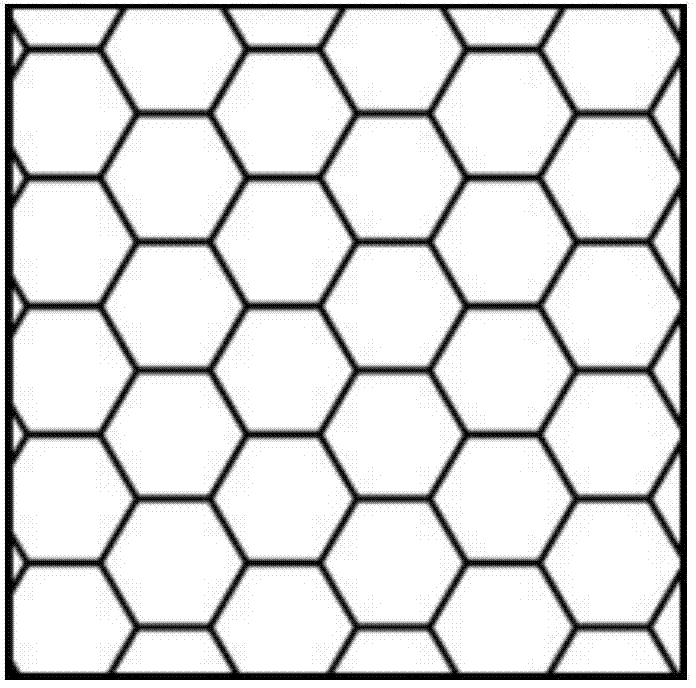

Z-direction orientation continuous fiber reinforced honeycomb core material as well as preparation process and application thereof

A technology of honeycomb core material and continuous fiber, which is applied in the field of Z-direction oriented continuous fiber reinforced honeycomb core material, which can solve the problems of poor Z-direction directional strength of honeycomb composite materials, improve the Z-direction structural strength and bearing capacity, and broaden the application field , Enhance the effect of continuous fiber reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

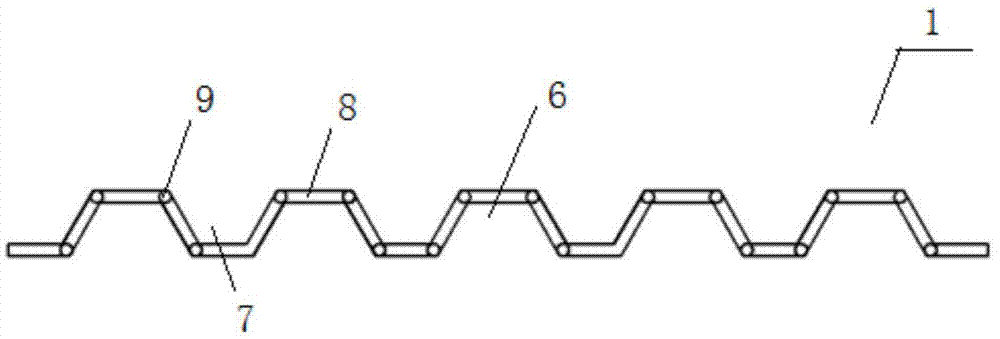

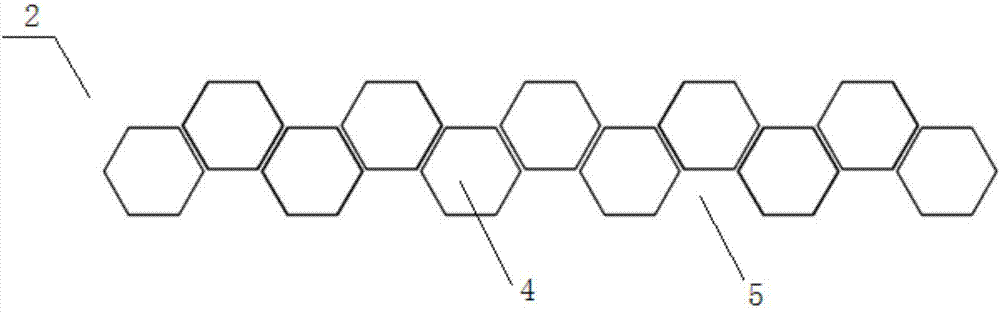

[0050] The process for preparing Z-direction oriented continuous fiber reinforced honeycomb core material described in this embodiment specifically includes the following steps:

[0051] (1) According to the size requirements of the prepared honeycomb core material, the carrier is installed in advance. There is a vertical plate at the beginning of the carrier, and the rear mold 2 is fixed on the front end of the vertical plate of the table, and the adjacent said The distance between the side walls of the regular hexagonal prisms 4 is 0.5 mm of the wall thickness of the honeycomb to be prepared. The hopper of the extruder is filled with high-density polyethylene pellets, and each heating section of the extruder enters a heating state, and the die size of the extruder is adjusted. Co-extrude and fully mix the polyethylene resin and glass fiber in molten state, based on the total amount of the long fiber material and resin, the mass content of the glass fiber is about 10%;

[005...

Embodiment 2

[0057] According to the method described in Example 1, basalt fiber is used as raw material, supplemented with polypropylene resin to prepare the described honeycomb core material, based on the total amount of the long fiber material and resin, the mass content of the basalt fiber is 20% .

Embodiment 3

[0059] According to the method described in Example 1, the aramid fiber is used as a raw material, supplemented with polyamide resin to prepare the described honeycomb core material, based on the total amount of the long fiber material and resin, the mass content of the aramid fiber is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com