Honeycomb paper-base plate and its producing method

A board and paper-based technology, applied in the field of honeycomb paper-based board and its processing, can solve the problems of poor compression and bending resistance of honeycomb paperboard, achieve simple processing method, good water resistance and anti-corrosion performance, and comply with national environmental protection. the effect of the policy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The honeycomb paper-based substrate of the present invention will be described below in conjunction with the embodiments and accompanying drawings.

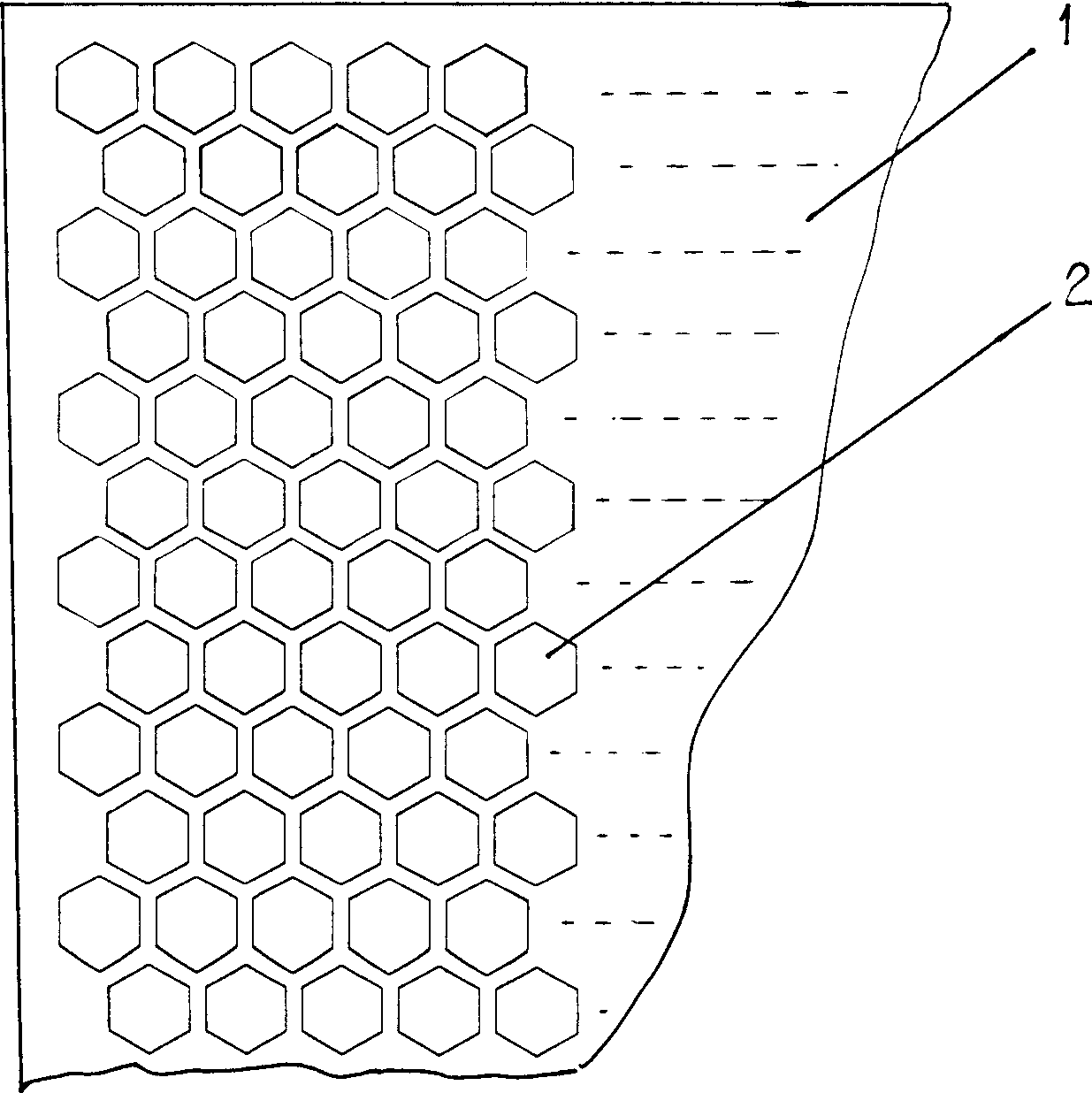

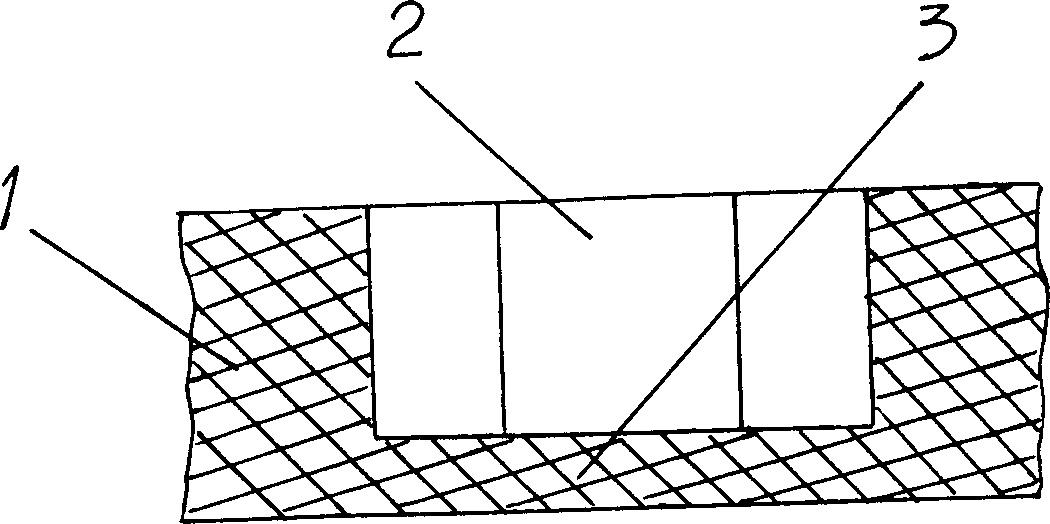

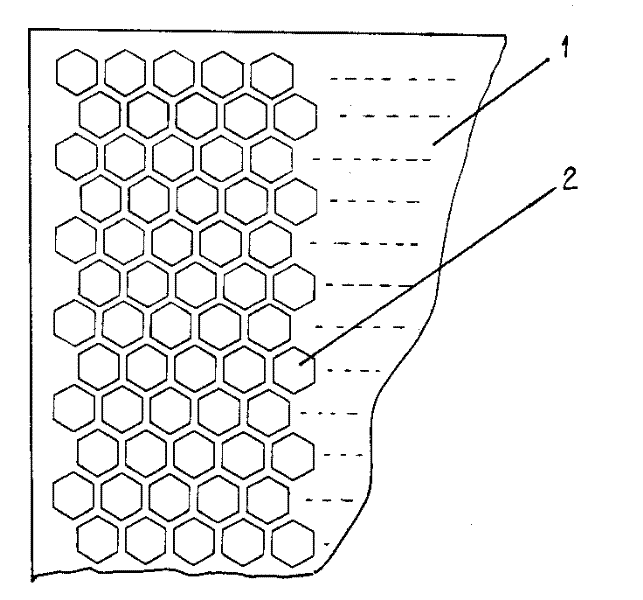

[0021] Such as figure 1 , 2 Example of the honeycomb paper-based substrate, one side of the honeycomb paper-based substrate 1 is evenly distributed with regular hexagonal dimples 2, the adjacent sides of each dimple are arranged in parallel, the distance between the dimples is 15.24mm, the thickness of the paper-based substrate is 12mm, and the thickness of the concave bottom 3 3mm.

[0022] The best implementation mode of this processing method is:

[0023] 1. To prepare the adhesive, add 6 parts by weight of cationic starch to 100 parts by weight of clear water at 30°C and mix evenly. Heat it to 95°C and keep it warm for 15 minutes. The adhesive has been fully matured into a paste, and then diluted with water to cationic A binder with a starch concentration of 1% was used for later use.

[0024] 2. Prepare a waterpro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com