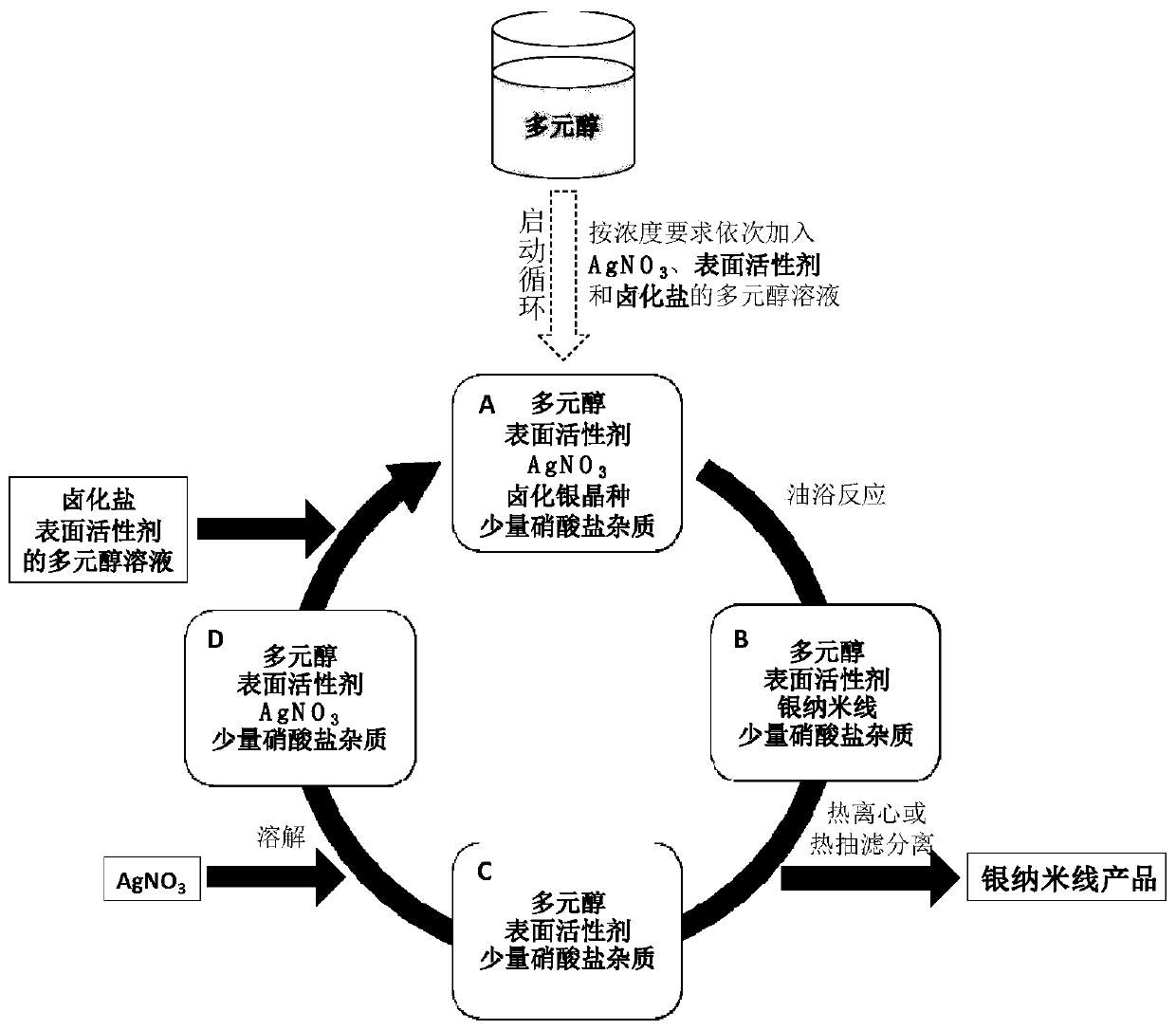

Silver nanowire continuous production method for solvent recovery and recycling

A technology of silver nanowires and production methods, which is applied in the field of continuous production of silver nanowires for solvent recovery and recycling, can solve problems such as limited supply, difficult polyol solvents, and inability to recycle, so as to improve efficiency and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Including the following steps:

[0037] S1. Add 0.58g polyvinylpyrrolidone (MW=1300000) to 40mL ethylene glycol at one time under magnetic stirring, and dissolve to obtain solution A;

[0038] S2. 0.59g of silver nitrate is added to solution A at one time, stirred and dissolved to obtain solution B;

[0039] S3. 5 mL of ethylene glycol solution of NaCl prepared in advance was slowly added dropwise to solution B under stirring to obtain solution C, and the concentration of NaCl in the gained solution C was 0.270 mmol / L;

[0040] S4. Put solution C in an oil bath at 155°C for 60 minutes to react to obtain suspension D;

[0041] S5. Immediately after the reaction, the suspension D was taken out, and separated by hot suction filtration at 150° C. (the pore size of the filter paper used was 0.5 micron), to obtain the silver nanowire product and the ethylene glycol filtrate E;

[0042] S6. Add the ethylene glycol solution of polyvinylpyrrolidone, silver nitrate and NaCl suc...

Embodiment 2

[0045] S1. Add 0.68g polyvinylpyrrolidone (MW=1300000) into 40mL ethylene glycol at one time under magnetic stirring, and dissolve to obtain solution A;

[0046] S2. 0.75g of silver nitrate is added to solution A at one time, stirred and dissolved to obtain solution B;

[0047] S3. 5 mL of the ethylene glycol solution of NaBr prepared in advance was slowly added dropwise to solution B under stirring to obtain solution C, and the concentration of NaBr in the gained solution C was 0.30 mmol / L;

[0048] S4. Put solution C in an oil bath at 145°C for 90 minutes to react to obtain suspension D;

[0049] S5. Immediately after the reaction, the suspension D was taken out, and thermal centrifugation (10000 rpm) was performed at 100° C. to obtain the silver nanowire product and the ethylene glycol supernatant E;

[0050] S6. Add the ethylene glycol solution of polyvinylpyrrolidone, silver nitrate and NaBr successively in the ethylene glycol supernatant E, make each material concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com