Double-side wedge-shaped cutting, tunneling and detonating method of especially-big fracture surface tunnel

A technology of extra-large cross-section and wedge-shaped cutting, which is applied in blasting and other directions, can solve the problems of lagging tunnel construction period, increased rock mass sandwiching effect, and increased tunnel construction cost, so as to improve construction efficiency, reduce construction cost, and increase The effect of blasthole utilization and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The double-sided wedge-shaped cutting excavation and blasting method of the extra-large cross-section tunnel in this embodiment is:

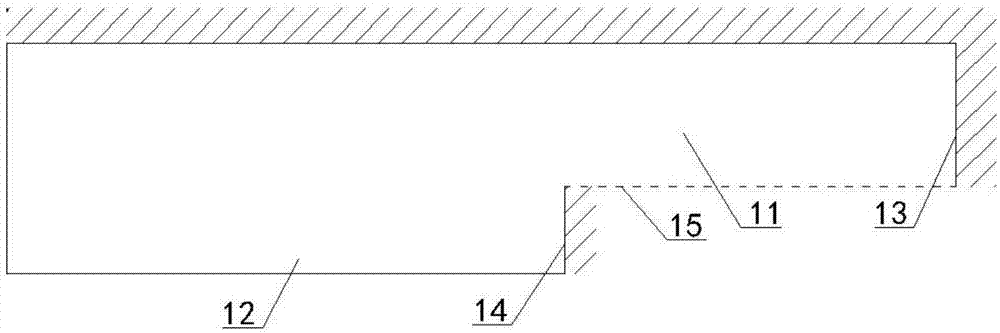

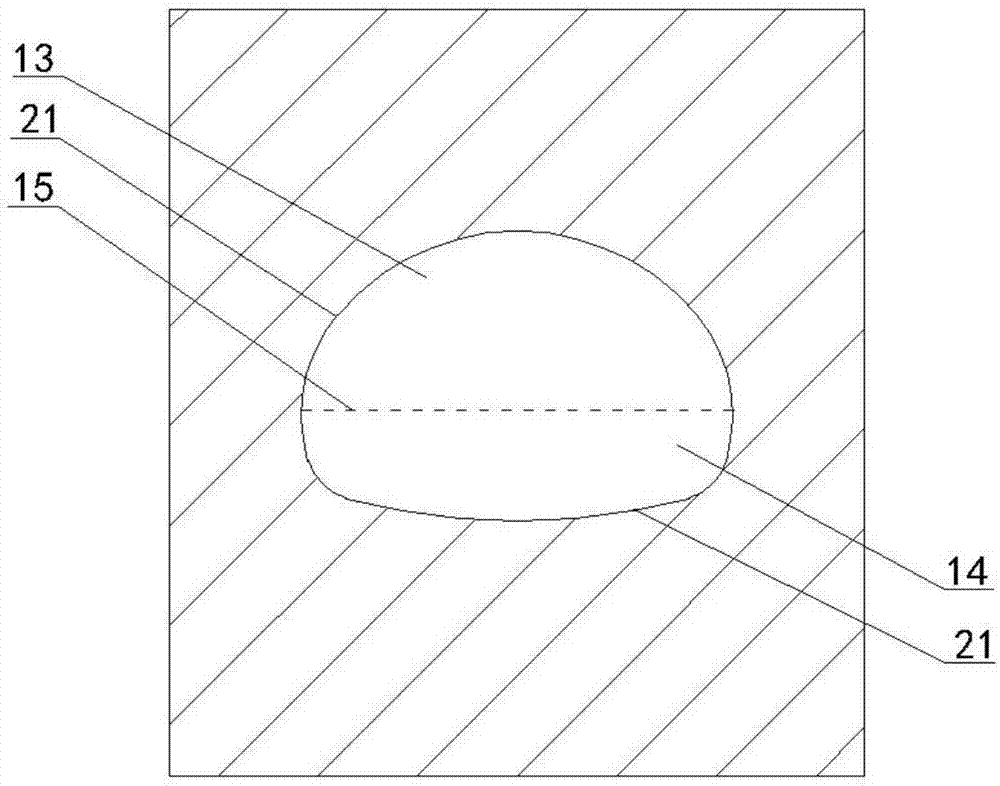

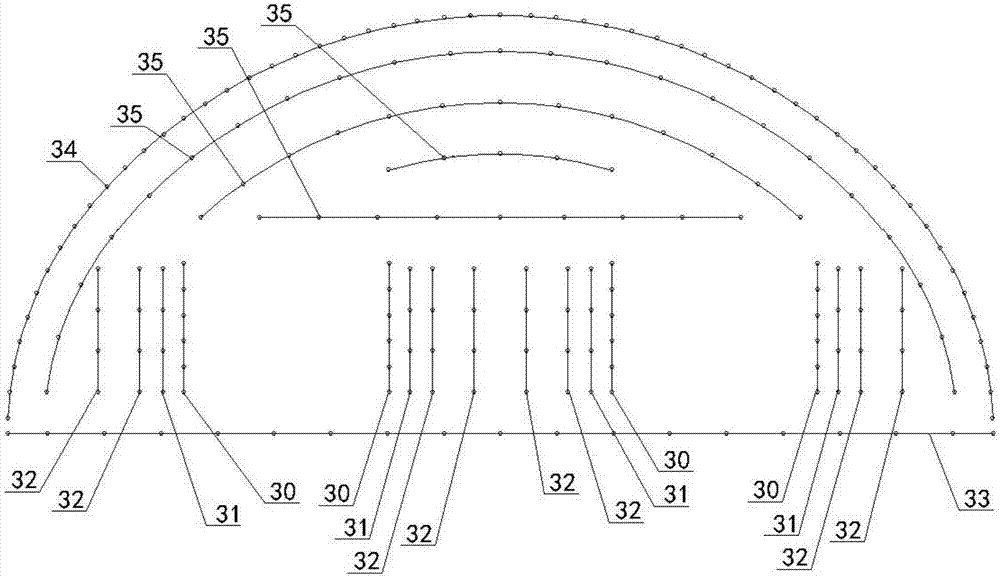

[0025] Such as figure 1 and figure 2 As shown, the super-large cross-section tunnel to be excavated is divided into upper and lower steps for construction. For the division of steps, the upper and lower step interface 15 is firstly determined on the super-large-section tunnel to be excavated, and the upper and lower step interface 15 is used to divide the upper and lower steps. The excavation area 11 of the upper step and the excavation area 12 of the lower step are used to determine the excavation contour 21 of the upper step and the excavation contour 22 of the lower step; wherein, the height of the upper step is 7-9m, the height of the lower step is not less than 4.5m, and the height of the upper step is not less than 4.5m. The distance between the working face 13 of the step and the working face 14 of the lower step is opened by 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com