Steel wire heat treatment electrolytic phosphating continuous production line equipment and process

A production line equipment, electrolytic phosphating technology, applied in heat treatment equipment, heat treatment furnace, phosphating, etc., can solve the problems of large slag production, long phosphating time, high energy consumption, etc., to reduce heat energy consumption, improve production efficiency, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

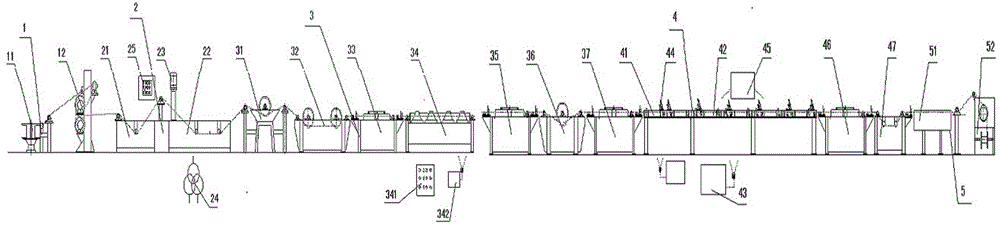

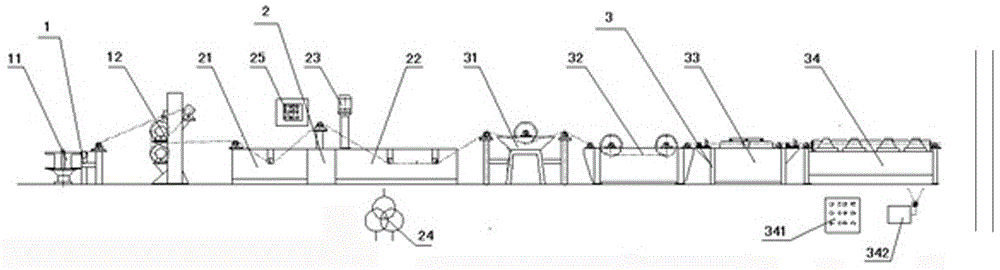

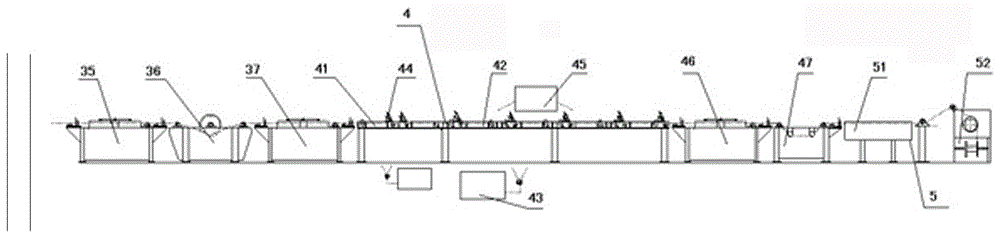

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0028] Among the figure, the heat treatment electrolytic phosphating continuous production line equipment of the present invention, it is made up of pay-off device 1, heat treatment system 2, steel wire surface cleaning system 3, electrolytic phosphating system 4 and take-up device 5, each device system is pressed 1 to 5. Install and arrange equipment in sequence to form a continuous production line. Each device is connected through the continuous electrolytic phosphating production line of steel wire heat treatment, and each device is not directly connected in structure.

[0029] The pay-off device 1 is composed of multiple sets of pay-off racks 11 and a traction mechanism 12;

[0030] The heat treatment system 2 is composed of a contact tank 21, a quenching tank 22, a lead liquid circulation pump 23, a transformer 24 and a heat treatment man-machine interface 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com