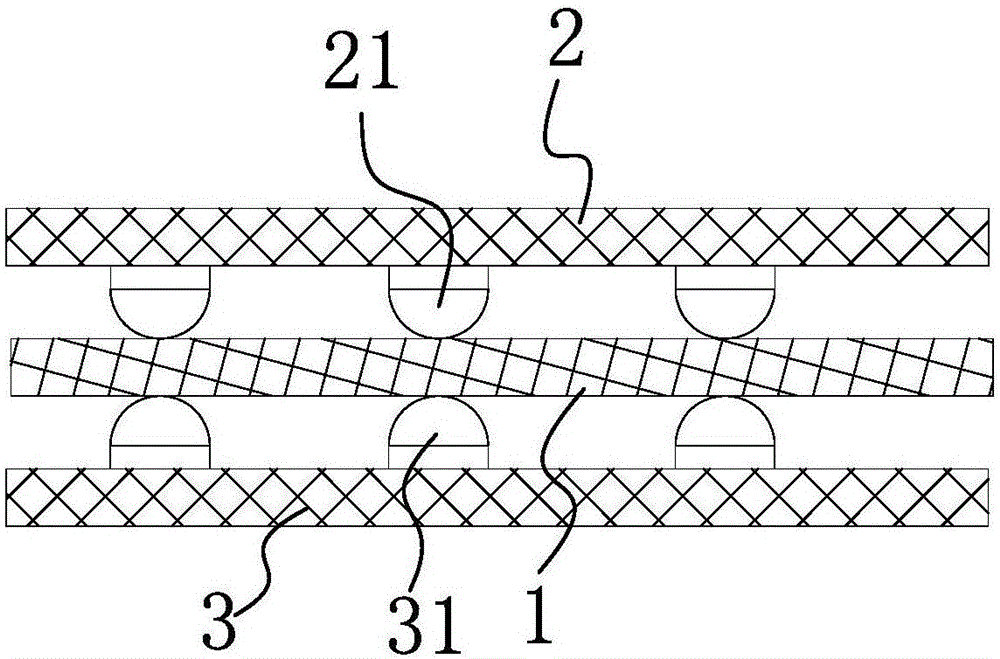

Three-layered composite automotive interior fabric and production process thereof

A technology of automobile interior decoration and production technology, which is applied in the field of fabrics and can solve problems such as air pollution, carbon black pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

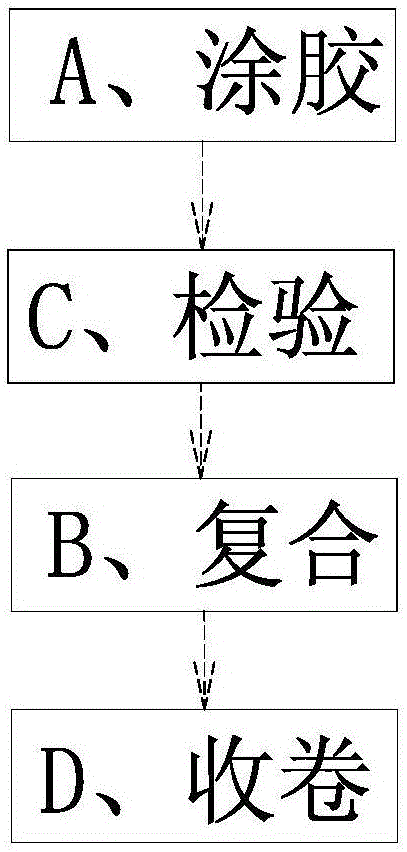

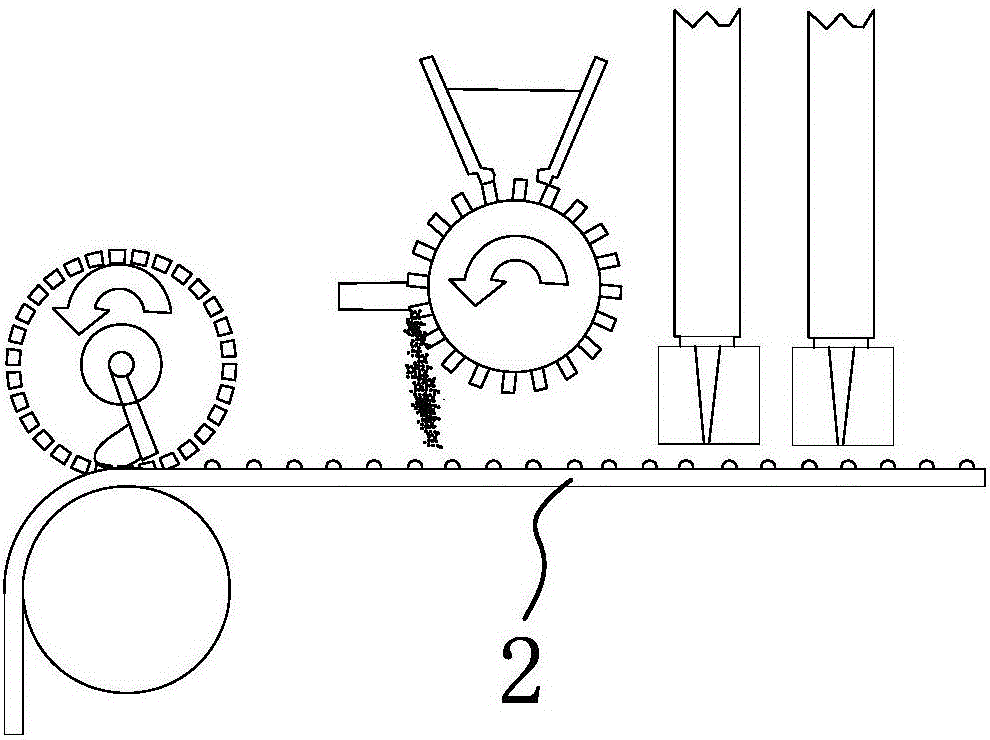

[0077] In the above step A, the water-repellent automotive fabric 2 is a gray warp-knitted water-repellent automotive fabric. After the gray warp-knitted water-repellent automotive fabric with a door width of 156 cm and a specification of 145 g / square meter is judged to be coated Put it on the unwinding frame of the double-point coating machine and put on the cloth. The speed of the double-point coating machine is set at 22 m / min, and the temperature of the drying room is raised to 180-185 °C; 180 holes arranged randomly by the computer are selected. / square centimeter, a wall thickness of 0.18 mm and a hole diameter of 0.22 mm, that is, a cp180 rotary screen; select polyacrylate primer and adjust the machine parameters according to the solid content of polyacrylate of 3.5-4.0 g / square meter of primer, The polyacrylate primer is transferred through the rotary screen and dot-coated on the coating surface of the gray warp-knitted water-repellent automotive fabric. The polyacrylat...

Embodiment 2

[0088] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0089] In the above-mentioned step A, the water-repellent automotive fabric 2 is a warp-knitted water-repellent automotive fabric, and the warp-knitted water-repellent automotive fabric with a width of 156 cm and a specification of 180 g / square meter is placed on the coated surface after being judged. Put the cloth on the unwinding rack of the double-point coating machine, set the speed of the double-point coating machine at 20 m / min, and raise the temperature of the drying room to 180-185°C; choose 180 holes / square arranged randomly by computer Centimeter, wall thickness 0.18 mm and hole diameter 0.22 mm; select polyacrylate primer and adjust the machine parameters according to the solid content of polyacrylate of 4.0-4.5 g / m2 of primer, pass the polyacrylate base through the cylinder The slurry is transferred and ...

Embodiment 3

[0097] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0098] In the above-mentioned step A, the water-repellent automotive fabric 2 is a warp-knitted water-repellent automotive fabric, and the warp-knitted water-repellent automotive fabric with a width of 156 cm and a specification of 160 g / square meter is placed on the coated surface after being judged. Put the cloth on the unwinding frame of the double-point coating machine, set the speed of the double-point coating machine at 22 m / min, and raise the temperature of the drying room to 180-185°C; choose 180 holes / square arranged randomly by computer Centimeter, wall thickness 0.18mm and hole diameter 0.22mm; choose polyacrylate primer and adjust the machine parameters according to the solid content of polyacrylate of 3.5-4.0 g / m2 of the primer, and pass the polyacrylate base through the cylinder The slurry is transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com