Conductive paste for solar cell and preparation method thereof

A technology of solar cells and conductive pastes, applied in the direction of conductive coatings, conductive materials, conductive materials, etc., can solve the problems of manufacturing personnel and environmental pollution, and achieve the effect of low raw material cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

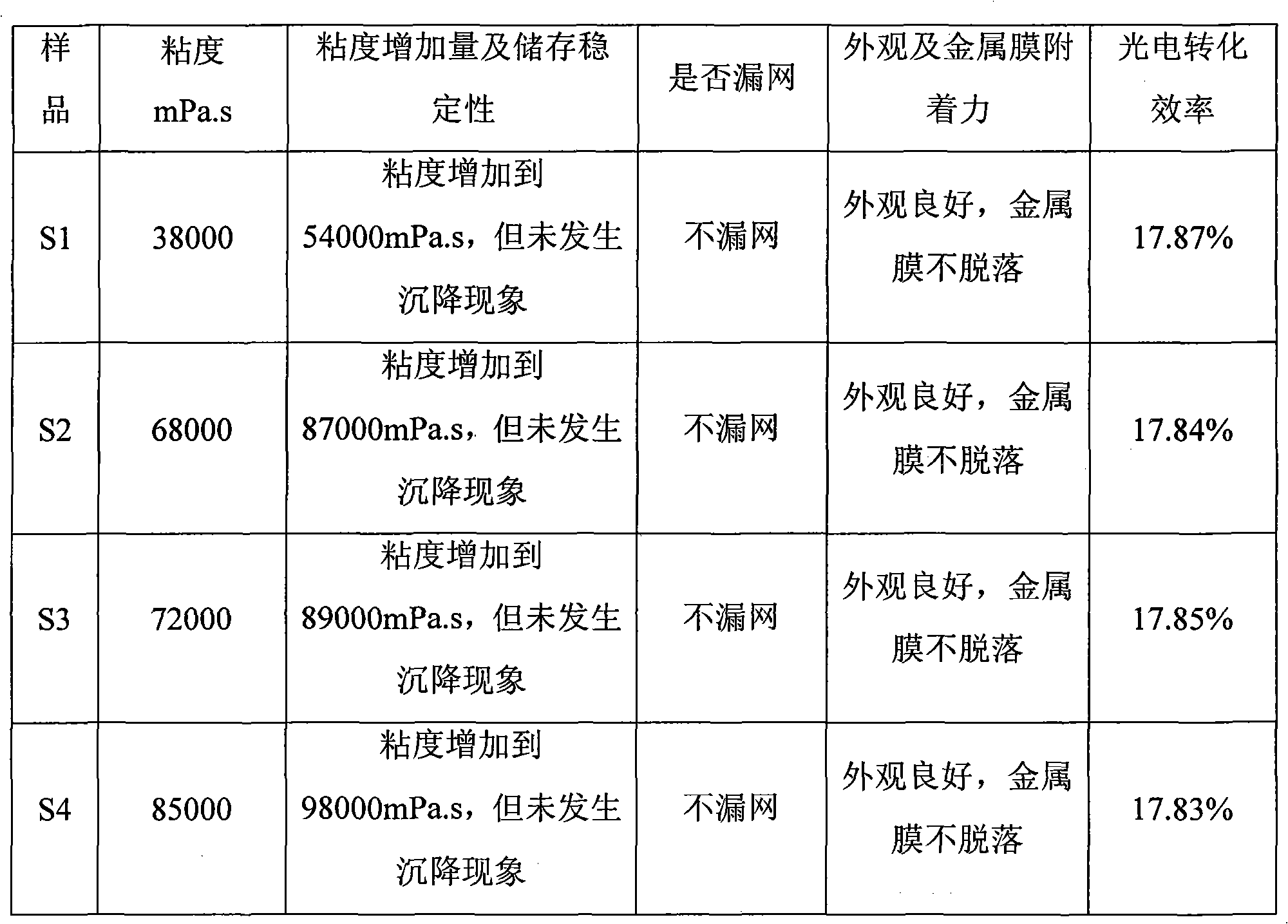

Examples

Embodiment 1

[0029] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0030] Step 1: Configuration of water-based adhesive

[0031] Based on the total weight of the water-based adhesive to be prepared, take 2 parts by weight of sodium carboxymethylcellulose (CMC) and dissolve it in 98 parts of deionized water, heat it to 70°C to fully dissolve it, and stir it evenly , to obtain a uniform and clear water-based adhesive A1.

[0032] Step 2: Preparation of Inorganic Adhesive

[0033] 65 parts by weight of bismuth oxide, 20 parts by weight of boron trioxide, 8 parts by weight of silicon dioxide, 6 parts by weight of zinc oxide, and 1 part by weight of aluminum oxide were added to a high-speed V-shaped mixer and mixed for 20 minutes. until uniform to obtain oxide mixture powder. Put the mixture into a porcelain crucible, put it into a silicon carbide rod furnace, heat it up to 500°C and keep it for 0.5 hours, t...

Embodiment 2

[0037] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0038] Step 1: Configuration of water-based adhesive

[0039] Based on the total weight of the water-based adhesive to be prepared, take 5 parts by weight of sodium carboxymethylcellulose (CMC) and dissolve it in 95 parts of deionized water, heat it to 70°C to fully dissolve it, and stir it evenly , to obtain a uniform and clear water-based adhesive A2.

[0040] Step 2: Preparation of Inorganic Adhesive

[0041] 63 parts by weight of lead oxide, 13 parts by weight of diboron trioxide, 9 parts by weight of silicon dioxide, 8 parts by weight of zinc oxide, 4.5 parts by weight of aluminum oxide, and 0.5 parts by weight of cobalt oxide are added to the high-speed V Mix in a type mixer for 20 minutes until uniform to obtain oxide mixture powder. Put the mixture into a porcelain crucible, put it into a silicon carbide rod furnace, heat it up t...

Embodiment 3

[0045] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0046] Step 1: Configuration of water-based adhesive

[0047] Based on the total weight of the water-based adhesive to be prepared, 6 parts by weight of hydroxyethyl cellulose (HEC) was dissolved in 94 parts of deionized water, heated to 75 ° C, fully dissolved, and stirred evenly, A homogeneous and clear aqueous binder A3 was obtained.

[0048] Step 2: Preparation of Inorganic Adhesive

[0049] Add 78 parts by weight of lead oxide, 8 parts by weight of diboron trioxide, 8 parts by weight of silicon dioxide, and 6 parts by weight of zinc oxide into a high-speed V-shaped mixer and mix for 60 minutes until uniform to obtain an oxide mixture powder. This oxide powder is used as an inorganic binder.

[0050] Step 3: Preparation of solar cell conductive paste

[0051] Based on the total weight of the solar cell conductive paste that needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com