Fully mechanized excavation construction method for rock roadway

A construction method and a fully mechanized excavation technology, which is applied in the field of rock roadway mechanized excavation, can solve problems affecting gangue and head-on operations, fatigue damage to the main shaft of a mechanized excavator, and affect the health of workers, so as to reduce adverse effects and improve cutting efficiency. Efficiency and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preferred specific implementation of the rock roadway fully mechanized excavation construction method of the present invention is:

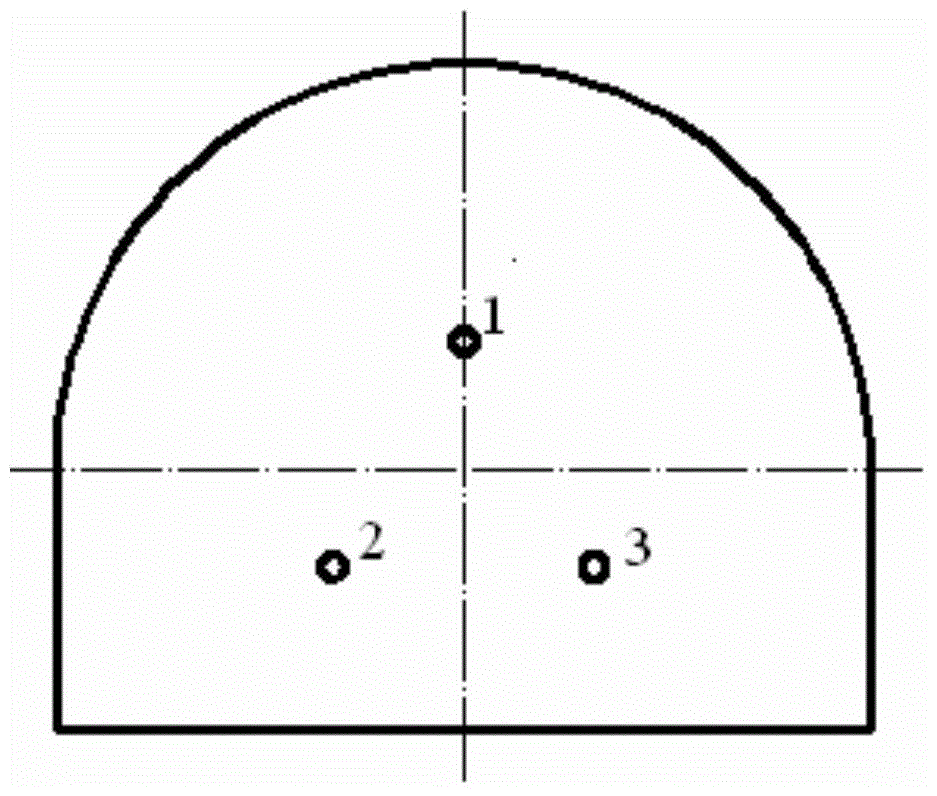

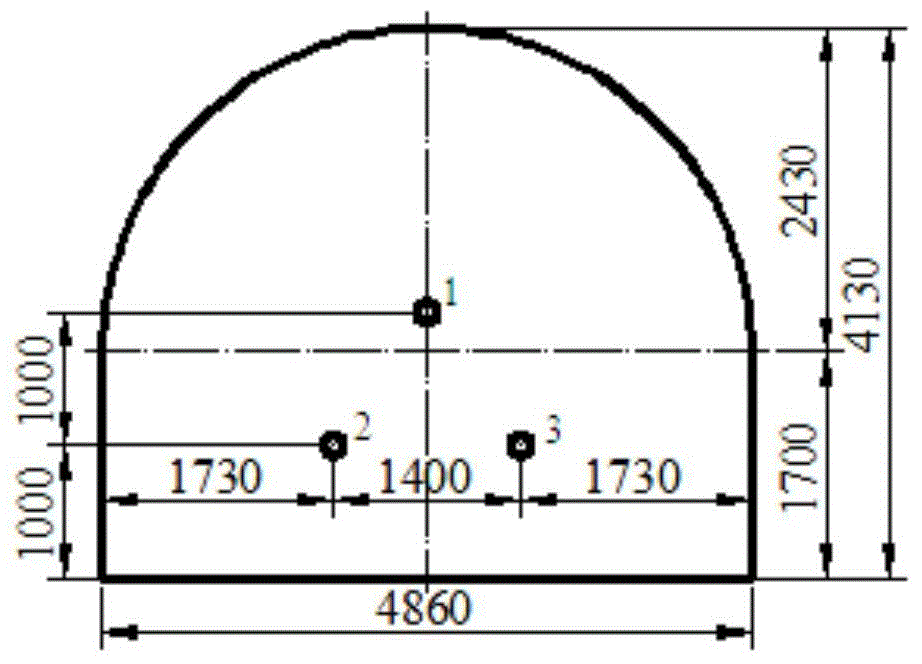

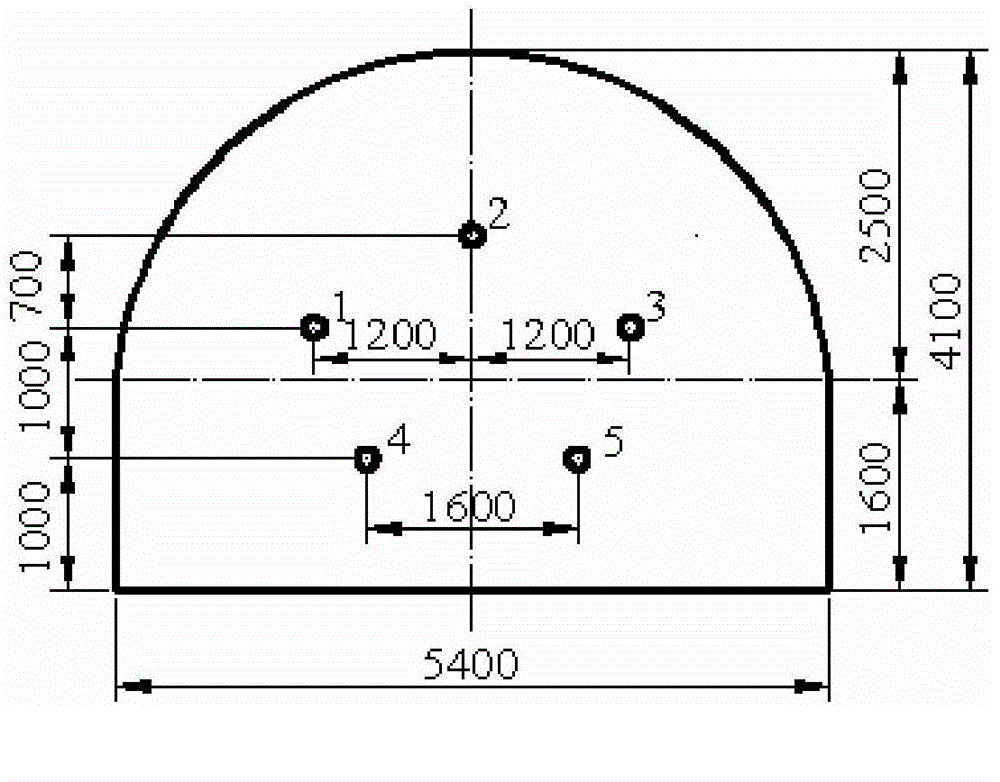

[0033] Such as figure 1 As shown in Fig. 1, the blasting technology of deep hole loosening and fracturing is firstly used to drill blastholes on the face of the roadway. After drilling to the design depth, the drill is pulled out, and the rock powder in the blastholes is blown away with compressed air; then the blastholes are filled. Explosives, water blasting mud, and then seal the blast hole, and carry out loosening and cracking blasting.

[0034] Finally, a fully mechanized excavator is used to cut the rock mass of the tunnel face.

[0035] Loosening fracturing blasting belongs to controlled blasting. The uncoupled charge structure can be used in loosening cracking blasting. The uncoupled charge structure means that the diameter of the charge coil is smaller than the diameter of the borehole, and there are other media, such as air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com