Compound steel groove, embedded groove channel and embedded groove channel production method

A pre-embedded channel and composite steel technology, which is applied in the field of pre-embedded channels and pre-embedded channel production, composite steel channels, can solve the problems that the surface anti-corrosion technology cannot guarantee the service life, exceed the project budget, and cannot be widely used. , to achieve the effect of maintaining anti-corrosion performance, improving safety and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

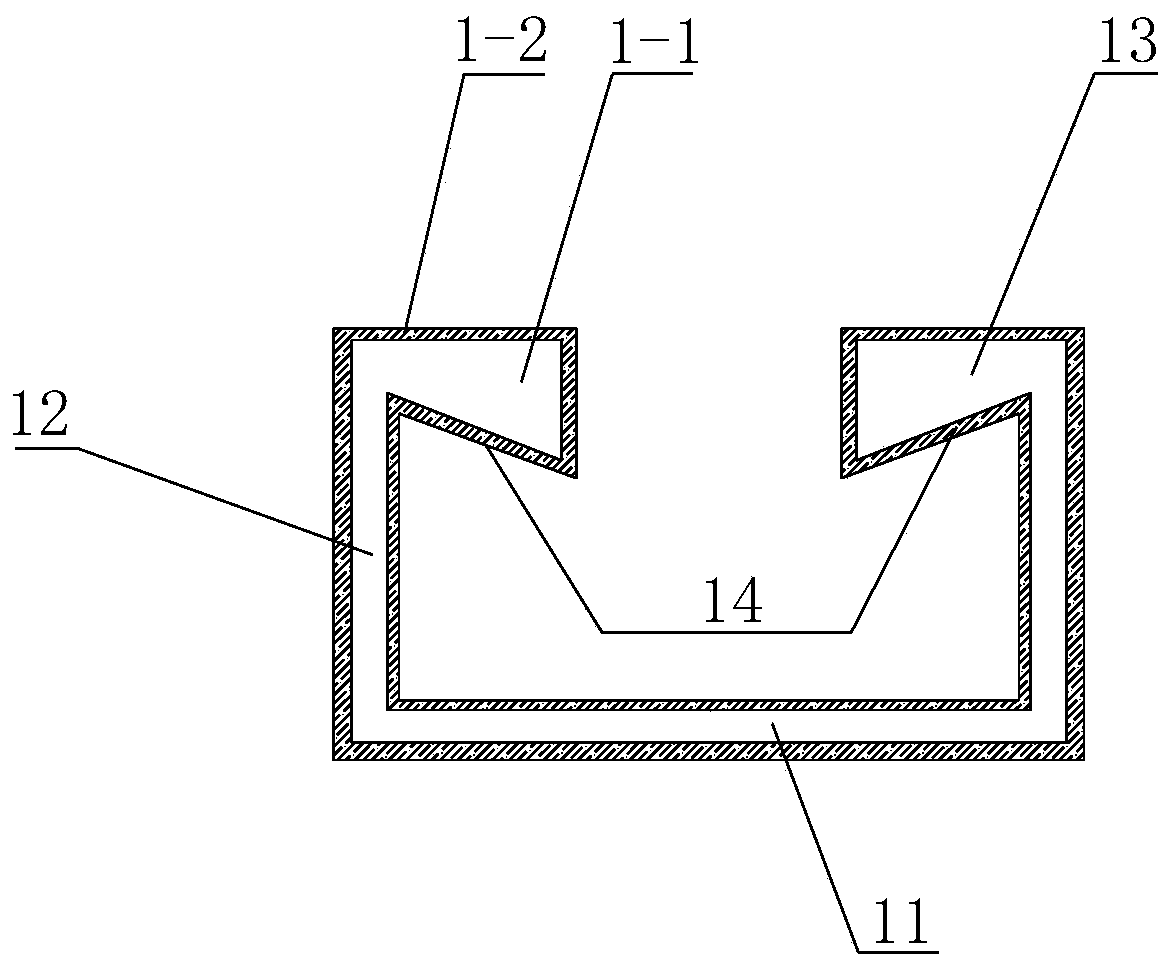

[0054] In this embodiment, the composite steel channel is a dovetail steel channel composited by stainless steel and carbon steel. The cross section of the composite steel channel is rectangular, with a width of 30mm and a height of 20mm. The metal of the surface layer is 316L stainless steel. The unilateral thickness of the 316L stainless steel layer is 0.3mm, accounting for 10% of the total thickness of the section (3mm), and the thickness of the 316L stainless steel layer at the outer surface of the groove leg hook is 0.3mm, accounting for 10% of the total thickness of the section (5.6mm). 5.4%, the thickness of the 316L stainless steel layer at the inner surface of the groove leg hook is 0.26mm, accounting for 4.6% of the total thickness of the section (5.6mm). The metal of the core is Q355 steel, and the thickness of the Q355 steel layer at the groove waist and groove leg is 2.4mm, accounting for 80% of the total thickness (3mm) of the section.

[0055] In this embodiment...

Embodiment 2

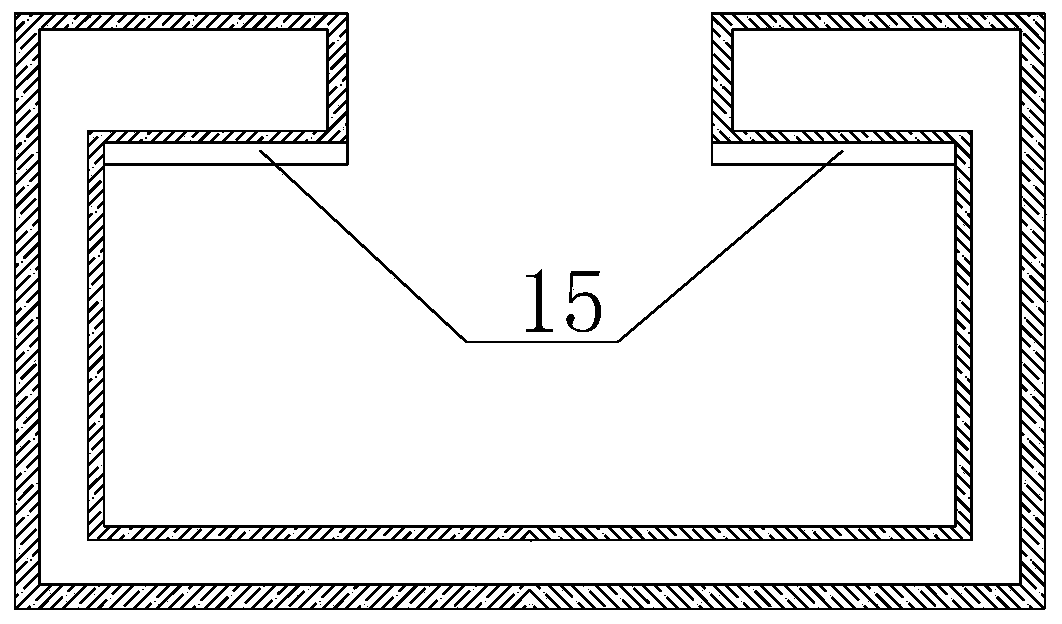

[0057] In this embodiment, the pre-buried channel includes a composite steel channel and a composite anchor rod. The surface layer metal of the composite steel channel is 304 stainless steel, the core metal is Q355 carbon steel, and the composite steel channel is a dovetail steel channel with a rectangular cross section. The width is 52mm, the height is 34mm, the length is 1000mm, and the bending radius is 6640mm.

[0058] The metal of the surface layer of the composite anchor is 304 stainless steel, the metal of the core of the anchor is Q355 carbon steel, the height is 125mm, the leg width is 40mm, and the length is 40mm.

[0059] Both ends of the composite steel channel and the composite anchor rod are coated with epoxy zinc-rich paint.

[0060] In this embodiment, since the entire outer surface of the pre-buried channel is covered by stainless steel layer and epoxy zinc-rich layer, it can achieve 2400 hours of neutral salt spray test without rust (equivalent to 100 years o...

Embodiment 3

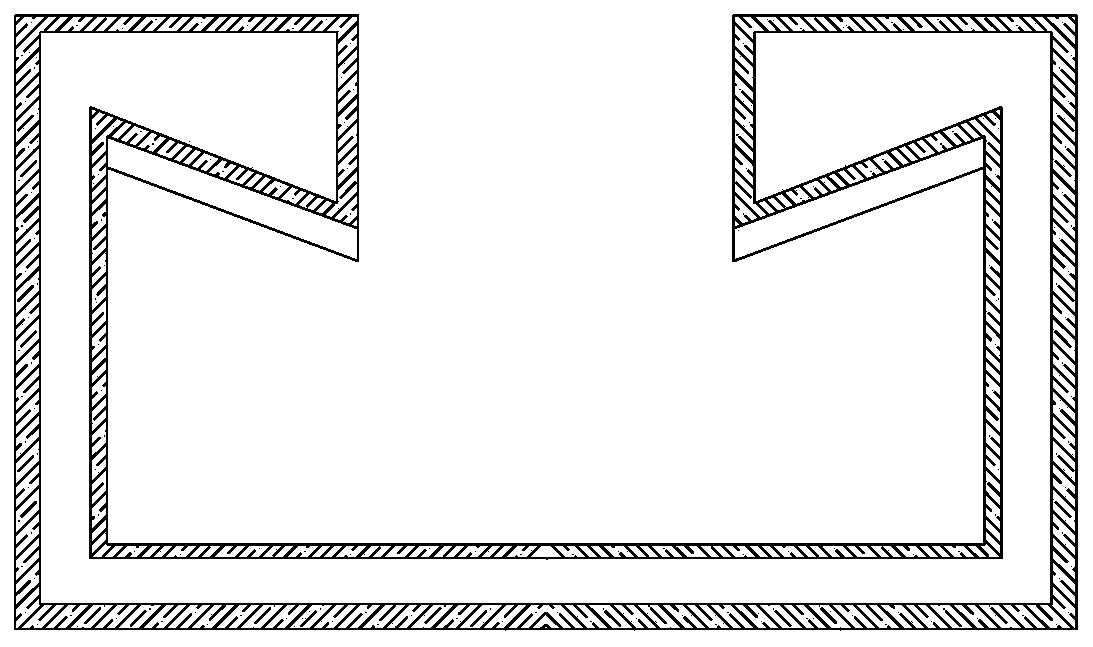

[0062] In the present embodiment, the production process of the composite steel channel described in [Example 1] is as follows:

[0063] 1. Use a crane to place the core metal Q355B continuous casting billet with a thickness of 150mm x 150mm x 1200mm on the transport roller table, transport it to the brushing machine for four-sided brushing, remove the iron sheet, sundries and oil stains on the surface, and brush it The temperature is 20°C, and the polishing machine uses four polishing and milling pieces to simultaneously polish the cross-section.

[0064] 2. Send the continuous casting billet after throwing and brushing into the pressing device of the roll forming machine on-line with the roller table, and cross-cut, transfer and press the 6mm thick × 150mm wide × 1200mm long after the roll forming machine The surface layer metal 316L stainless steel plates are combined together along the diagonal direction of the continuous casting billet to make a combined billet.

[0065]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com