A surface-strengthened clear glass

A technology of transparent glass and surface strengthening, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., and can solve the problems of surface strengthening induced by cooling spontaneous crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

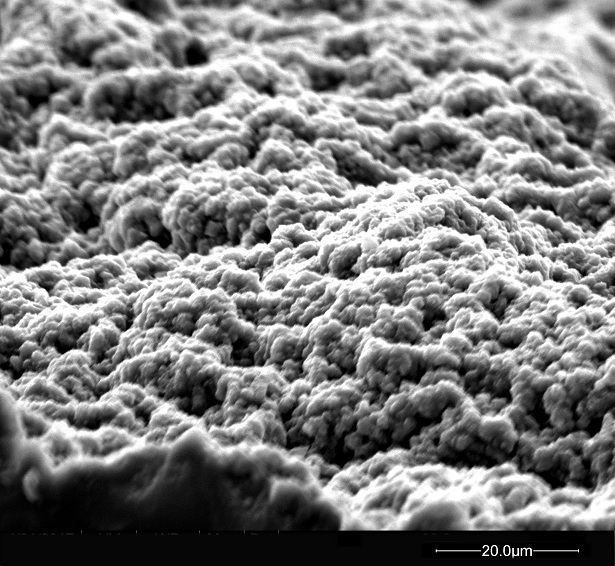

Image

Examples

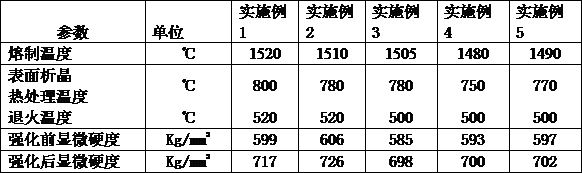

Embodiment 1

[0020] The parts by weight of raw materials used consist of:

[0021] 67.68 parts of quartz powder, 1.55 parts of aluminum hydroxide, 3.57 parts of boric acid, 19.00 parts of sodium carbonate, 12.66 parts of magnesium oxide, 3.61 parts of calcium carbonate, and 7.33 parts of sodium fluorosilicate.

[0022] The weight percent (wt%) of the active ingredient of raw material used is:

[0023] SiO 2 67, Al 2 o 3 1.0, B 2 o 3 2.0, Na 2 O 11.0, MgO 12.6, CaO 2.0, F 4.4.

[0024] The concrete steps of manufacturing method are as follows:

[0025] (1) After mixing the above raw materials evenly, heat them in a silicon-molybdenum rod electric furnace at 1520°C for 2 hours to prepare a uniform molten glass;

[0026] (2) Cast the molten glass in a heat-resistant cast iron mold with a preheating temperature of 800°C, then keep it in a muffle furnace at 800°C for 20 minutes, then cool to 520°C at a rate of 2°C / min and anneal for 30 minutes Stop heating, and cool down to room tem...

Embodiment 2

[0029] The parts by weight of raw materials used consist of:

[0030] 64.60 parts of quartz powder, 2.32 parts of aluminum hydroxide, 4.46 parts of boric acid, 21.59 parts of sodium carbonate, 12.26 parts of magnesium oxide, 5.41 parts of calcium carbonate, and 7.25 parts of sodium fluorosilicate.

[0031] The weight percent (wt%) of the active ingredient of raw material used is:

[0032] SiO 2 63.95, Al 2 o 3 1.50, B 2 o 3 2.00, Na 2 O 12.50, MgO 12.20, CaO 3.00, F 4.35.

[0033] The specific steps of the manufacturing method are as follows:

[0034] After mixing the above raw materials evenly, heat them in a silicon-molybdenum rod electric furnace at 1510°C for 2 hours to obtain a uniform molten glass;

[0035] (2) Cast the molten glass in a heat-resistant cast iron mold with a preheating temperature of 780°C, then keep it in a muffle furnace at 780°C for 20 minutes, then cool it to 520°C at a rate of 2°C / min and anneal for 30 minutes Stop heating, and cool down ...

Embodiment 3

[0038] The parts by weight of raw materials used consist of:

[0039] 62.63 parts of quartz powder, 3.09 parts of aluminum hydroxide, 5.36 parts of boric acid, 22.46 parts of sodium carbonate, 12.26 parts of magnesium oxide, 6.22 parts of calcium carbonate, and 7.25 parts of sodium fluorosilicate.

[0040]The weight percent (wt%) of the active ingredient of raw material used is:

[0041] SiO 2 62.00, Al 2 o 3 2.00, B 2 o 3 3.00, Na 2 O 13.00, MgO 12.20, CaO 3.45, F 4.35.

[0042] The specific steps of the manufacturing method are as follows:

[0043] (1) After mixing the above raw materials evenly, heat them in a silicon-molybdenum rod electric furnace at 1505°C for 2 hours to obtain a uniform molten glass;

[0044] (2) Cast the molten glass in a heat-resistant cast iron mold with a preheating temperature of 780°C, then keep it in a muffle furnace at 780°C for 20 minutes, then cool to 500°C at a rate of 2°C / min and anneal for 30 minutes Stop heating, and then cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com