A kind of preparation method of fluorine-containing polyurethane leather waterproof coating

A polyurethane leather, waterproof coating technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. The problems of biological toxicity and environmental pollution of fluorine water repellant have achieved remarkable solvent resistance, easy large-scale production, and simple and practical preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, TDI is selected as the isocyanate, 1,4-butanediol (BDO) is selected as the chain extender, ethanol is selected as the fluorine-free monomer, and the preparation method of the fluorine-containing polyurethane waterproof coating is carried out according to the following steps:

[0033] (1) Preparation of ethanol / FA-terminated FPU solution

[0034] BDO (1g) and TDI (4g) were heated to 60°C in 15g DMF and reacted for 1.5 hours, then the system was heated to 70°C. After the temperature was reached, 2g FA was added under nitrogen protection, and the reaction was continued for 2 hours. After cooling to 60° C., 1 g of ethanol was added, and the reaction was carried out for 1 hour to obtain a FPU solution.

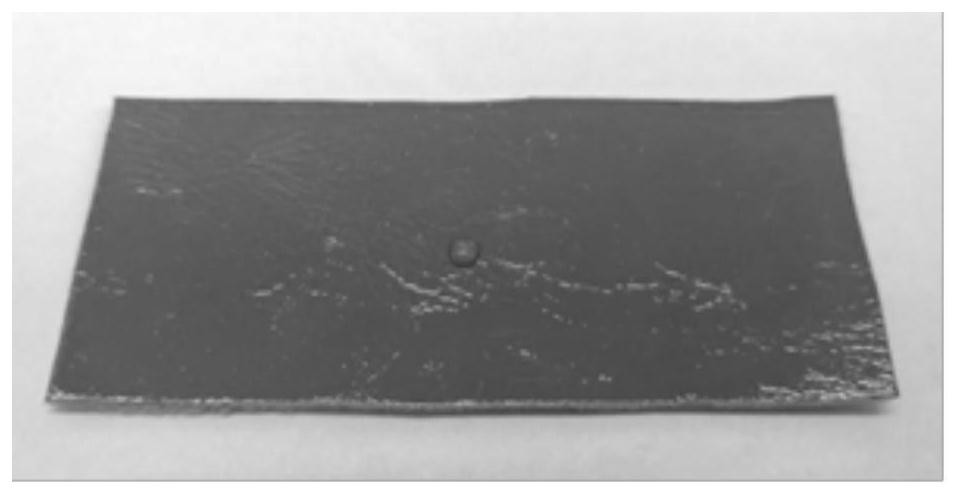

[0035] (2) Preparation of FPU waterproof coating

[0036] Dip a small amount of FPU solution with a glass rod and coat it on leather (artificial leather, the specific material is PU), coat 1-5 ml per 13 square centimeters of substrate, and place it in a ...

Embodiment 2

[0042] In this embodiment, TDI is selected as the isocyanate, 1,4-butanediol (BDO) is selected as the chain extender, n-octanol is selected as the fluorine-free monomer, and the preparation method of the fluorine-containing polyurethane waterproof coating is carried out according to the following steps:

[0043](1) Preparation of n-octanol / FA-terminated FPU solution

[0044] BDO (1g) and TDI (4g) were heated to 60°C in 15g DMF and reacted for 1.5 hours, then the system was heated to 70°C. After the temperature was reached, 2g FA was added under nitrogen protection, and the reaction was continued for 2 hours. After cooling to 60° C., 1.2 g of n-octanol was added and reacted for 1 hour to obtain an FPU solution.

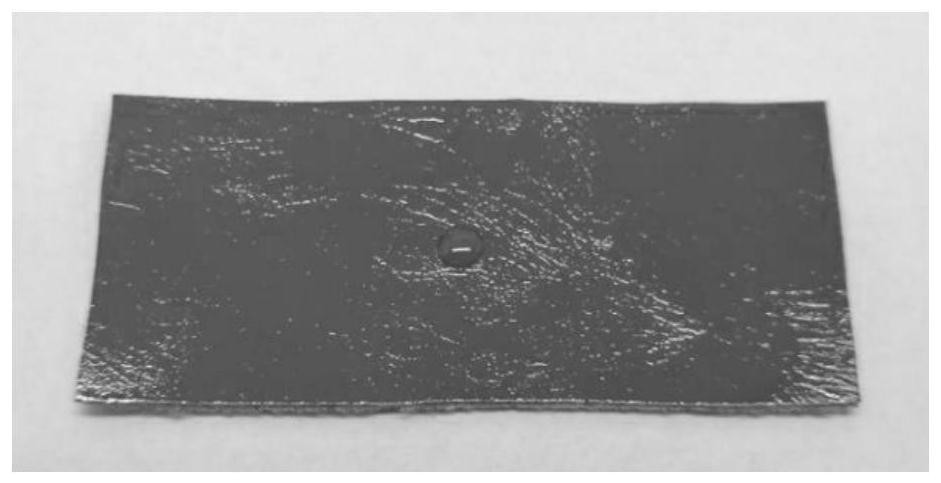

[0045] (2) Preparation of FPU waterproof coating

[0046] Dip a small amount of FPU solution with a glass rod and coat it on leather (artificial leather, the specific material is PU), coat 1-5 ml per 13 square centimeters of substrate, and place it in a 130° oven for ...

Embodiment 3

[0048] In this embodiment, TDI is selected as the isocyanate, 1,4-butanediol (BDO) is selected as the chain extender, n-heptanol is selected as the fluorine-free monomer, and the preparation method of the fluorine-containing polyurethane waterproof coating is carried out according to the following steps:

[0049] (1) Preparation of n-heptanol / FA-terminated FPU solution

[0050] BDO (1g) and TDI (4g) were heated to 60°C in 15g DMF and reacted for 1.5 hours, then the system was heated to 70°C. After the temperature was reached, 2g FA was added under nitrogen protection, and the reaction was continued for 2 hours. After cooling to 60° C., 1.5 g of n-heptanol was added, and the reaction was carried out for 1 hour to obtain a FPU solution.

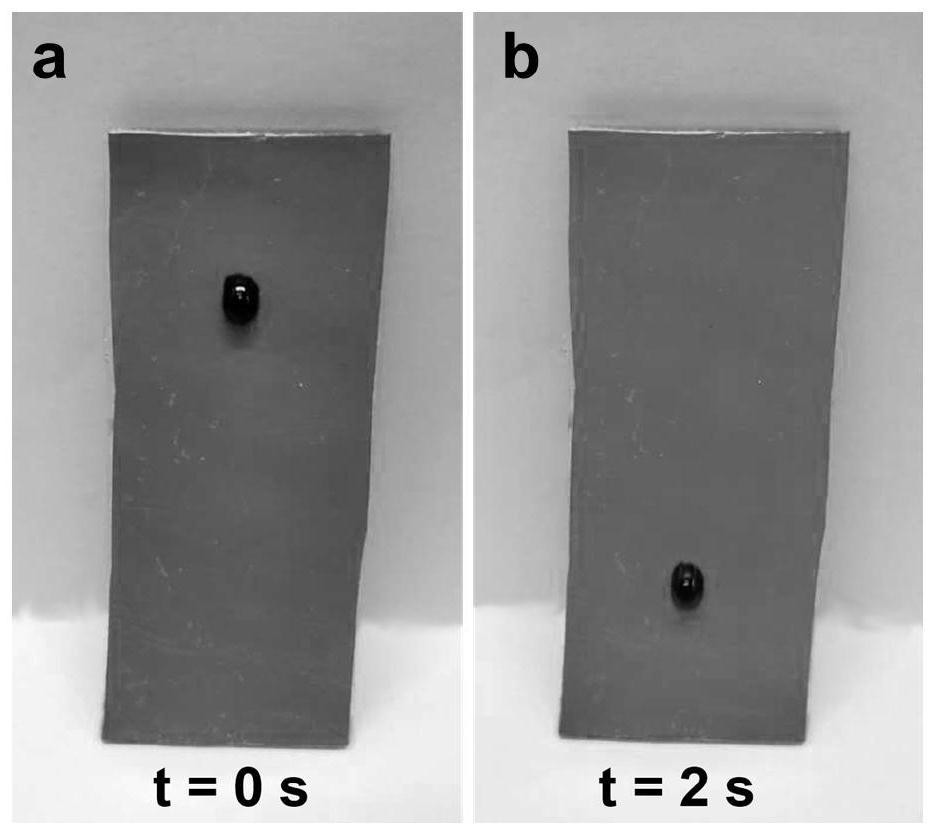

[0051] (2) Preparation of FPU waterproof coating

[0052] Dip a small amount of FPU solution with a glass rod and coat it on leather (artificial leather, the specific material is PU), coat 1-5 ml per 13 square centimeters of substrate, and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com