Device for simultaneously producing surface layer waterproof agent and core layer waterproof agent of shaving board and method for preparing surface layer waterproof agent and core layer waterproof agent of shaving board

A technology of waterproofing agent and particleboard, which is applied in the direction of flat products, mechanical equipment, household components, etc., and can solve the problems of reducing the production process of particleboard, unsatisfactory waterproofing effect of waterproofing agent, and high requirements for system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

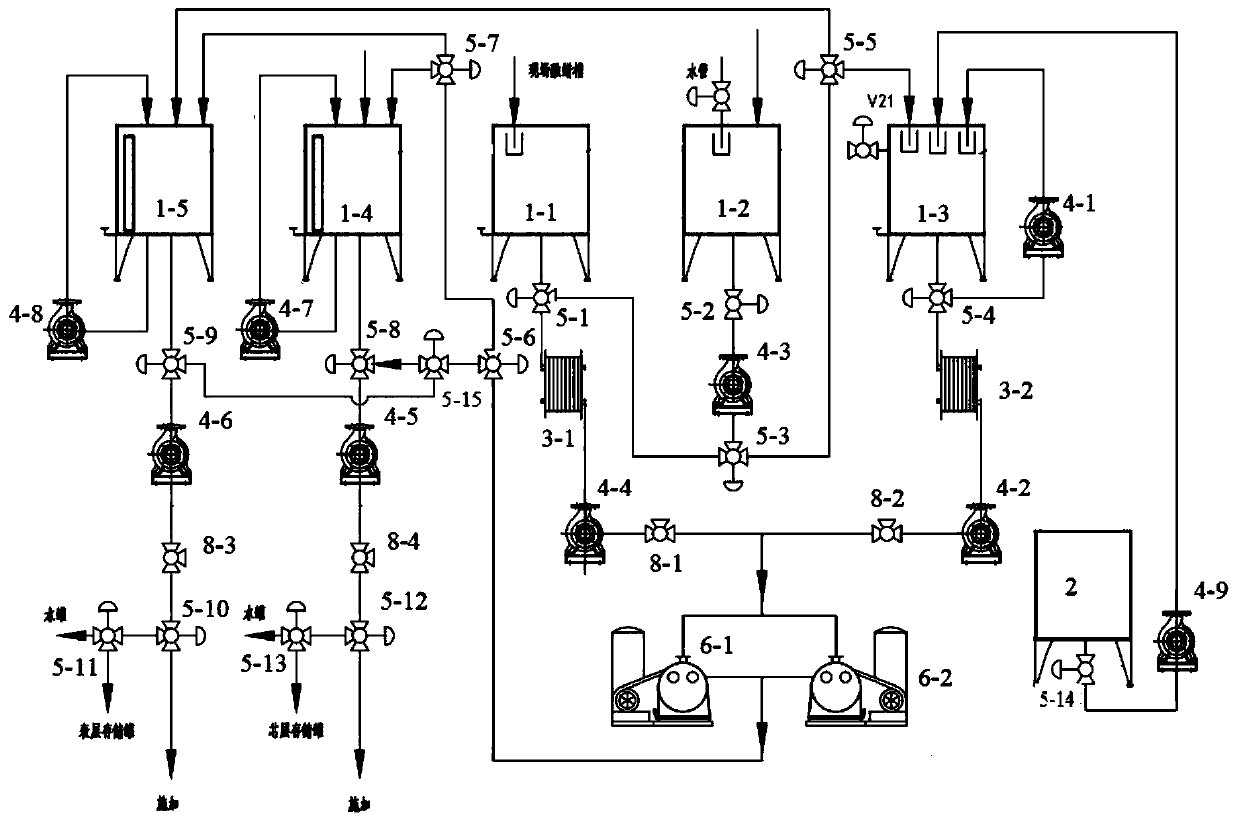

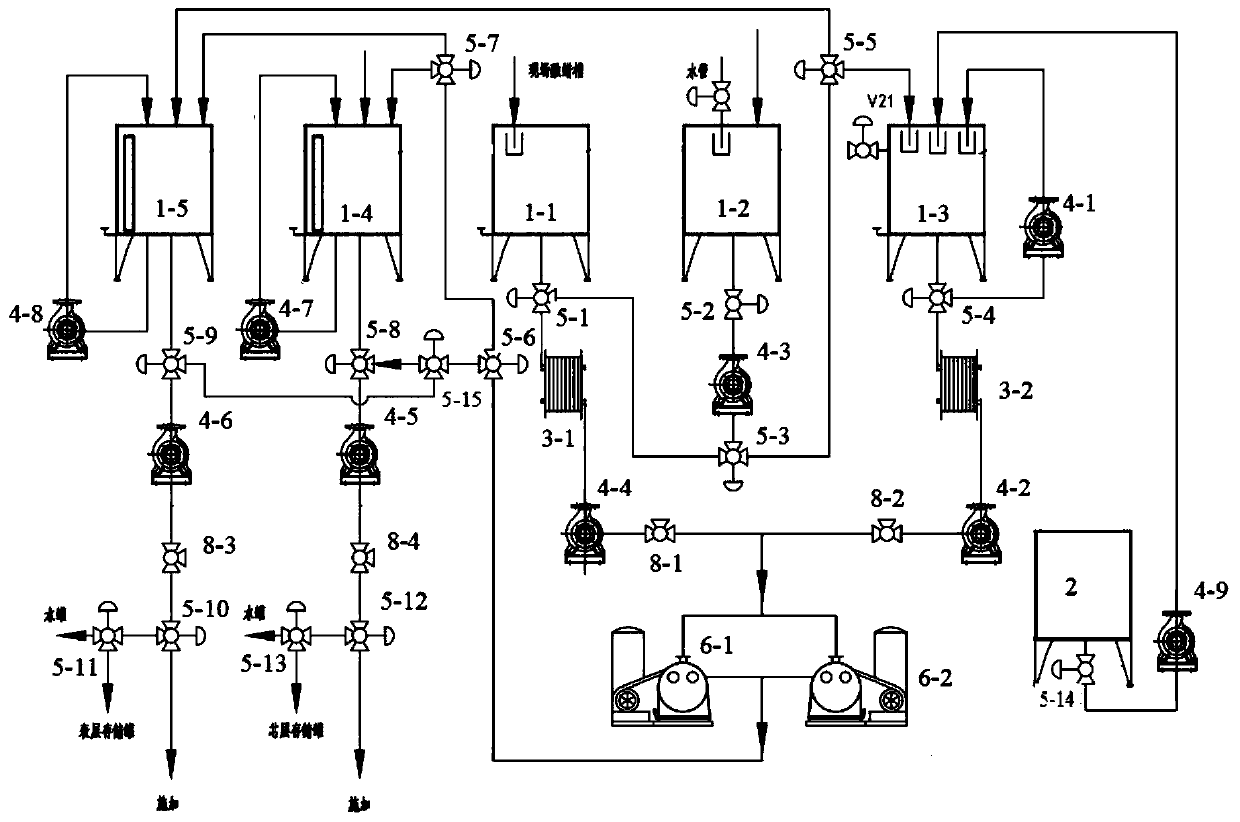

[0080] Add lignosulfonate aqueous solution with a mass concentration of 50% into metering tank 1-3, heat to 90°C, and set aside;

[0081] Add liquid paraffin into the metering tank 1-1, heat to 90°C, and set aside;

[0082] After controlling the lignosulfonate aqueous solution and liquid paraffin to pass through a pipeline type multistage homogeneous pump 6-1 with a mass ratio of 1:20 at a rate of 10,000 rpm for shearing and mixing, pass through a three-way valve 5 -6 The water repellent obtained is pumped into the surface layer storage tank 1-5 and the core layer storage tank 1-4 respectively;

[0083] The waterproof agent in the core layer storage tank 1-4 is directly transported by the hydraulic diaphragm metering pump 4-5 to obtain a particleboard core layer waterproof agent with a solid content of 65%, and is directly applied to the preparation process of the particleboard core layer;

[0084] Dilute the waterproofing agent in the surface storage tank 1-5 with the hot wa...

Embodiment 2

[0087] Add lignosulfonate aqueous solution with a mass concentration of 45% into metering tank 1-3, heat to 90°C, and set aside;

[0088] Add liquid paraffin into the metering tank 1-1, heat to 90°C, and set aside;

[0089] After controlling the lignosulfonate aqueous solution and liquid paraffin to pass through a pipeline type multistage homogeneous pump 6-1 with a mass ratio of 1:20 at a rate of 10,000 rpm for shearing and mixing, pass through a three-way valve 5 -6 The water repellent obtained is pumped into the surface layer storage tank 1-5 and the core layer storage tank 1-4 respectively;

[0090] The waterproof agent in the core layer storage tank 1-4 is directly transported by the hydraulic diaphragm metering pump 4-5 to obtain a particleboard core layer waterproof agent with a solid content of 60%, and is directly applied to the preparation process of the particleboard core layer;

[0091] Dilute the waterproofing agent in the surface storage tank 1-5 with the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com