Method and device for manufacturing hydrophilic copper pipe

A production method and hydrophilic technology, applied in the field of parts and components, can solve the problems of high input cost, inability to realize continuous batch industrial production, and low production efficiency, and achieve easy quality control, good corrosion resistance and hydrophilicity, and low investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

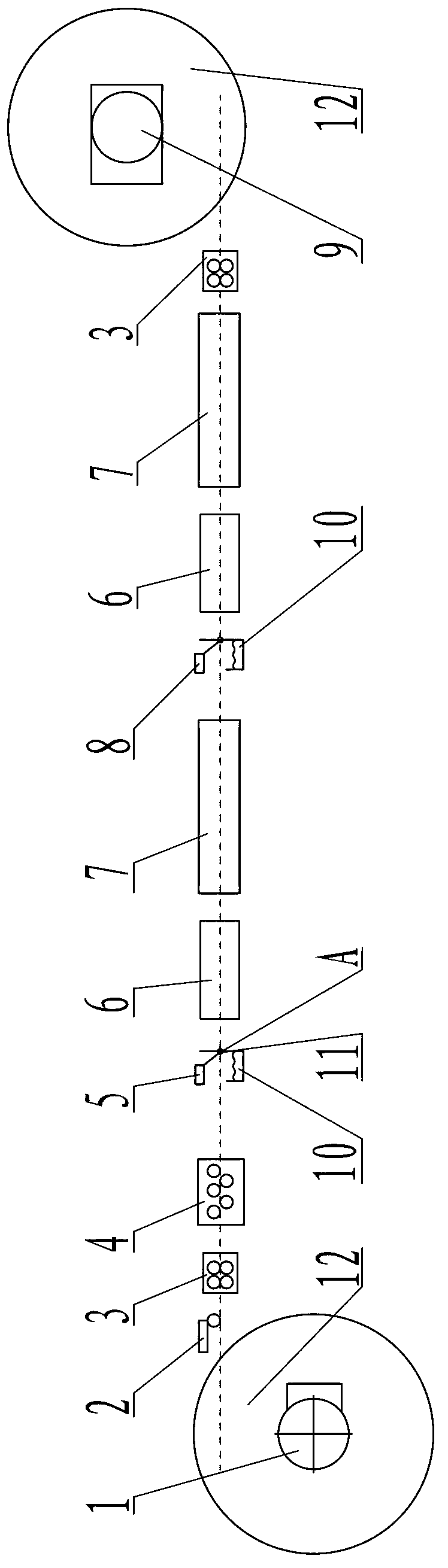

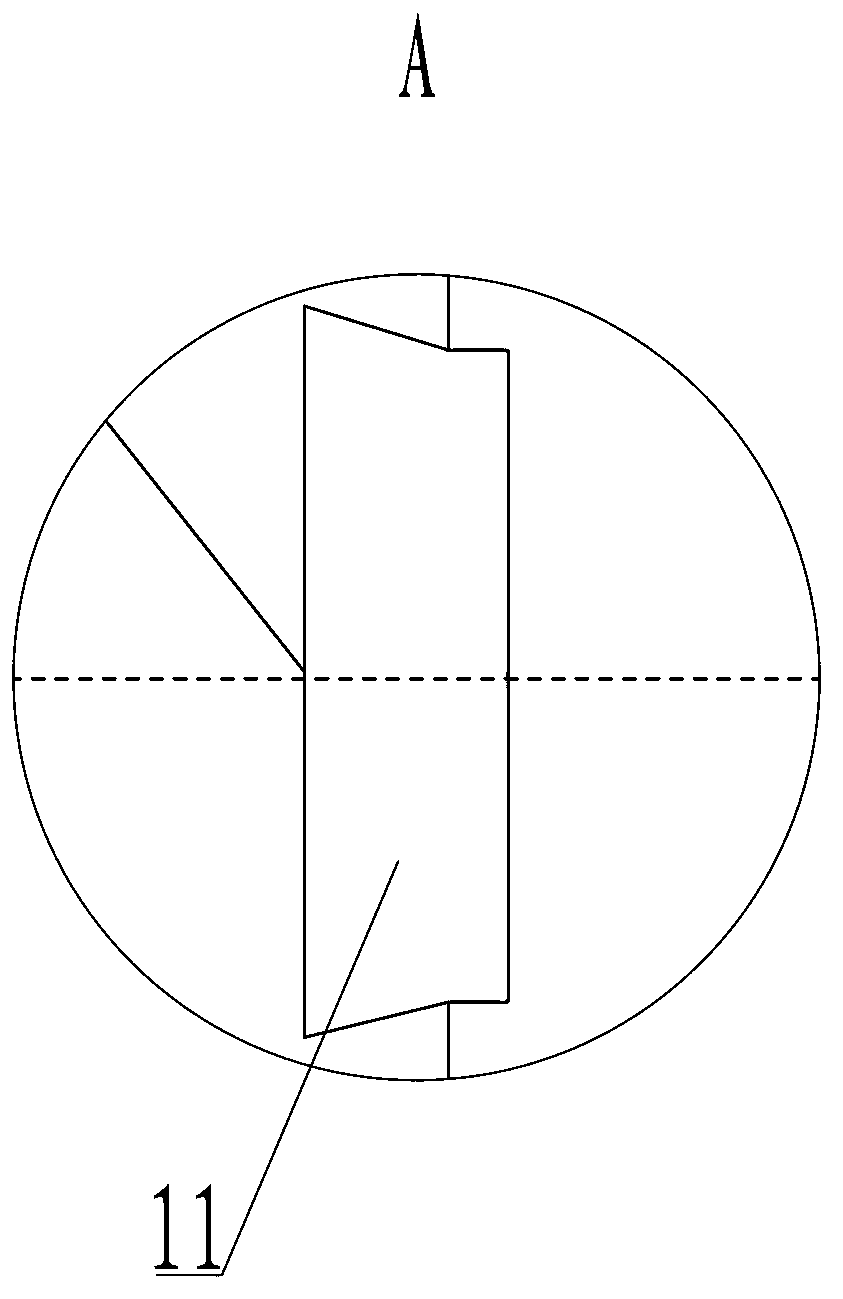

[0029] Such as figure 1 The manufacturing device of a kind of hydrophilic copper pipe shown comprises the feeding plate 1 that is arranged in sequence, guide wheel 2, guide roller 3, is used for the straightening roller 4 that copper coil pipe 12 is straightened, is used for straightening The copper coil 12 is coated with an anti-corrosion primer 5, a drying device 6 for drying the coating material, a cooling device 7 for cooling the coating material, and a coating for the copper coil 12. A surface coating device 8 for hydrophilic materials, a drying device 6 for drying the coating material, a cooling device 7 for cooling the coating material, a guide roller 3 and a receiving tray 9 .

[0030] In the present embodiment, the primer device 5 and the top coat device 8 adopt a solvent tank plus a conduit device, and the paint conduit is introduced into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com