Steel-concrete interface damage monitoring and reinforcing method based on shape memory alloy

A technology of memory alloy and damage monitoring, which is applied in measuring devices, building maintenance, instruments, etc., can solve the problem that there is no effective method for damage monitoring of steel-concrete composite beam interface, so as to prevent serious structural damage and ensure structural safety Good effect with durability, compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

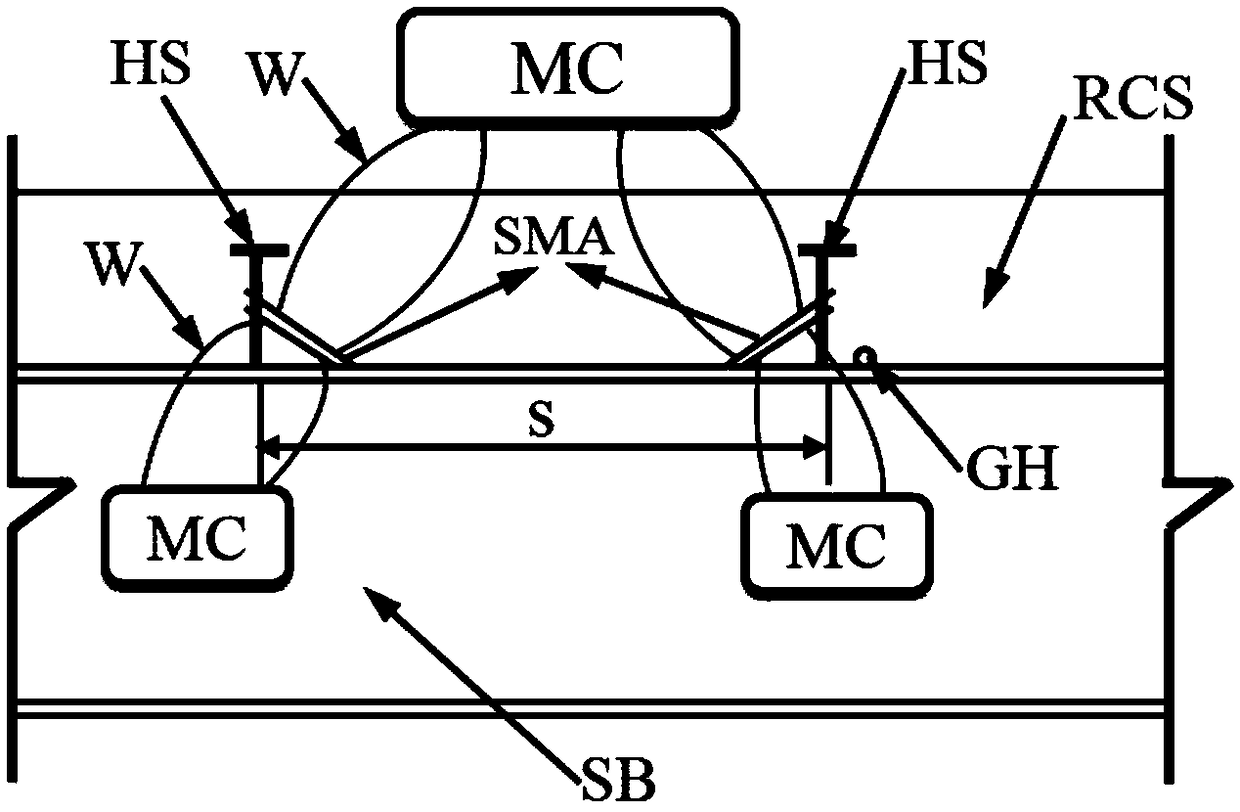

[0038] Such as figure 1 As shown, this embodiment discloses a steel-concrete interface monitoring and active adjustable reinforcement method based on shape memory alloys, which monitors the damage state of the composite beam interface in real time, and imposes controllable reverse constraints on the composite beam interface according to the damage situation. force. The implementation plan includes: shaped steel beam SB, reinforced concrete slab RCS, interface connecting stud HS, shape memory alloy wire SMA, both ends of shape memory alloy wire SMA are connected with interface connecting stud HS and shaped steel beam SB, grouting port GH , wire W, measurement control system MC, etc.

[0039] The shape memory alloy wire SMA is obliquely arranged on the tensile side of the interface connection stud HS in the composite beam, one end is connected with the interface connection stud HS, and the other end is connected with the steel beam SB, and the shape memory alloy wire SMA is con...

Embodiment 2

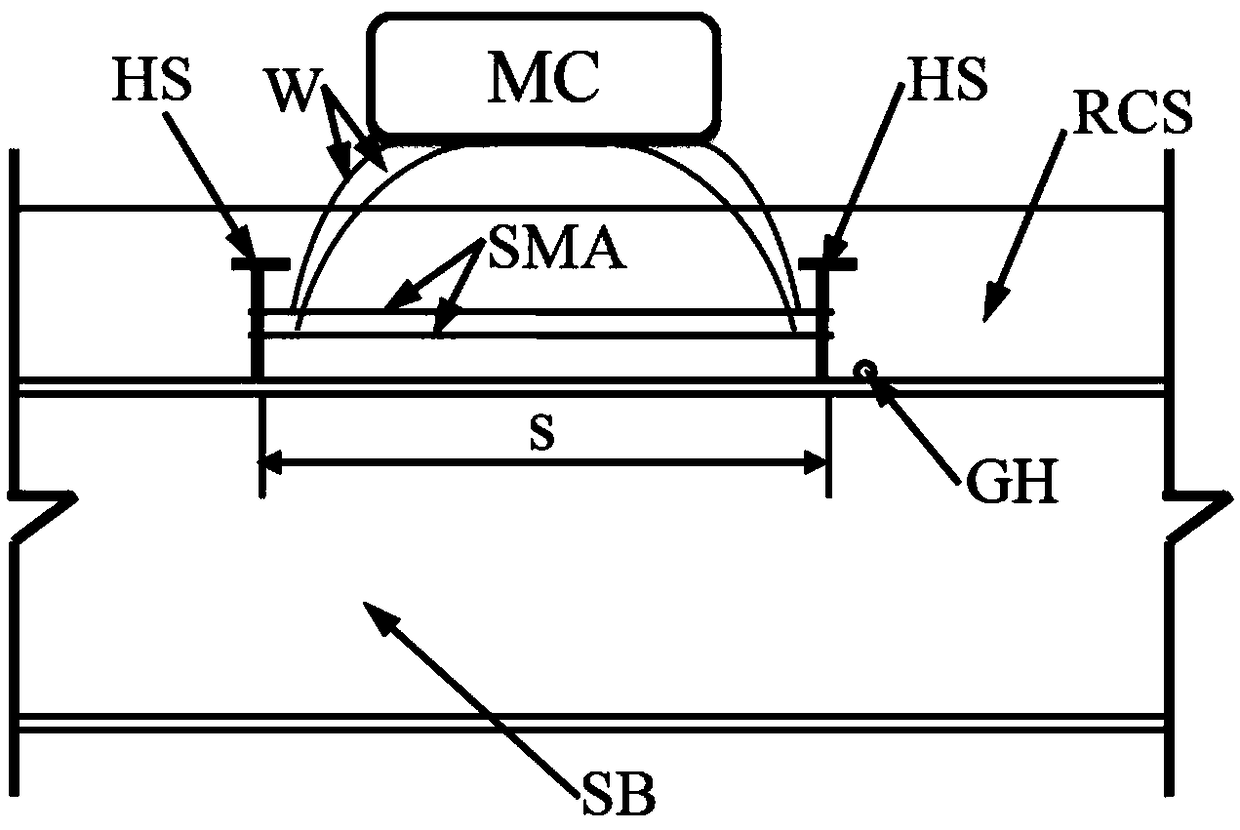

[0043] Such as figure 2 As shown, in this embodiment, the two ends of the shape memory alloy wire SMA are respectively connected to two adjacent interfacial connection pegs HS, and are arranged parallel to the upper surface of the shaped steel beam SB. During the specific implementation process, the interface connecting studs HS undergo relative deformation under the action of external load, causing the shape memory alloy wire SMA to deform and change in resistance. The measurement and control system MC directly measures the relative deformation between the interface connecting studs HS, and indirectly calculates the composite beam Interface slip, finally determine the damage degree of composite beam interface. According to different interface damage levels, the measurement and control system MC controls the temperature of the shape memory alloy wire SMA to different degrees to make it recover and deform, and exerts different degrees of reverse recovery force on the interface...

Embodiment 3

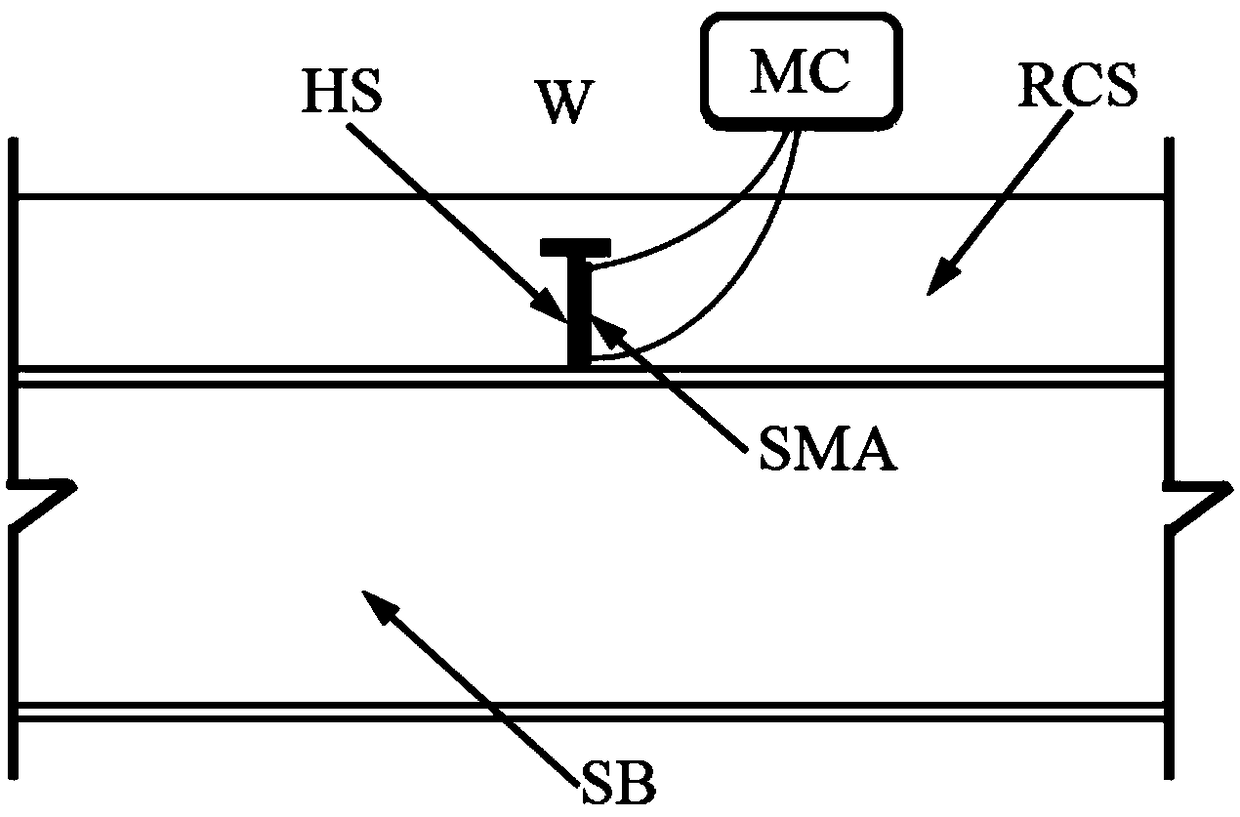

[0045] Such as image 3 As shown, this embodiment discloses a method for monitoring and reinforcing studs at the steel-concrete interface connection based on shape memory alloys. This embodiment includes: shaped steel beam SB, reinforced concrete slab RCS, interface connecting stud HS, shape memory alloy wire SMA, wire W, measurement control system MC and so on.

[0046] In this embodiment, the shape memory alloy wire SMA is fixed on the tension side of the interfacial connection stud HS, and the two are co-deformed. The two ends of the shape memory alloy wire SMA are connected with the same interfacial connection peg HS, and the resistance and length of the shape memory alloy wire SMA change. It directly reflects the deformation of the interfacial connection stud HS. According to the different damage levels of the interface connecting stud HS, the measurement and control system MC controls the temperature of the shape memory alloy wire SMA to cause different degrees of recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com