Direct shear-seepage test device and test method for single fracture rock specimen under hydrostatic pressure condition

A rock test piece, hydrostatic pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of sound wave transmission, poor sealing of cracked rocks, and no reliable monitoring, etc., to achieve guarantee Uniform distribution, large shear displacement, and the effect of achieving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

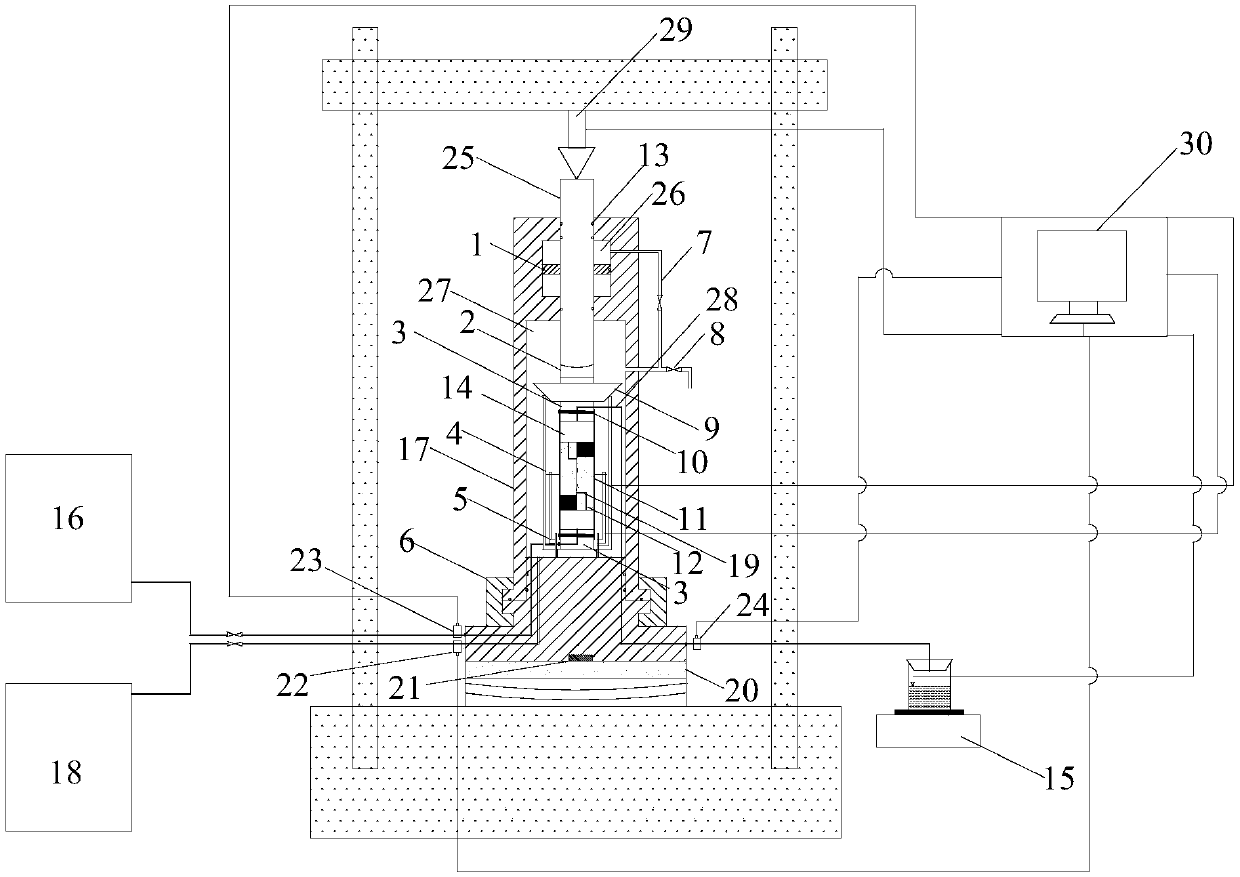

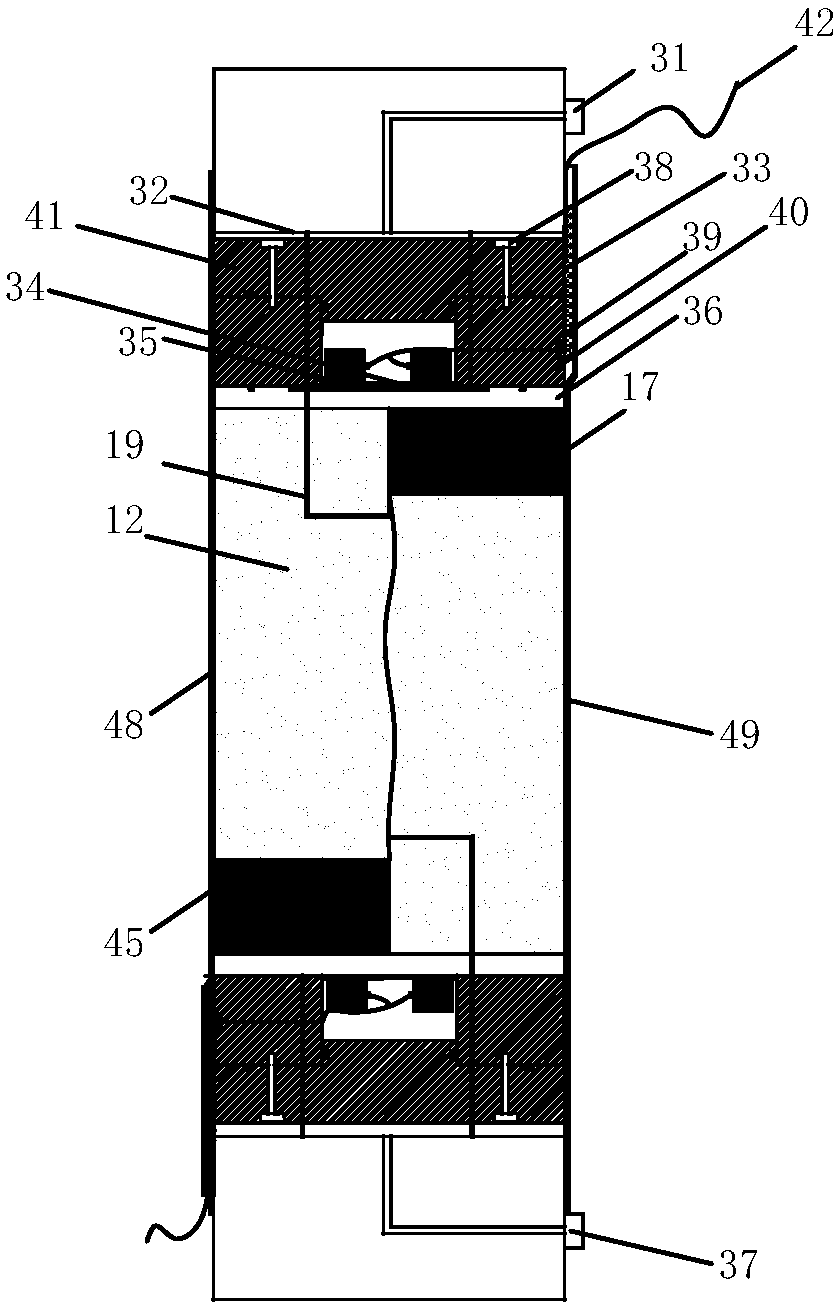

Method used

Image

Examples

Embodiment approach

[0037] Implementation method: Taking the square specimen of fine sandstone of 50×50×100mm as an example, the change of permeability characteristics of the single-crack sandstone specimen during the direct shear-test is studied. The specific test steps are as follows:

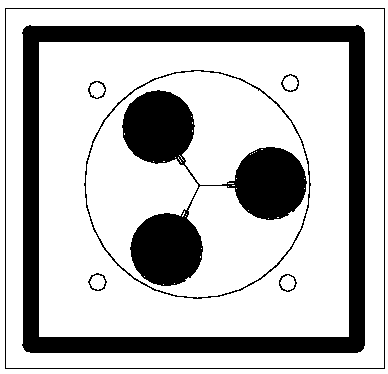

[0038] Step 1: Preparation of single-crack rock specimen. Use a Brazilian splitting device to split a square specimen of fine sandstone with a size of 50×10×200 mm into two halves to obtain a single-crack rock specimen, and then cut the A block 48 and B block 49 of the single-crack rock specimen 12 The length of the opposite ends of each block is about 20 mm, and the end face of the block is polished to ensure that the maximum error of the unevenness of the end face does not exceed 0.02 mm; , and a diversion seam 47 with a width of about 80 mm and a depth of about 2 mm. Afterwards, the treated two cracked blocks are tightly joined together and placed in a steel abrasive tool with a size of 50×50×100 mm, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com