Pattern rolling forming unit and welded pipe production system with same

A forming unit and pattern technology, which is applied in the field of welded pipe manufacturing, can solve problems such as pipe gaps and leakage inspections, and achieve the effects of flexible use, strong adaptability, and promotion of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Product type: The total length of a single high-efficiency heat exchange tube is 6.0m, of which the length of the external thread of the rolling section is 5.6m, the length of the smooth section at both ends is 0.2m, and the pattern depth of the rolling section is 0.15mm.

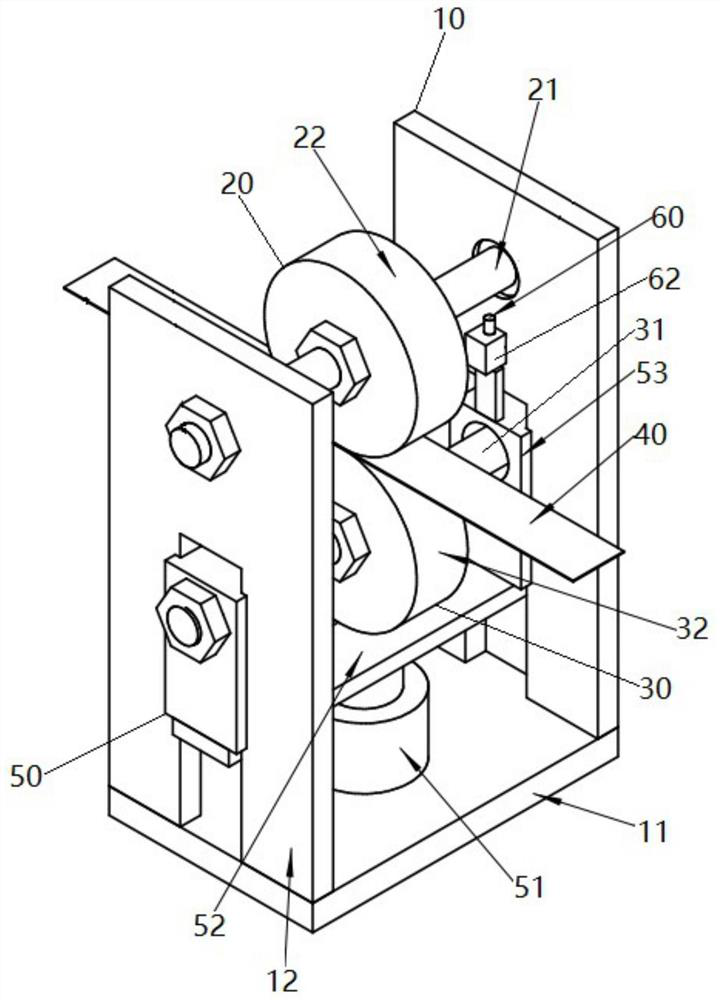

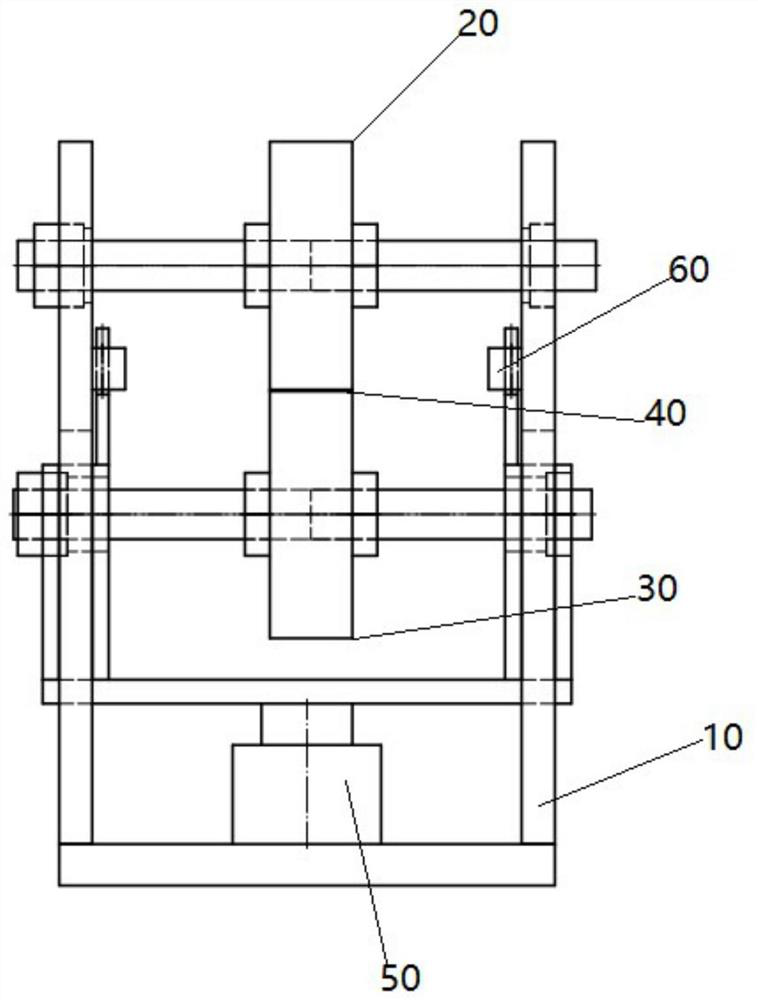

[0047] A combined form in which the first roll 20 is a smooth roll and the second roll 30 is a pattern roll is adopted. The operation of the servo motor is controlled by PLC and touch screen. When the linear speed of the embossing roll is set to 2.0m / min, that is, the forward speed of the strip is 2.0m / min, and the set value of the limit member and pressure sensor is 15 tons. Therefore, The squeeze time and release time of the rolls can be determined. The motor is turned on to push the hydraulic cylinder, the embossing roller moves up, presses against the smooth roller, and applies a pressing force to the strip. When the set pressure is reached, the hydraulic cylinder stops working and maintains the ...

example 2

[0049] Product type: The total length of a single high-efficiency heat exchange tube is 6.0m, and the inner wall of the tube is required to have continuous internal threads.

[0050] A combined form in which the first roll 20 is an embossed roll and the second roll 30 is a smooth roll is adopted. The operation of the servo motor is controlled by PLC and touch screen. When the linear speed of the embossing roll is set to 2.0m / min, that is, the forward speed of the strip is 2.0m / min, and the set value of the limit member and pressure sensor is 15 tons. When the set pressure is reached, the hydraulic cylinder stops working and maintains the current pressure to realize the rolling of the strip surface pattern, and the pattern depth is 0.15mm, and the above-mentioned strip can be produced. After the subsequent forming unit, welding unit, annealing treatment, pre-diameter and secondary sizing, etc. of the production line, a high-efficiency heat exchange tube with threads on the inne...

example 3

[0052] Product type: The total length of a single high-efficiency heat exchange tube is 6.0m, of which the length of the external thread in the rolling section is 5.6m, and the external thread is divided into two directions. 0.15mm.

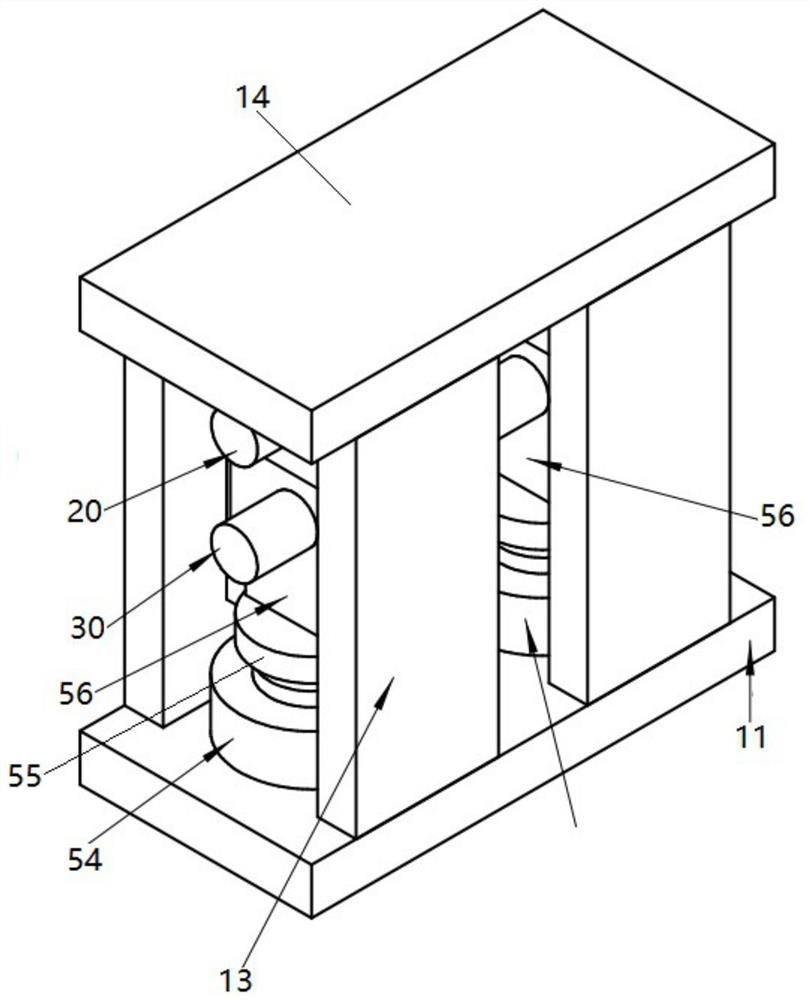

[0053] A combined form in which the first roll 20 is a smooth roll and the second roll 30 is a pattern roll is adopted. At the same time, two sets of racks are arranged in front and back, and the embossing rollers are set at 45° and 135° respectively. The two sets of embossing rollers are connected to the motor through a worm gear reducer. The operation of the servo motor is controlled by the PLC and the touch screen, and the switch of the hydraulic station is controlled by the PLC to ensure that the two groups of embossing rollers are controlled separately and realize the continuity of the pattern. When the line speed of the embossing roll is set to 2.0m / min, that is, the forward speed of the strip is 2.0m / min, and the setting value of the limi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com