Test method for compact reservoir volume fracture conductivity

A technology for tight reservoirs and conductivity, which is applied in earth-moving drilling, wellbore/well components, etc. It can solve the problem that the conductivity of fractures cannot be simulated realistically, the influence of fracture conductivity of the fracture coupling surface cannot be quantified, and the accuracy of fracture conductivity cannot be accurately simulated. Expression cracks etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

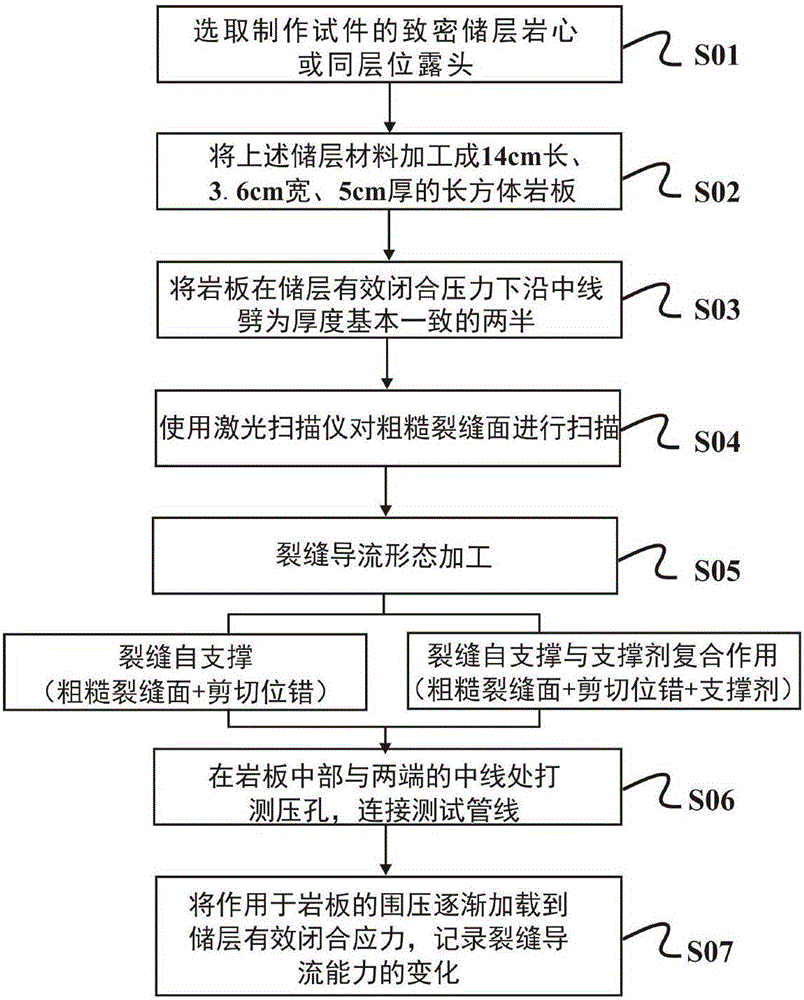

[0059] A method for testing the conductivity of volume fractures in tight reservoirs, the method comprising the following steps:

[0060] Step S01: Select the tight reservoir core or the outcrop of the same layer as the tight reservoir material; when selecting the tight reservoir material, first clean the weathered rock layer near the outcrop, and then excavate a large piece of fresh rock along the thickness direction of the tight reservoir. core

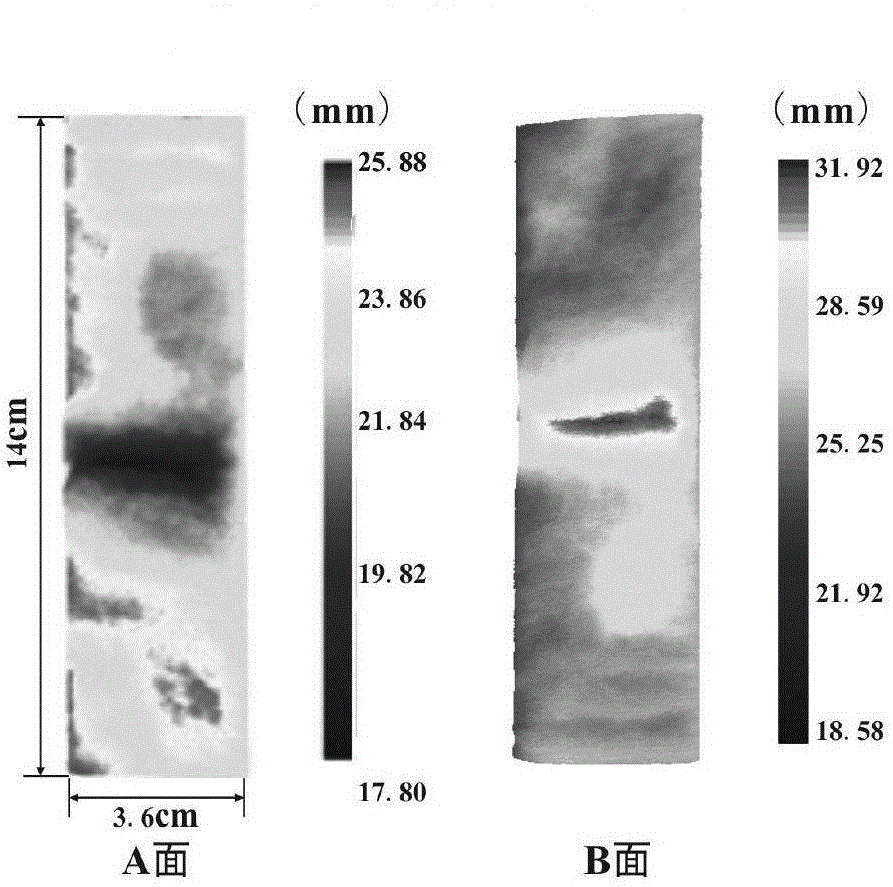

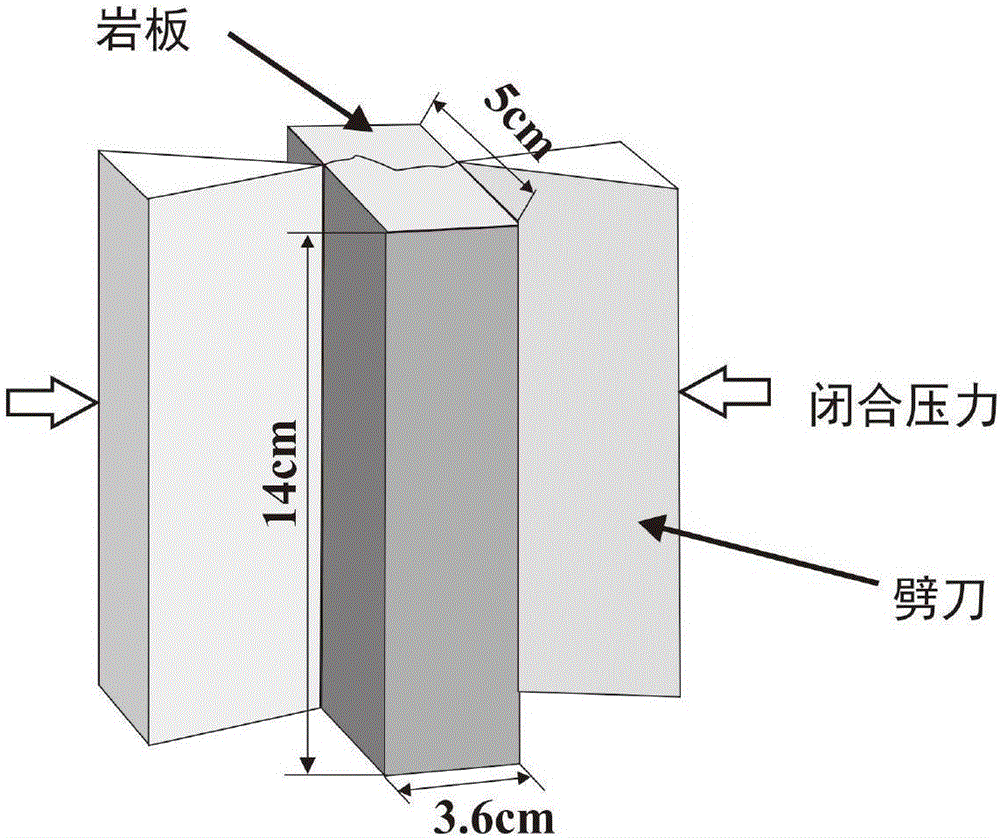

[0061] Step S02: Process the tight reservoir material into a cuboid rock slab with a length of 14 cm, a width of 5 cm, and a thickness of 3.8 cm; during the process of prefabricating the rock slab, the contact time with water should be reduced or an inert gas medium should be used;

[0062] Step S03: split the rock slab into two halves along the midline under the effective closure pressure of the reservoir; wrap the rock slab processed in S02 with adhesive tape to maintain the viscous force between the rock slab bedding, and then U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com