Waterborne graphene anticorrosive paint and preparation method thereof

A technology of water-based graphene and anti-corrosion coatings, applied in anti-corrosion coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor water resistance, salt spray resistance, limited development of water-based coatings, and difficult anti-corrosion performance. Achieve the effects of reducing environmental pollution, increasing the curing effect, and preventing the infiltration of corrosion factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

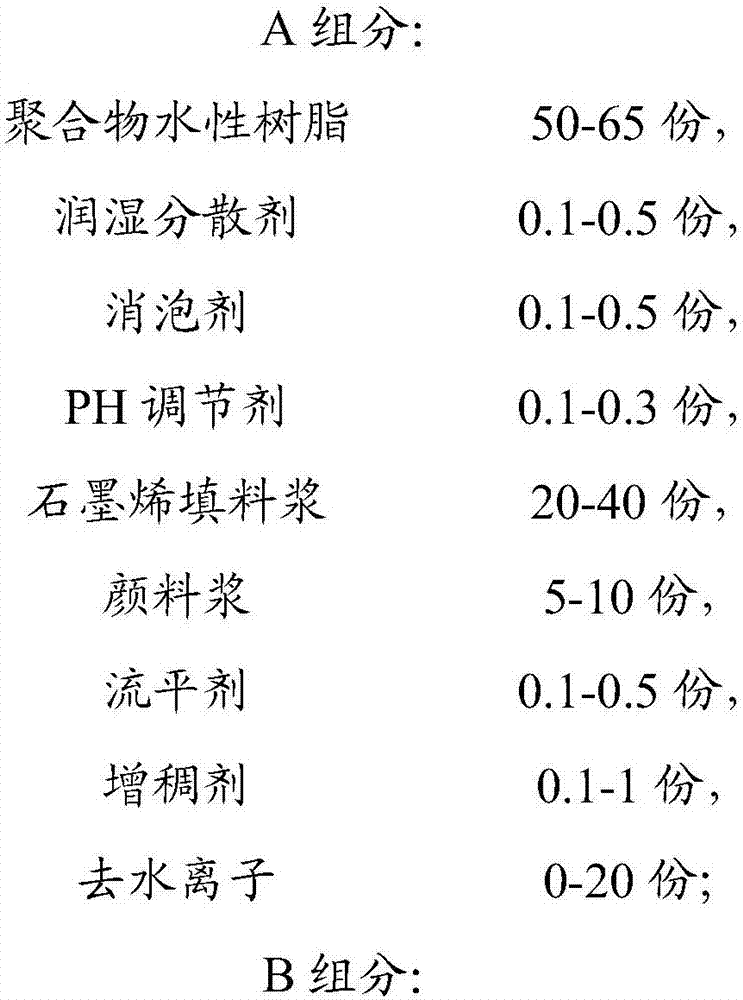

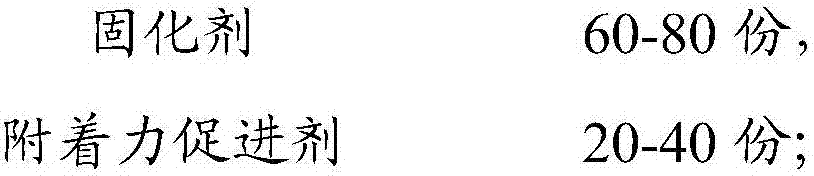

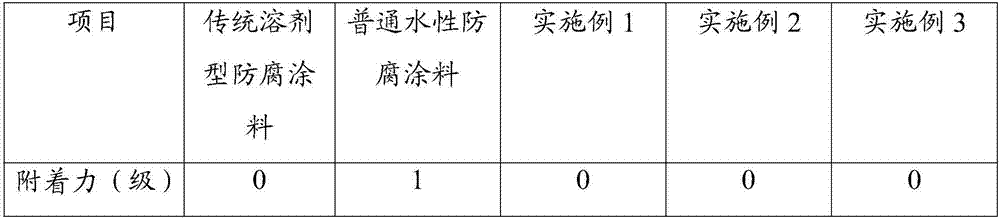

[0030] Embodiment 1, a kind of water-based graphene anticorrosion coating comprises the following materials in parts by weight: A component: 40 parts of water-based acrylic resins, 5 parts of water-based polyester resins, polyoxyethylene alkylphenyl ether (wetting and dispersing agent ) 0.2 parts, DREWPLUSL-1311 (defoamer) 0.2 parts, AMP-95# (PH regulator) 0.3 parts, graphene filler paste 30 parts, pigment paste 8 parts, dimethyl siloxane (leveling agent) 0.3 parts, 0.5 parts of polyurethane thickener, 15.5 parts of deionized water; component B: 70 parts of toluene diisocyanate (curing agent), 30 parts of silane coupling agent S-401 (adhesion promoter). Among them, A:B=6:1.

[0031] The preparation process is as follows: (1) Add the polymer water-based resin, graphene filler slurry, and pigment slurry into the mixing tank and stir for 45 minutes at a stirring speed of 700 rpm. After the mixture is uniformly mixed, the mixture is obtained; Add wetting and dispersing agent, def...

Embodiment 2

[0033] A kind of water-based graphene anticorrosion coating, comprises following material by weight: A component: 30 parts of water-based alkyd resins, 20 parts of water-based polyurethane resins, 0.2 part of polyoxyethylene succinate (wetting and dispersing agent), DREWPLUS L -1311 (defoamer) 0.2 parts, ammonia water (PH regulator) 0.2 parts, graphene filler slurry 40 parts, pigment slurry 5 parts, alkyl modified organosiloxane (leveling agent) 0.5 parts, polyurethane thickener 0.3 parts of agent, 3.6 parts of deionized water; B component: 60 parts of toluene diisocyanate (curing agent), 40 parts of vinyl silane coupling agent (adhesion promoter). Among them, A:B=5:1.

[0034] The preparation process is as follows: (1) Add the polymer water-based resin, graphene filler slurry, and pigment slurry into the mixing tank and stir for 40 minutes at a stirring speed of 600 rpm, and the mixture is obtained after the mixture is uniformly mixed; Add wetting and dispersing agent, defoa...

Embodiment 3

[0036] A waterborne graphene anticorrosion coating comprises the following materials in parts by weight: A component: 45 parts of waterborne polyester resin, 0.3 part of polyoxyethylene fatty acid ester (wetting and dispersing agent), 0.2 part of mineral oil defoamer , 0.3 parts of DMAE (PH regulator), 40 parts of graphene filler paste, 10 parts of pigment paste, 0.5 part of modified acrylic leveling agent, 0.3 part of alkali swelling thickener, 3.4 parts of deionized water; Group B Parts: 80 parts of toluene diisocyanate (curing agent), 20 parts of silane coupling agent S-401 (adhesion promoter). Among them, A:B=4:1.

[0037] The preparation process is as follows: (1) Add polymer water-based resin, graphene filler slurry, and pigment slurry into a mixing tank and stir for 50 minutes at a stirring speed of 600 rpm, and obtain a mixture after the mixture is uniformly mixed; Add wetting and dispersing agent, defoamer, and leveling agent, then adjust the speed to 700 rpm and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com