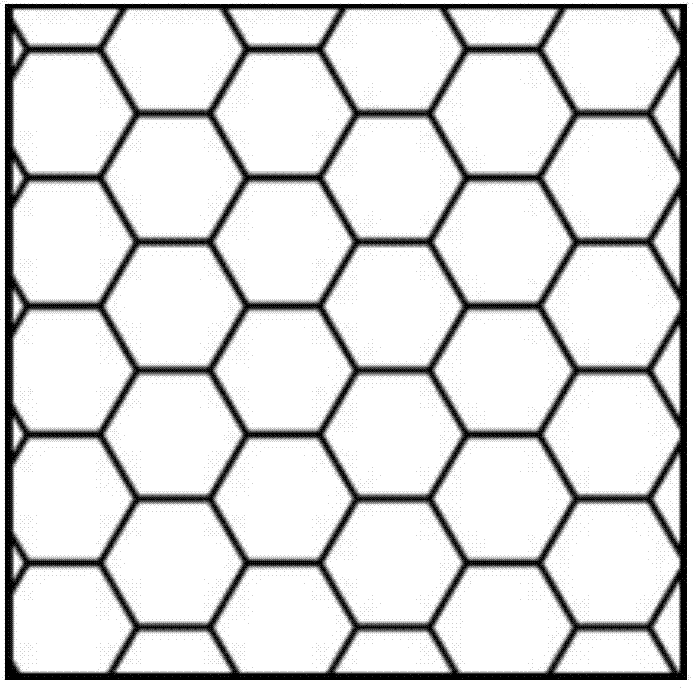

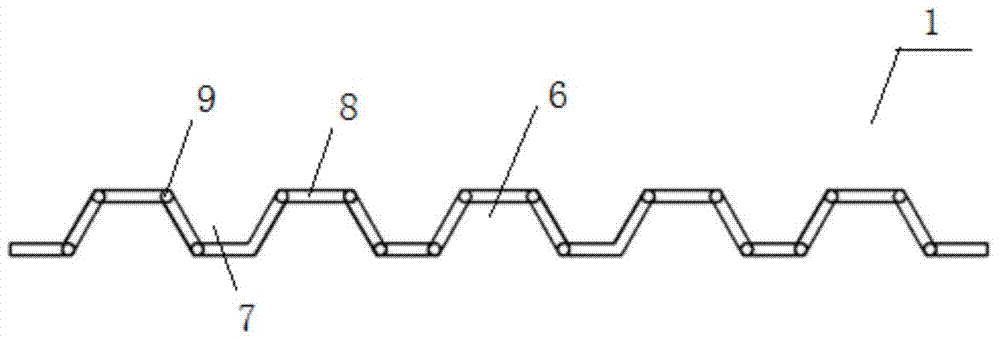

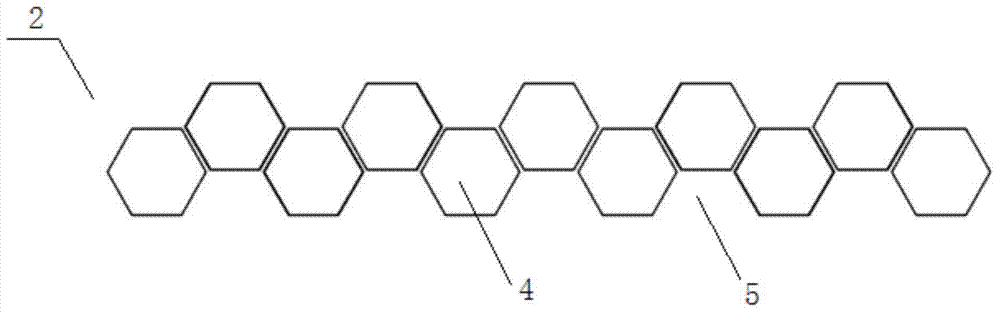

Mold and device capable of producing honeycomb core material continuously, and using method of mold

A honeycomb core material and mold technology, applied in the field of composite material manufacturing, can solve the problems of complex process and difficult continuous production, and achieve the effect of broadening the application field, improving the enhancement capacity, and improving the Z-direction structural strength and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] According to the above method, glass fiber is used as a reinforcing material and polyethylene resin is used as a matrix material to prepare the honeycomb core material. Based on the total amount of the long fiber material and resin, the mass content of the glass fiber is about 10%. .

Embodiment 2

[0055] According to the method described in Example 1, basalt fiber is used as raw material, supplemented with polypropylene resin to prepare the described honeycomb core material, based on the total amount of the long fiber material and resin, the mass content of the basalt fiber is 20% .

Embodiment 3

[0057] According to the method described in Example 1, the aramid fiber is used as a raw material, supplemented with polyamide resin to prepare the described honeycomb core material, based on the total amount of the long fiber material and resin, the mass content of the aramid fiber is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com