Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

A technology of fire-resistant and flame-retardant coatings and nano-flame retardants, applied in fire-resistant coatings, coatings, latex paints, etc., can solve problems such as smoke safety, environmental pollution, poisoning of escaped people and firefighters, and achieve low VOC content , Excellent physical and chemical properties, excellent fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

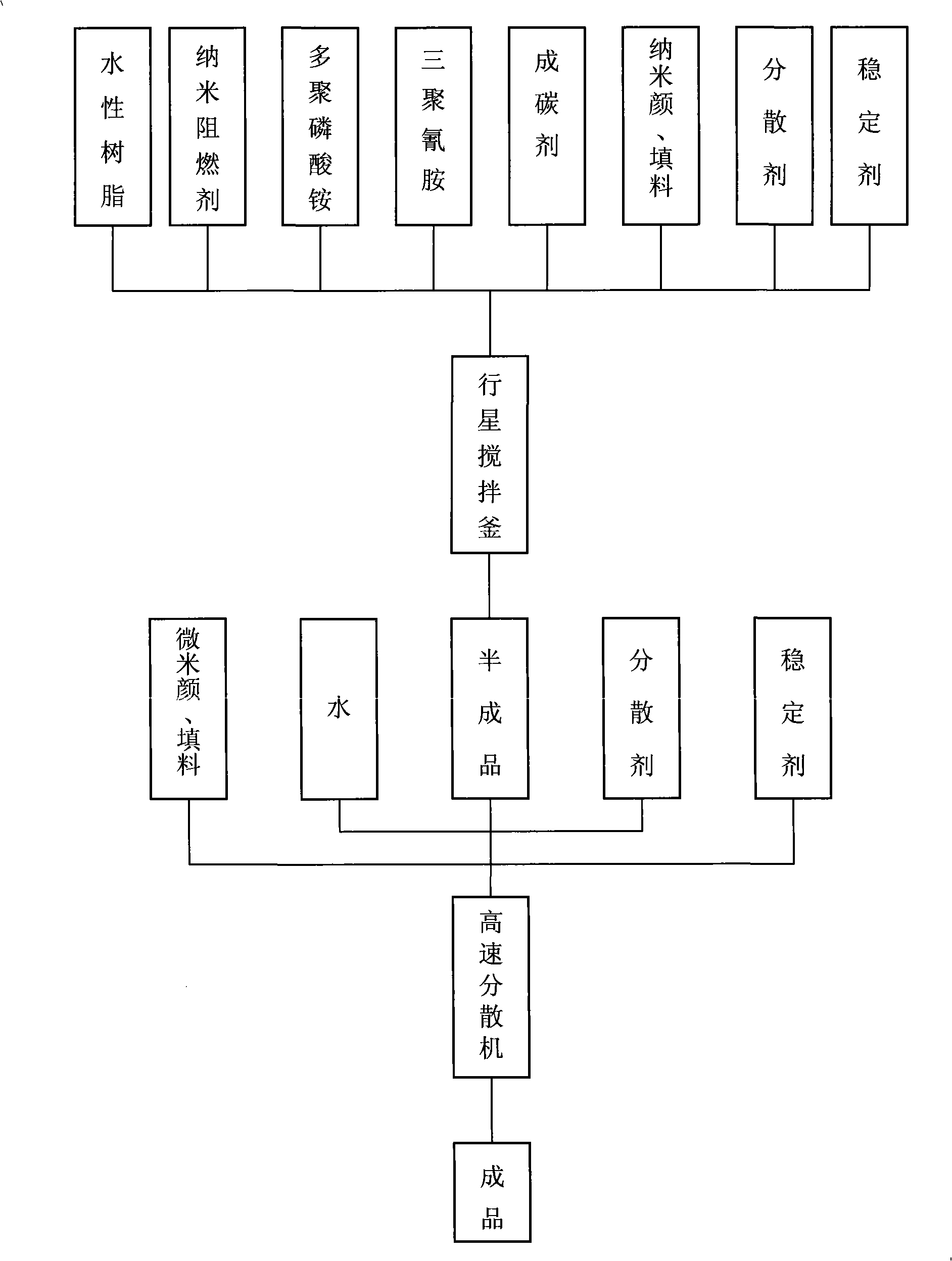

Method used

Image

Examples

Embodiment Construction

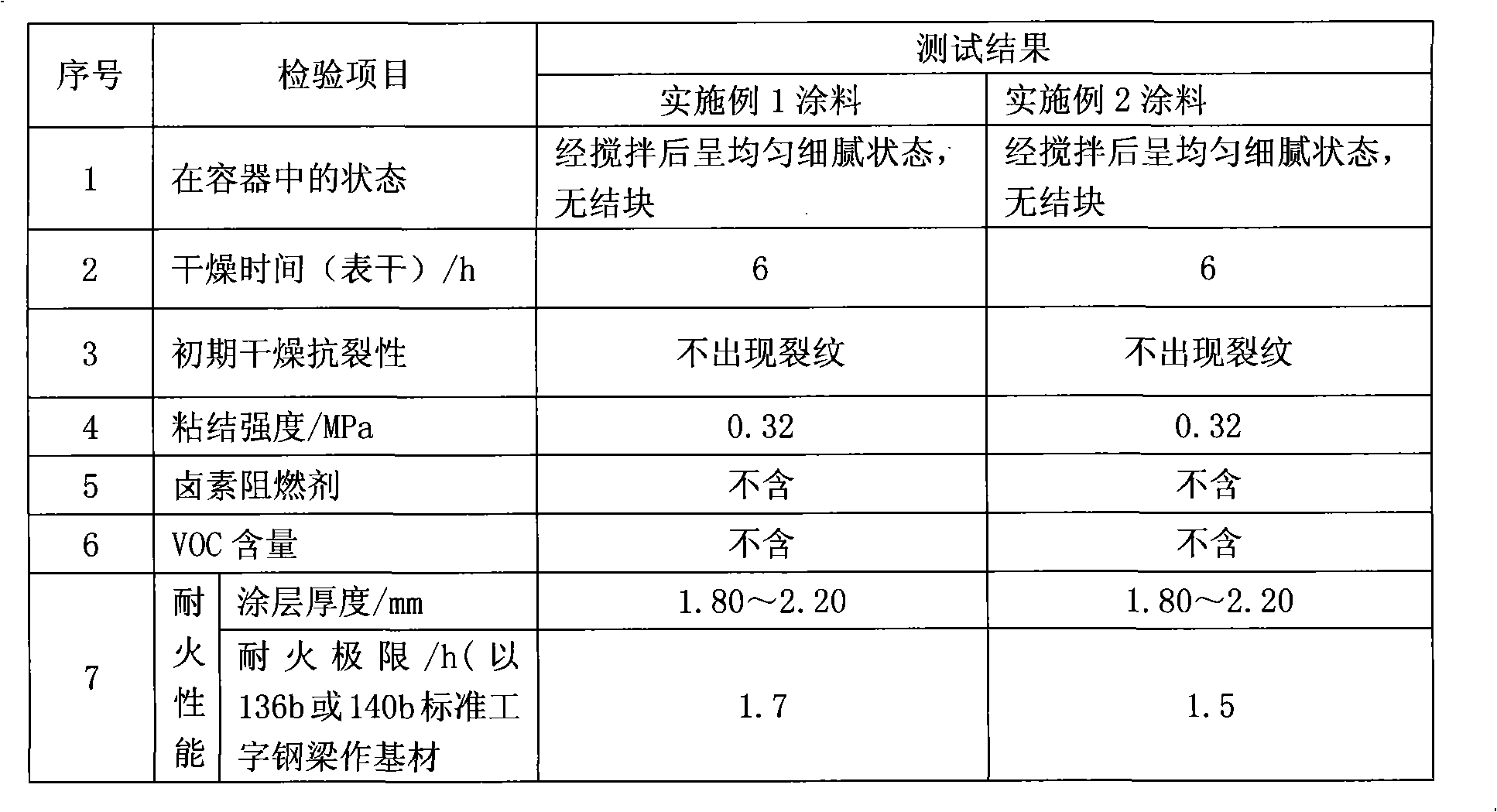

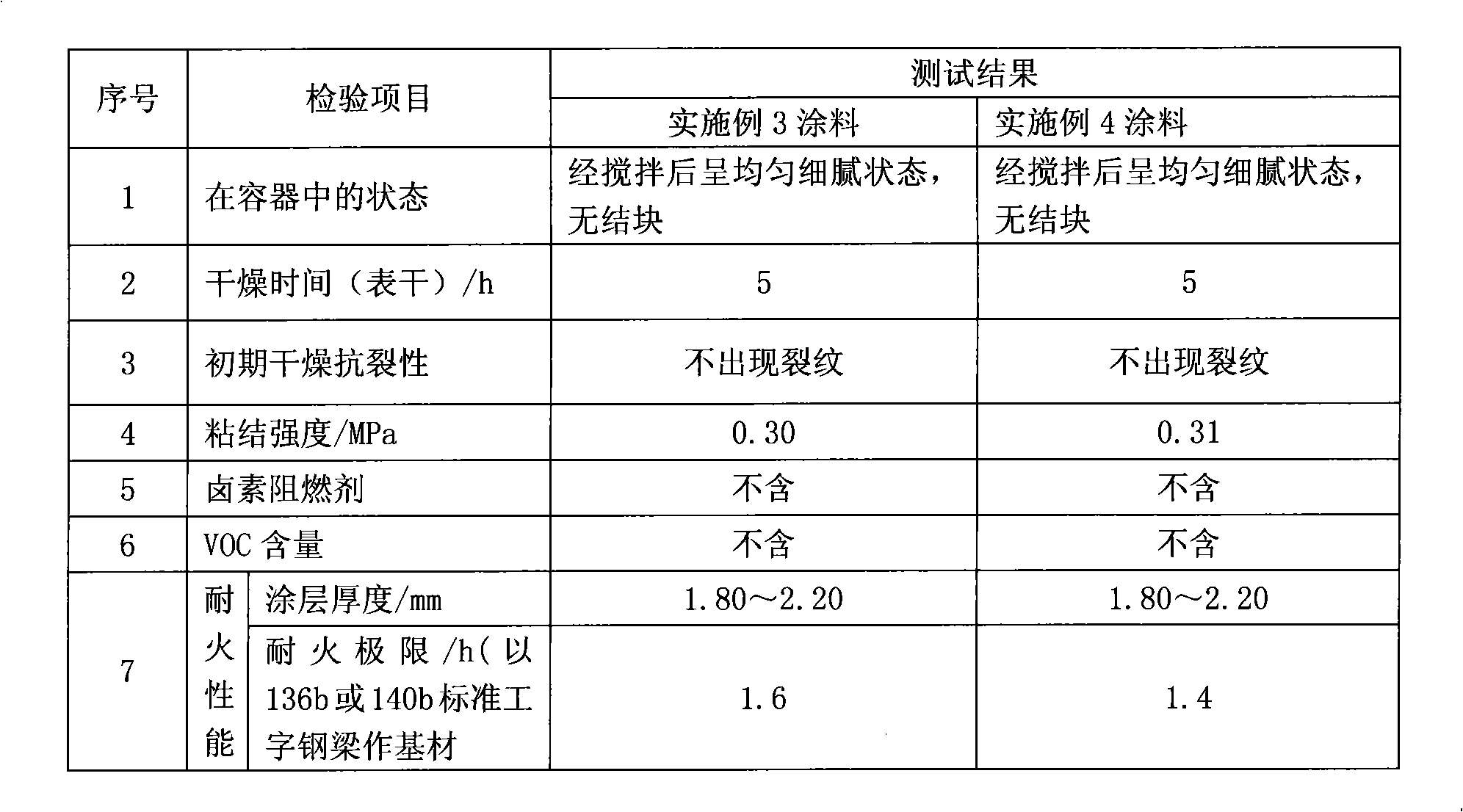

[0063] The present invention will be further described below in conjunction with embodiment.

[0064] The embodiment of the present invention 1 environment-friendly water-based nano fire-proof flame-retardant coating, its component and weight percent are:

[0065] Waterborne Acrylic 32%

[0066] Layered silicate nano-flame retardant containing phosphorus and nitrogen organic intercalation 8%

[0067] Polymer coated nano magnesium hydroxide flame retardant 4%

[0068] Pentaerythritol 4%

[0069] Ammonium polyphosphate 20%

[0070] Melamine 7%

[0071] nano-SiO 2 1.5%

[0072] Nano-TiO 2 1.5%

[0073] TiO 2 5%

[0074] Talc 3%

[0075] Polyacrylate dispersant 1%

[0076] Titanate coupling agent 0.3%

[0077] water 10%

[0078] Micron carbon black amount

[0079] The preparation method of the above-mentioned environment-friendly water-based nano fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com