Hybrid polyurethane-polyacrylacid ester dispersion containing fluorine and/or siloxane and preparation method thereof

A technology of polyurethane dispersion and polyacrylate, which is applied in the direction of coating, etc., can solve the problems of not being able to provide waterproof and antifouling performance, and achieve the effect of excellent antifouling performance, good application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

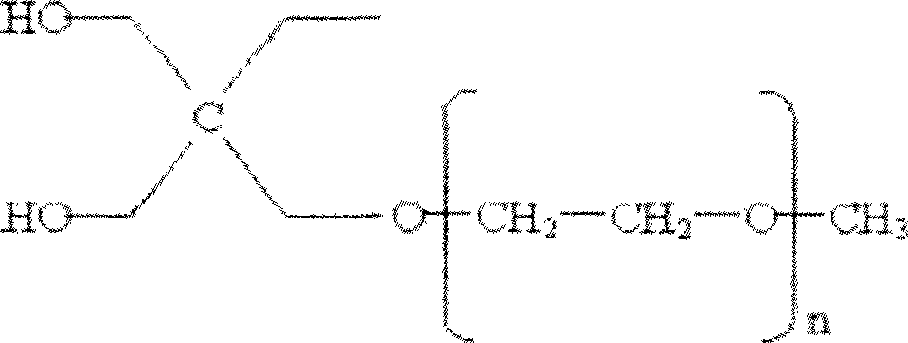

Method used

Image

Examples

Embodiment 1

[0079] Press the raw material consumption specified in table 1, with 80.48 gram PTMG (Mw=1000), 48.23 gram IPDI, 5.00 gram DMPA, 9.05 gram HPMA, 1.03 gram BDO and 4.00 gram IPDA, 2.74 gram TEA and 0.08 gram DBTDL in nitrogen protection and Under the condition of maintaining mechanical stirring, the reaction was carried out at 68° C. for 6 hours. At the same time, 75 grams of acetone was added during the reaction. After the reaction, the temperature was lowered to 30-40° C., and then 2.74 g of triethylamine was added. The solution was dispersed into 200.00 grams of deionized water with vigorous stirring. The acetone was distilled off under reduced pressure and cooled to room temperature to obtain a double bond-containing polyurethane dispersion.

[0080] 85.00 g of FMA-1, 13.10 g of FMA-4 (perfluoroalkylethyl acrylate), 129.00 g of MMA, 60.0 g of BA, 20 g of LA, 6 g of MAA, and 0.50 g of NDM were mixed with 5.00 g of SDS, 7.50 g of 0- 9 and 7.50 grams of 0-10 were mixed with...

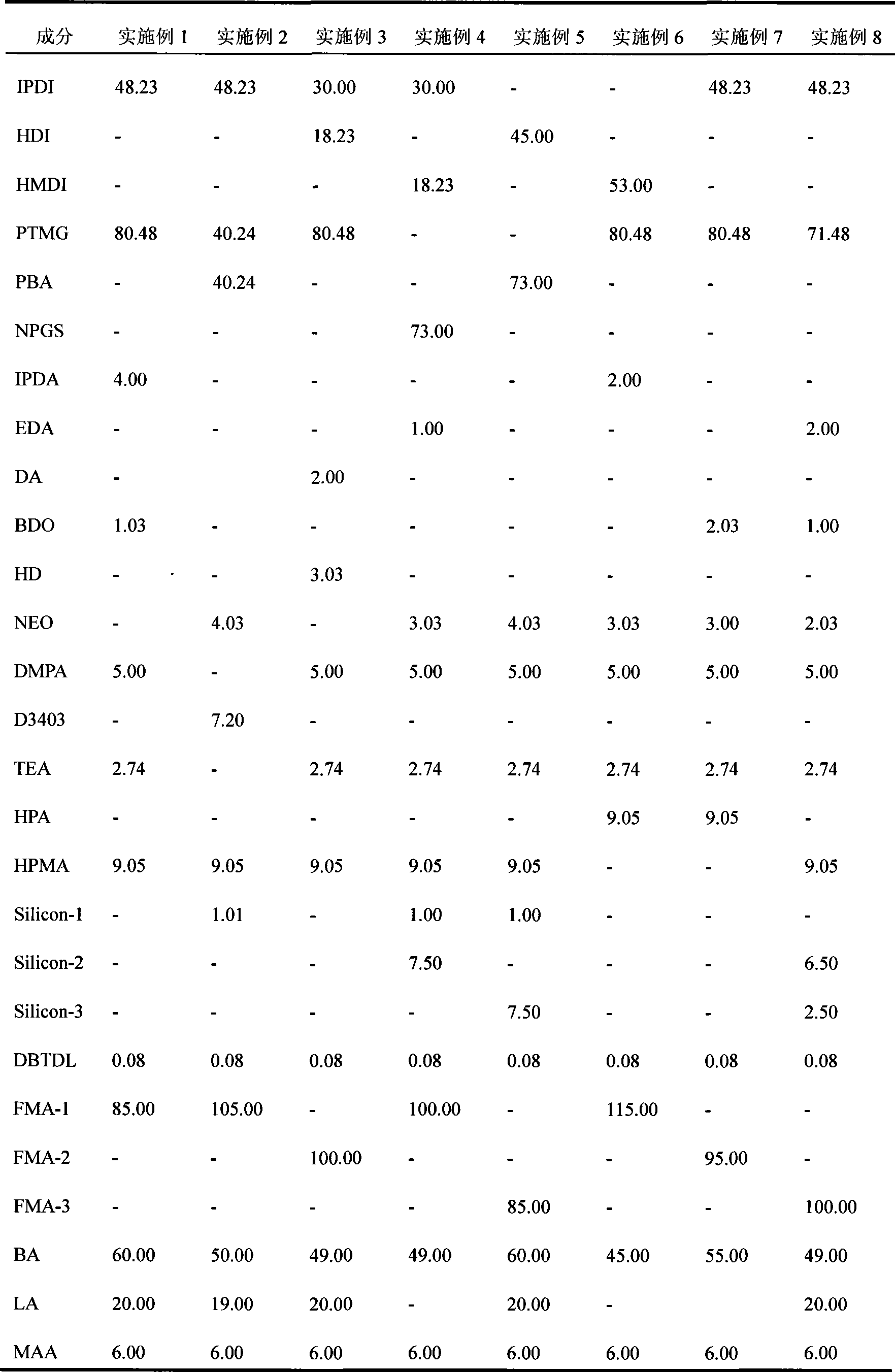

Embodiment 2-8

[0082] Examples 2-8 According to the amount of raw materials specified in Table 1, the same preparation method as in Example 1 was used to prepare the products respectively.

Embodiment 9

[0084] The obtained dispersion was coated on a glass substrate or a tin plate, dried at room temperature for 30 minutes, and then treated in an oven at 60° C. for 2 hours, and the obtained film thickness was about 10 μm. The contact angle and surface energy tests of the coating film were carried out on glass substrates, and the tests of other physical properties of the coating film were carried out on tinplate plates. The results are shown in Table 2.

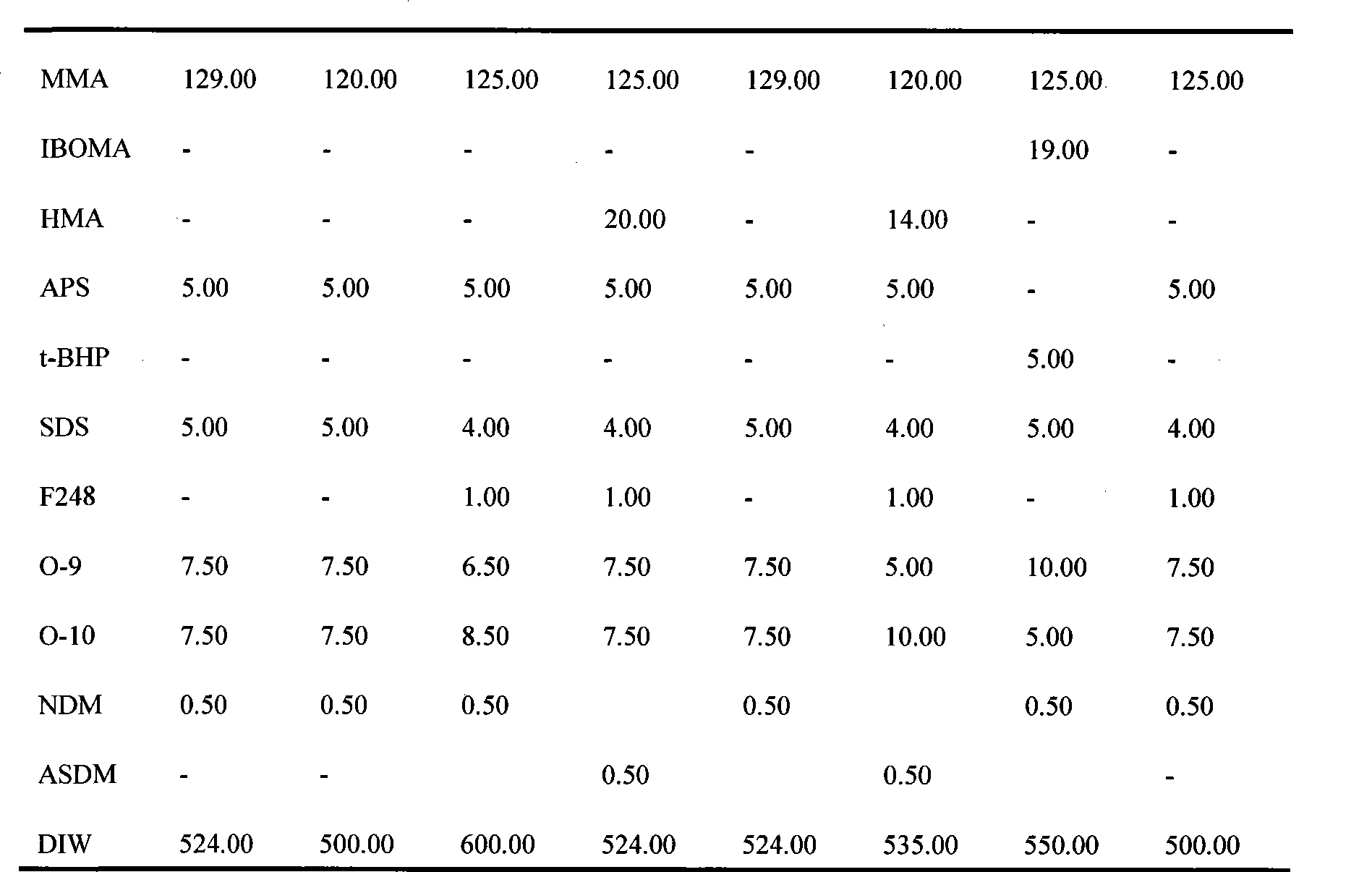

[0085] The raw material consumption (g) in the different examples of table 1

[0086]

[0087]

[0088] Table 2 Coating properties

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com