EUV pod with fastening structure

a technology of reticles and fastenings, which is applied in the field of reticle pods, can solve the problems of unable to ensure the positioning status of the reticles in the inner container, and unable to determine whether the inner container is occupied, so as to prevent the cracking of the reticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]As the present invention discloses a reticle pod, and more particularly, a reticle pod with fastening / retaining structure; the inner container, outer container, and the filtering material employed in the embodiments of reticle pod of the present invention are achieved by using current technologies and the description of which is thus omitted. Moreover, the drawings referred to in the following description are not made according to the actual scale and only function as illustrations demonstrating characteristics of the present inventions.

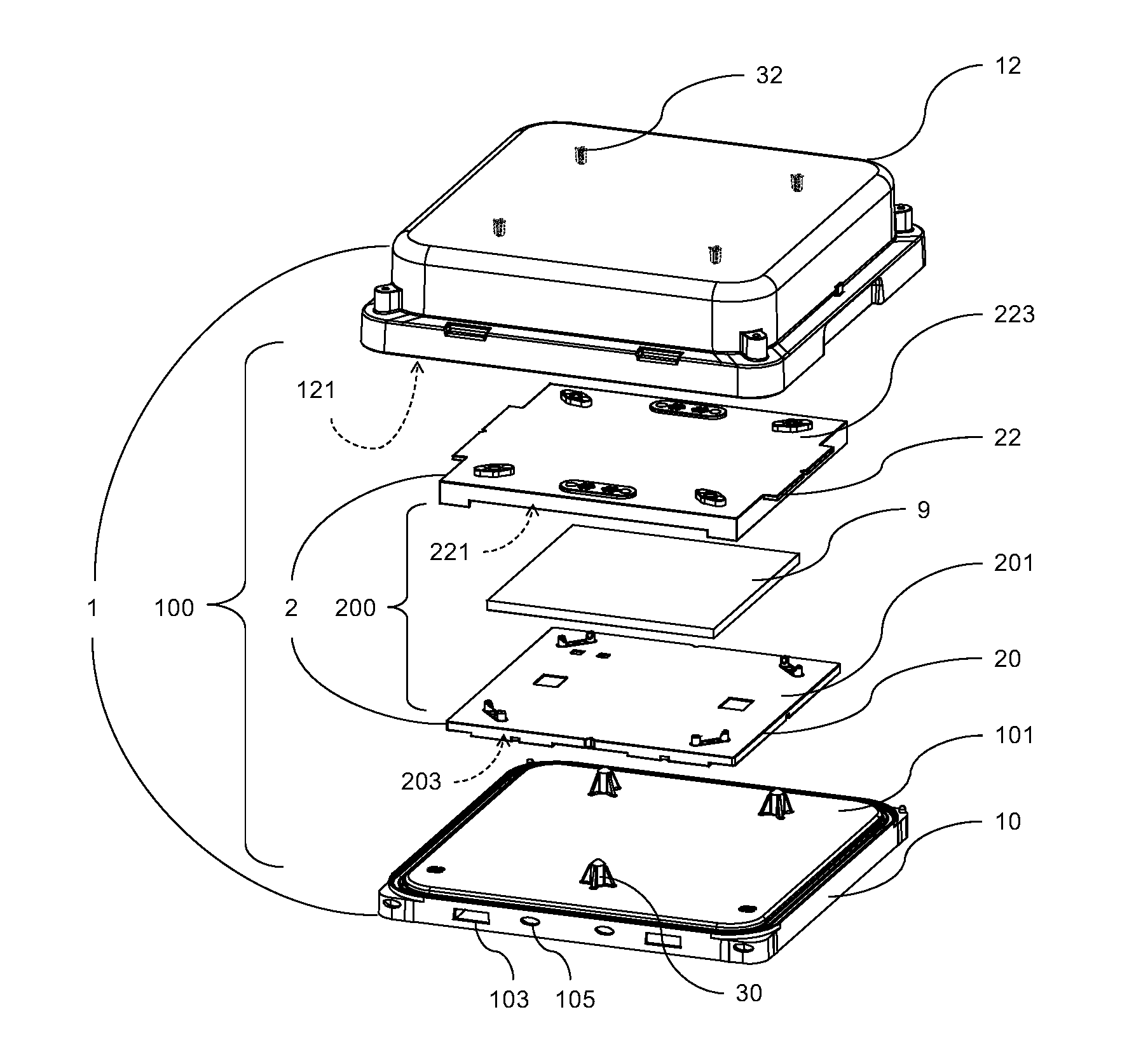

[0025]First, referring to FIG. 1, which is an explosive view of the reticle pod of the present invention. As shown in FIG. 1, the reticle pod comprises an outer container 1 and an inner container 2, wherein the outer container 1 comprises a lower cover of outer container 10 having a first inner surface 101 on which a plurality of first supporters 30 are formed, and an upper cover of outer container 12 having a second inner surface 121 on which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com