Production process of low-basis-weight damp-proof waterproof coveying paper

A production process and technology of protective paper, which is applied in the direction of surface covering paper, paper, papermaking, etc., can solve the problems of high cost, low quantitative moisture-proof and waterproof face-covering paper, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

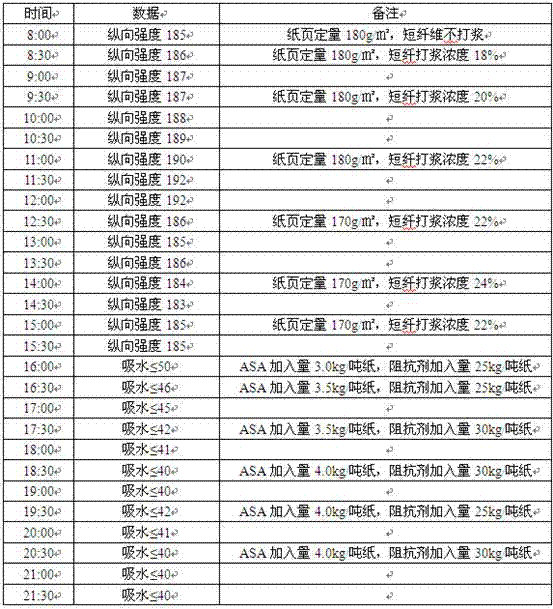

Image

Examples

Embodiment Construction

[0014] A kind of production technology of low-quantity moisture-proof and waterproof face-protecting paper, comprises the following steps:

[0015] The first step is pulping, which is divided into two production lines: deinked pulp and OCC production line. The process parameters of the deinking pulp production line are: the ratio of raw materials is 50% of 9# American waste + 50% of national newspaper, and then they are evenly mixed and then added to the drum pulper, and deinking chemicals are added: deinking agent 0.6kg / ton of waste paper , hydrogen peroxide 15kg / ton of waste paper, sodium hydroxide 6kg / ton of waste paper, sodium silicate 3kg / ton of waste paper, in the pulper, the waste paper reacts with chemicals and beats to form a thick pulp with a weight concentration of 4%. Heavy impurities in the slurry, such as iron nails, stones, glass, etc., are removed through the high-concentration slag remover, and then diluted to a concentration of about 3% in the slurry storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com