A kind of ultraviolet light curing composition

A composition and ultraviolet light technology, applied in the field of coatings, can solve the problems of poor friction resistance of steel wool, anti-fingerprint, poor friction resistance, general surface wear resistance, etc., and achieve good coating adhesion and excellent friction resistance. Performance, excellent waterproof effect

Active Publication Date: 2017-10-03

江苏卡乐新材料有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When UV-curable coatings are used on the surface of optical films, optical discs, electronic equipment exteriors, optical lenses (plexiglass), etc., there are often shortcomings such as waterproof, oil-proof, anti-fouling, anti-fingerprint, and poor friction resistance.

The application number is 201110064999.2 which discloses a kind of UV-curable coating, and the surface wear resistance of the coating is general; Poor resistance to steel wool friction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

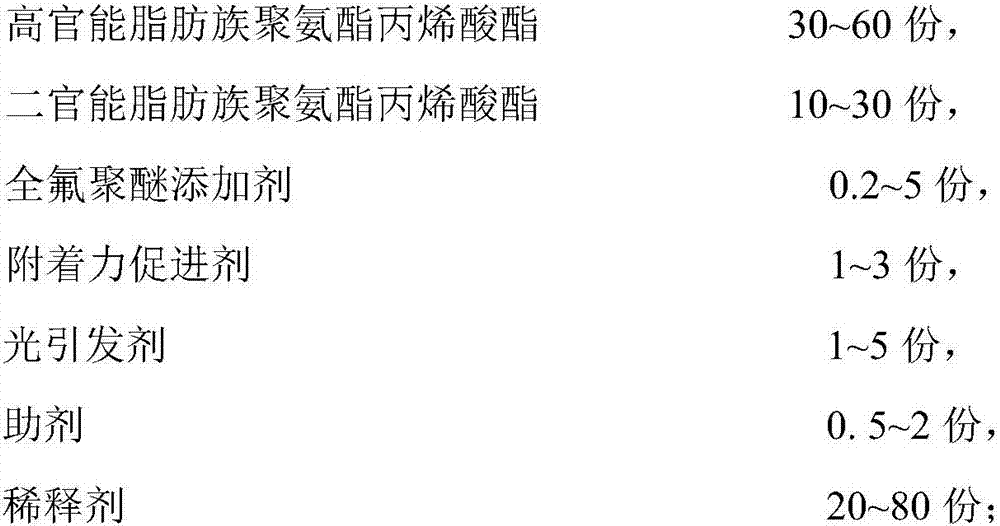

[0054] The components of the UV-curable composition provided in this embodiment are:

[0055] composition components

Embodiment 2

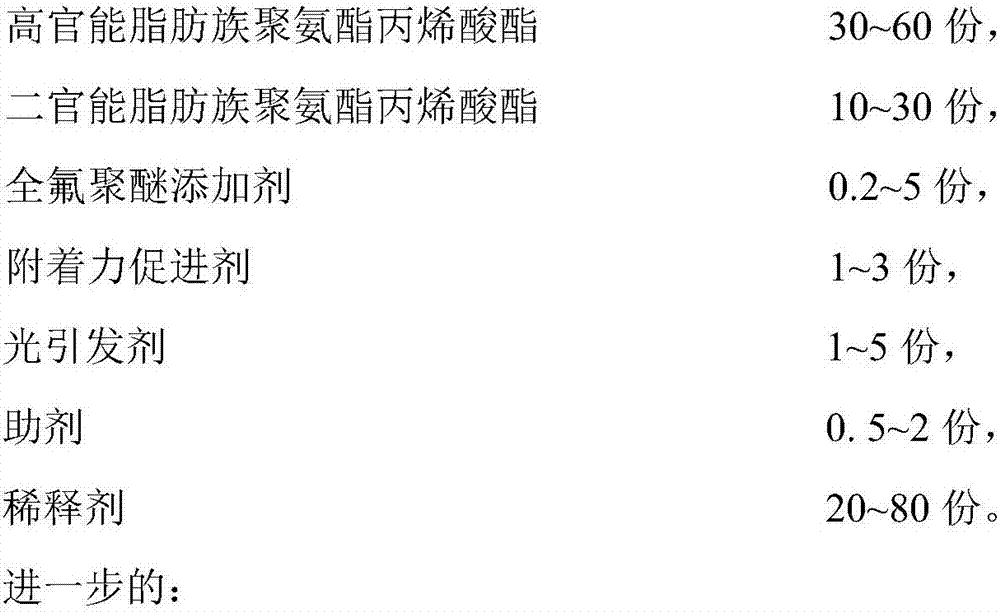

[0057] The components of the UV-curable composition provided in this embodiment are:

[0058] composition components

Embodiment 3

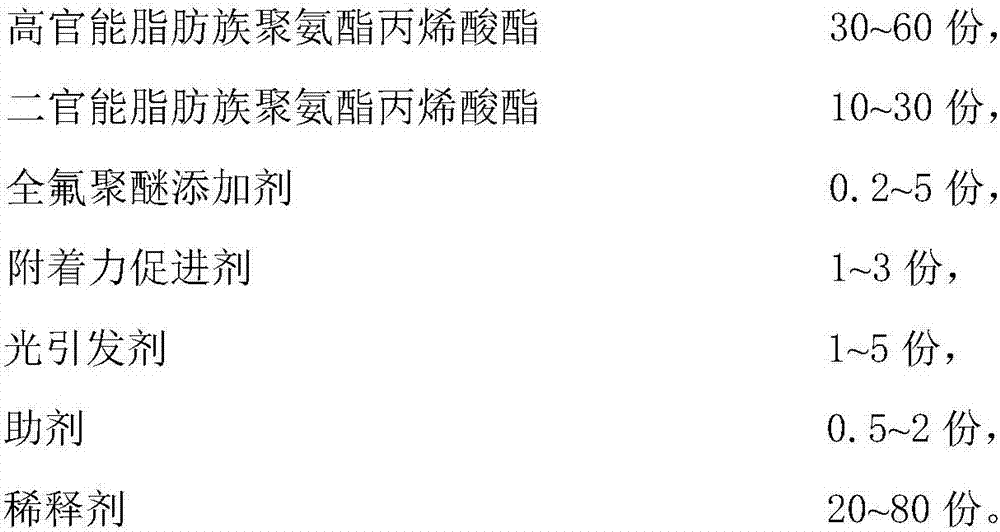

[0060] The components of the UV-curable composition provided in this embodiment are:

[0061]

[0062]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an ultraviolet-cured composition. The ultraviolet-cured composition is prepared from the following raw materials in parts by weight: 30-60 parts of high function aliphatic urethane acrylate, 10-30 parts of difunctional aliphatic polyurethane acrylate, 0.2-5 parts of perfluoropolyether additive, 1-3 parts of adhesion promoter, 1-5 parts of photoinitiator, 0.5-2 parts of aid and 20-80 parts of diluent. The ultraviolet-cured composition provided by the invention is cured into a hard film, so that superior performance such as smoothness, water resistance, oil resistance, fingerprint resistance and scratch resistance is provided for a substrate. The ultraviolet-cured composition is mainly applied to exteriors of optical films, optical disks and electronic equipment, the surfaces of optical lenses (organic glasses) and the like.

Description

technical field [0001] The invention relates to the field of coatings, in particular to an ultraviolet light curing composition. Background technique [0002] When UV-curable coatings are used on the surfaces of optical films, optical discs, electronic equipment exteriors, optical lenses (plexiglass), etc., they often have shortcomings such as waterproof, oil-proof, anti-fouling, anti-fingerprint, and poor friction resistance. Application No. 201110064999.2 discloses a UV curable coating, the surface wear resistance of the coating is general; Resistance to steel wool friction is poor. [0003] In order to improve the waterproof, oil-proof, anti-fouling, anti-fingerprint, and friction-resistant properties of UV-curable coatings, additives containing perfluoropolyether structures are introduced into UV-curable coatings, as disclosed in the patent application number 200780007318.0 In a high energy ray curable composition, the patent application number is 201080021080.9, which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D175/14C09D175/08C09D7/12

CPCC08K2201/011C08L2205/025C08L2205/03C09D7/61C09D7/63C09D175/14C08L75/14C08L75/08C08K5/5425C08K3/36C08K2003/265

Inventor 向德轩汤艳陈迪钊舒友

Owner 江苏卡乐新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com