementsHigh energyElectrical impulse

The invention discloses a method for preparing a functional gradient titanium alloy strip. The method comprises the following steps: driving a raw material strip to move at a constant speed; electrically connecting a high energy pulse power supply with a moving strip by virtue of two immovable electric contact devices which are arranged along the strip moving direction at an interval, intermittently introducing high energy pulse current with the frequency of 60-760Hz, the voltage of 10-600V and the pulse width of 10-6000mu s into the strip, and performing high energy pulse treatment on the strip; cutting the treated strip, thereby obtaining the functional gradient titanium alloy strip. The invention also provides a functional gradient TC4 titanium alloy strip which is prepared from a TC4 titanium alloy strip with single mechanical property by adopting the preparation method, and the elasticity modulus of the strip continuously changes along the length direction of the strip. The preparation process is simple and low in cost, online continuous production can be realized, and an oxidation phenomenon on the strip surface is avoided in the preparation process. The titanium alloy strip does not cause the failure and breakage phenomena and is good in mechanical properties.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

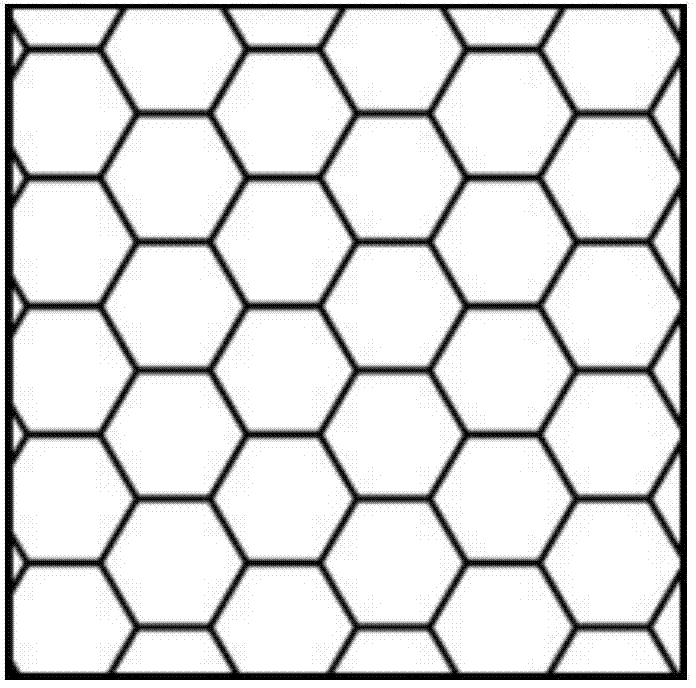

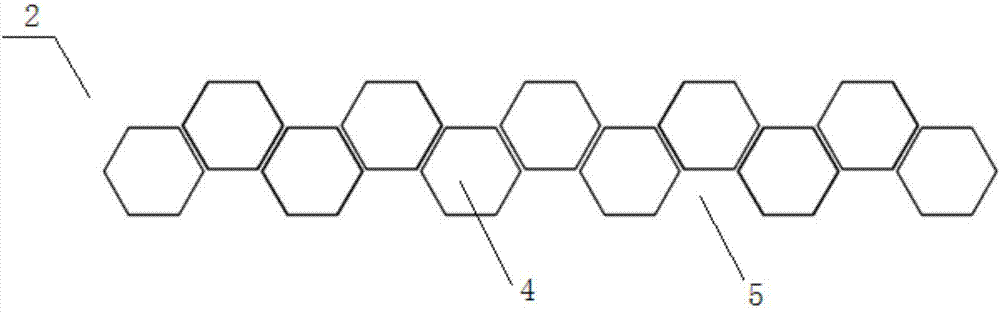

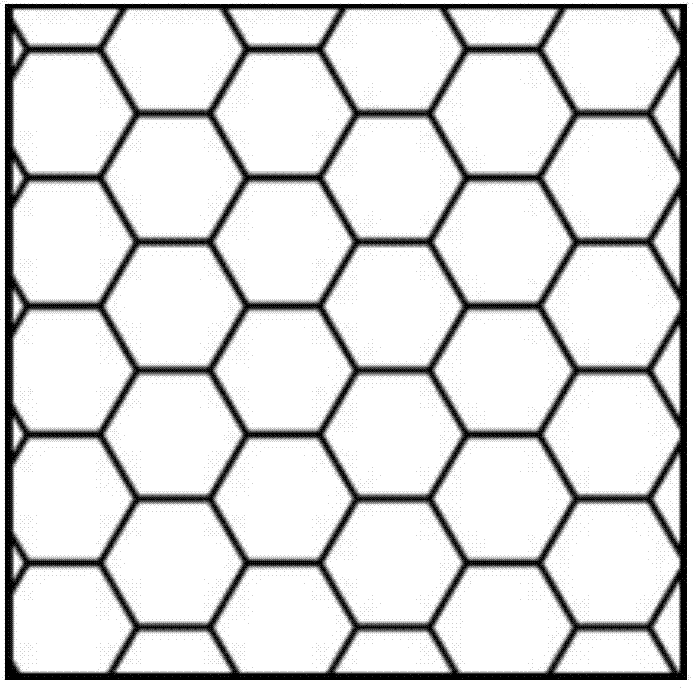

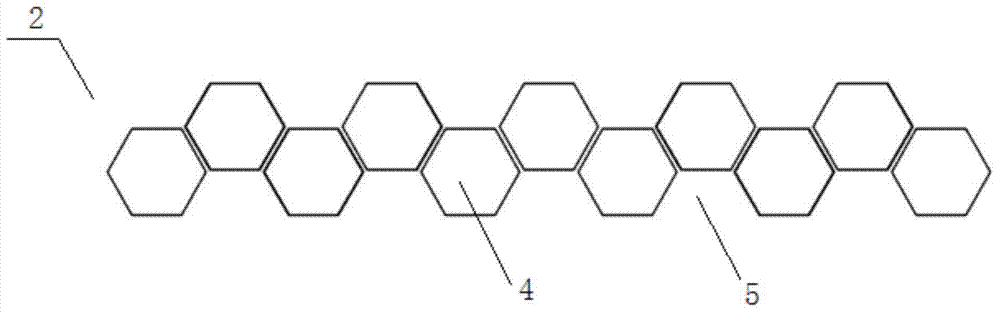

Z-direction orientation continuous fiber reinforced honeycomb core material as well as preparation process and application thereof

ActiveCN104494214AImprove acceleration performanceHigh strengthSynthetic resin layered productsLaminationMolten stateUltimate tensile strength

The invention belongs to the field of composite materials, and in particular relates to a Z-direction orientation continuous fiber reinforced honeycomb core material as well as a preparation process and application thereof. The preparation process comprises the following steps: (1) by taking long fibers which are continuous in the Z direction as a reinforcing material, piling according to the shape of the honeycomb core material so as to form the side wall of the honeycomb core material; (2) coating and moistening the fibers by using molten thermoplastic resin; (3) piling the long fiber material and the thermoplastic resin by using an co-extrusion process, cooling and fixing to form the side wall of the honeycomb core material, and repeating the piling process until the honeycomb core material is obtained. As the long fibers are directly adopted as the raw material to produce the honeycomb core material together with the thermoplastic resin in the method, the pressure resistance of the honeycomb core material in the Z direction is further improved, the Z-direction structural strength and the bearing capability of a prepared honeycomb structure core are greatly improved, and the application field is greatly widened.

Owner:山东三达科技发展有限公司

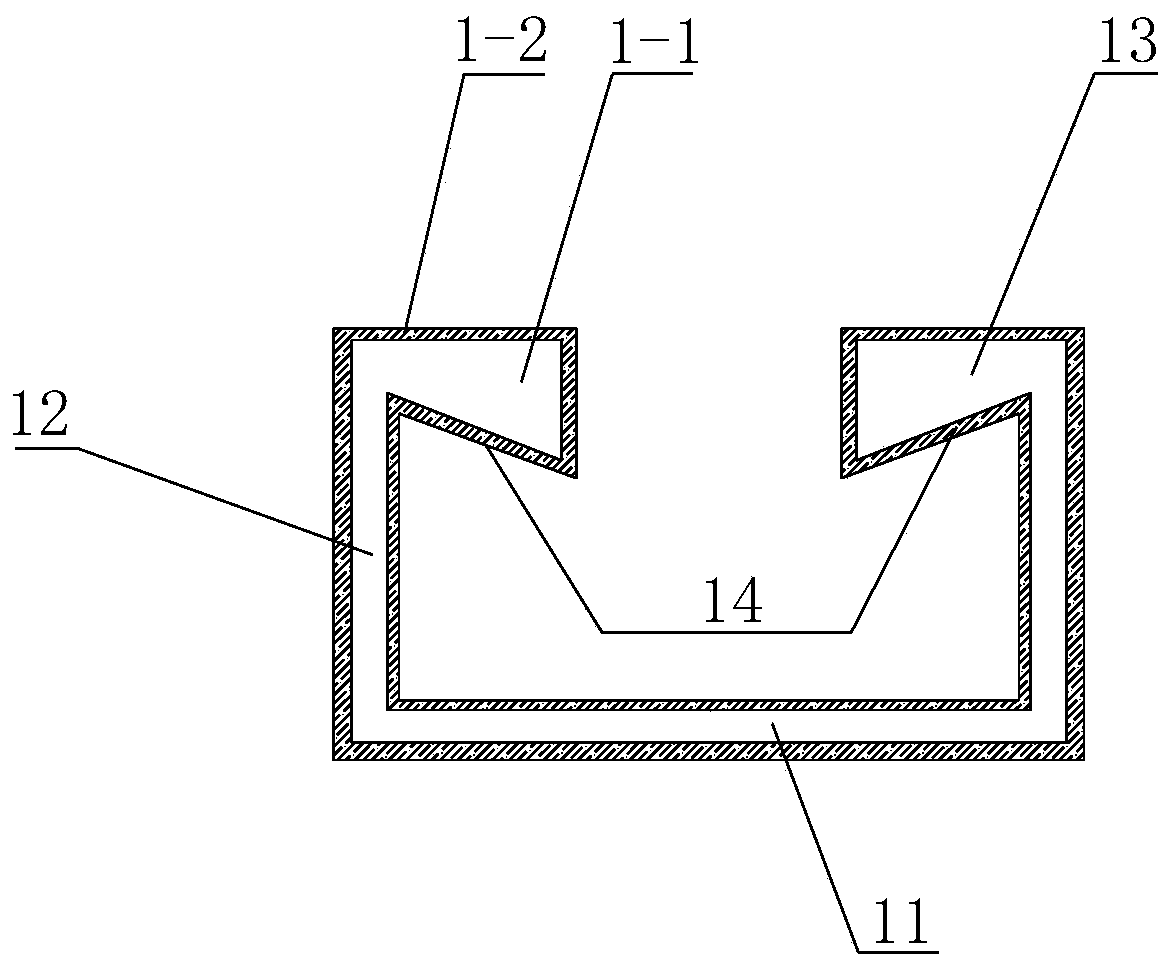

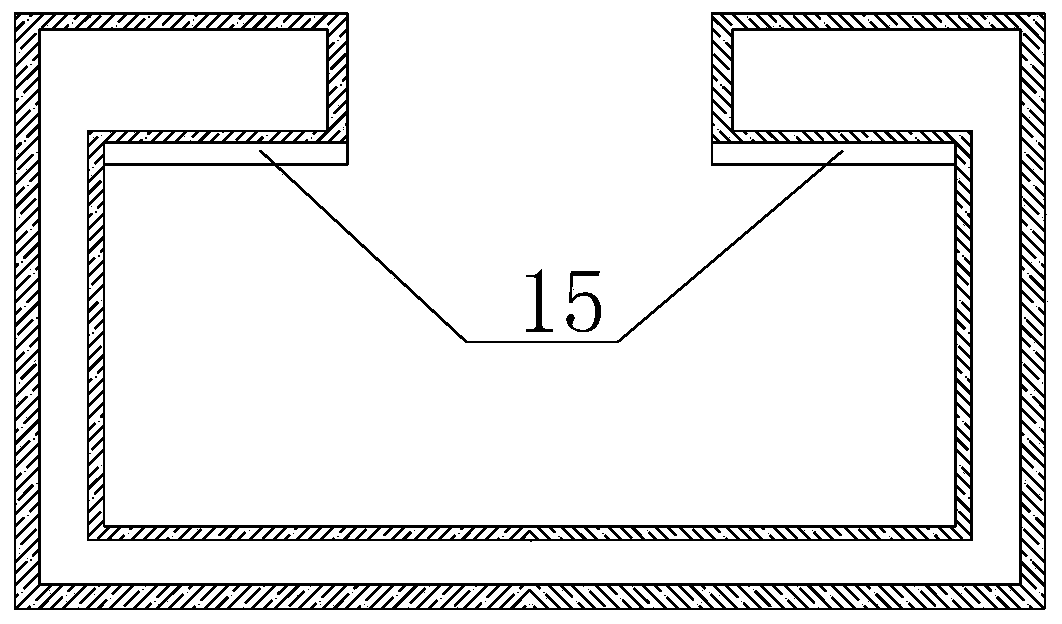

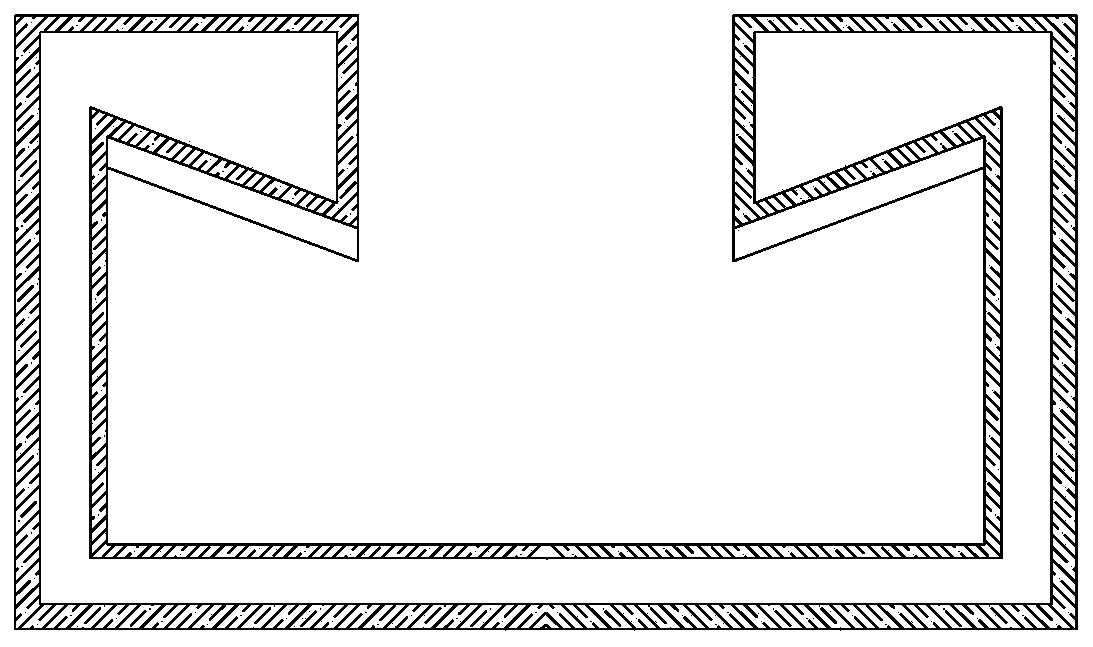

Compound steel groove, embedded groove channel and embedded groove channel production method

PendingCN111255096AGuaranteed corrosion resistanceHigh strengthLaminationLamination apparatusRock boltMaterials science

The invention relates to a compound steel groove, an embedded groove channel and an embedded groove channel production method. The compound steel groove is compounded by a core part metal and a surface layer metal, wherein the surface layer metal and the core part metal are completely coated in the compound steel groove and are subjected to metallurgical bonding. The embedded groove channel comprises the compound steel groove, a compound anchor rod and an end surface nonmetal protection layer, wherein the compound anchor rod is a cylindrical anchor rod or an I-shaped anchor rod and is compounded by an anchor rod core part metal and an anchor rod surface layer metal; and the fracture surface of the compound steel groove and the fracture surface of the I-shaped anchor rod are provided with the end surface nonmetal protection layer. According to the invention, on a premise that the anti-corrosion service life period requirement of the embedded groove channel guarantees to be met, constructional engineering cost is lowered to a maximum extent, and building safety is guaranteed.

Owner:罗显龙 +1

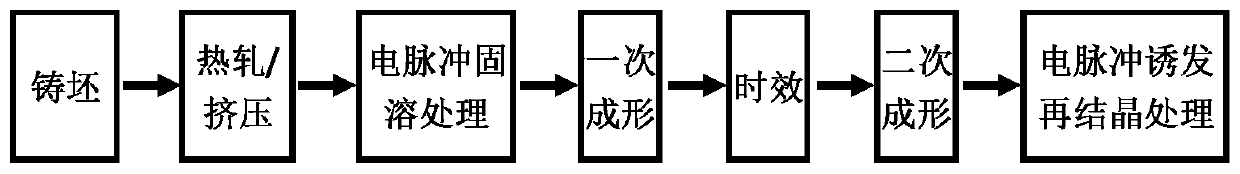

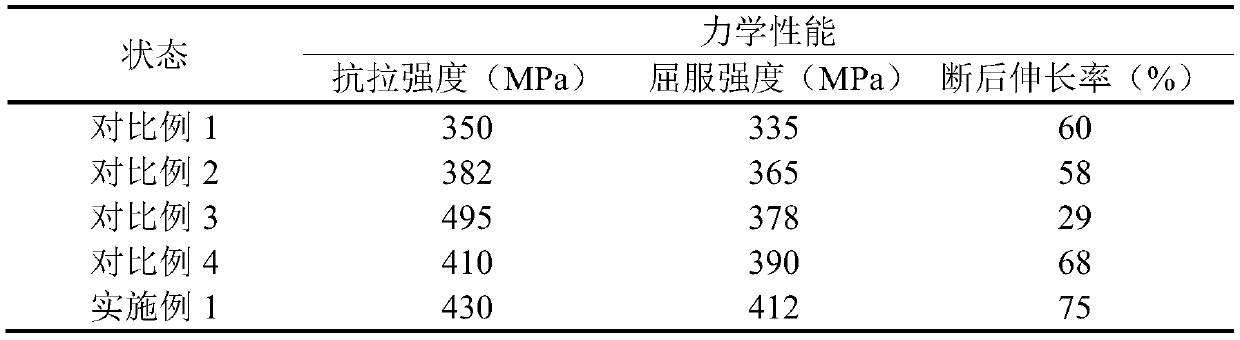

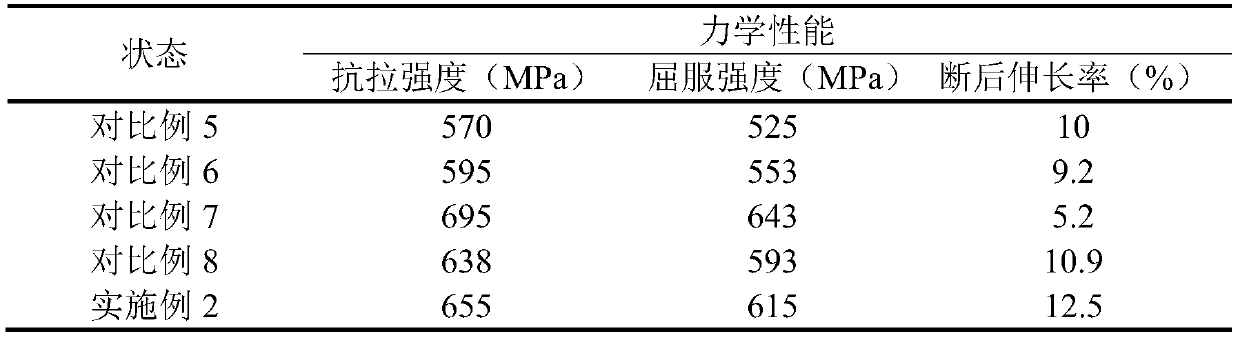

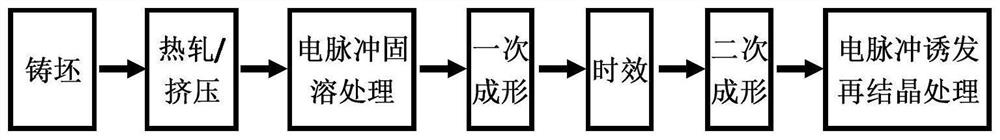

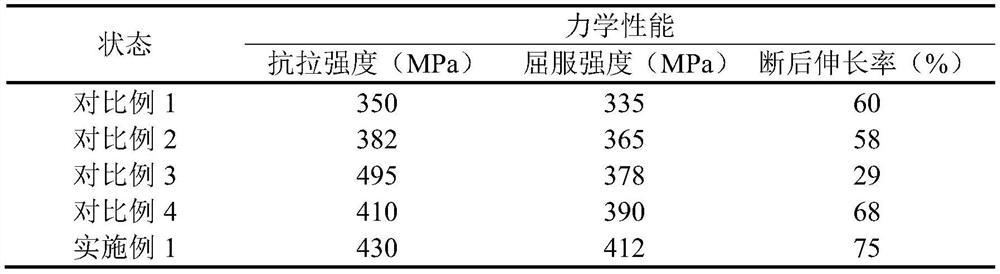

Strengthening and toughening method of non-ferrous metal material

ActiveCN111575612AImprove solid solution effect and surface qualityFacilitates diffusion of solute atomsNon-ferrous metalMetallic materials

The invention discloses a strengthening and toughening method of a non-ferrous metal material, and aims to solve the problems of easiness in oxidation, coarse grains, the limited improvement degree ofstrength and plasticity, high energy consumption and the like in a conventional heat treatment process of the non-ferrous metal material. According to the strengthening and toughening method, the non-ferrous metal material is subjected to rapid solution treatment by adopting electric pulses and then is subjected to primary forming, then alloys obtained after primary forming are subjected to agingtreatment, then the alloys subjected to aging treatment is subjected to secondary forming, and finally, electric pulse induced recrystallization treatment is carried out on a material subjected to secondary forming. Matrix grains and a precipitated phase are quickly fined through the electric pulses to prevent grain growth, so that the structure with the wee and even matrix grains and a dispersedstrengthening phase is obtained; and the high-strength and high-toughness non-ferrous metal material is prepared through the synergistic strengthening and toughening effect of the fine grains and theprecipitated phase. Compared with a traditional heat treatment process, the strength and the percentage elongation after fracture of the non-ferrous metal material prepared through the process are improved by 10% or above and 20% or above correspondingly.

Owner:CENT SOUTH UNIV

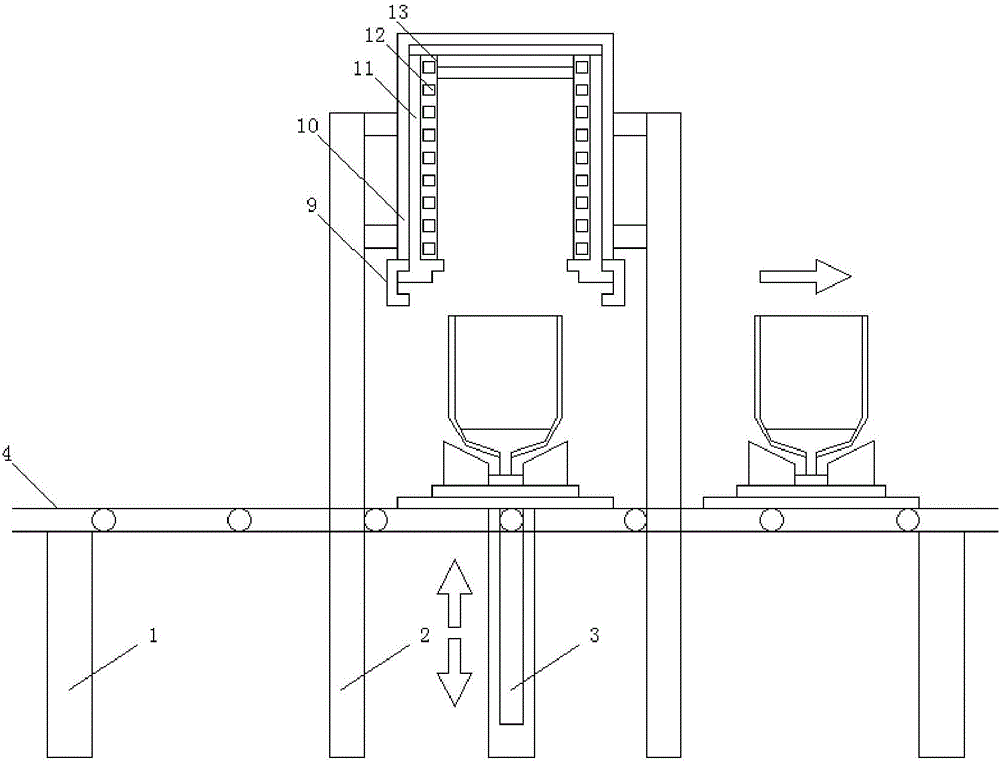

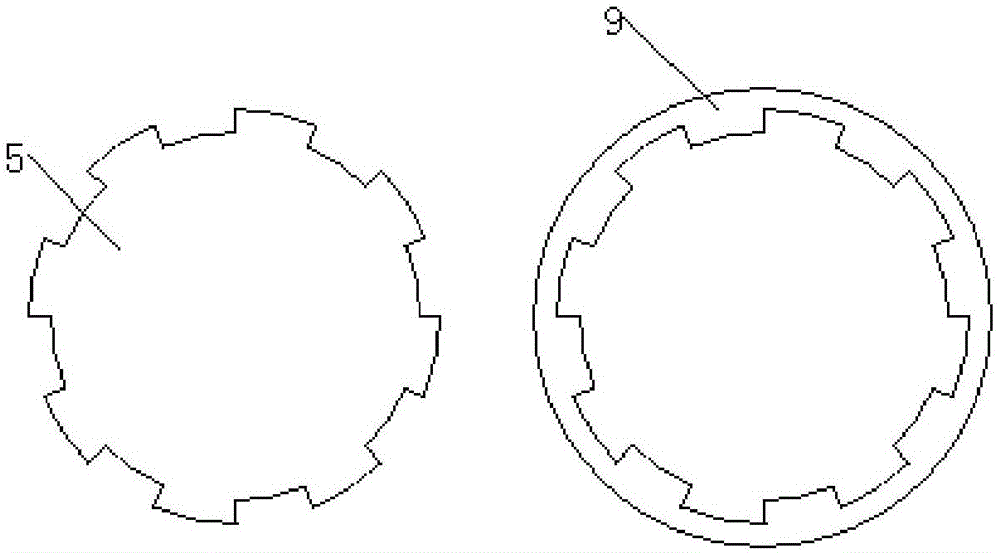

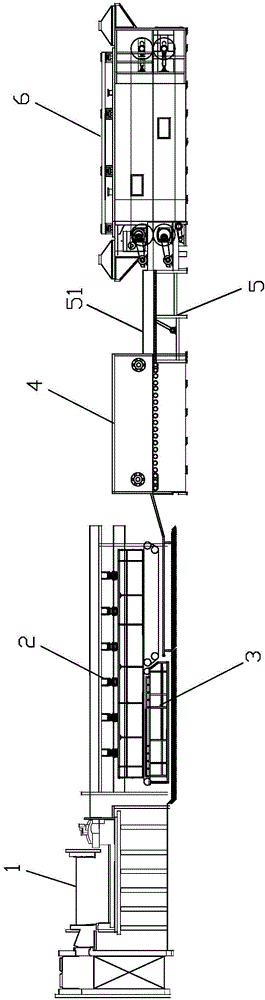

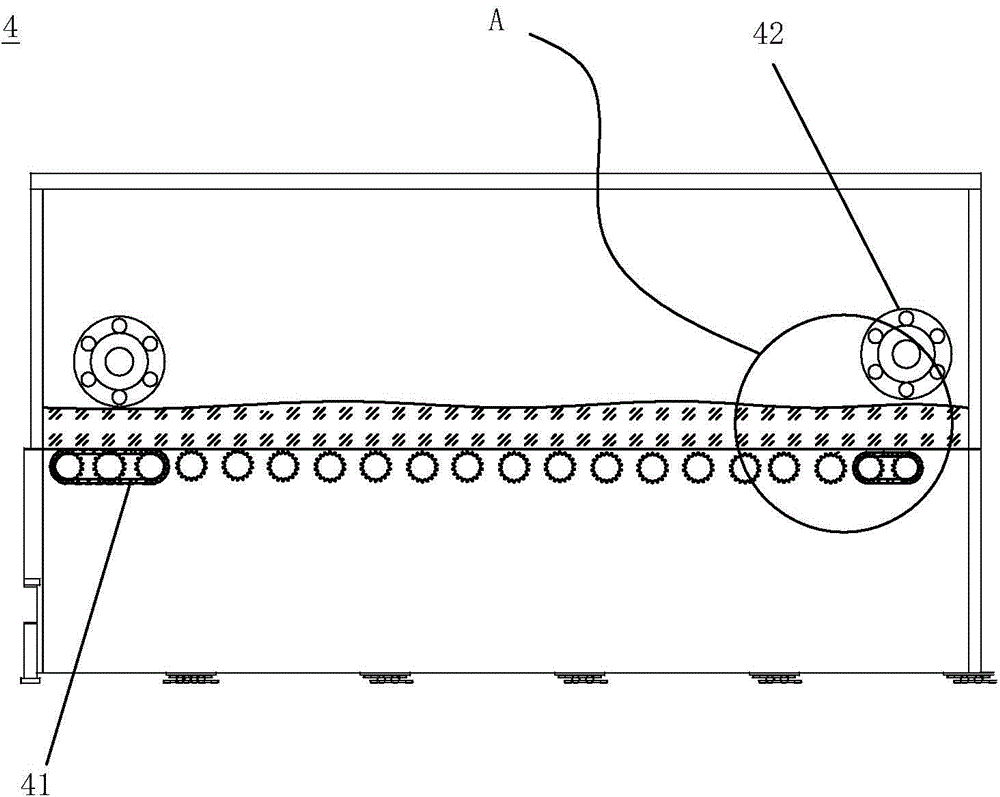

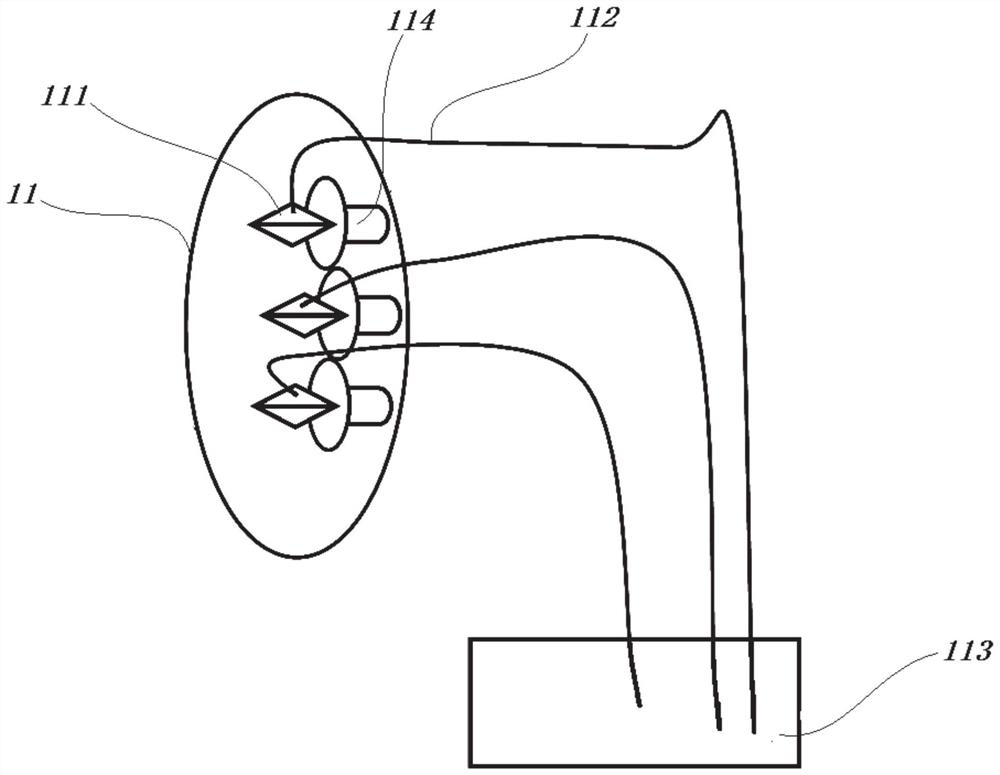

Crystal growing furnace capable of realizing continuous production

InactiveCN106637383AHigh synthesis efficiencyReduce process linksPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention provides a crystal growing furnace capable of realizing continuous production. The crystal growing furnace capable of realizing continuous production comprises a horizontal moving mechanism, a furnace body, a vertical lifting mechanism and crucible assemblies, wherein the plurality of crucible assemblies are moved into the furnace body sequentially through the horizontal moving mechanism and the vertical lifting mechanism to realize on-line continuous production. The crystal growing furnace capable of realizing continuous production adopts a VGF growing method to continuously produce single crystals, improves the synthesis efficiency, reduces the process link and can grow other III-V group compound single crystals.

Owner:珠海鼎泰芯源晶体有限公司

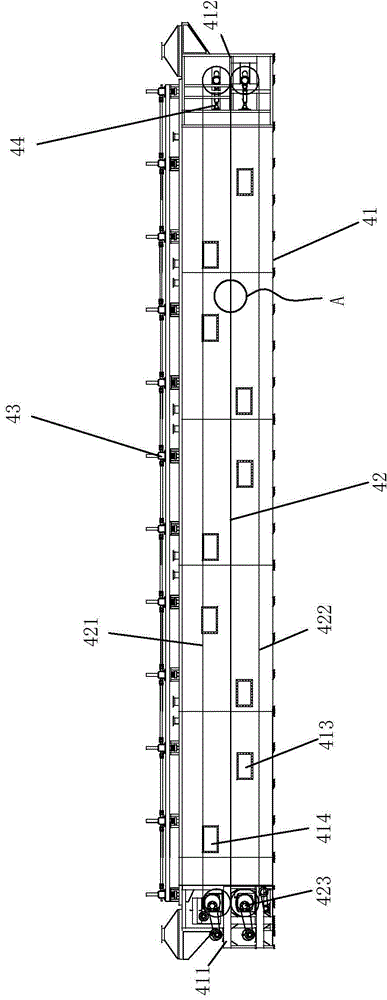

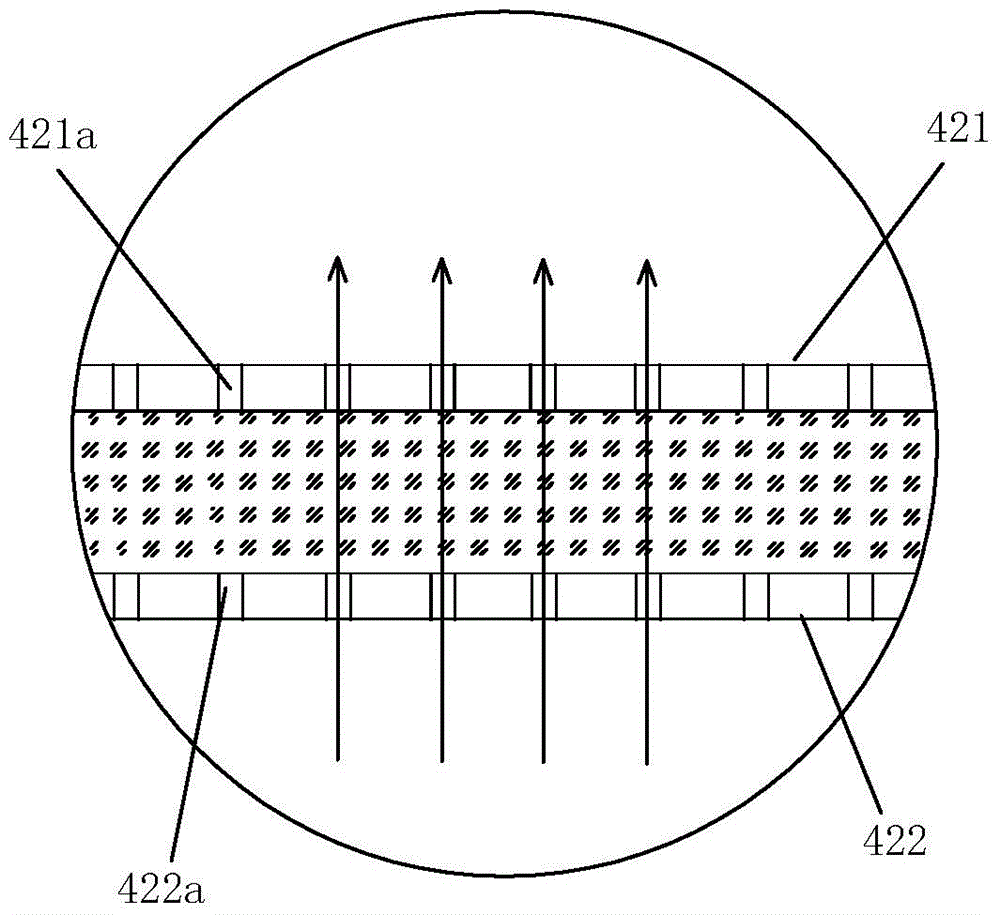

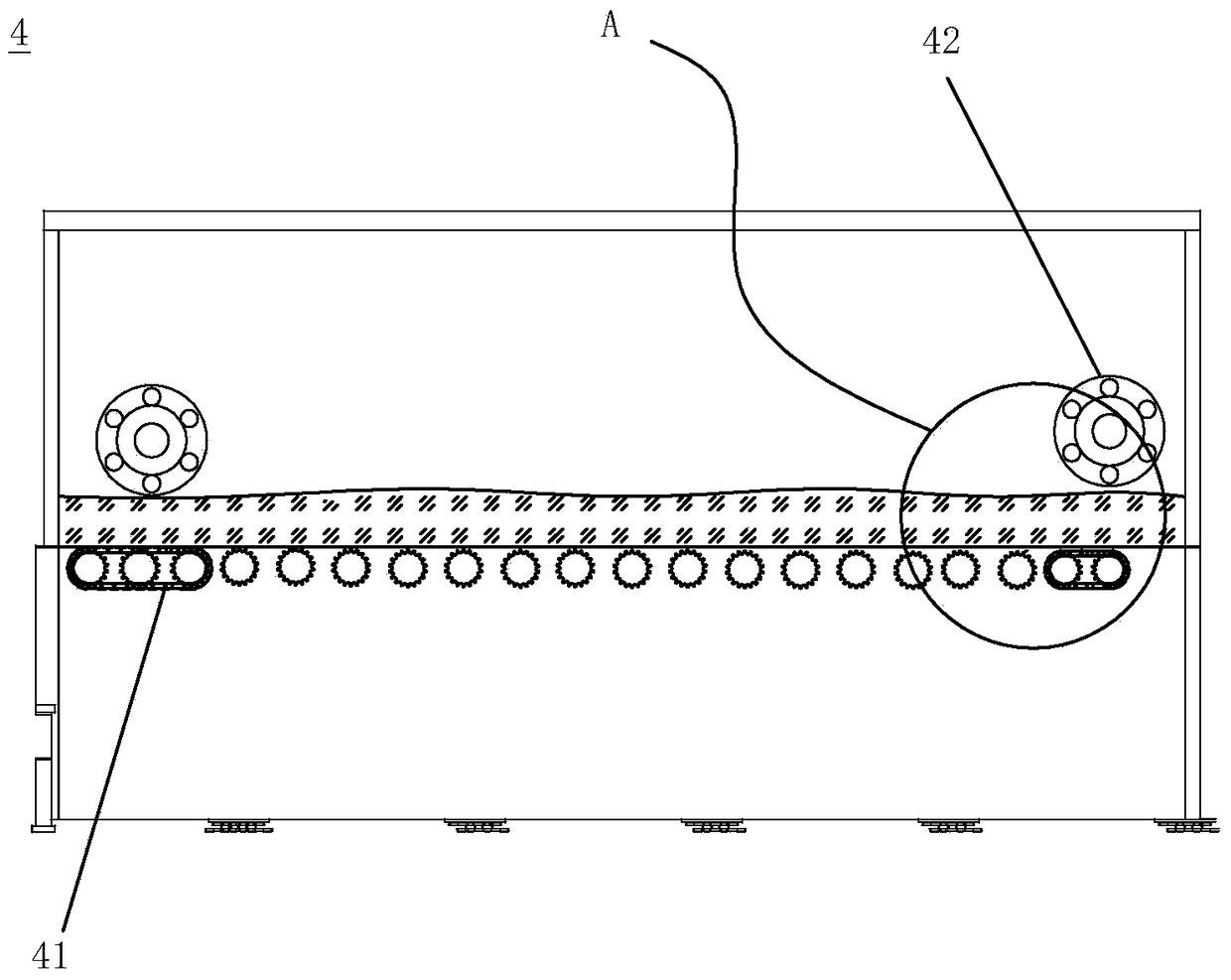

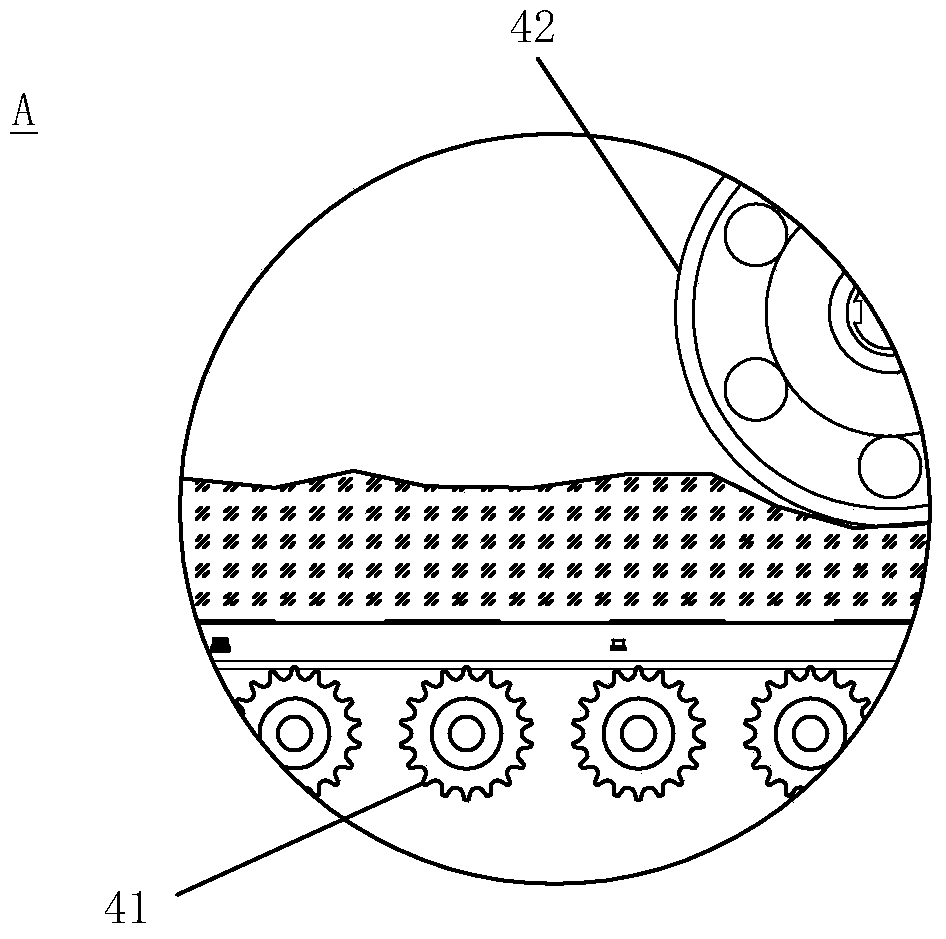

Online dry-process production system and method of glass wool vacuum insulation board core material

ActiveCN106145660ARealize online continuous productionIncrease productivityGlass making apparatusHeating furnaceGlass wool

The invention discloses an online dry-process production system of a glass wool vacuum insulation board core material, the online dry-process production system comprises a smelting furnace, a centrifuge, a cotton collecting machine, a heating furnace and a shaping device. The shaping device adopts upper and lower chain plates to cooperate to form a pressing gap. A glass wool layer heated by the heating furnace at high temperature is pressed in the pressing gap, and can be continuously hot-pressed in the process of transmission. The present invention also provides a production method based on the above production system. Compared with the prior art, online continuous production is realized, production efficiency is high, equipment cost is low, and the obtained glass wool core material has stable structure and good insulation effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

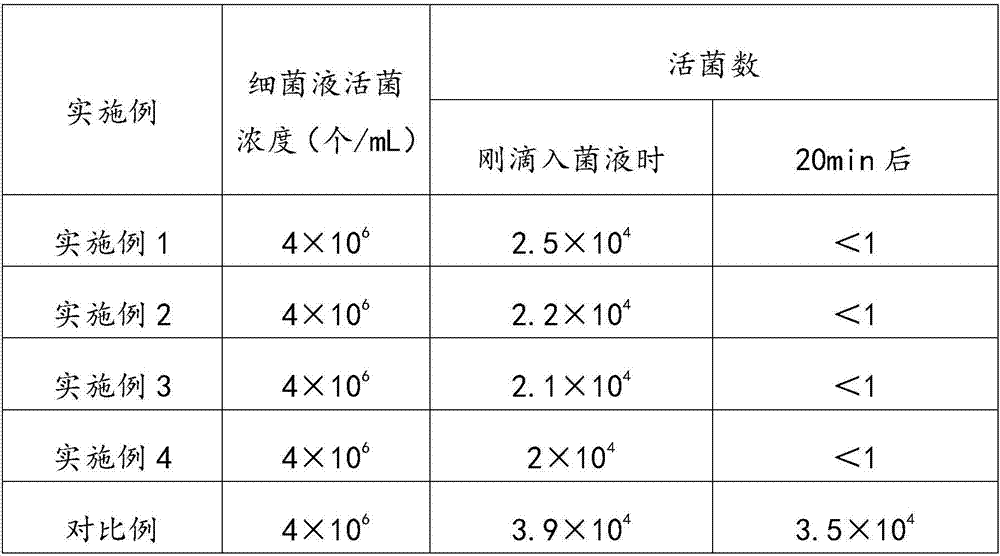

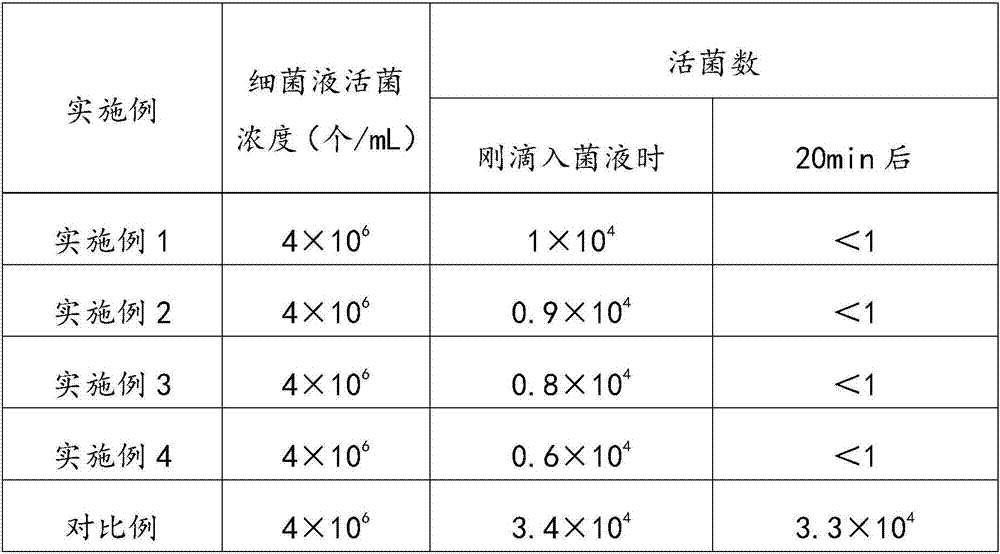

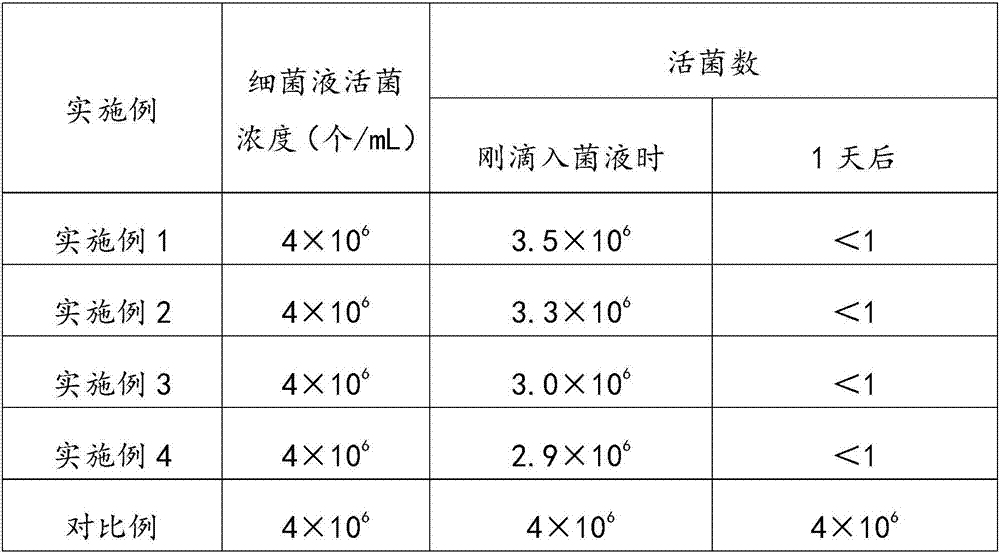

Terahertz super-electric water, and preparation method and application thereof

InactiveCN106865687ASimple processRealize online continuous productionBiocideWater/sewage treatment by irradiationUnicellular organismAlkaline water

The invention provides terahertz super-electric water, and a preparation method and application thereof. A specific method is adopted for preparing the terahertz super-electric water provided by the invention. The method comprises the following steps: electrifying and applying far infrared irradiation to the flowing water in which the plant raw material and the mineral substance raw material are simultaneously soaked, thereby obtaining the terahertz super-electric water. The method provided by the invention is simple in process; no complex preparation device is required; the flowing water is adopted for realizing online continuous production; and the terahertz super-electric water product can be collected from an outlet of the device. The terahertz super-electric water provided by the invention is a weak alkaline water extract, has various effects, has an obvious activating effect to the function of the human body, can not cause anaphylactic reaction, can be used for preparing external articles and internal articles in direct and / or indirect contact with the human body, can be used for killing unicellular organisms and viruses, and has an obvious effect.

Owner:李磊

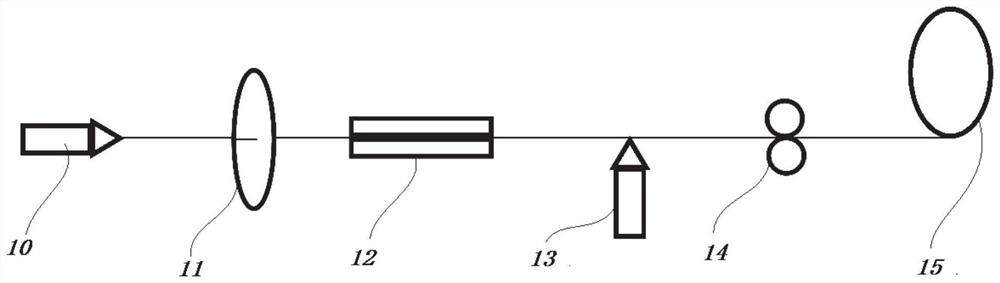

Method and device for manufacturing hydrophilic copper pipe

ActiveCN102909166ARealize online continuous productionImprove anti-corrosion performancePretreated surfacesSpecial surfacesCopper coilBatch manufacturing

The invention relates to a method for manufacturing a hydrophilic copper pipe, which comprises the steps of continuously conveying, straightening, coating an anticorrosive material, drying, cooling, coating a hydrophilic material, drying, cooling and completing manufacturing. A device for manufacturing the hydrophilic copper pipe comprises a loading disk, a receiving disk, a straightening roll, a bottom coating device and a surface coating device, wherein the straightening roll, the bottom coating device and the surface coating device are sequentially arranged between the loading disk and the receiving disk; the straightening roll is used for straightening a copper coil; the bottom coating device is used for coating the anticorrosive material on the copper coil; the surface coating device is used for coating the hydrophilic material on the copper coil; film reduction devices for controlling thicknesses of the coating materials are arranged on the bottom coating device and the surface coating device; and a drying device for drying the coating materials and a cooling device for cooling the coating materials are arranged behind the bottom coating device and the surface coating device. According to the invention, by designing an online continuous dual-drying dual-coating method, the produced hydrophilic copper pipe has a contact angle of less than 10 degrees and has excellent anticorrosion and hydrophilicity; and the method is low in investment, is easy to control the quality and is convenient to implement the industrial mass production.

Owner:江苏仓环铜业股份有限公司 +1

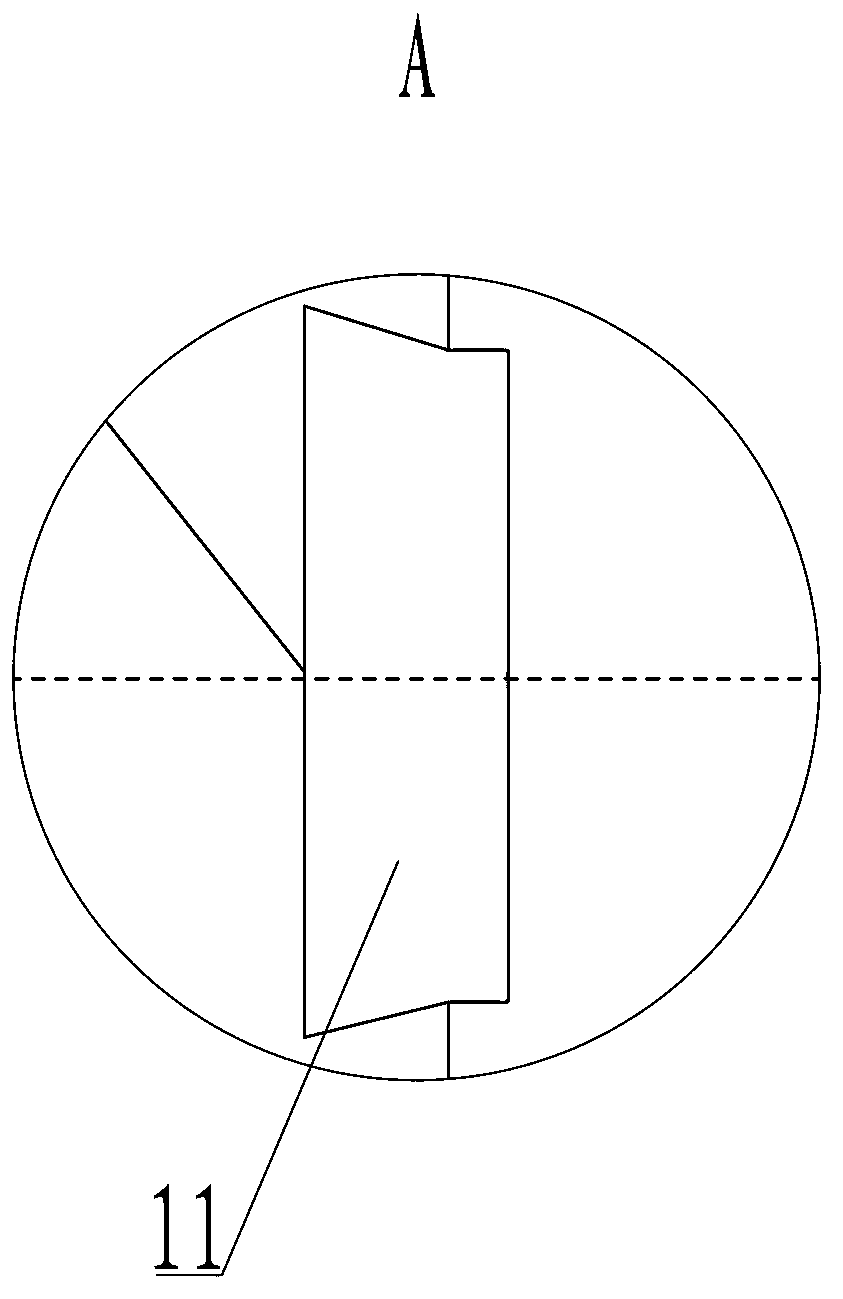

Silver nanowire continuous production method for solvent recovery and recycling

InactiveCN110270693ARealize online continuous productionRealize recyclingMaterial nanotechnologyTransportation and packagingPolyolFiltration

The invention relates to a silver nanowire continuous production method for solvent recovery and recycling. The silver nanowire continuous production method for the solvent recovery and recycling comprises the following steps that polyol solutions of silver nitrate, a surfactant and halide salt are sequentially added into polyol, the solutions are uniformly stirred to obtain a reaction solution, after the reaction solution reacts in a 100-200 DEG C oil bath for 40-120 min, and the reaction solution is subjected to thermal centrifugation or thermal filtration separation under 50-200 DEG C to obtain a silver nanowire product and a polyol clear solution; and a polyol solution of the silver nitrate and a polyol solution of the halide salt are sequentially supplemented and added into the polyol clear solution, the polyol clear solution is uniformly stirred to obtain a reaction solution, the reaction solution reacts and is subjected to thermal separation under the reaction conditions to obtain a silver nanowire product and a polyol clear solution again, the steps are performed in a reciprocated mode, and the silver nanowire continuous production and the polyol recycling are finished. According to the silver nanowire continuous production method for the solvent recovery and recycling, the thermal centrifugation or the thermal filtration technology is adopted, the recycling of the polyol solvent in the process of preparing the silver nanowire by the polyol method is achieved, online continuous production is achieved, the cost is reduced, the efficiency is improved, and the method is green and environment-friendly.

Owner:刘松青

A production system and method for an on-line dry-process glass wool vacuum insulation board core material

ActiveCN106149196BRealize online continuous productionIncrease productivityNon-woven fabricsState of artEngineering

The invention discloses an online dry method glass wool vacuum insulated panel core material production system. The system comprises a smelting furnace, a centrifuge, a wool collector and a hot-press shaping device. According to the hot-press shaping device, an upper chain plate and a lower chain plate are matched to form a press-fit interval, glass wool is pressed in the press-fit interval, and continuous hot-pressing can be carried out in the transmission process. The invention further provides a production method based on the production system. Compared with the prior art, online continuous production is achieved, production efficiency is high, and a manufactured glass wool core material is simple in structure and good in heat insulating effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Pattern rolling forming unit and welded pipe production system with same

ActiveCN113714284AAdjustable lengthEasy to control the lengthRoll force/gap control deviceMetal rolling stand detailsControl systemMolding machine

The invention discloses a pattern rolling forming unit and a welded pipe production system with the same. The pattern rolling forming unit comprises a mounting rack, a first roller and a second roller which cooperate with each other are arranged on the mounting rack, the first roller is rotationally supported on the mounting rack, the second roller is connected with a sliding driving mechanism, and the first roller and the second roller are connected with a rotation driving mechanism for driving the first roller and the second roller to rotate respectively. The sliding driving mechanism is connected with a sliding control system used for controlling the sliding driving mechanism to act, so that under the control of the sliding control system, the sliding driving mechanism drives the second roller to apply adjustable intermittent rolling pressure on strips, and intermittent patterns with the adjustable depth are rolled on the strips. According to the pattern rolling forming unit, the lengths of an embossing section and a smooth surface section on the strips are adjustable, and the pattern depth of the embossing section is controllable, so that the tightness of expanded connection between a heat exchange tube prepared and formed by the strips and a tube plate in the later use process is ensured, and the problems of unqualified leakage inspection and the like existing in a continuous pattern welded tube are solved.

Owner:HUNAN XIANGTOU GOLDSKY NEW MATERIALS CO LTD

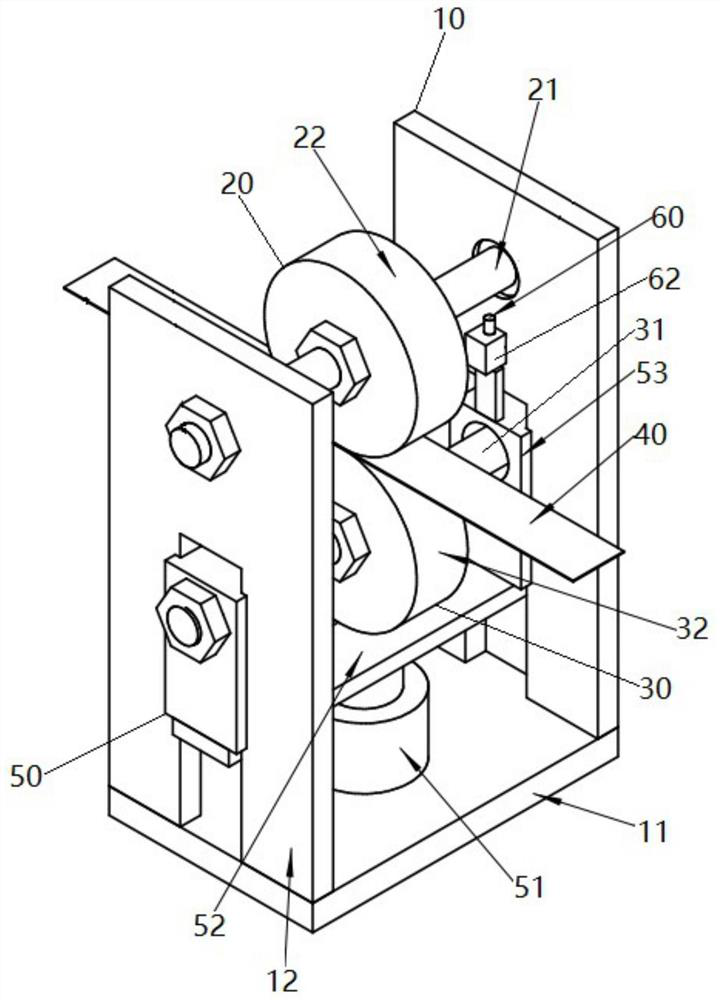

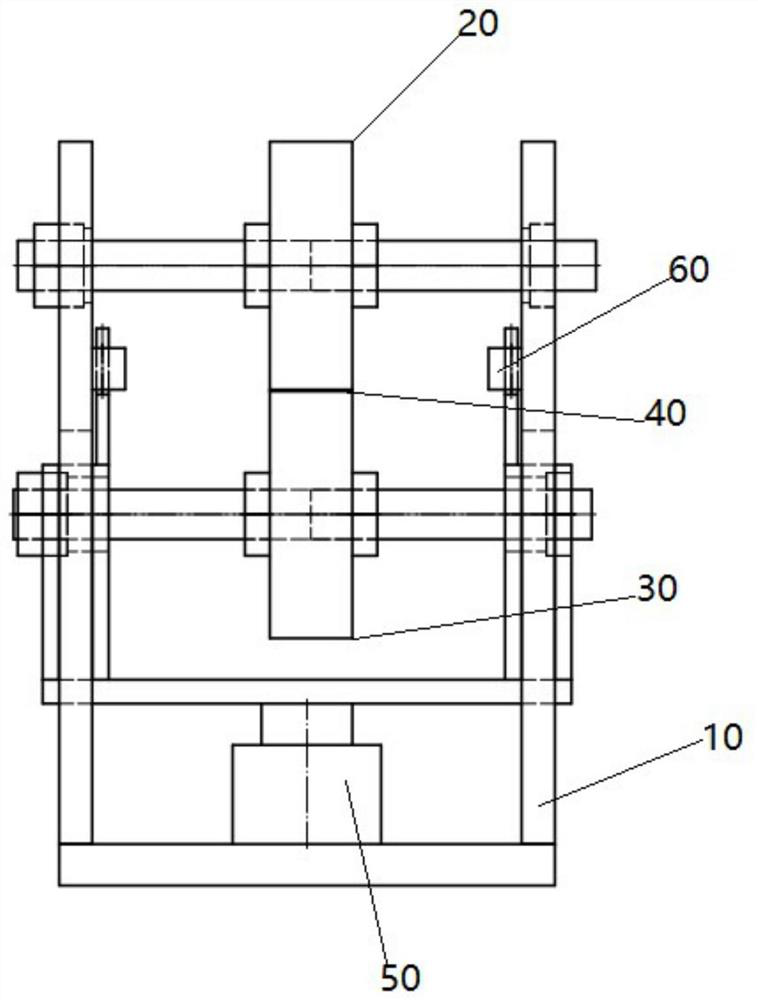

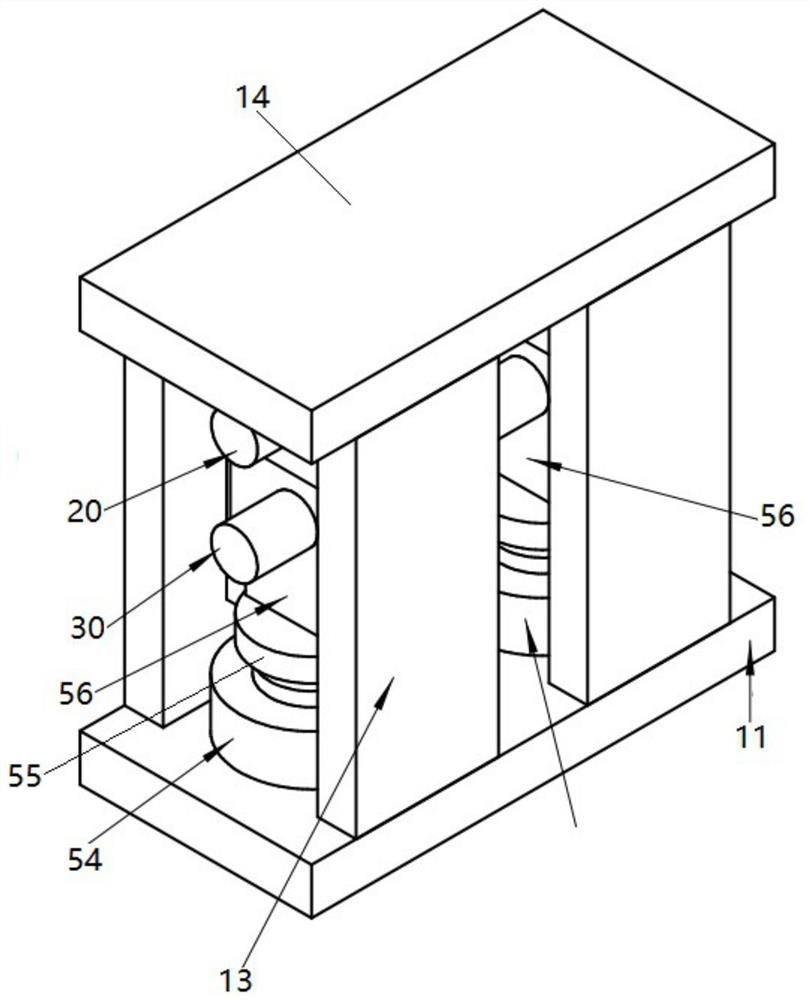

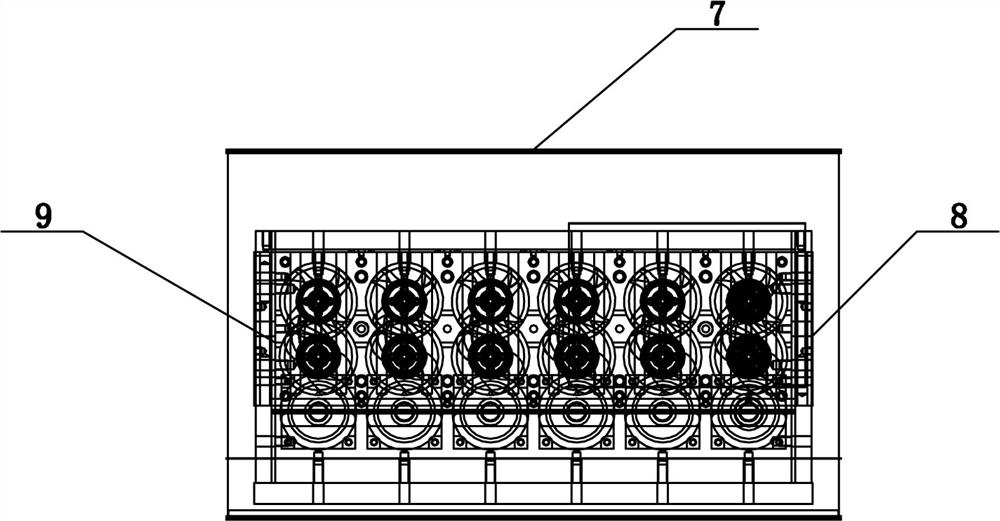

Mold and device capable of producing honeycomb core material continuously, and using method of mold

The invention belongs to the technical field of composite material manufacturing and in particular relates to a mold and a device capable of producing a honeycomb core material continuously, and a using method of the mold. The mold capable of producing the honeycomb core material continuously comprises a front mold and a rear mold which are matched mutually; the rear mold comprises a plurality of regular hexagonal prisms arranged in a staggered manner, and a gap for forming the thickness of the side wall of the honeycomb core material is formed between the side walls of the two adjacent regular hexagonal prisms; and after the front mold and the rear mold are matched, a certain gap is formed between the side wall of each regular hexagonal prism of the rear mold and the front mold, and each gap is used for forming the thickness of the side wall of the honeycomb core material. According to the mold, a honeycomb structure can extend in any direction, and the honeycomb core material can be produced continuously due to application of movable structures of the rear mold and the front mold; and particularly, a long fiber material and thermoplastic resin are used as materials and can be used for preparing the honeycomb core material reinforced by Z-directional continuous fibers.

Owner:山东三达科技发展有限公司

Glass fiber reinforced plastic flexible composite pipe, production device and production method

PendingCN112664729ARealize online continuous productionContinuous processingFlexible pipesTubular articlesGlass fiberContinuous production

The invention discloses a glass fiber reinforced plastic flexible composite pipe, a production device and a production method, and belongs to the field of resin molding. A glass fiber reinforced plastic flexible composite pipeline which can be continuously produced and coiled by changing a processing method and components of glass fiber reinforced plastic raw materials, is large in continuous length and small in joint use quantity, and the effectiveness, safety and reliability of conveying of the pipeline are ensured. The composite pipe comprises a thermoplastic resin lining layer and a glass fiber reinforced plastic reinforcing layer which are sequentially and tightly attached from inside to outside, and the glass fiber reinforced plastic reinforcing layer comprises glass fibers wound around the outer side of the thermoplastic resin lining layer, thermosetting resin attached to the glass fibers and a thermoplastic resin mixture.

Owner:WEIHAI NACHUAN PIPE FITTINGS

Device for simultaneously producing surface layer waterproof agent and core layer waterproof agent of shaving board and method for preparing surface layer waterproof agent and core layer waterproof agent of shaving board

PendingCN110005953ARealize online continuous productionSimple structureWood working apparatusPipeline systemsSurface layerEngineering

The invention relates to the technical field of shaving board waterproof agents, in particular to a device for simultaneously producing a surface layer waterproof agent and a core layer waterproof agent of a shaving board and a method for preparing the surface layer waterproof agent and the core layer waterproof agent of the shaving board. According to the device for simultaneously producing the surface layer waterproof agent and the core layer waterproof agent of the shaving board, the device is simple in structure, and on-line continuous production of the surface layer waterproof agent and the core layer waterproof agent of the shaving board can be realized without using expensive parts.

Owner:ZHAOQING LIHE TECH DEV +1

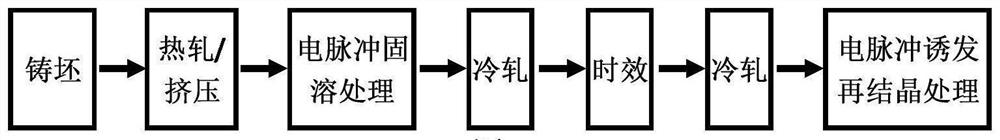

A method for strengthening and toughening magnesium alloy strips

The invention discloses a method for strengthening and toughening magnesium alloy strips. Aiming at the problems of easy oxidation, coarse crystal grains, limited improvement of strength and plasticity, and high energy consumption in the traditional heat treatment process of magnesium alloys, the invention first uses electric pulses to treat magnesium alloys. The alloy strip is subjected to rapid solution treatment, and then processed by rolling, the primary cold-rolled strip is subjected to aging treatment, the aging-treated strip is subjected to secondary cold-rolling, and finally the secondary cold-rolled strip is subjected to electric pulse induction. Recrystallization treatment uses electric pulses to quickly refine the matrix grains and precipitated phases to hinder the growth of grains, so as to obtain a structure with fine and uniform matrix grains and a dispersed distribution of strengthening phases. Through the synergistic toughness of fine grains and precipitated phases Chemical reaction to prepare high-strength and high-toughness magnesium alloy strips. Compared with the magnesium alloy strip in the prior art, the strength and elongation after fracture of the magnesium alloy strip prepared by the process of the invention are respectively increased by more than 10% and 30%.

Owner:CENT SOUTH UNIV

Core material for dry-method vacuum insulation panel and preparation method thereof

InactiveCN112032475AImprove uniformityExtended service lifeThermal insulationPipe protection by thermal insulationGlass fiberAdhesive

The invention provides a core material for a dry-method vacuum insulation panel and a preparation method thereof. The core material for the dry-method vacuum insulation panel comprises glass fibers and an adhesive, wherein the solid content of the adhesive is 0.3-2% of the mass of the glass fibers. The preparation method comprises the following steps of firstly, fully mixing the adhesive with water according to a weight ratio of 1:(3-20), and then carrying out atomizing; secondly, in the process of centrifugally spraying the glass fibers by adopting a centrifugal machine, mixing and adding themixture of the atomized adhesive and water, wherein the mixing ratio is that the solid content of the adhesive is 0.3-2% of the mass of the glass fibers; and finally, drying, curing and hot-pressingthe glass fibers mixed with the adhesive to form the core material for a vacuum insulation panel, wherein the density of the hot-pressed core material is 60-200 Kg / m<3>. According to the core materialfor the dry-method vacuum insulation panel and the preparation method thereof, reasonable proportioning and continuous production process control are adopted, so that the quality uniformity of the core material is greatly improved, there are no slag balls, and the heat insulation performance is good.

Owner:南京聚力纤维材料有限公司

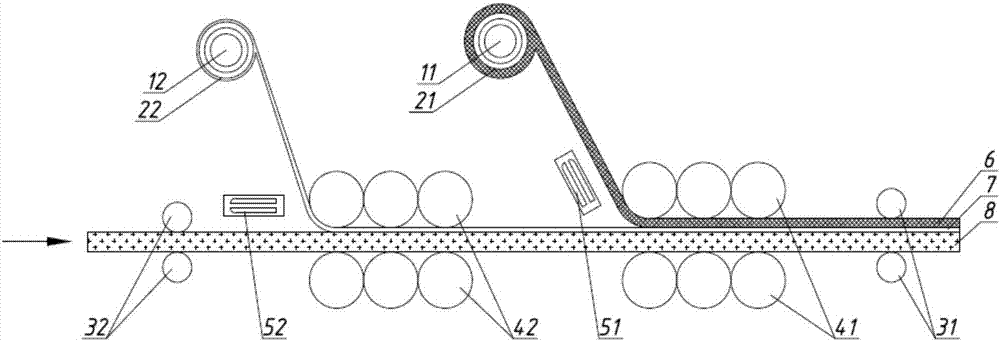

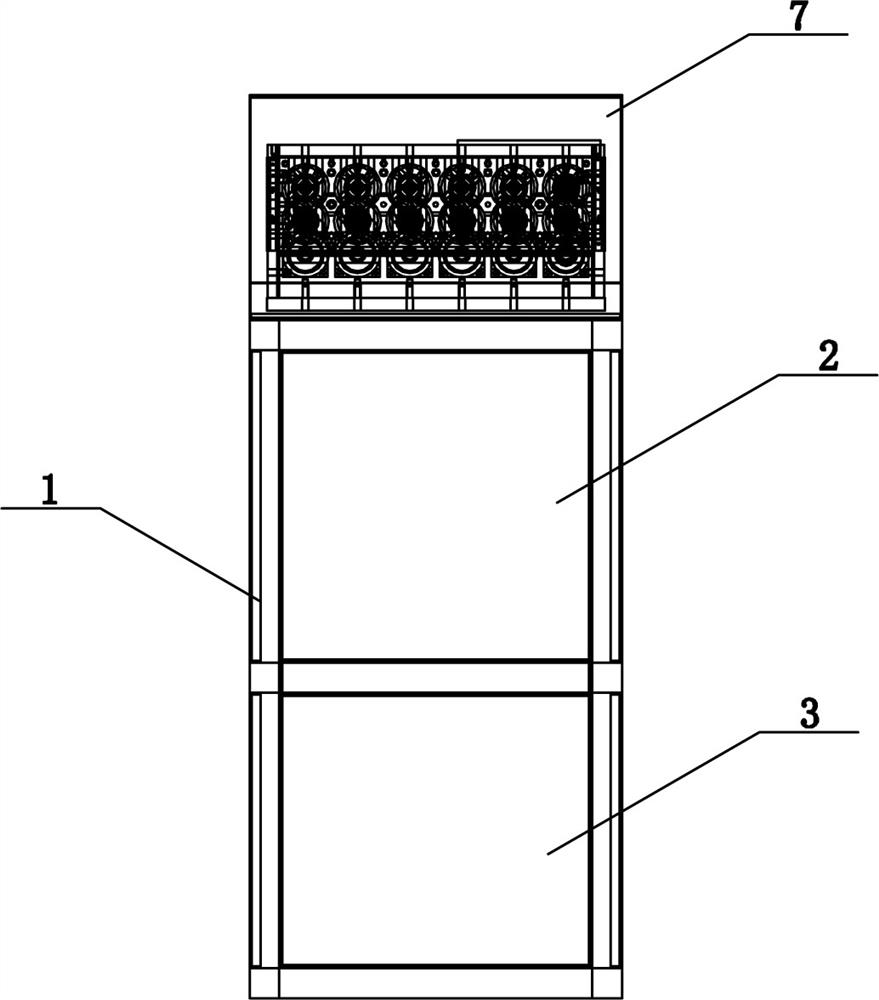

Production equipment and preparation method for wear-resistant and puncture-resistant polypropylene plate

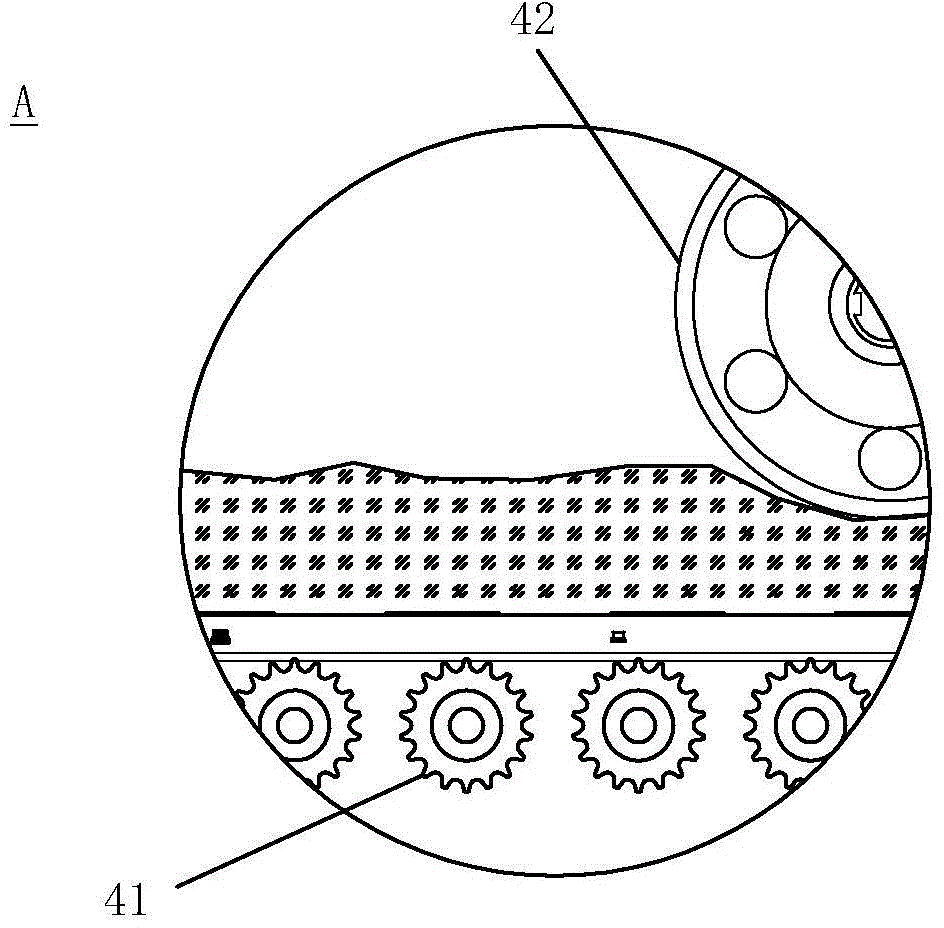

InactiveCN107283973AImprove wear resistanceImprove puncture resistanceLayered product treatmentSynthetic resin layered productsWear resistantEngineering

The invention discloses a polypropylene plate production equipment, which comprises a coil placement device, a heating device, a pressing device and a traction device, and the above parts are connected in sequence. The coil placement device includes a front film roll frame (11) and a rear film roll frame (12); the heating device includes a front infrared heating lamp tube (51) and a rear infrared heating lamp tube (52); the pressing The device includes a front pressure roller (41) and a rear pressure roller (42), forming a pressing device through pneumatic pressure; the traction device includes a front traction guide roller (31) and a rear traction guide roller (32), and the pressure Form a traction device. The invention also discloses a method for preparing polypropylene sheets by using the above-mentioned production equipment: according to the order from top to bottom, the front film layer, the rear film layer, and the polypropylene sheet are laid flat, pressed, heated, and pulled to obtain the polypropylene sheet. sheet. The production equipment of the invention can be conveniently connected with the extrusion equipment of the polypropylene plate to realize online continuous production.

Owner:QINGHAI CHAIDAMU JIEQING TECH CO LTD

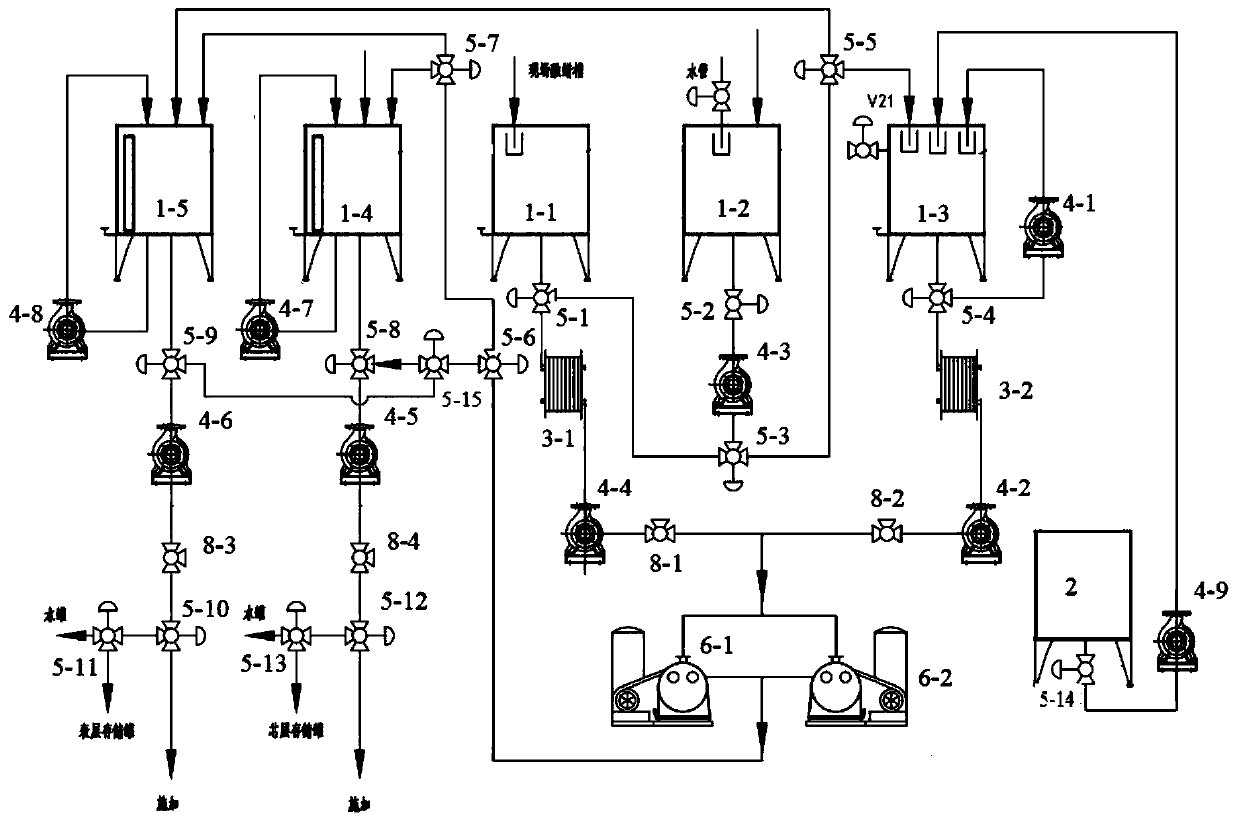

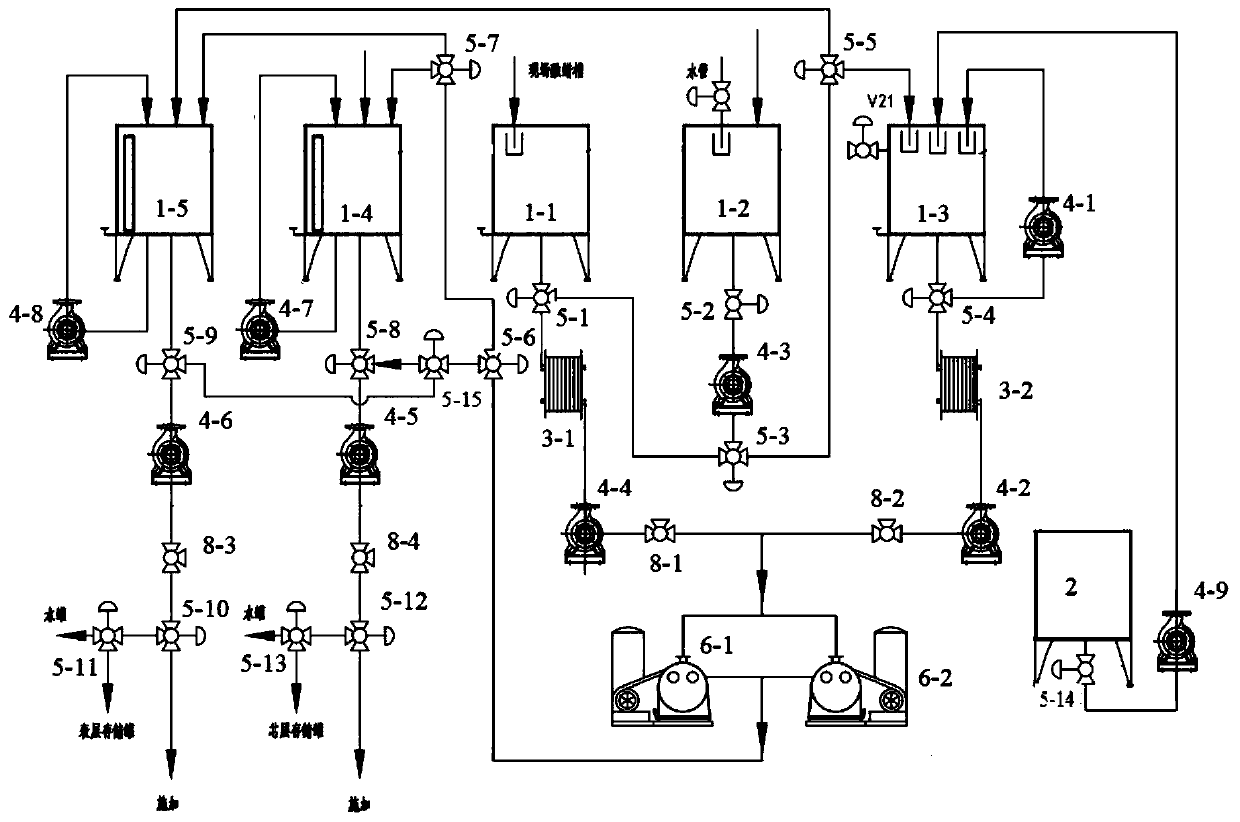

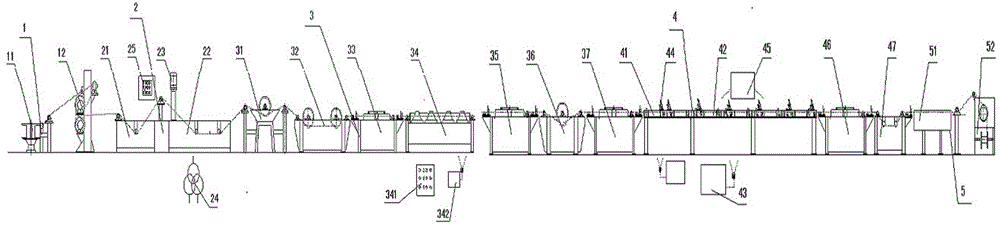

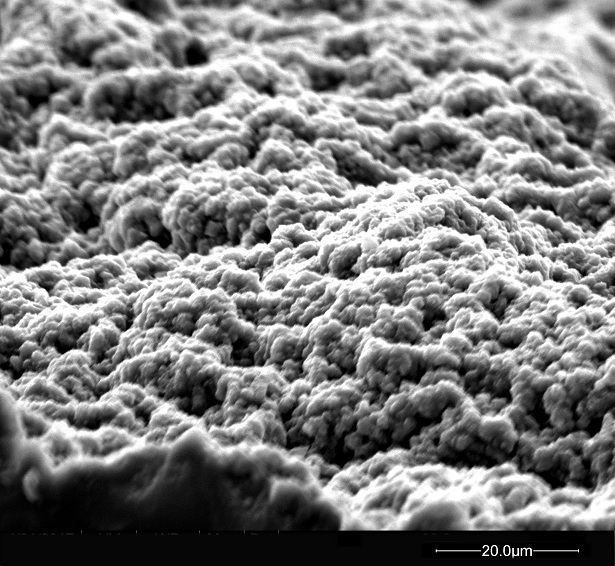

Steel wire heat treatment electrolytic phosphating continuous production line equipment and process

ActiveCN103603022BRealize online continuous productionReduce consumptionPhosphatisationFurnace typesElectrical conductorElectrolysis

The invention relates to a continuous production line equipment of electrolytic phosphating for heat treatment of steel wire, which is composed of a wire unwinding device, a heat treatment system, a steel wire surface cleaning system, an electrolytic phosphating system and a wire take-up device arranged in sequence to form a continuous production line equipment. After the steel wire is heat-treated and surface-treated, the steel wire in the electrolytic phosphating solution is energized, the steel wire is used as the cathode, and the inert conductor is used as the anode, and a hydrolysis reaction occurs. Under alkaline conditions, zinc ions in the phosphating solution combine with phosphate ions Together, zinc phosphate crystals (Zn 3 (PO 4 ) 2 ), the electrolytic phosphating process controls the thickness of the phosphating film on the steel wire by controlling the current density of the steel wire, the phosphating speed is fast, and no phosphating slag is generated during the electrolytic phosphating process.

Owner:GUIZHOU WIRE ROPE

Continuous mixing reactor

PendingCN112808220ARealize online continuous productionTransportation and packagingRotary stirring mixersProcess engineeringContinuous production

The invention discloses a continuous mixing reactor and relates to the technical field of mechanical manufacturing and processing. The continuous mixing reactor comprises a main machine frame, an electric control system, a cooling and lubricating system, a reaction cavity, a gearbox, a servo motor, a mixing and stirring mechanism, a material inlet, a material outlet, an upper rotor and a lower rotor, the electric control system is installed on the upper portion of the interior of the main machine frame, the cooling and lubricating system is installed below the electric control system, the reaction cavity is formed in the electric control system, and the gearbox is electrically connected with the servo motor and connected with the reaction cavity. A mixing and stirring mechanism is arranged above the main machine frame; after the technical scheme is adopted, the high-precision mixing device has the beneficial effects that high-viscosity materials can be mixed at high precision, the problems of batch type, long time, non-uniform mixing and the like of existing equipment are solved, and online continuous production is realized.

Owner:东莞市星东升实业有限公司

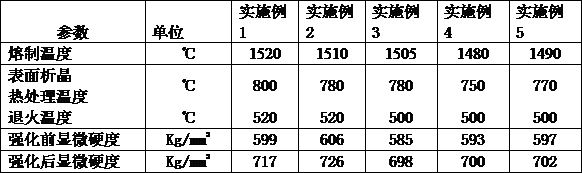

A surface-strengthened clear glass

ActiveCN108623154BLow priceReduce thicknessGlass shaping apparatusGrinding machinesAluminium hydroxidePhysical chemistry

Owner:QILU UNIV OF TECH

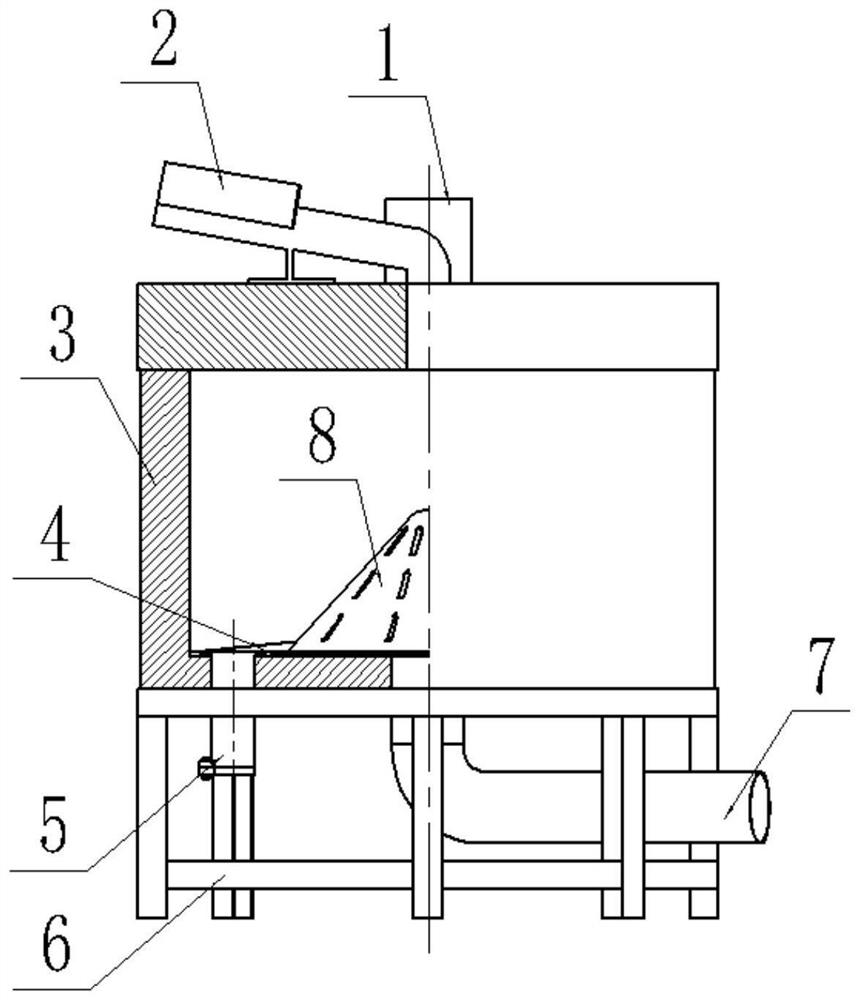

A tempering device for skew rolling ball mill steel balls that can utilize waste heat

ActiveCN112813247BEvenly heatedImprove the tempering effectFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to the technical field of metal plastic forming technology and equipment, and provides a tempering device for skew-rolled ball milling steel balls that can utilize waste heat, including a frame, a thermal insulation shell, and a ball storage unit; the ball storage unit is installed in the thermal insulation shell, Including ball storage cylinder, air inlet cylinder, air outlet cylinder, ball inlet track, ball outlet mechanism, conical cooling cylinder, and arc-shaped bottom plate; the conical cooling cylinder is installed in the center of the bottom of the ball storage cylinder, and the heat enters the conical The heat dissipation cylinder is evenly released in the ball storage cylinder; the steel balls enter the ball storage cylinder through the ball entry track, and are evenly distributed around the conical heat dissipation cylinder. After the tempering process is completed, they are discharged from the device through the ball discharge mechanism. The invention has a simple structure and is easy to manufacture, and the steel balls are convenient to enter and exit. The conical cooling tube releases heat evenly, increases the overall heating area of the steel balls, and has a good tempering effect. .

Owner:UNIV OF SCI & TECH BEIJING

Method and device for manufacturing hydrophilic copper pipe

ActiveCN102909166BRealize online continuous productionImprove anti-corrosion performancePretreated surfacesCoatingsCopper coilBatch manufacturing

Owner:江苏仓环铜业股份有限公司 +1

Gradient function titanium alloy strip material and preparation method

InactiveCN104630679BSimple preparation processLow costMetal rolling arrangementsElectricityHigh energy

The invention discloses a method for preparing a functional gradient titanium alloy strip. The method comprises the following steps: driving a raw material strip to move at a constant speed; electrically connecting a high energy pulse power supply with a moving strip by virtue of two immovable electric contact devices which are arranged along the strip moving direction at an interval, intermittently introducing high energy pulse current with the frequency of 60-760Hz, the voltage of 10-600V and the pulse width of 10-6000mu s into the strip, and performing high energy pulse treatment on the strip; cutting the treated strip, thereby obtaining the functional gradient titanium alloy strip. The invention also provides a functional gradient TC4 titanium alloy strip which is prepared from a TC4 titanium alloy strip with single mechanical property by adopting the preparation method, and the elasticity modulus of the strip continuously changes along the length direction of the strip. The preparation process is simple and low in cost, online continuous production can be realized, and an oxidation phenomenon on the strip surface is avoided in the preparation process. The titanium alloy strip does not cause the failure and breakage phenomena and is good in mechanical properties.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

A kind of online dry production system and method of glass wool vacuum insulation board core material

ActiveCN106145660BRealize online continuous productionIncrease productivityGlass making apparatusHeating furnaceGlass wool

The invention discloses an online dry-process production system of a glass wool vacuum insulation board core material, the online dry-process production system comprises a smelting furnace, a centrifuge, a cotton collecting machine, a heating furnace and a shaping device. The shaping device adopts upper and lower chain plates to cooperate to form a pressing gap. A glass wool layer heated by the heating furnace at high temperature is pressed in the pressing gap, and can be continuously hot-pressed in the process of transmission. The present invention also provides a production method based on the above production system. Compared with the prior art, online continuous production is realized, production efficiency is high, equipment cost is low, and the obtained glass wool core material has stable structure and good insulation effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

A method for strengthening and toughening non-ferrous metal materials

ActiveCN111575612BImprove quality stabilityImprove quality consistencySolution treatmentMetallic materials

The invention discloses a method for strengthening and toughening non-ferrous metal materials. Aiming at the problems of easy oxidation, coarse crystal grains, limited improvement of strength and plasticity, and high energy consumption in the traditional heat treatment process of non-ferrous metal materials, the invention proposes the use of electric pulses to Non-ferrous metal materials are subjected to rapid solution treatment, and then formed once, then aging treatment is performed on the alloy formed once, and secondary forming is performed on the alloy after aging treatment, and finally electric pulse-induced recrystallization treatment is performed on the material formed twice. The characteristics of rapid pulse refinement of matrix grains and precipitated phases that hinder grain growth can be obtained to obtain a microstructure with fine, uniform matrix grains and dispersed strengthening phases. Through the synergistic strengthening and toughening effect of fine grains and precipitated phases, high strength and high Tough non-ferrous materials. Compared with the traditional heat treatment process, the strength and elongation after breaking of the non-ferrous metal material prepared by the process of the invention are respectively increased by more than 10% and more than 20%.

Owner:CENT SOUTH UNIV

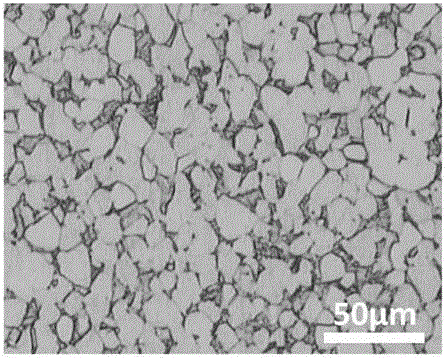

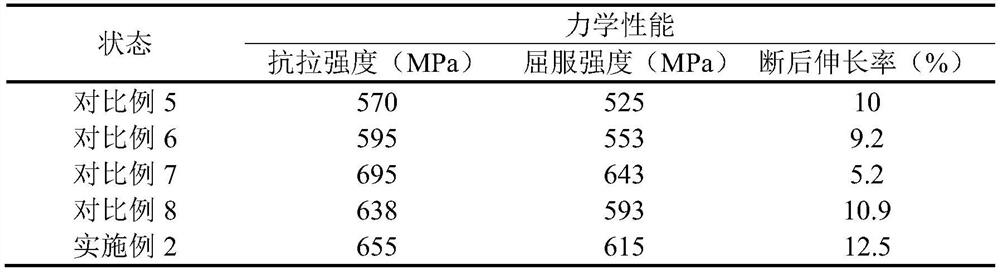

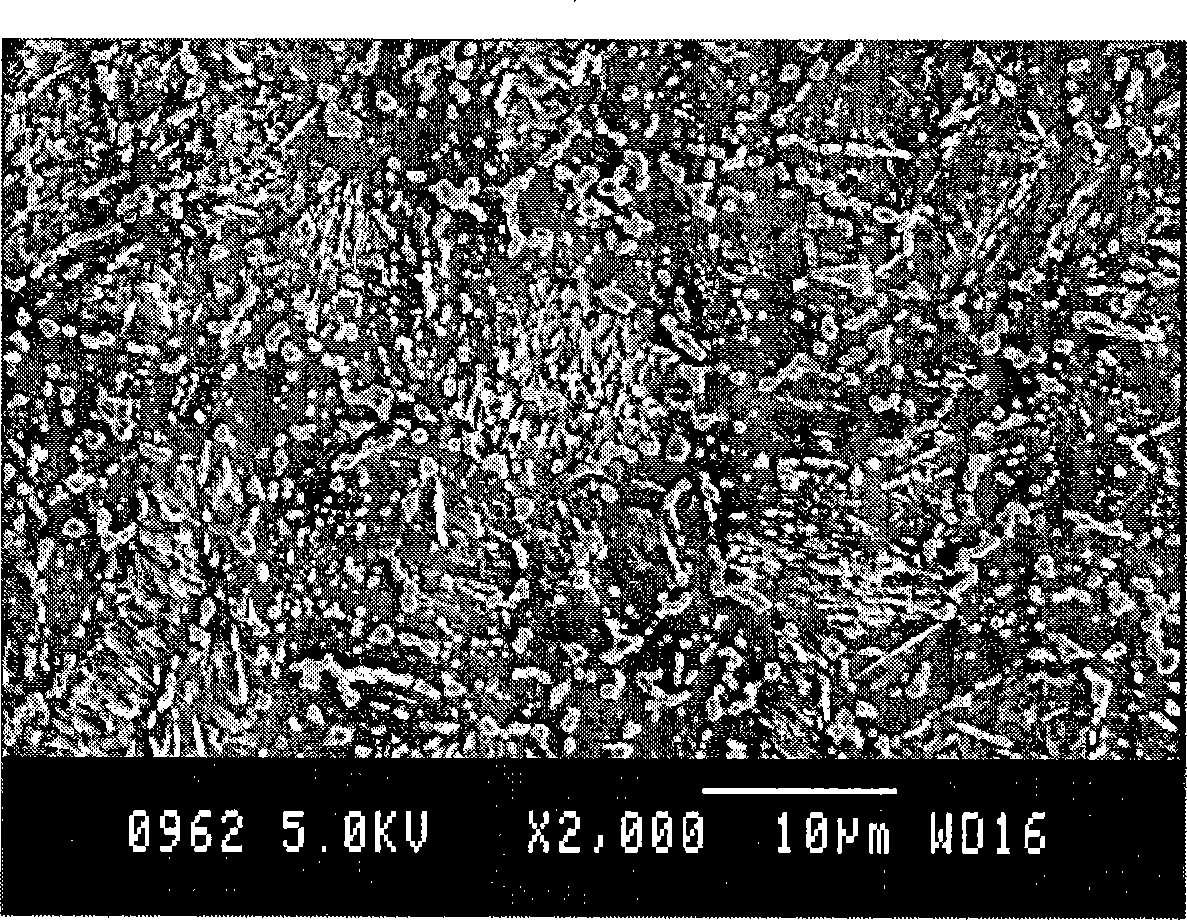

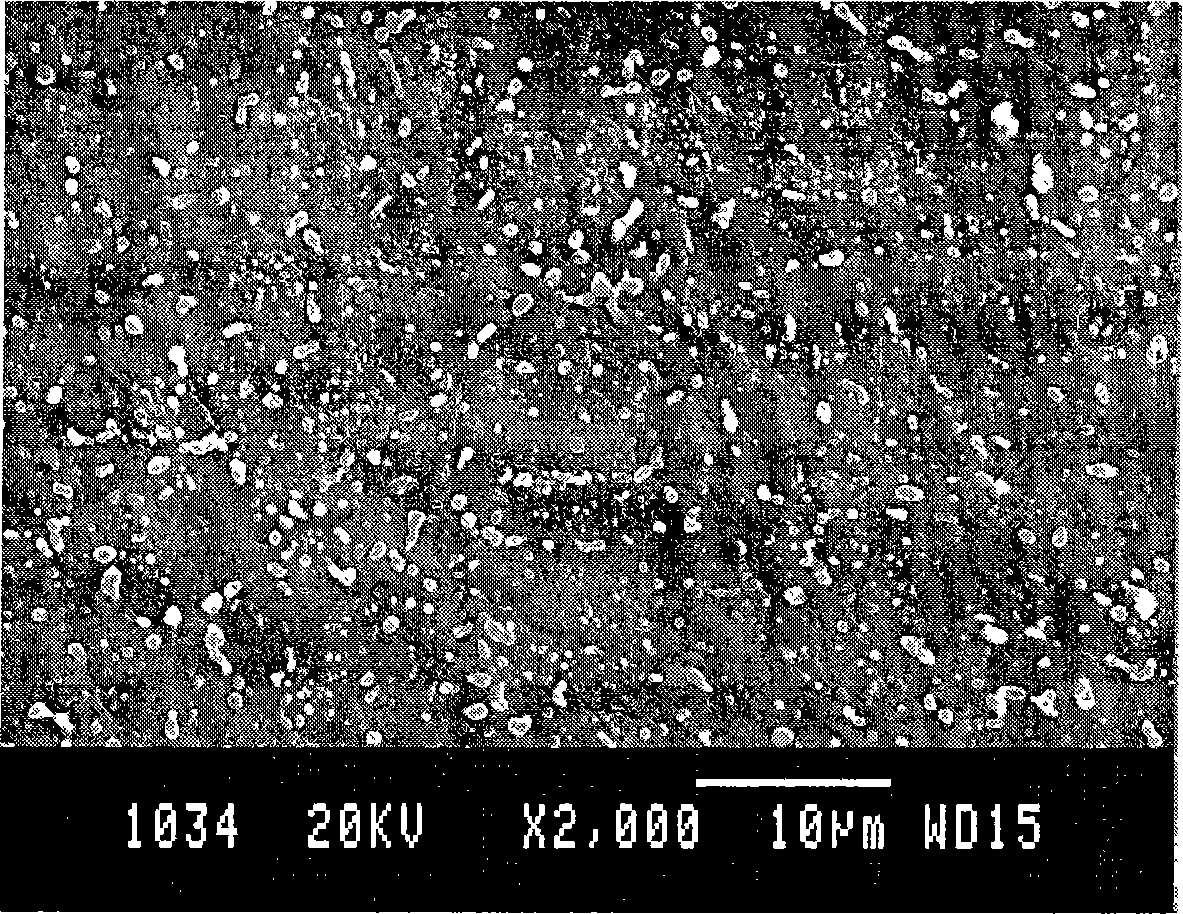

High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

The invention discloses an electro-strengthening and toughening processing method of a belt material of AZ91 magnesium alloy and a system thereof. The electro-strengthening and toughening processing method comprises following steps: when the belt material of magnesium alloy is transmitted at a certain speed which is driven by a roller on an electro plastic rolling machine, high-energy impulse current that is output by an impulse power source through an electrode is input into an electriferous region section of the moving belt material of magnesium alloy, and the Joule heating effect and the non-heating effect are generated in the electriferous region section, thus causing the phase transition of internal microscopic constitution from bulky lath-shaped Beta-Mg17Al12 that are gathering and agglomerating in an initial state to Beta-Mg17Al12 particles that are evenly distributed and approximately sphere-shaped, or causing the solid solution effect that leads Beta-Mg17Al12 to be dissolved in a substrate; the processed belt material can be naturally air cooled at room temperature. The electro-strengthening and toughening processing method of the belt material of AZ91 magnesium alloy hasshort processing time and high production efficiency, and simultaneously avoids the high-temperature oxidation of the magnesium alloy. After the electro-strengthening and toughening processing, the microscopic constitution of the belt material of magnesium alloy can be remarkably improved, the unit extension of the microscopic constitution is increased from 11.8 percent in the initial aging stateto over 20 percent, and the tensile strength of the microscopic constitution is not dramatically lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com