Patents

Literature

36results about How to "Reliable quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

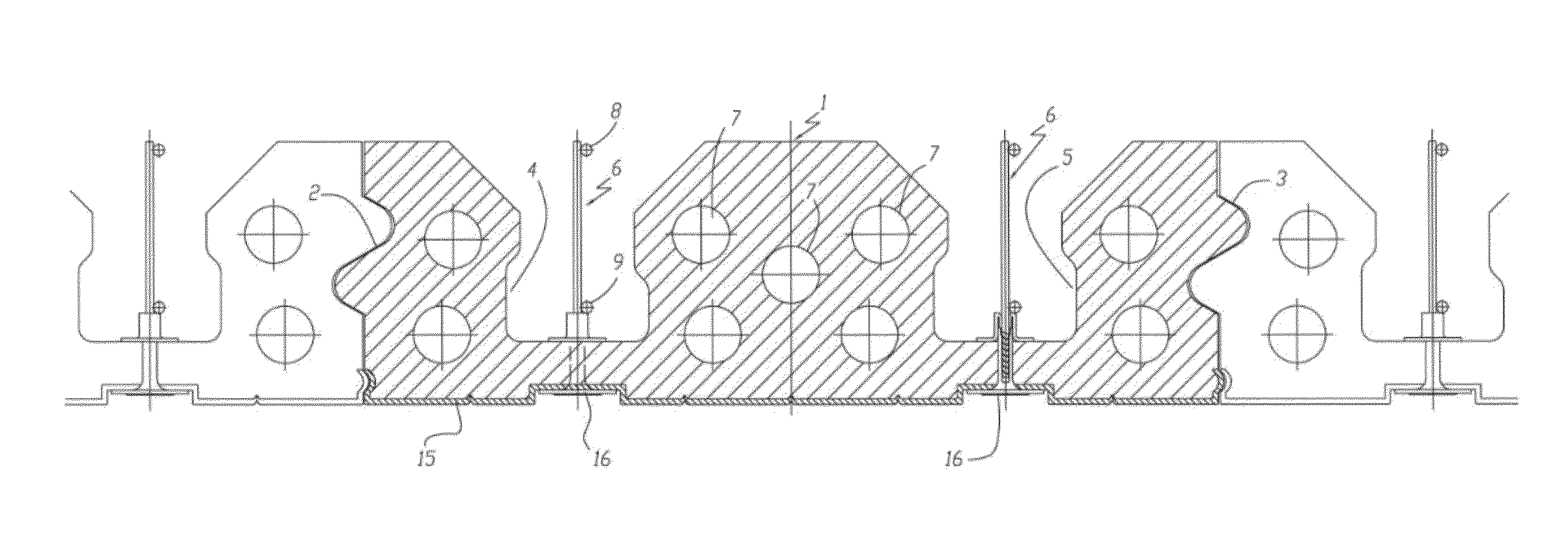

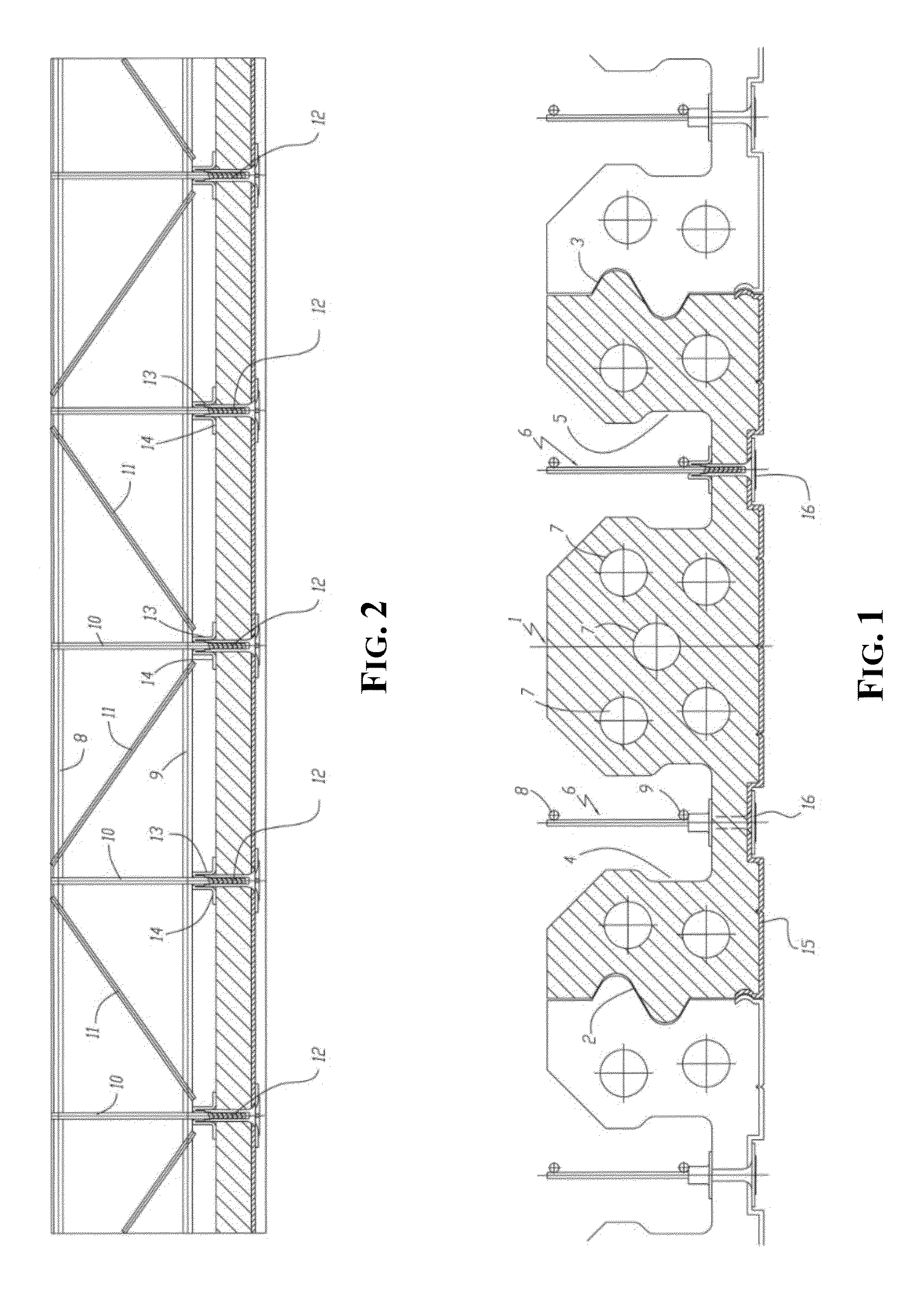

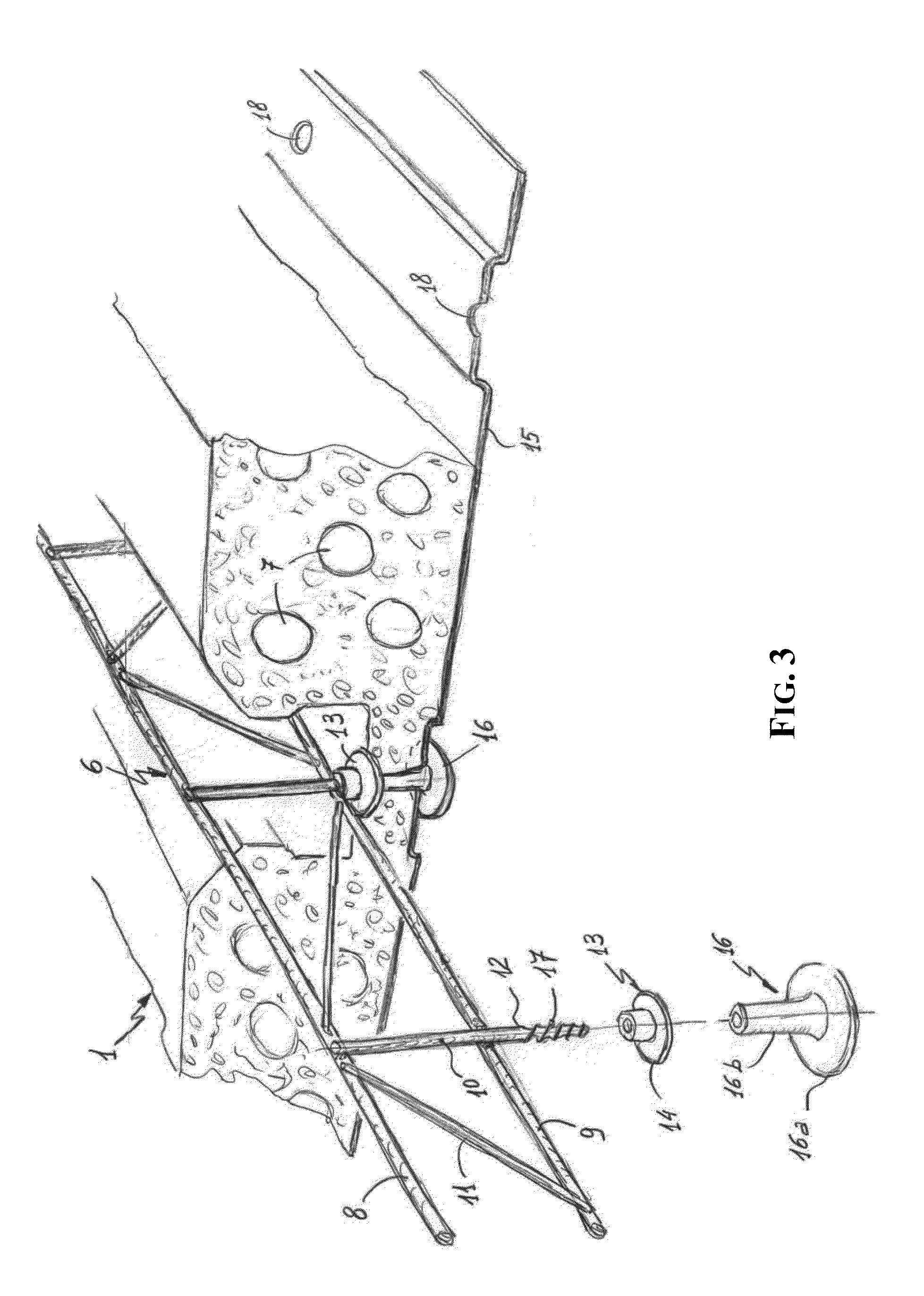

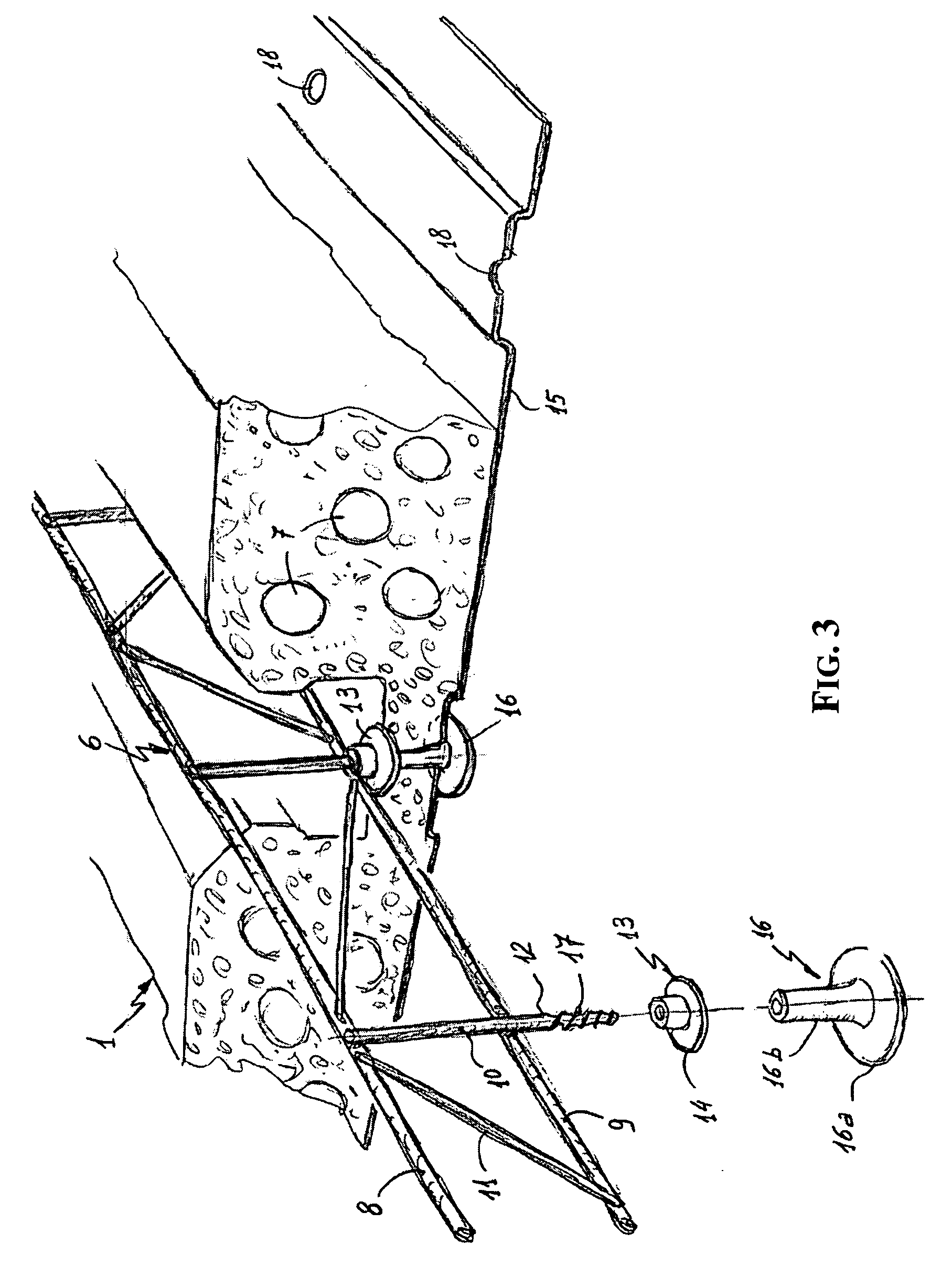

Composite article for constructing floors

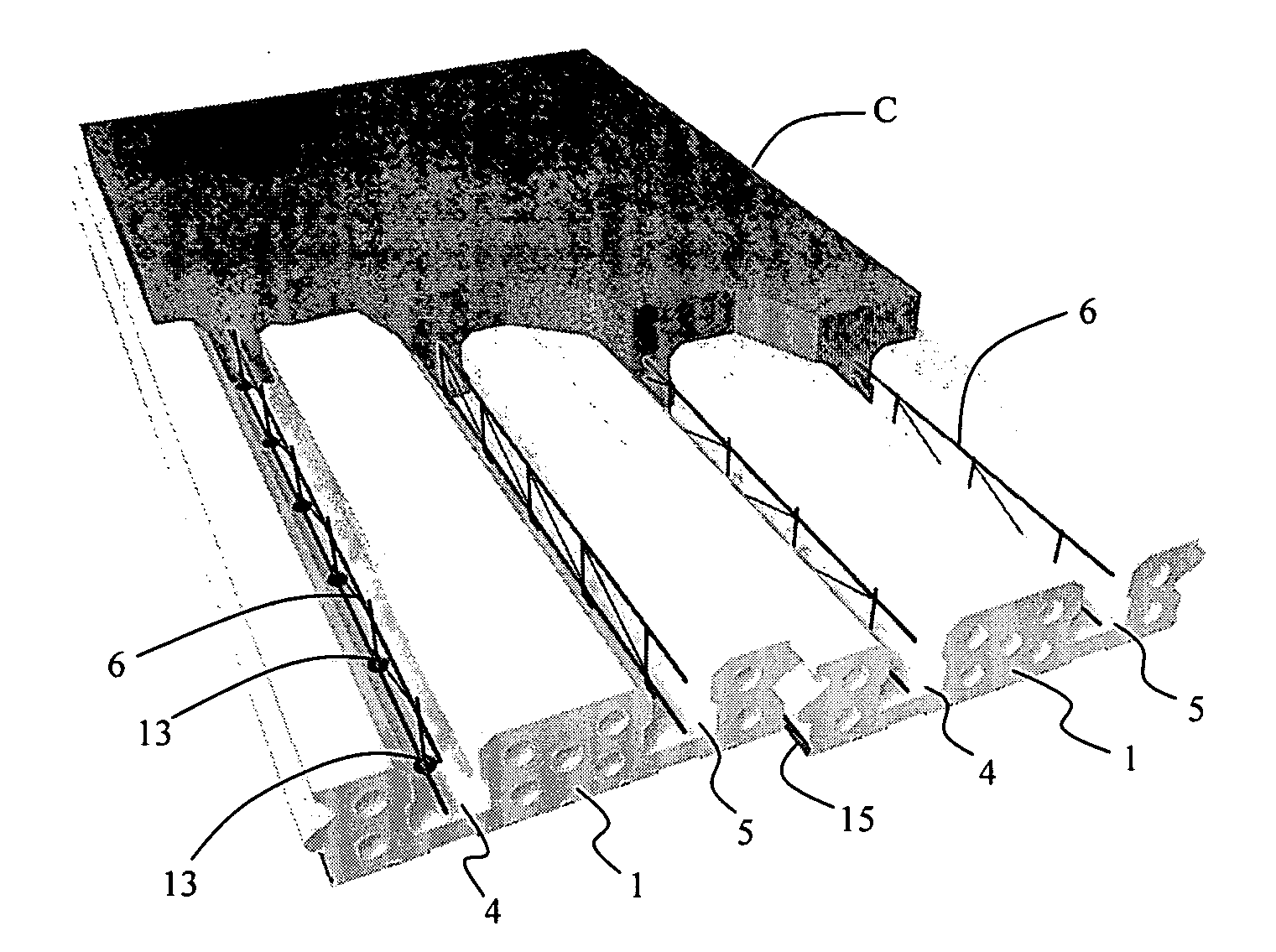

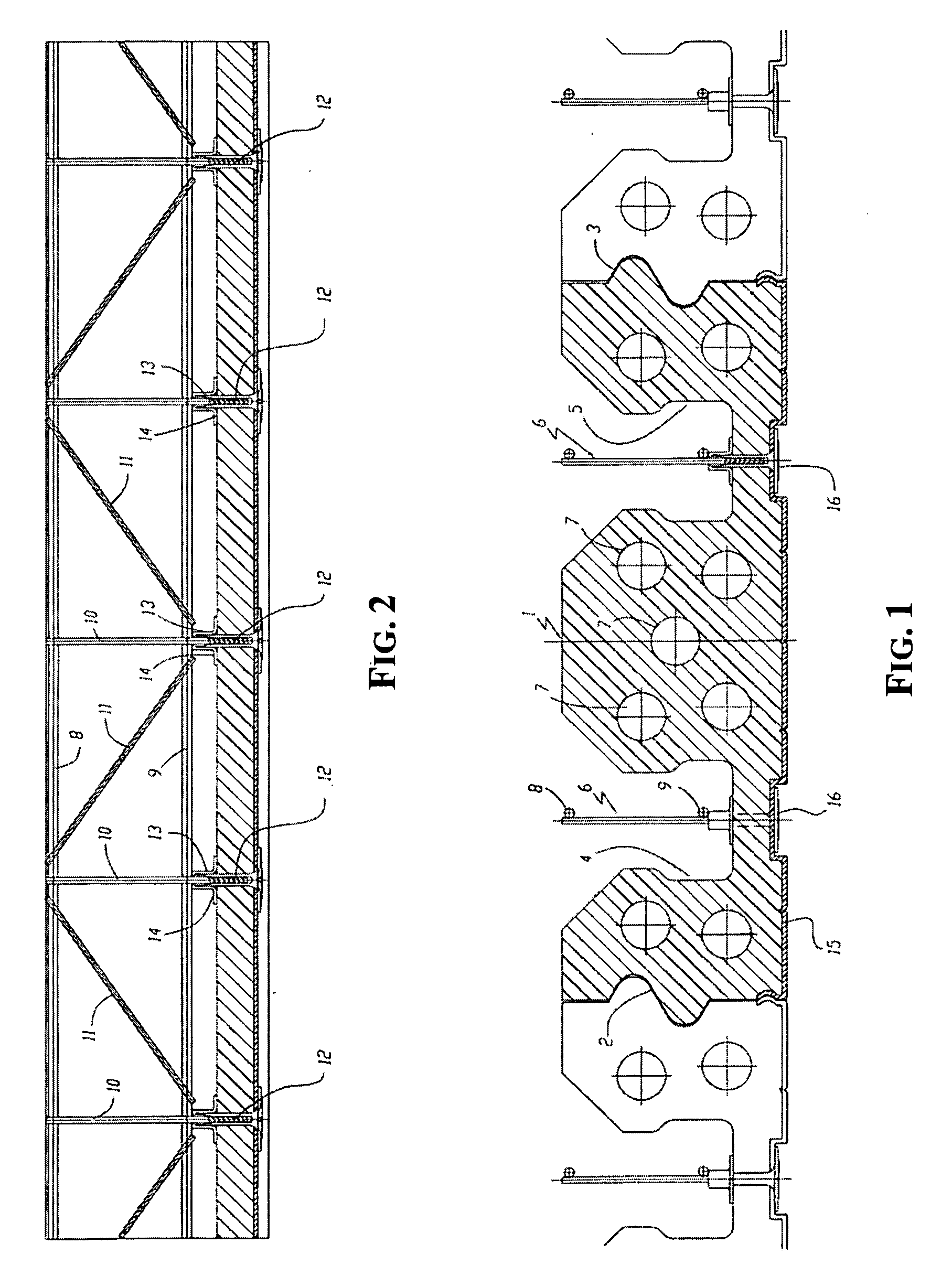

A composite for constructing concrete floors is completely factory assembled and comprises a body of expanded plastic having at least two parallel channels, open on the upper surface of the panel, extending the length of the article, adapted to be filled with concrete. A steel reinforcement bar fabric is installed into each channel, which may comprise at least two parallel steel bars connected by cross bars. At least some cross bars extend beyond a lowest reinforcement fabric bar to provide spikes long enough to pass through the plastic bottom and protrude therefrom. One or more sheet metal shrouds with at least one row of aligned holes matching those of the protruding spike ends are applied to the underside surface of the plastic body hung from the protruding ends of the spike by fasteners

Owner:PLASTEDIL

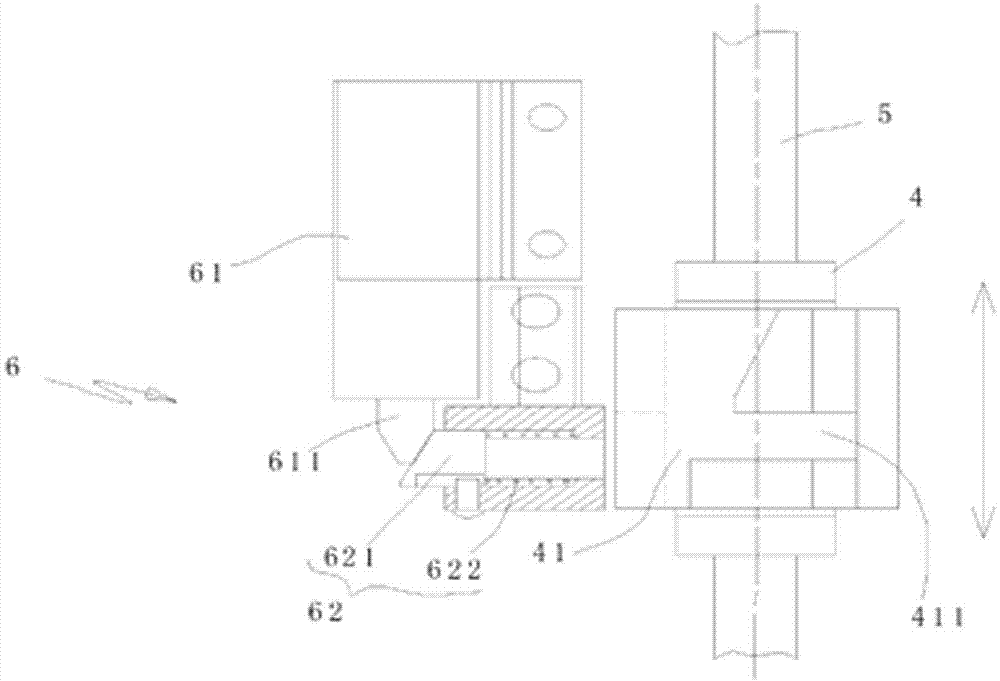

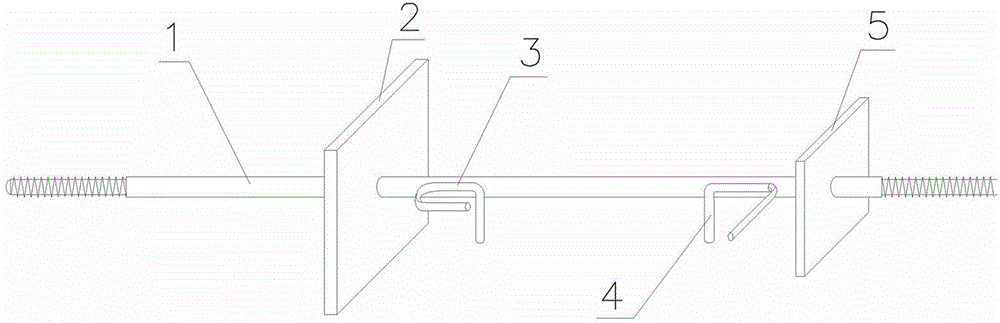

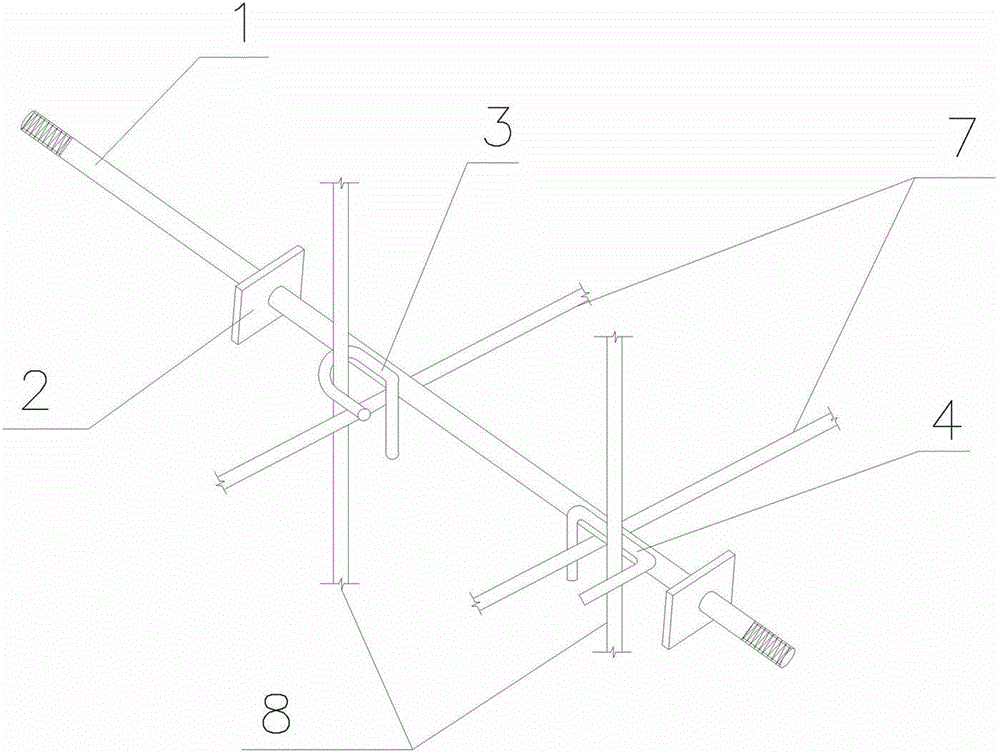

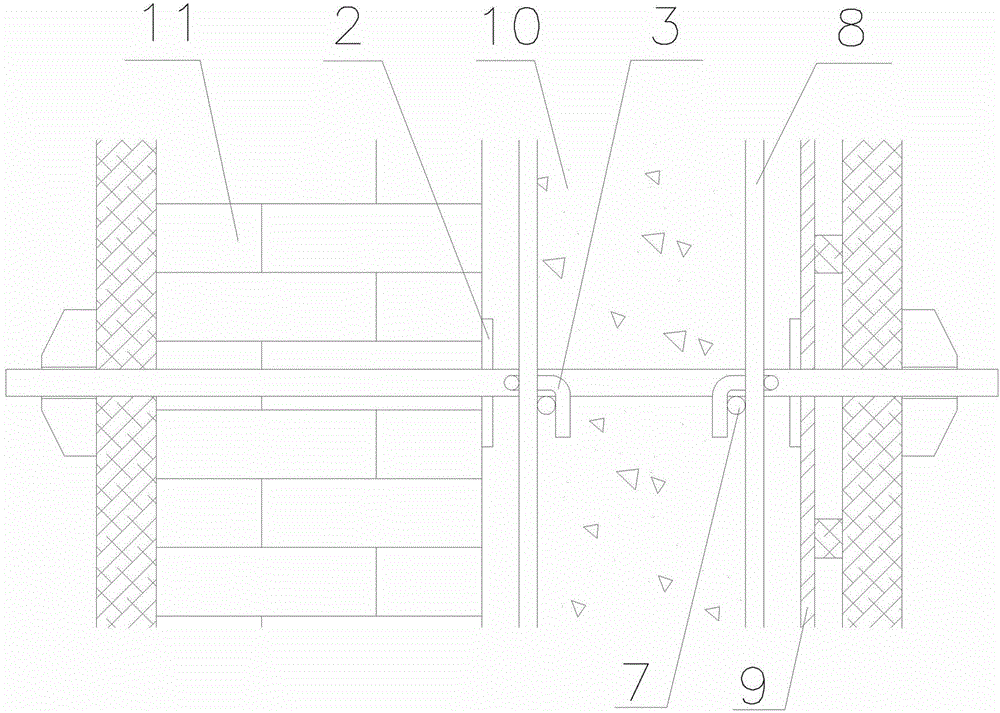

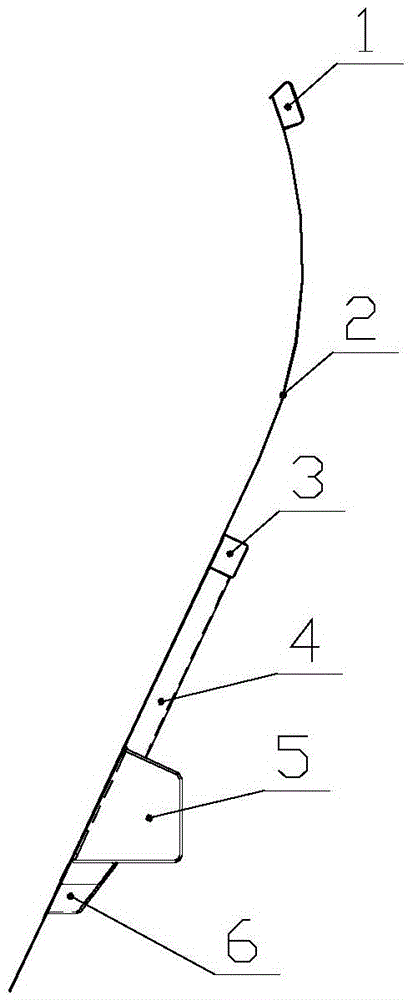

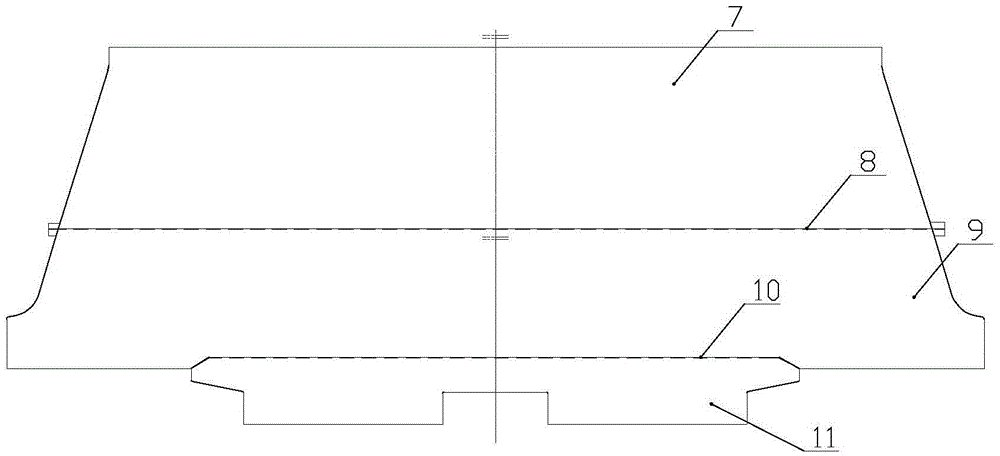

Multifunctional split bolt and application thereof

ActiveCN103061505AImprove performanceReliable functionAuxillary members of forms/shuttering/falseworksBuilding reinforcementsArchitectural engineeringUsability

The invention discloses a multifunctional split bolt and application thereof. Steel plates are penetratingly mounted at two ends of a bolt bar. The bolt bar is fixedly connected one steel plate by means of welding. A pair of positioning clamps for fixing rebar positions is welded on the bolt bar between the two steel plates. Fastening nuts are fitted at two ends of the bolt bar. When the split bolt is used in a composite structure with building prior to pouring, construction speed is increased, construction efficiency is improved, bonding degree and tightness of interfaces of different materials are enhanced, overall performance of a structure is improved, usability of the structure is more reliable, maintenance is reduced, service life of a project is prolonged, accuracy and reliability of rebar protective layer control are higher, soakage resistance and erosion resistance of concrete is guaranteed to be more reliable, formwork mounting and strengthening are more convenient and faster, influence of building verticality and evenness can be eliminated, construction accuracy is higher, common signal side formwork lateral supports can be reduced, construction difficulty can be lowered, cost is saved, and the split bolt is suitable for double-side formwork construction and embedded part positioning mounting of walls and board components.

Owner:河北省第四建筑工程有限公司

Composite article for constructing floors

A composite for constructing concrete floors is completely factory assembled and comprises a body of expanded plastic having at least two parallel channels, open on the upper surface of the panel, extending the length of the article, adapted to be filled with concrete. A steel reinforcement bar fabric is installed into each channel, which may comprise at least two parallel steel bars connected by cross bars. At least some cross bars extend beyond a lowest reinforcement fabric bar to provide spikes long enough to pass through the plastic bottom and protrude therefrom. One or more sheet metal shrouds with at least one row of aligned holes matching those of the protruding spike ends are applied to the underside surface of the plastic body hung from the protruding ends of the spike by fasteners

Owner:PLASTEDIL

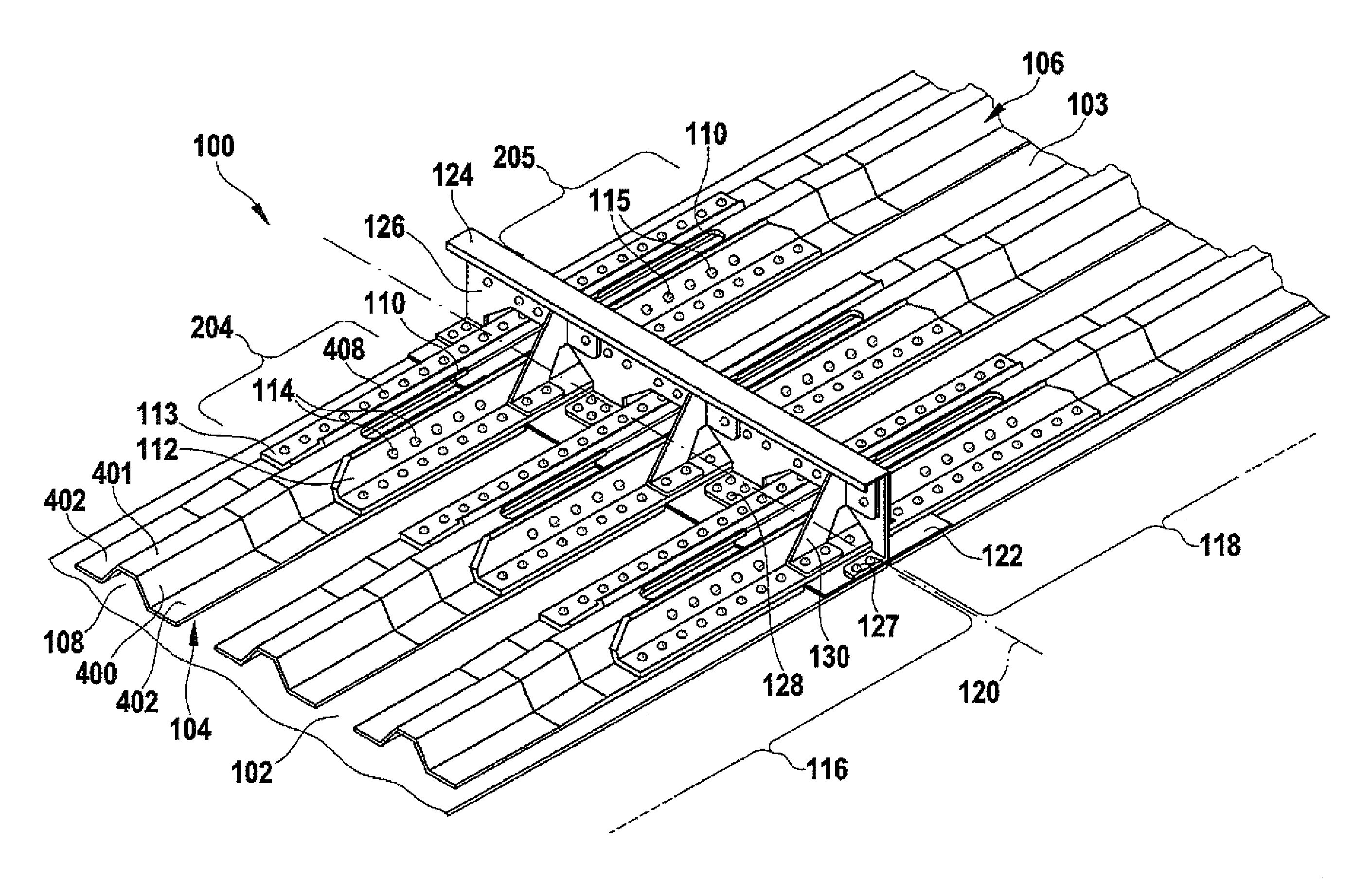

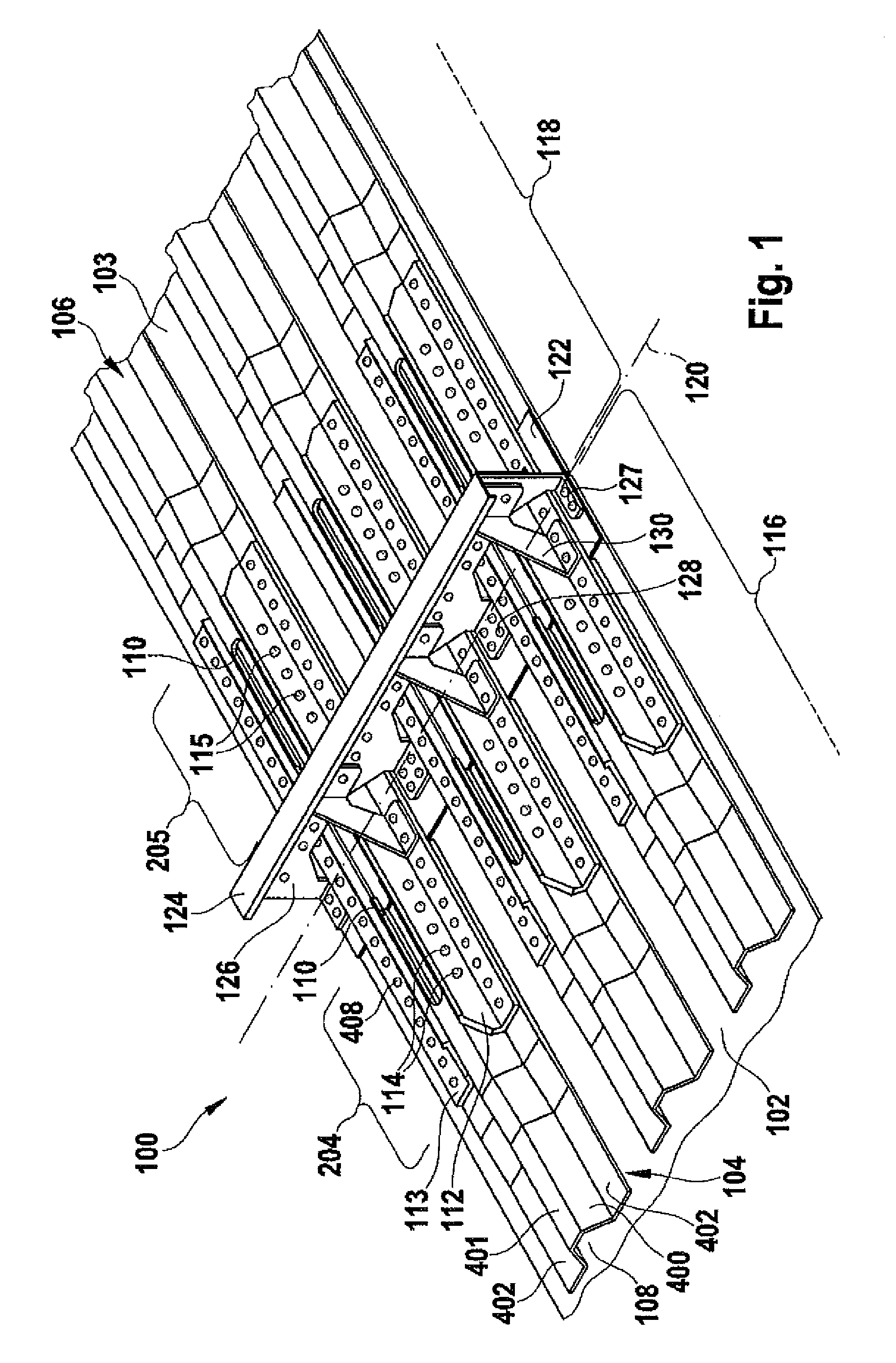

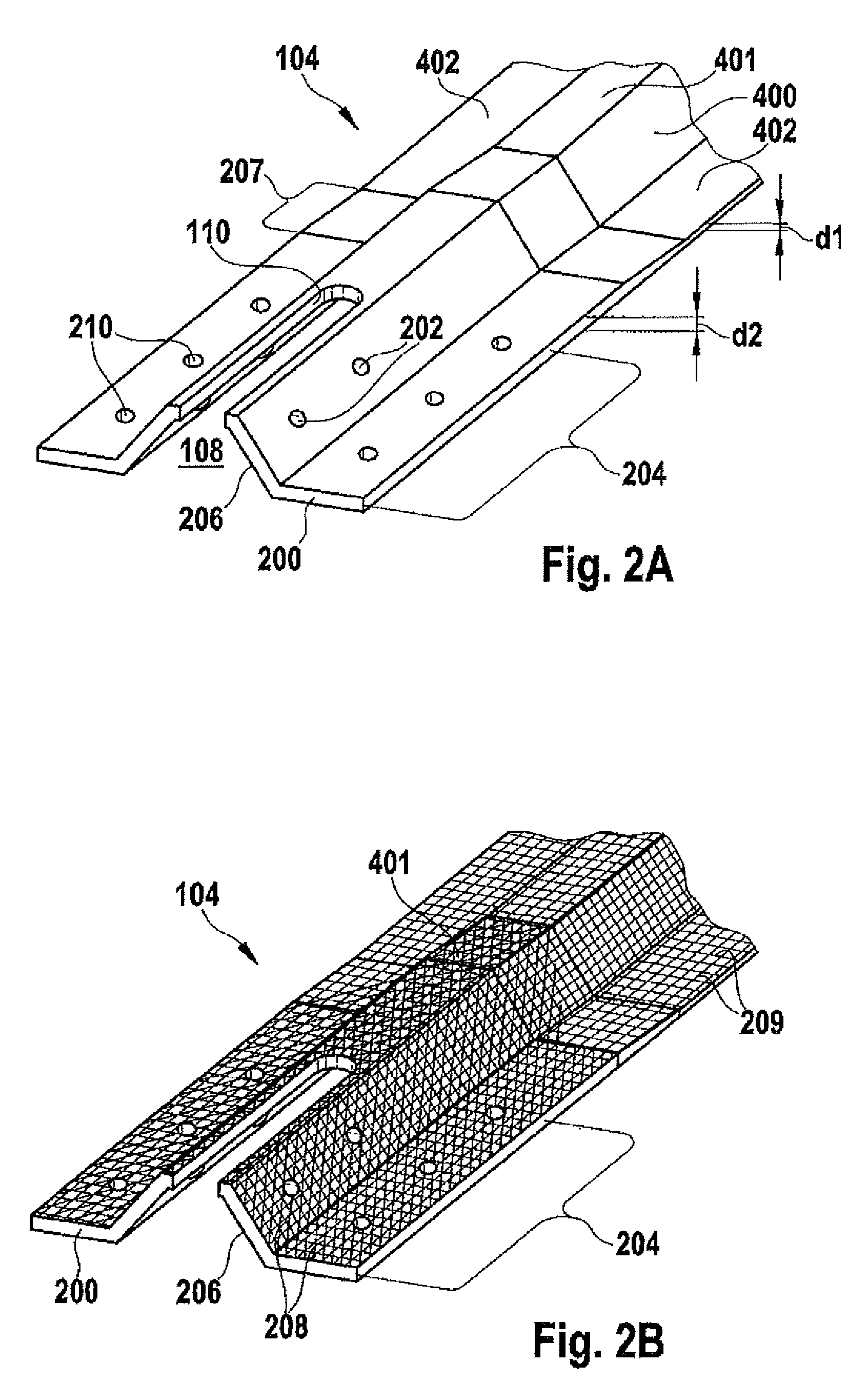

Method for coupling stiffening profile elements and structural component

ActiveUS8715808B2Reliable quality controlEnhanced couplingFuselage framesCellulosic plastic layered productsCouplingEngineering

This invention provides a coupling method for coupling a first and a second stiffening profile element for an outer skin of an aircraft or space craft. In a first step the stiffening profile elements are arranged on the outer skin in such a manner that the stiffening profile elements oppose each other with their respective front sides and enclose within themselves a cavity. Furthermore, a fixing hole is formed through a wall of at least one of the stiffening profile elements in the cavity inside a coupling zone of the stiffening profile element. An access opening is formed through the wall in the cavity along the coupling zone. A coupling strap, which couples the stiffening profile elements together, is fastened to the coupling zone by means of a fastening element guided through the fixing hole.

Owner:AIRBUS OPERATIONS GMBH

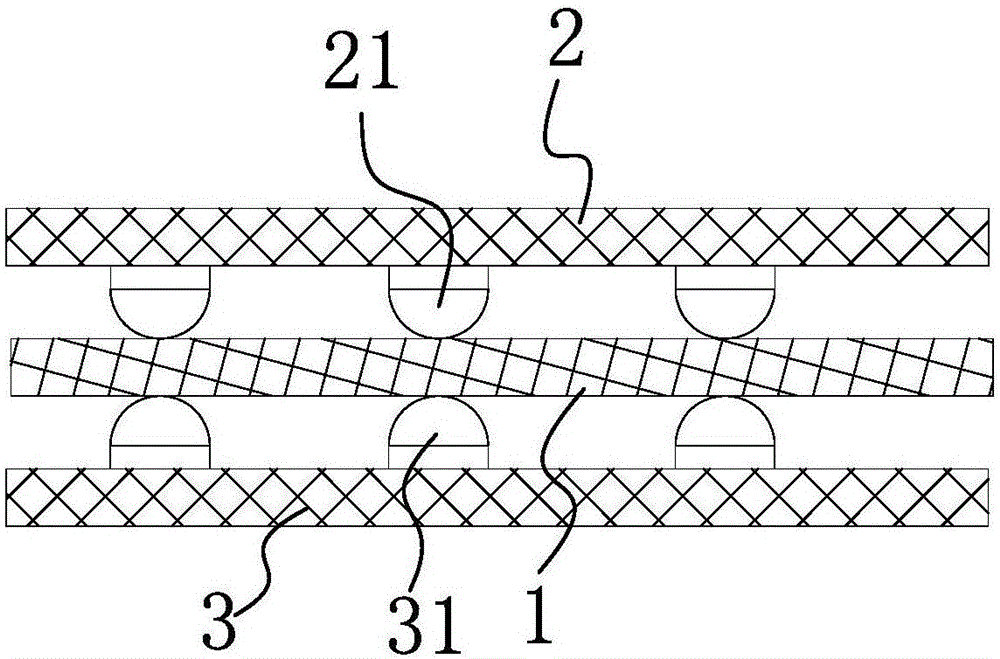

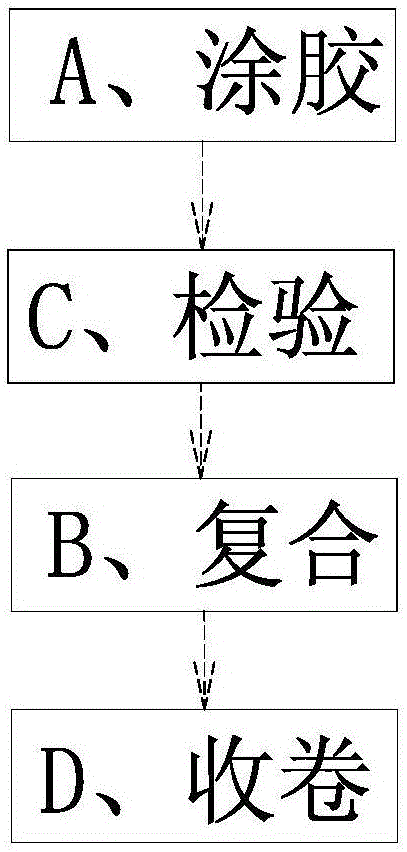

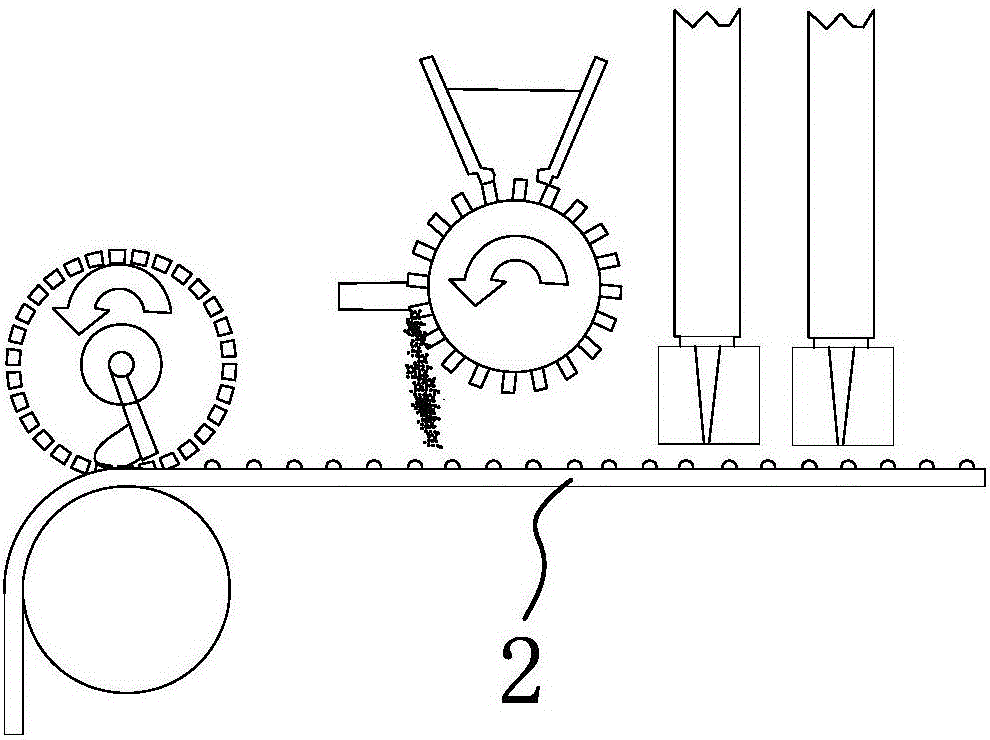

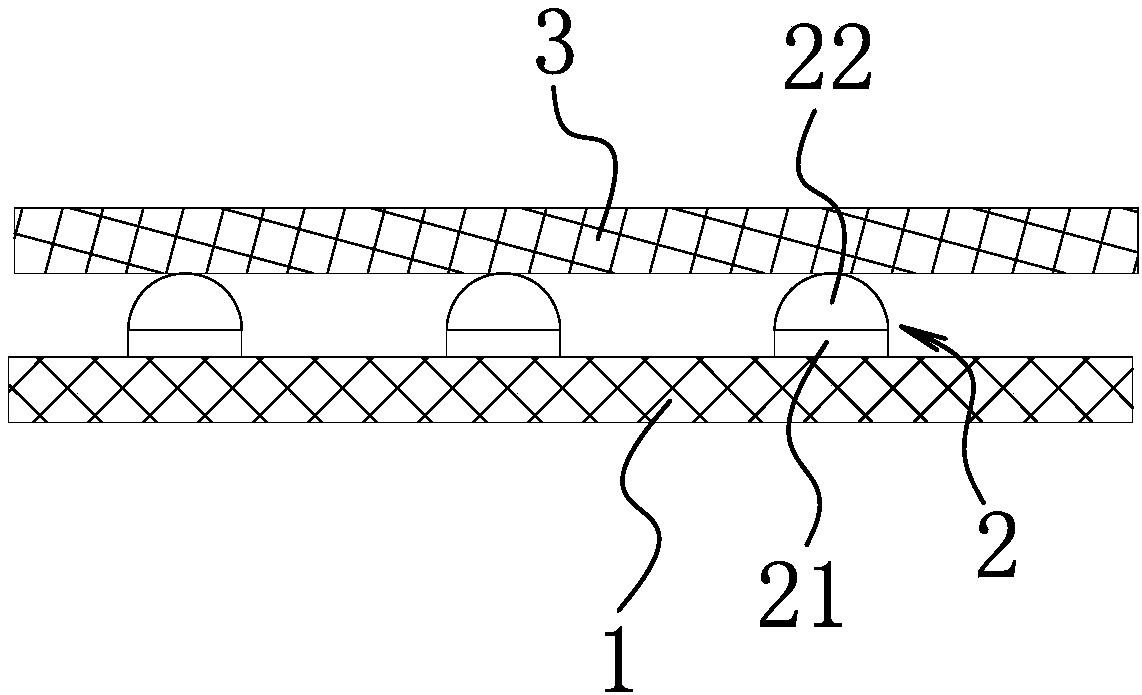

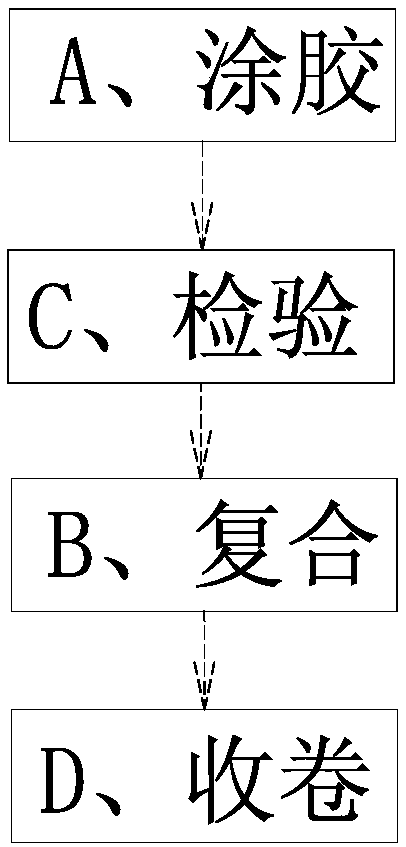

Three-layered composite automotive interior fabric and production process thereof

ActiveCN106183134AIncreasing the thicknessEasy dischargeLaminationLamination apparatusManufacturing cost reductionNonwoven fabric

The invention belongs to the technical field of fabrics and in particular relates to a three-layered composite automotive interior fabric and a production process thereof, and aims at solving the problems in the prior art that pocks are easy to generate and the fabric is not environment-friendly and the like. The three-layered composite automotive interior fabric comprises sponge, a water-repelling automotive fabric and a non-woven fabric; a first double-point coating is arranged on one face of the water-repelling automotive fabric and the water-repelling automotive fabric is compounded on one face of the sponge through the first double-point coating; a second double-point coating is arranged on one face of the non-woven fabric and the non-woven fabric is compounded on the other face of the sponge through the second double-point coating. The production process of the three-layered composite automotive interior fabric comprises the following steps: A, gluing; B, compounding. The three-layered composite automotive interior fabric and the production process thereof have the advantages that the manufacturing cost can be reduced and the pocks can be avoided; the peeling strength can be improved and the fabric is more environment-friendly.

Owner:CPL NEW MATERIAL TECH CO LTD

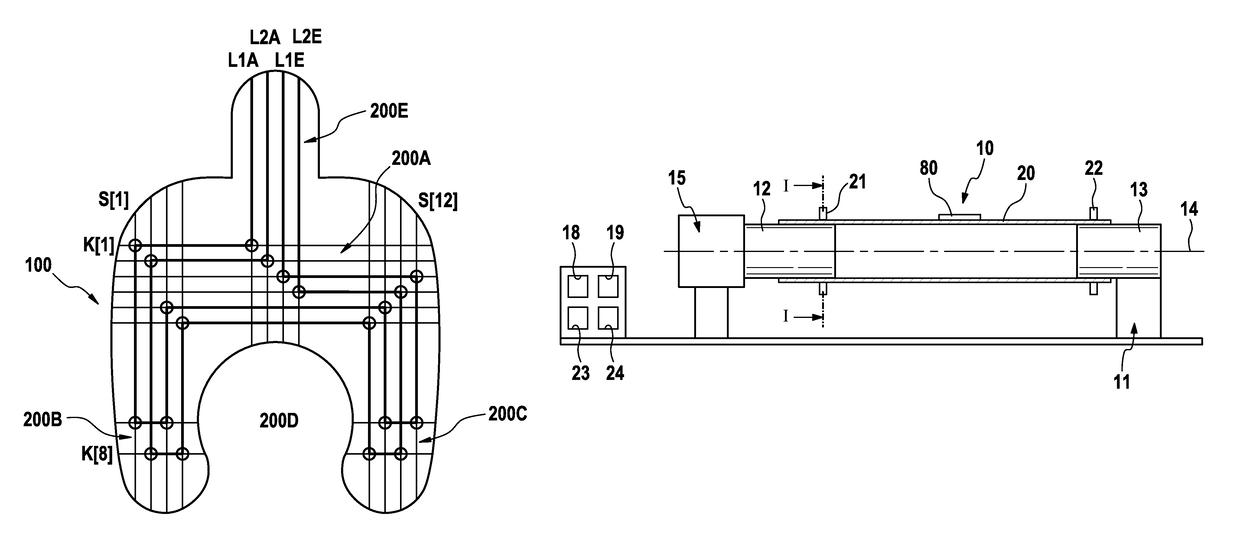

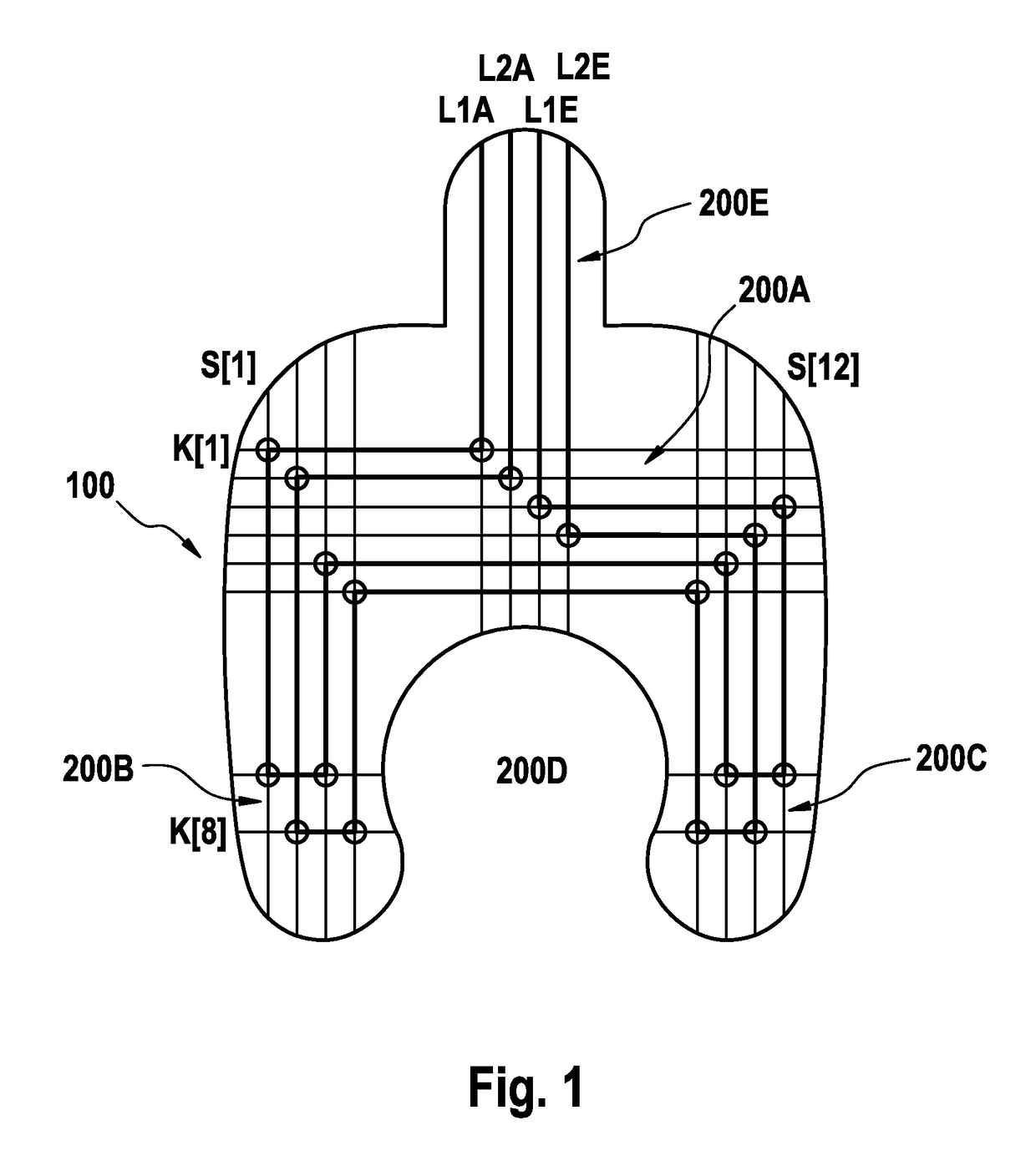

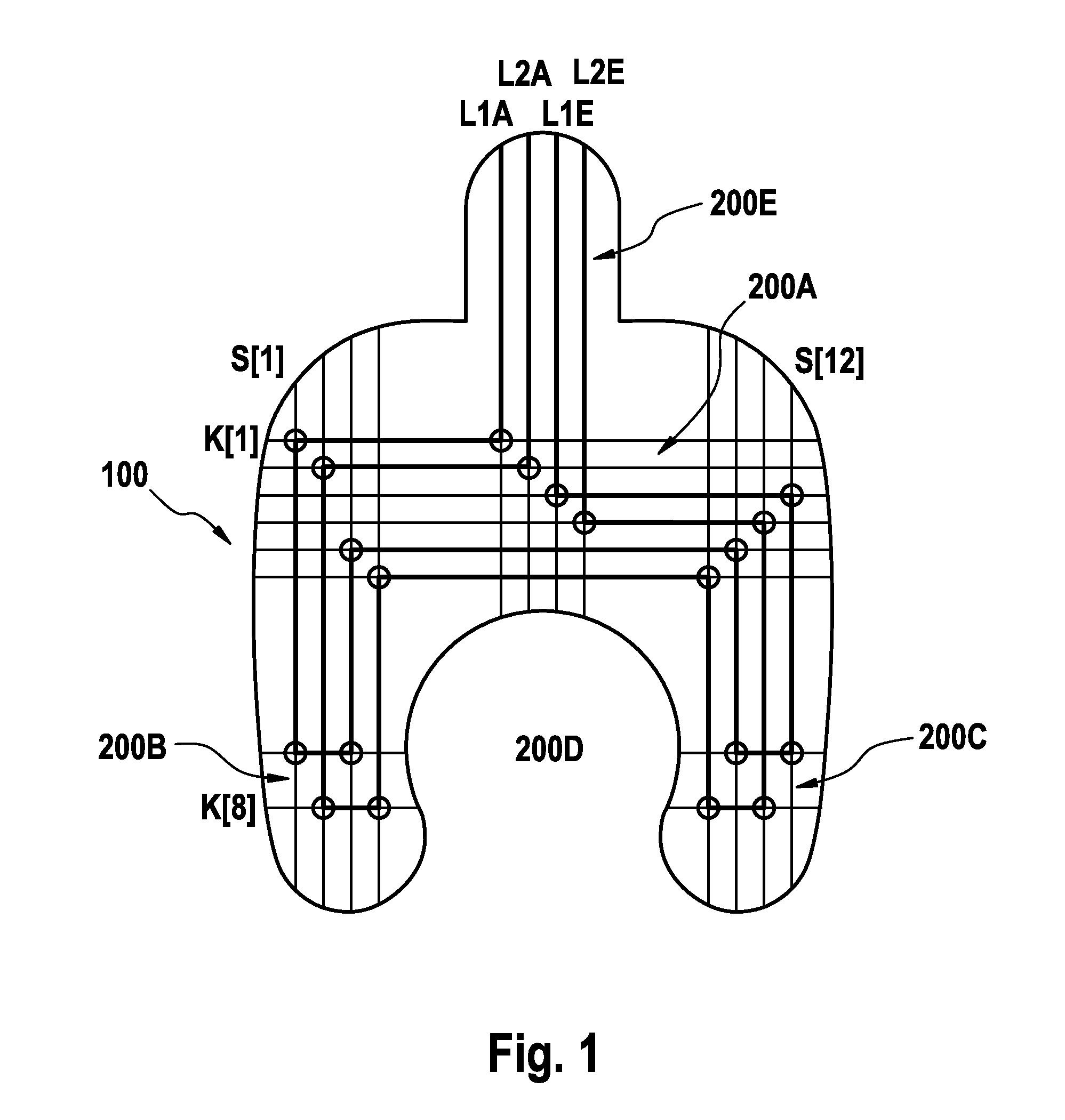

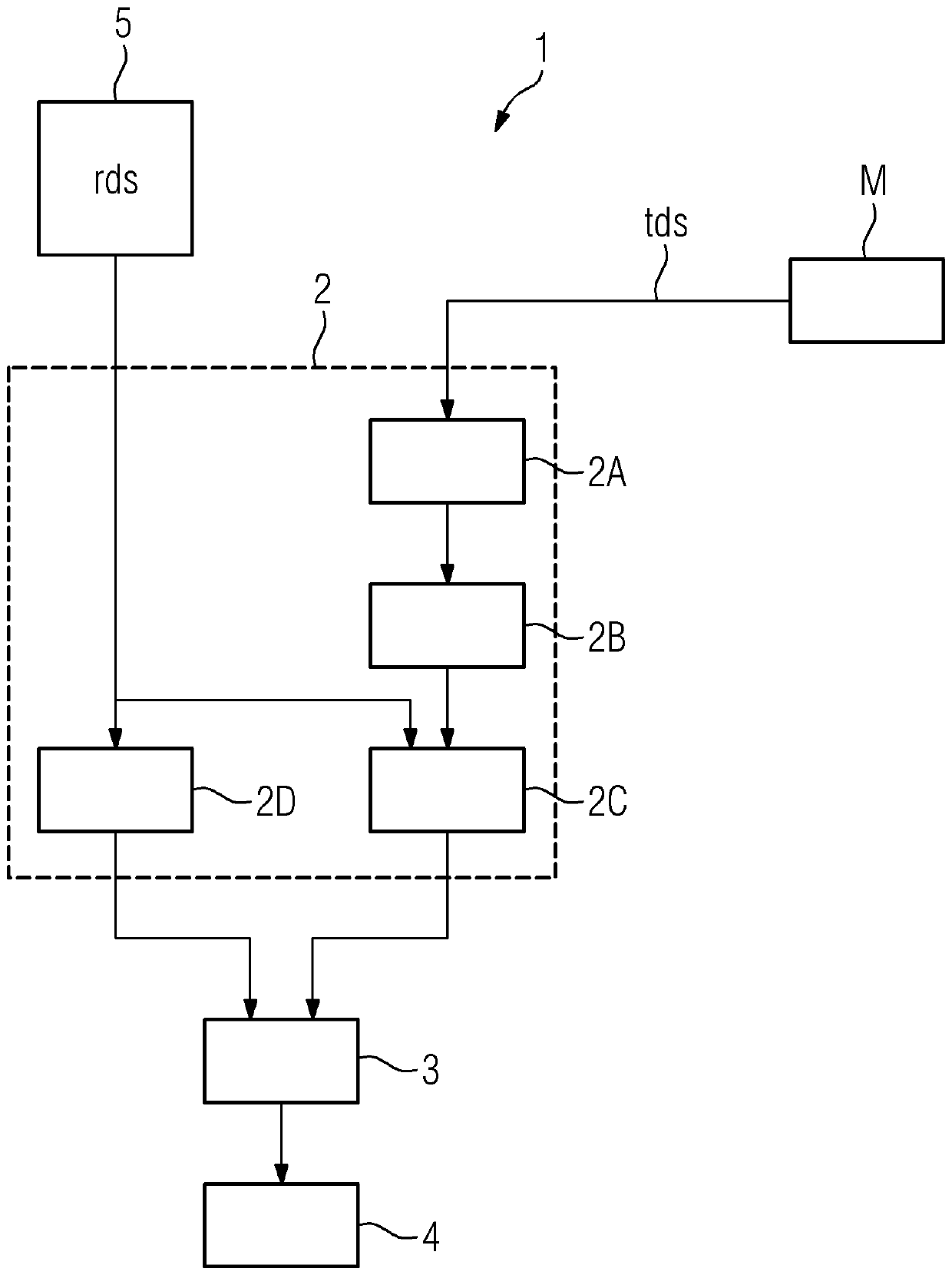

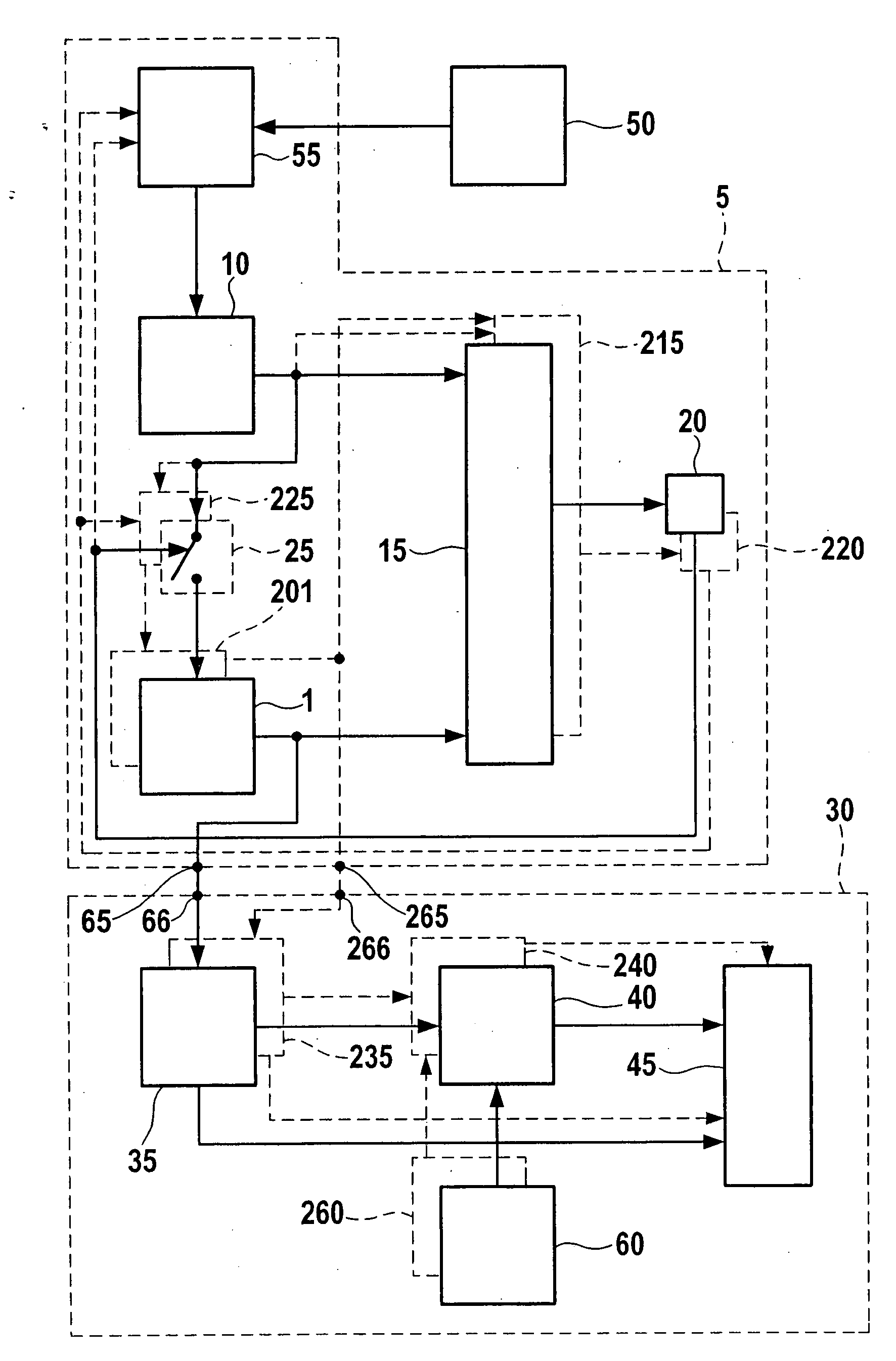

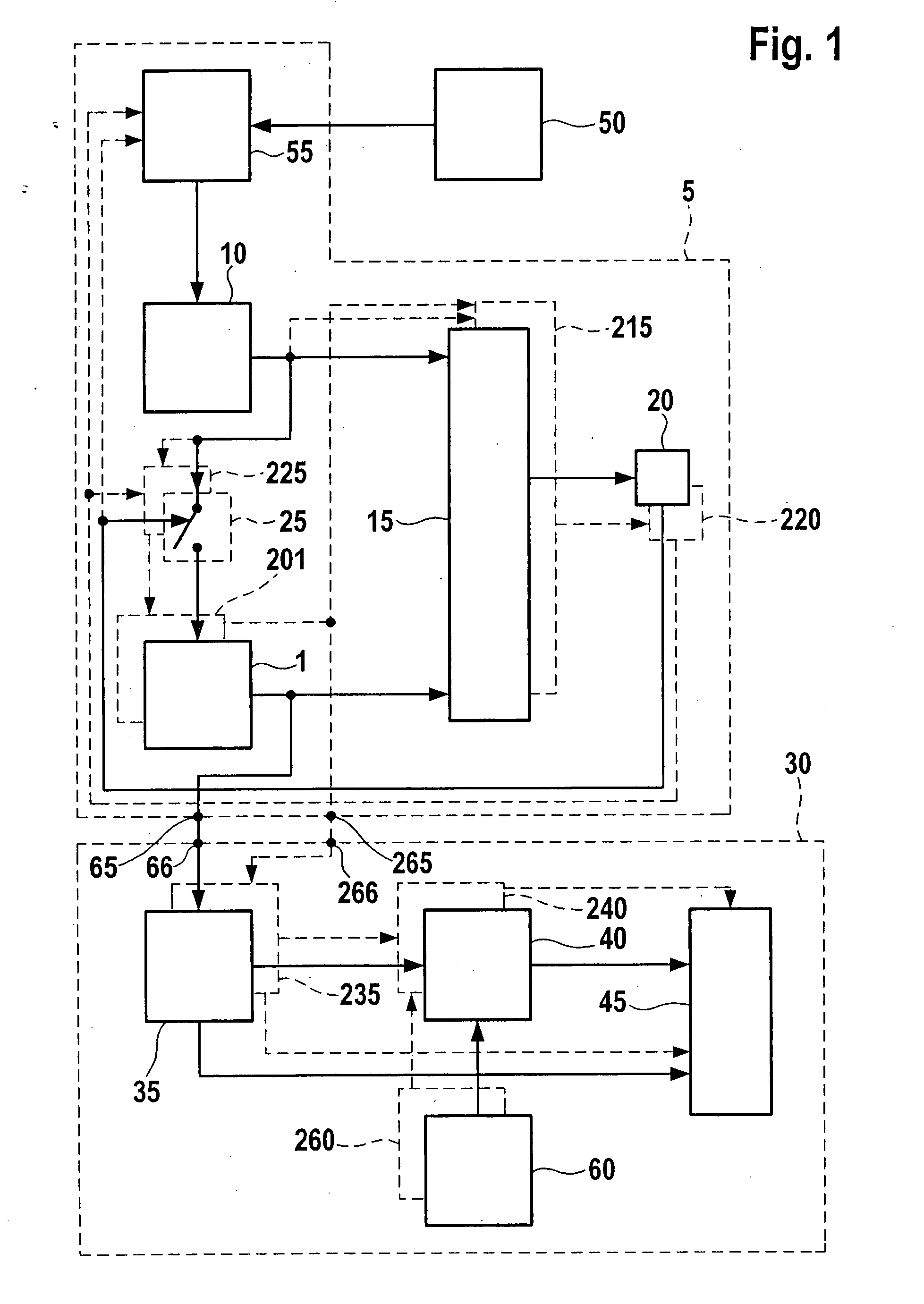

Method and device for testing sensors to be applied on a patient's skin for the detection of fluid or moisture

ActiveUS9645218B2Reliable quality controlLarge movementDetection of fluid at leakage pointOther blood circulation devicesVeinBlood treatments

A method and device for testing sensors to be applied on a patient's skin for detection of liquid or moisture are described, in particular for monitoring vascular access in an extracorporeal blood treatment, in which a patient's blood is carried away from the patient via an arterial line and is fed to the patient via a venous line. A method for producing sensors to be applied on a patient's skin for detection of liquid or moisture is also described. The method and device according to the present invention are based on the testing of one or more moisture sensors which are taken from current production. The method includes providing a large number of twists of the moisture sensor applied onto a torsion body, the mechanical stresses thus recreating the stresses that can occur in practice when the moisture sensor is applied or stuck onto the patient's skin or forearm.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

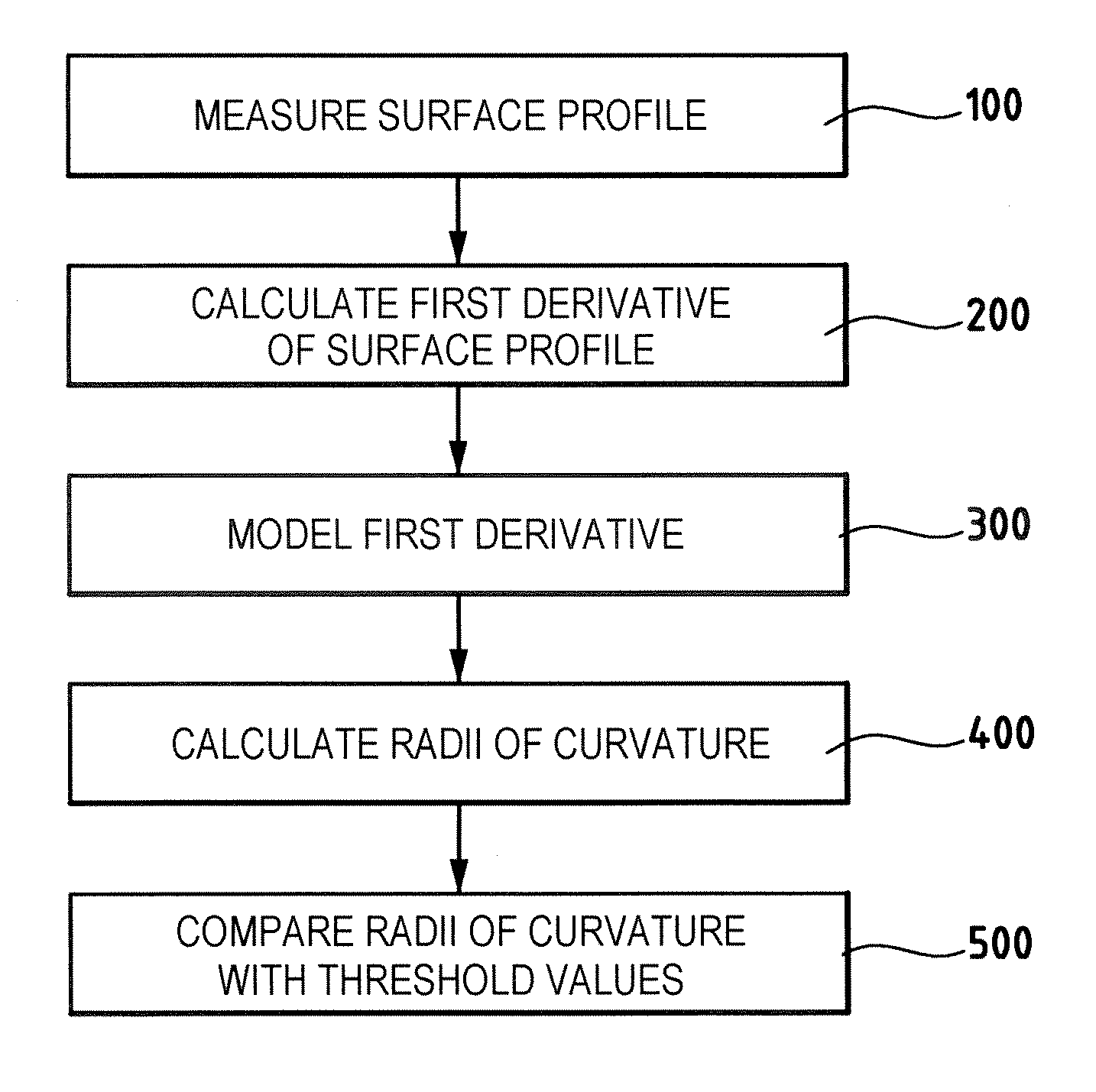

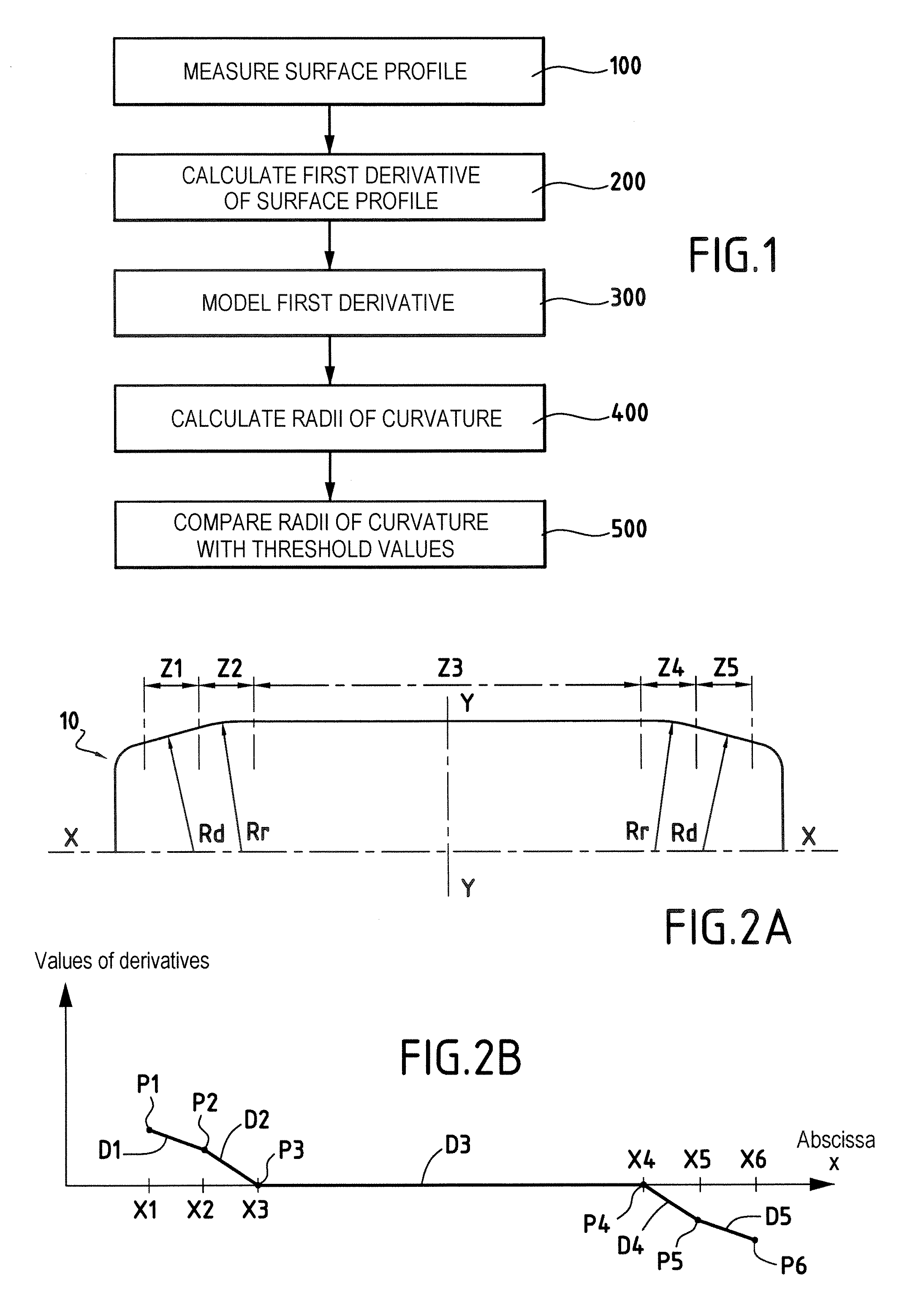

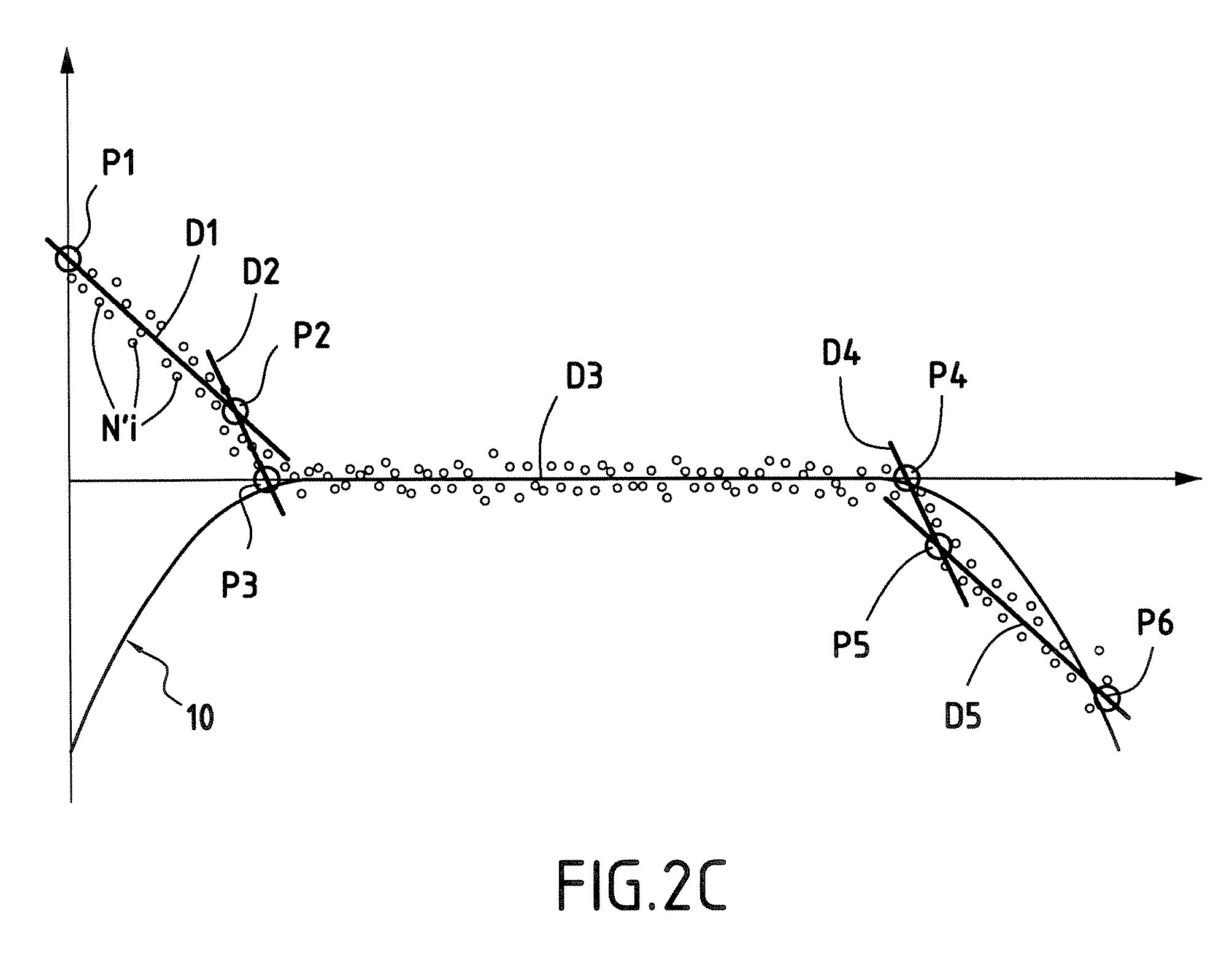

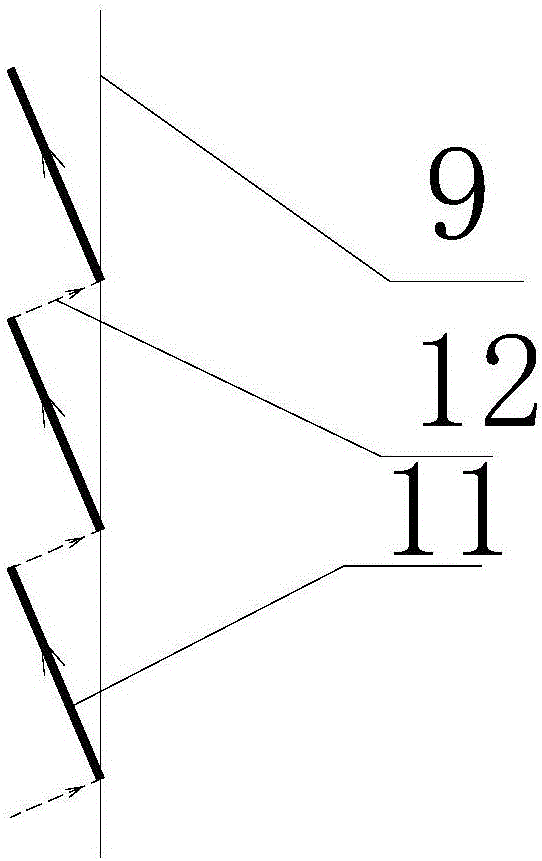

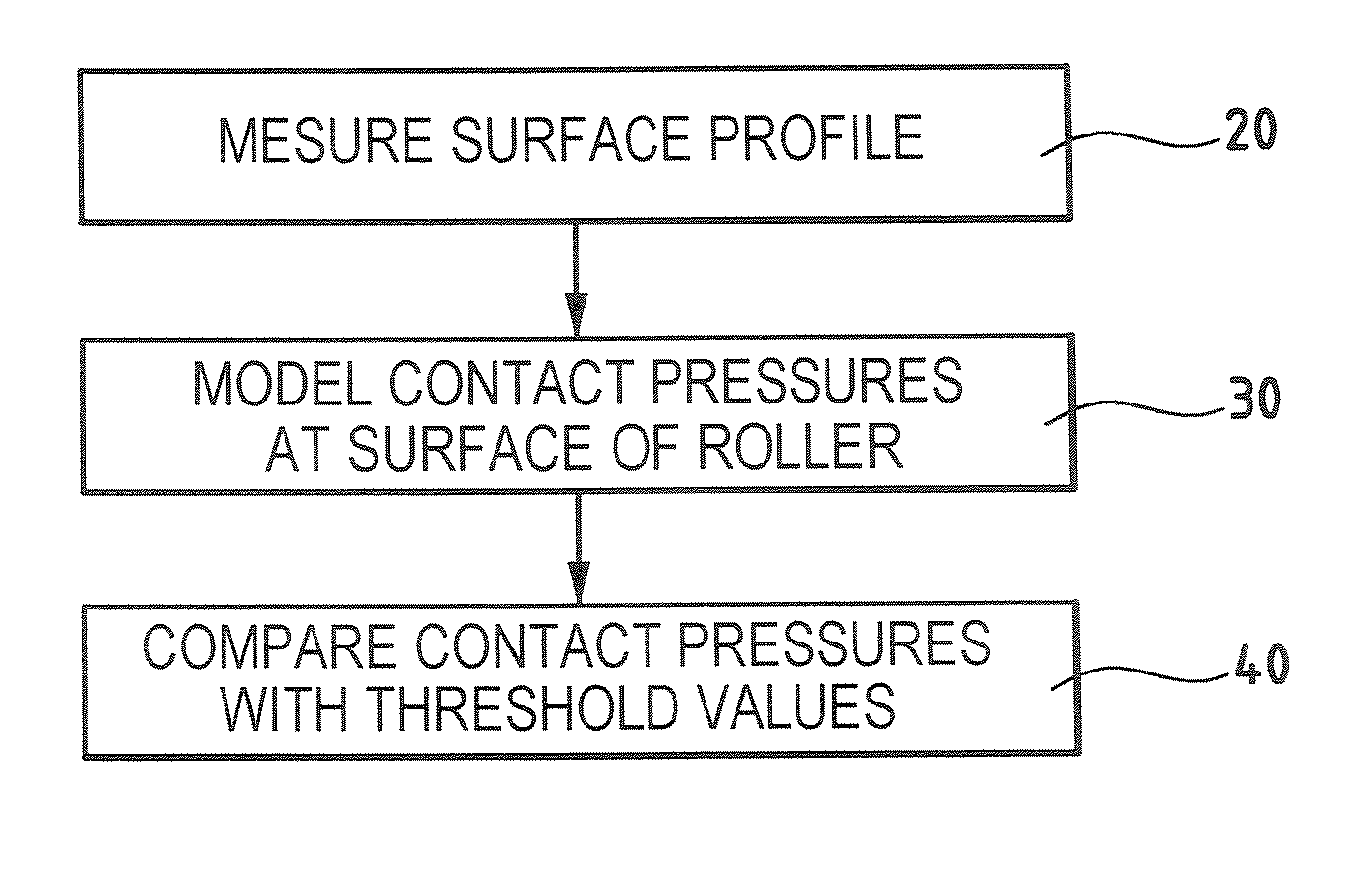

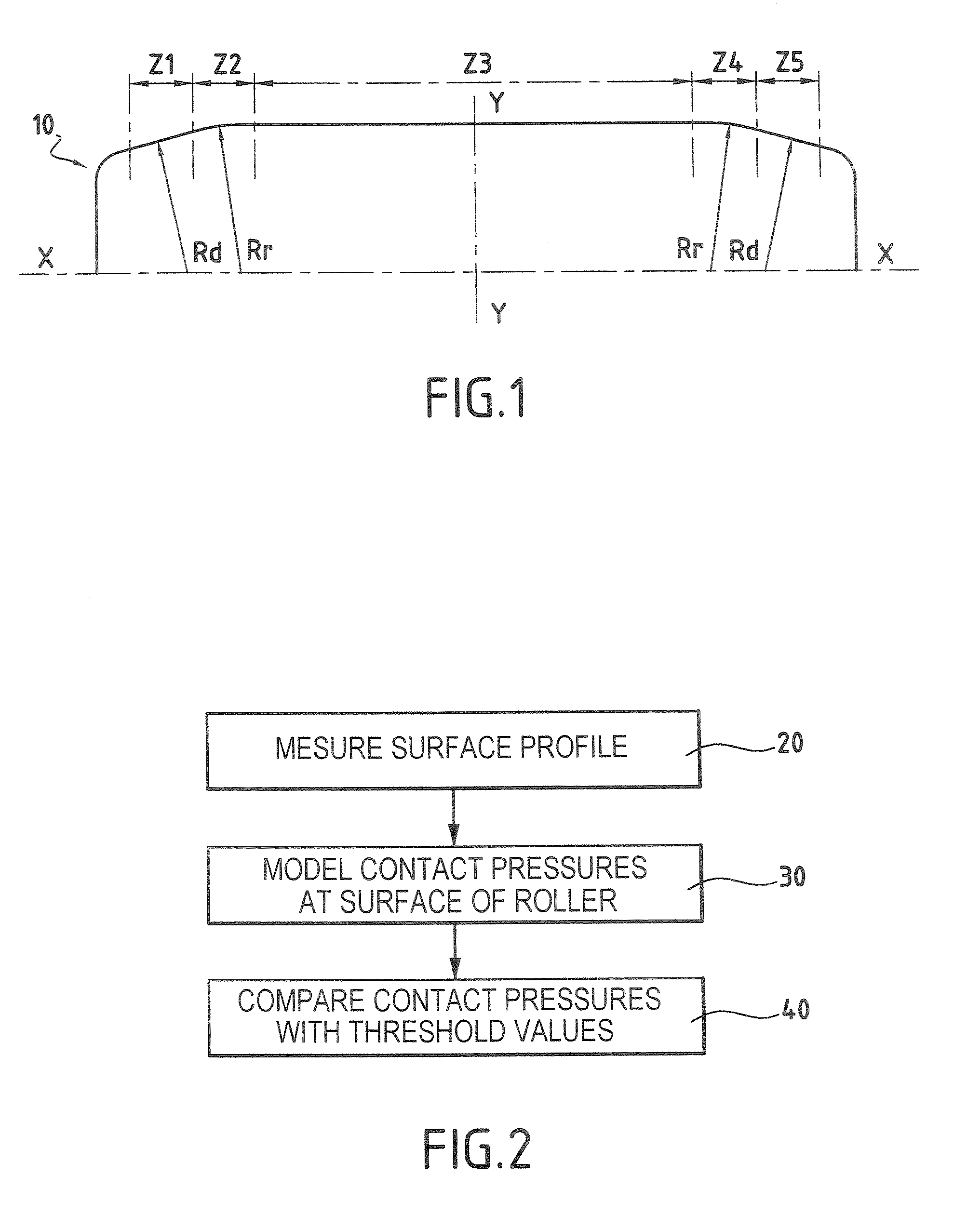

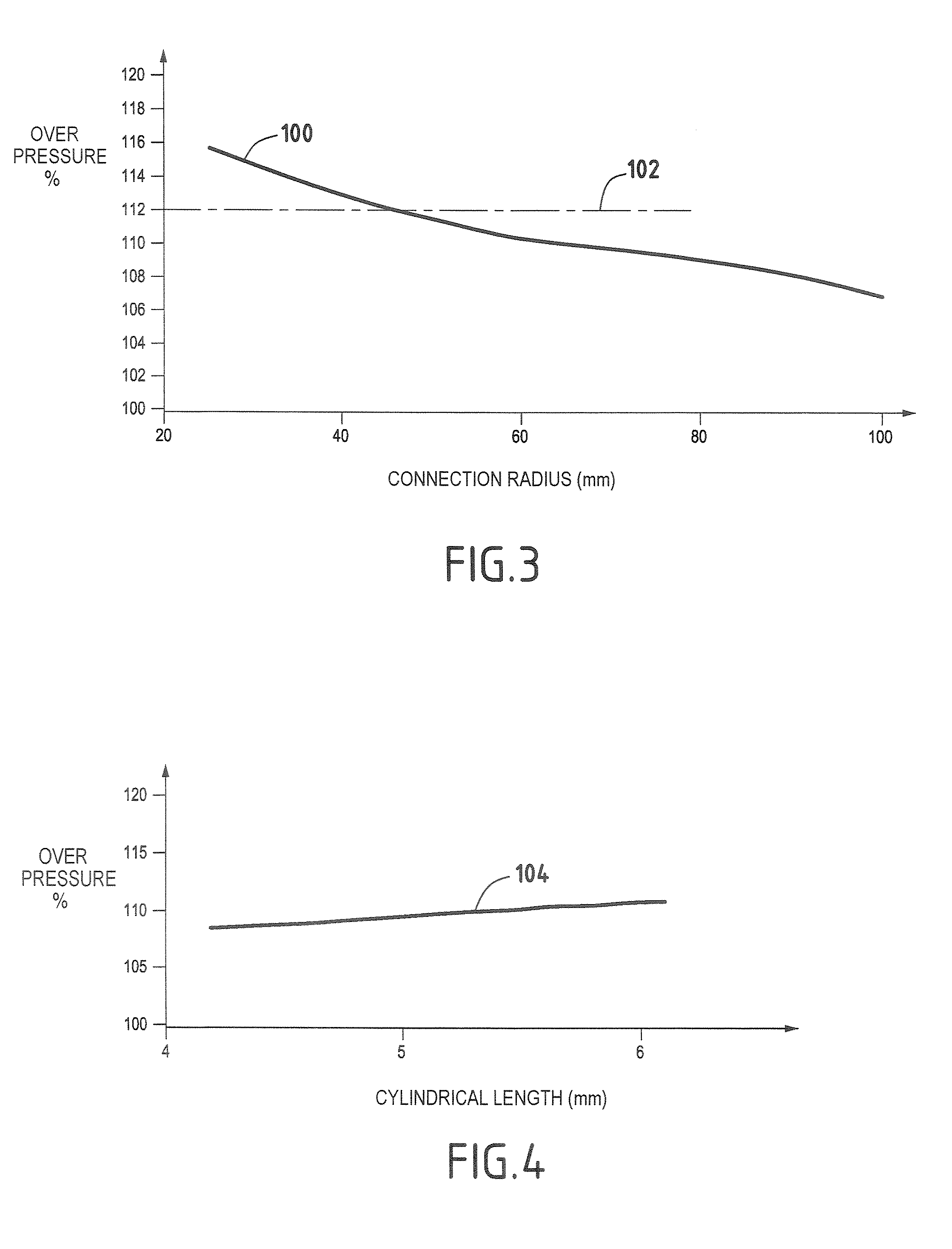

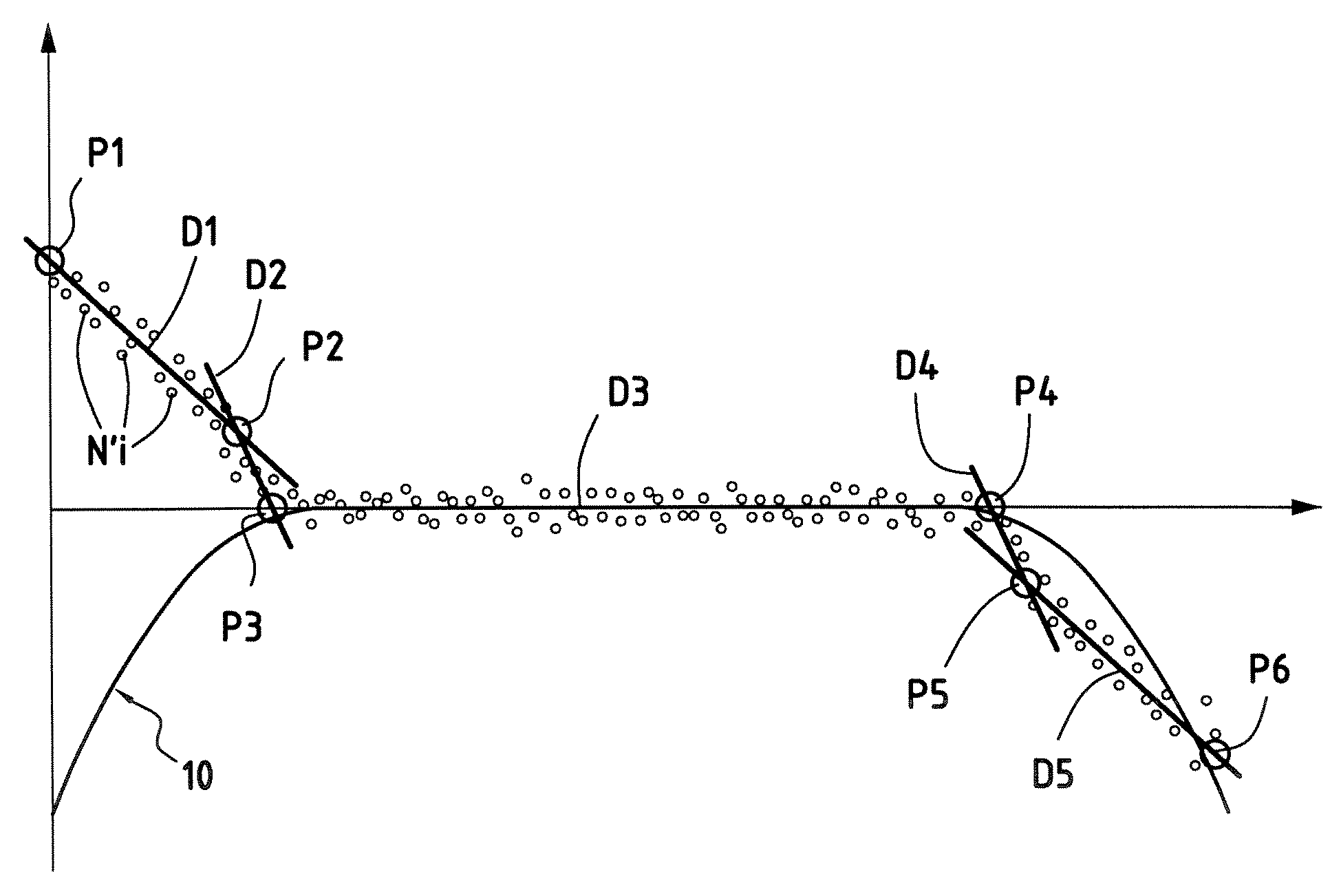

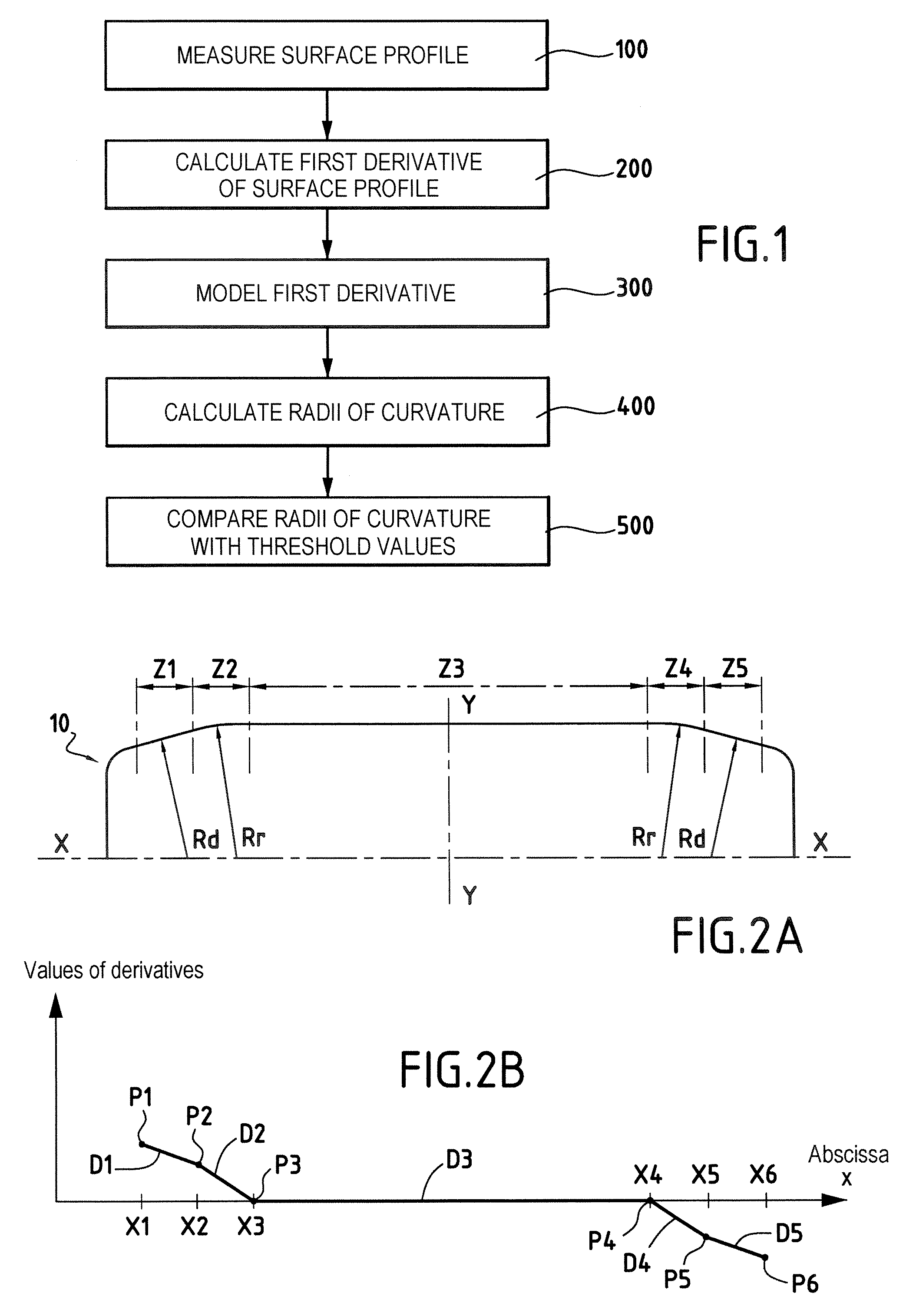

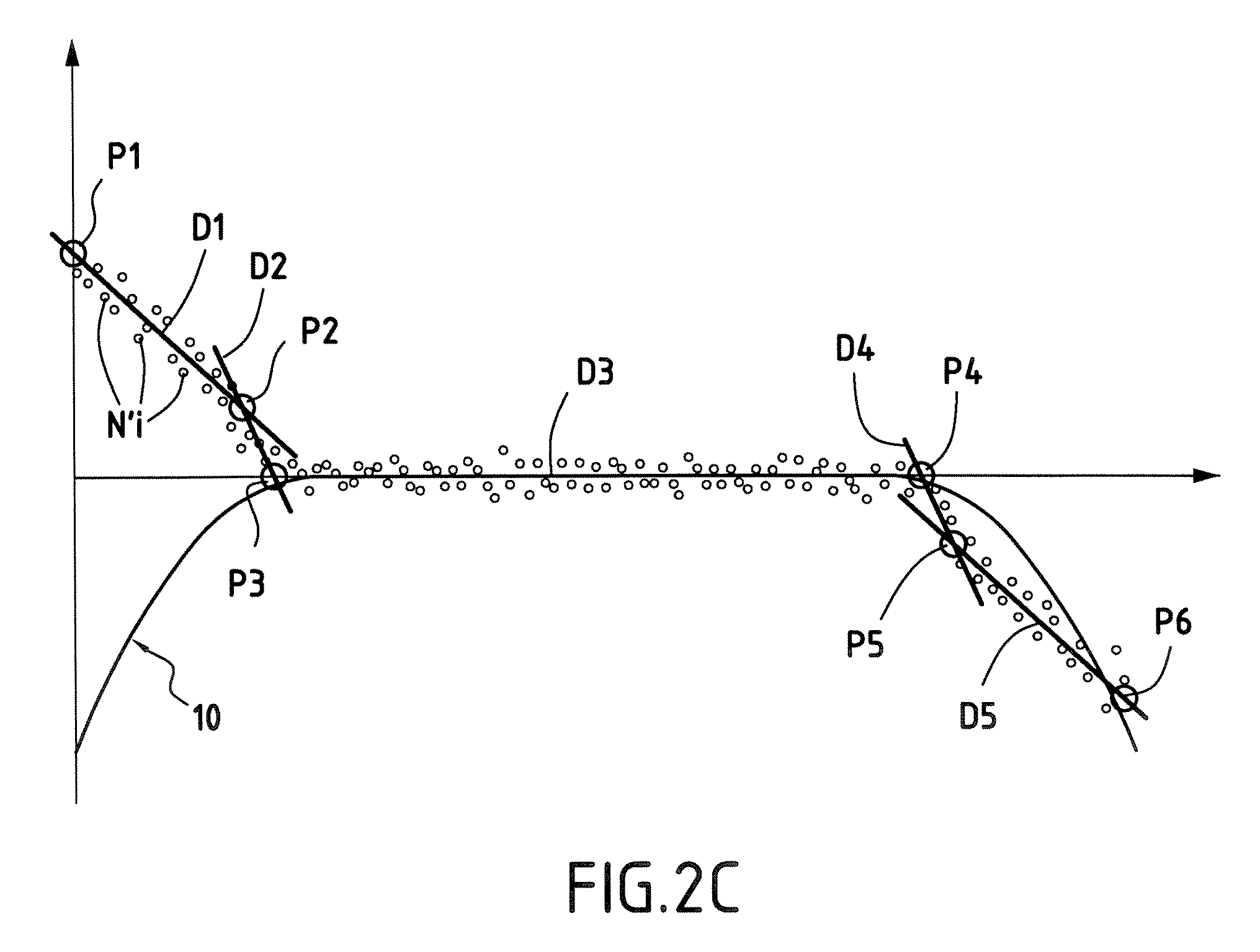

Method of inspecting the profile of the connection zone between the cylindrical portion and the taper of a roller for a turbomachine roller bearing

ActiveUS20070005295A1Reliable quality controlDistance minimizationFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansLine segmentEngineering

A method of inspecting the profile of the connection zone between the cylindrical portion and the taper of a roller for a turbomachine roller bearing. The surface profile is geometrically defined by a first zone corresponding to the taper of the roller, a second zone corresponding to the connection between the cylindrical portion and the taper, and a third zone corresponding to the cylindrical portion of the roller. The method consists in taking a measurement of the surface profile of the roller; on the basis of a calculation of the first derivative of the measured profile, in calculating straight line segments for each of the geometrical zones of the roller, where said straight line segments model the first derivative of the measured profile; in calculating the radii of curvature of the surface profile of the roller by taking the first derivative of the straight line segments; and in comparing the calculated radii of curvature with predefined threshold values in order to verify continuity thereof.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

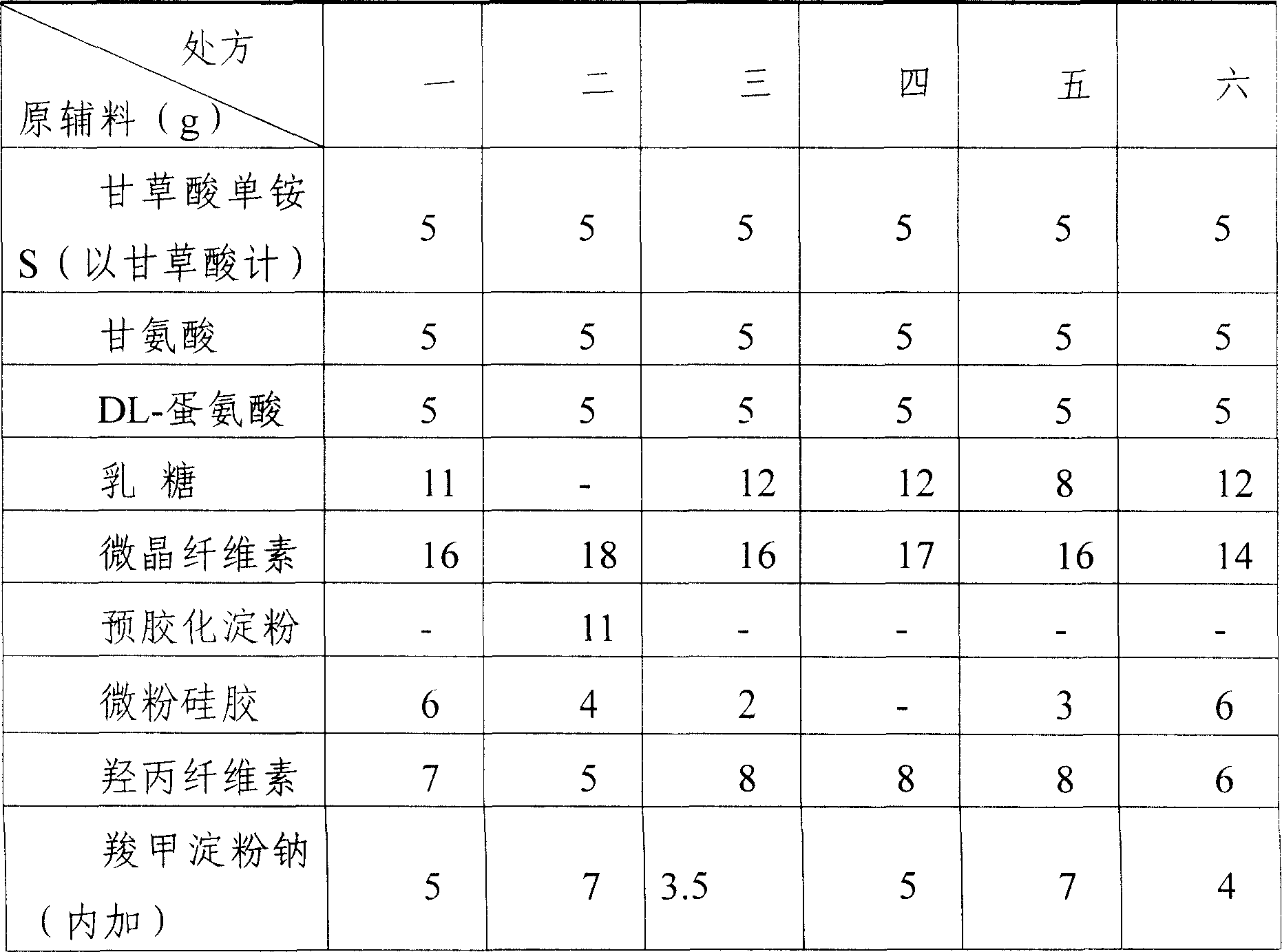

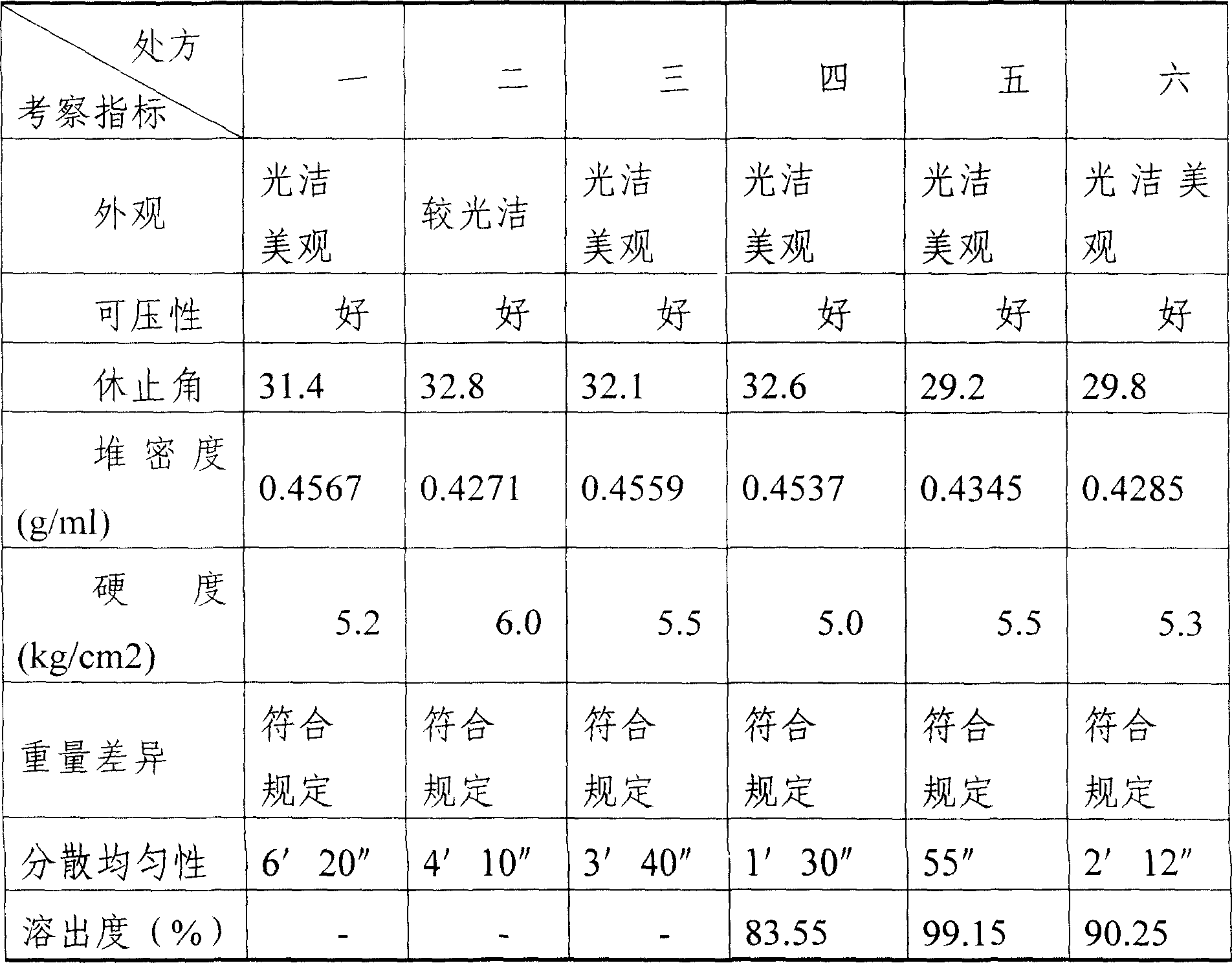

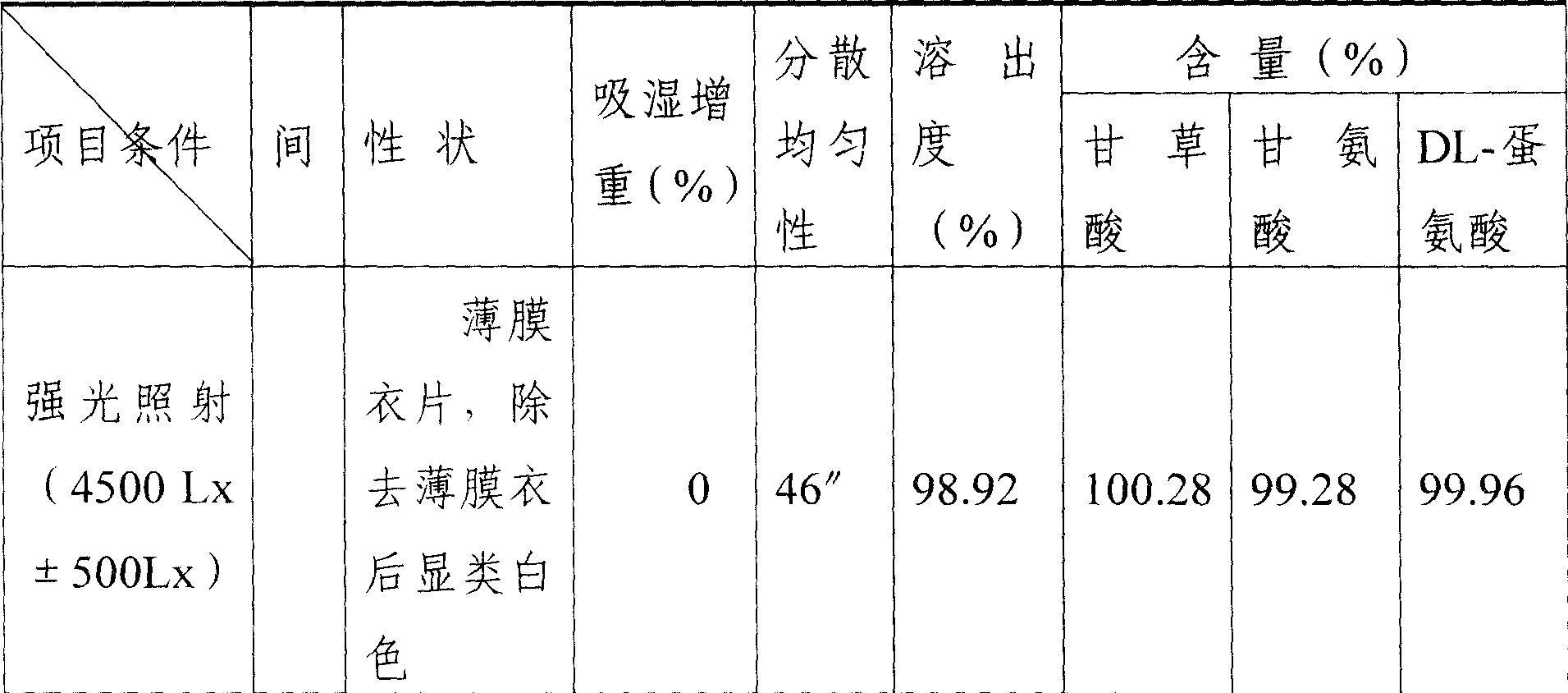

Compound ammonium glycyrrhizinato S dispersed tablet and its preparing process

InactiveCN1919185AImprove complianceSimple production processOrganic active ingredientsDigestive systemGlycineDL-methionine

The invention discloses a compound ammonium glycyrrhizinate S dispersible tablet, wherein the dispersible tablet is prepared from the following raw materials (by weight portion): monoammonium glycyrrhizinate S (calculated by glycyrrhizinic acid) 5-30 parts, glycine 5-30 parts, DL-methionine 5-30 parts, bulking agent 55-220 parts, crumbling agent 32-160 parts, lubricating agent 0.2-5 parts. The dispersible tablet has the advantages of shorter disintegration time, better dispersion state, faster medicament dissolving, quicker absorption, and higher biological availability, thus is especially suitable for the elder people and patients suffering from swallowing difficulty.

Owner:黄本东

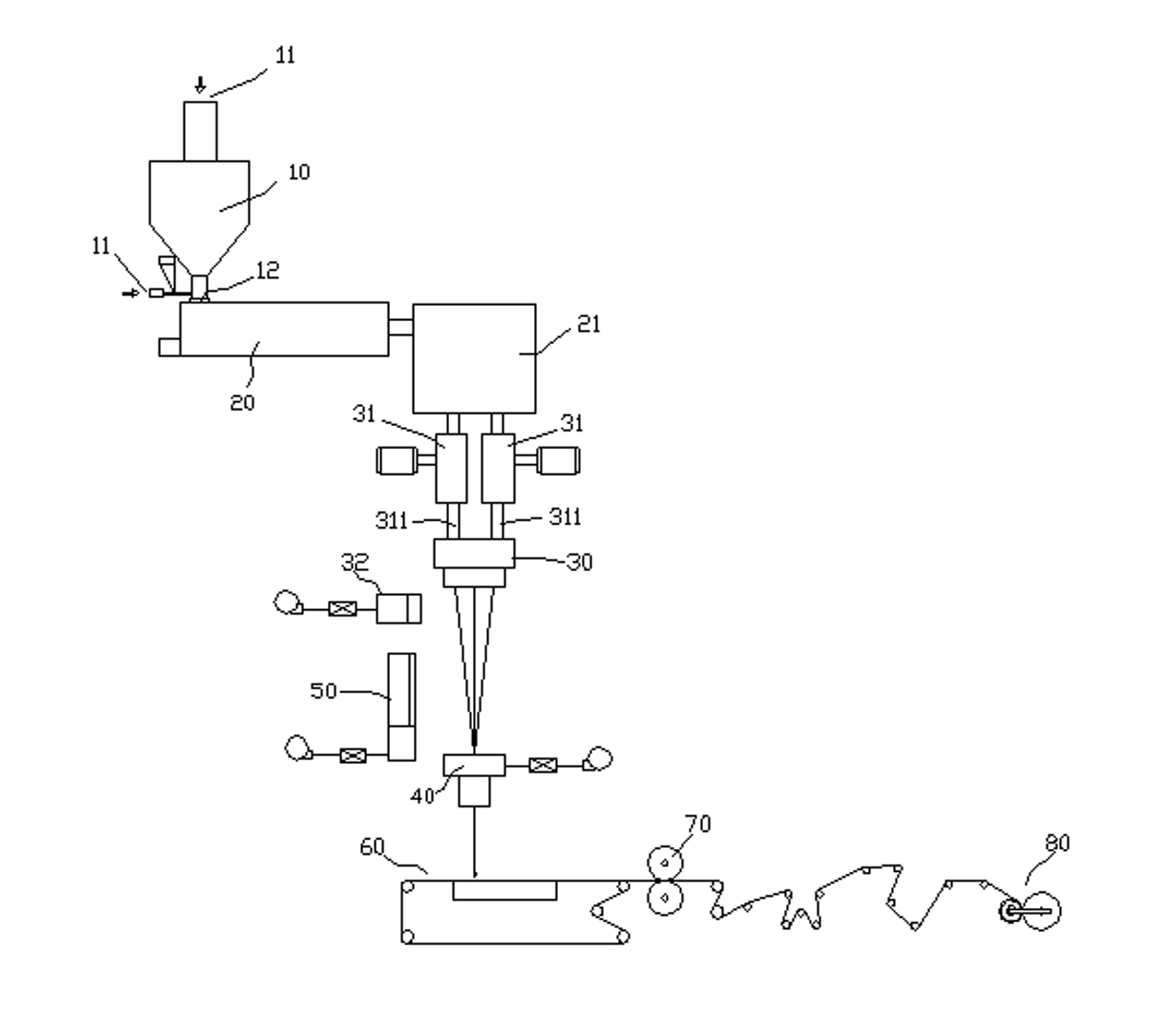

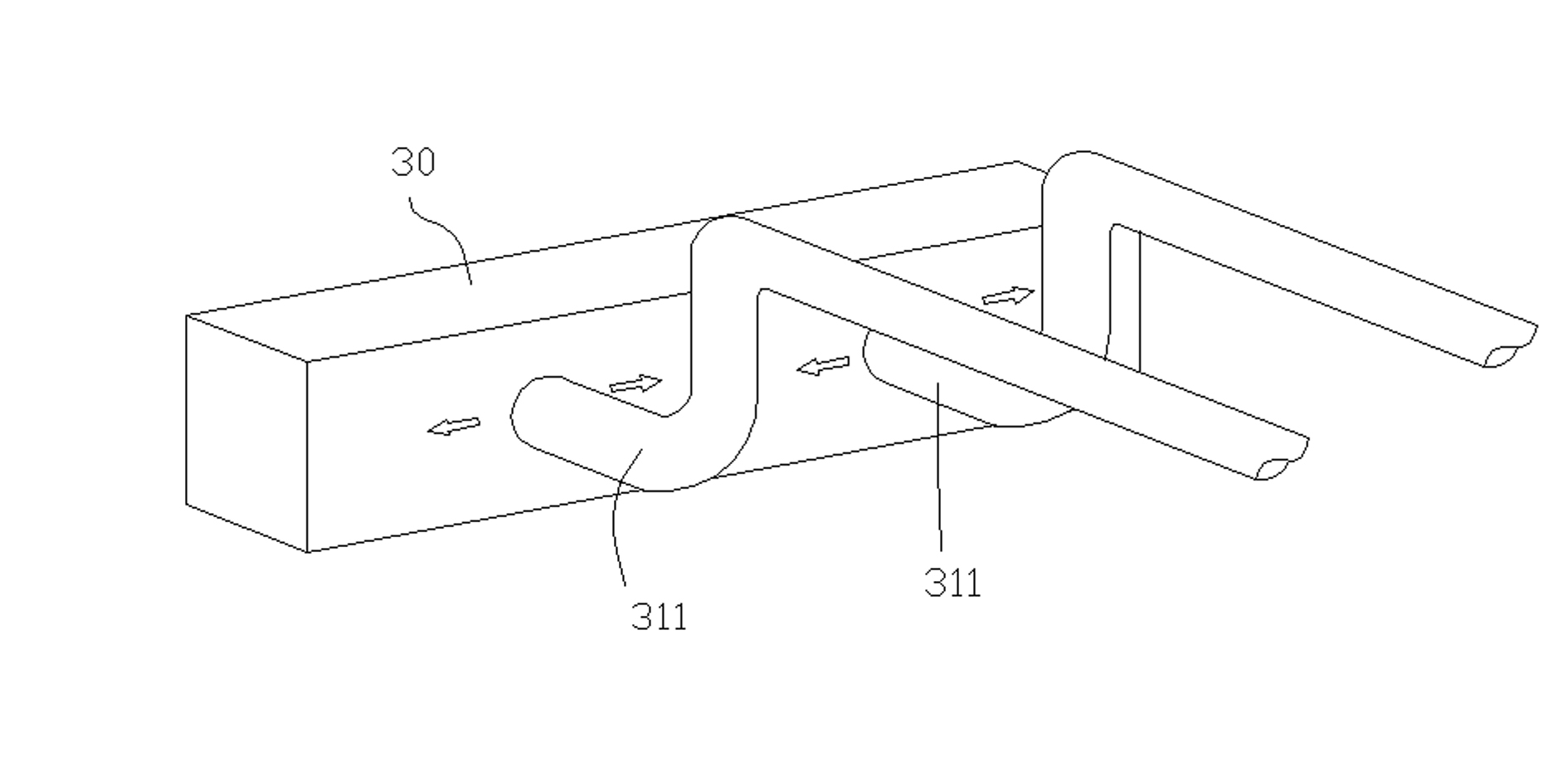

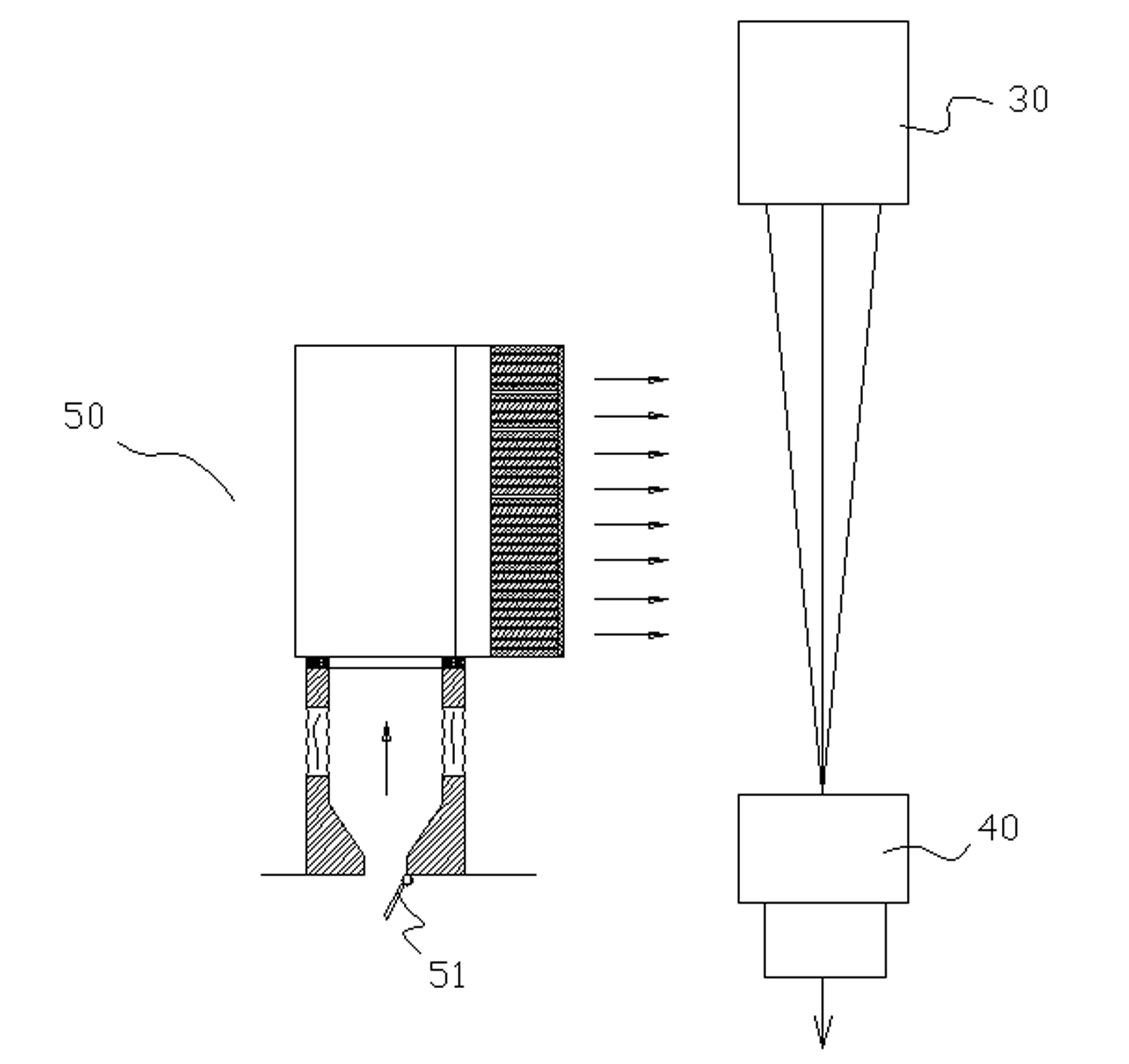

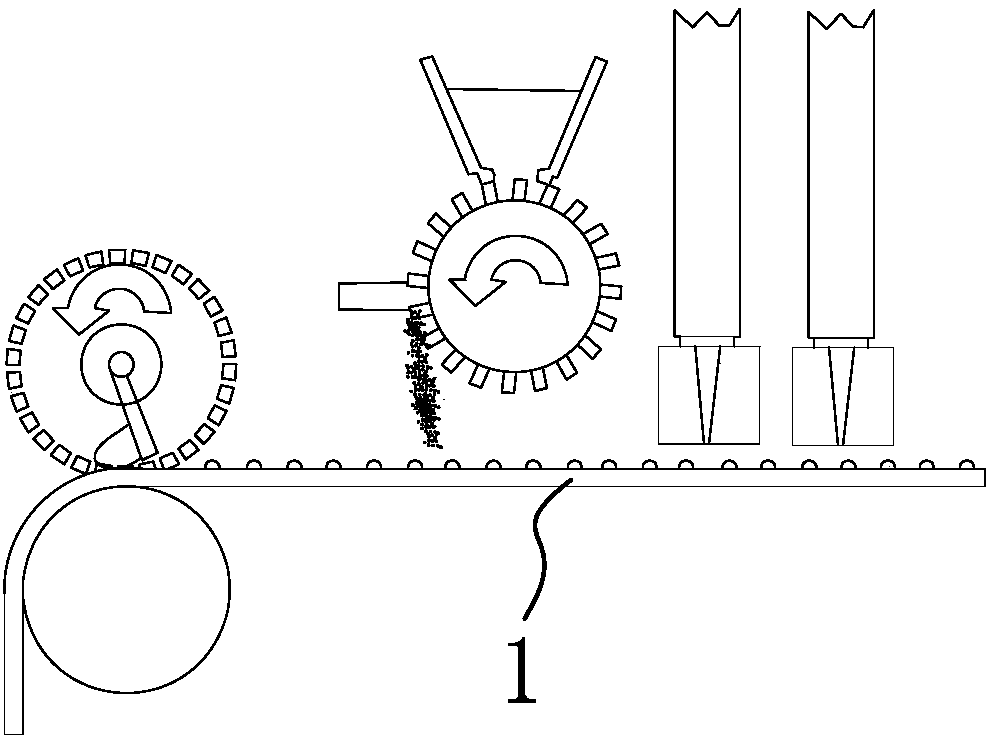

Automatic production equipment for 3.2-meter wide non-woven fabrics

ActiveCN101979744ASimple structureLow investment costNon-woven fabricsAir volumeProgrammable logic controller

The invention relates to the technical field of non-woven fabrics, in particular to manufacturing equipment for the non-woven fabrics. The equipment is controlled by the program of a programmable logic controller (PLC) and comprises a feeding unit, a screw extruder, an extension box body, an airflow drafting unit, a cooling side-blowing unit, a wet forming unit, a rolling mill and a winding unit,wherein the screw extruder is used for extruding raw materials by heating; a filter is arranged at the extrusion port of the screw extruder; the input end of the extension box body is connected to the filter through at least two counters which are connected in parallel; the airflow drafting unit is in vertical butt joint with the output end of the extension box body; a single body drawn by the extension box body is intertwined and staggered by the airflow drafting unit; the cooling side-blowing unit is arranged on the side of a single body drafting region between the extension box body and the airflow drafting unit; and a regulating valve capable of regulating air quantity is arranged on an air channel of the cooling side-blowing unit. The equipment can produce 3.2-meter wide non-woven fabrics, meets new state requirements of non-woven fabric industries and has a simple, scientific and reasonable structure.

Owner:东莞市威骏不织布有限公司

Method and device for testing sensorsto be applied on a patient's skin forthe detection of fluid or moisture

ActiveUS20140059837A1Large freedom of movementSignificant stressDetection of fluid at leakage pointHumidity sensorsBlood treatmentsMoisture sensor

A method and device for testing sensors to be applied on a patient's skin for detection of liquid or moisture are described, in particular for monitoring vascular access in an extracorporeal blood treatment, in which a patient's blood is carried away from the patient via an arterial line and is fed to the patient via a venous line. A method for producing sensors to be applied on a patient's skin for detection of liquid or moisture is also described. The method and device according to the present invention are based on the testing of one or more moisture sensors which are taken from current production. The method includes providing a large number of twists of the moisture sensor applied onto a torsion body, the mechanical stresses thus recreating the stresses that can occur in practice when the moisture sensor is applied or stuck onto the patient's skin or forearm.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

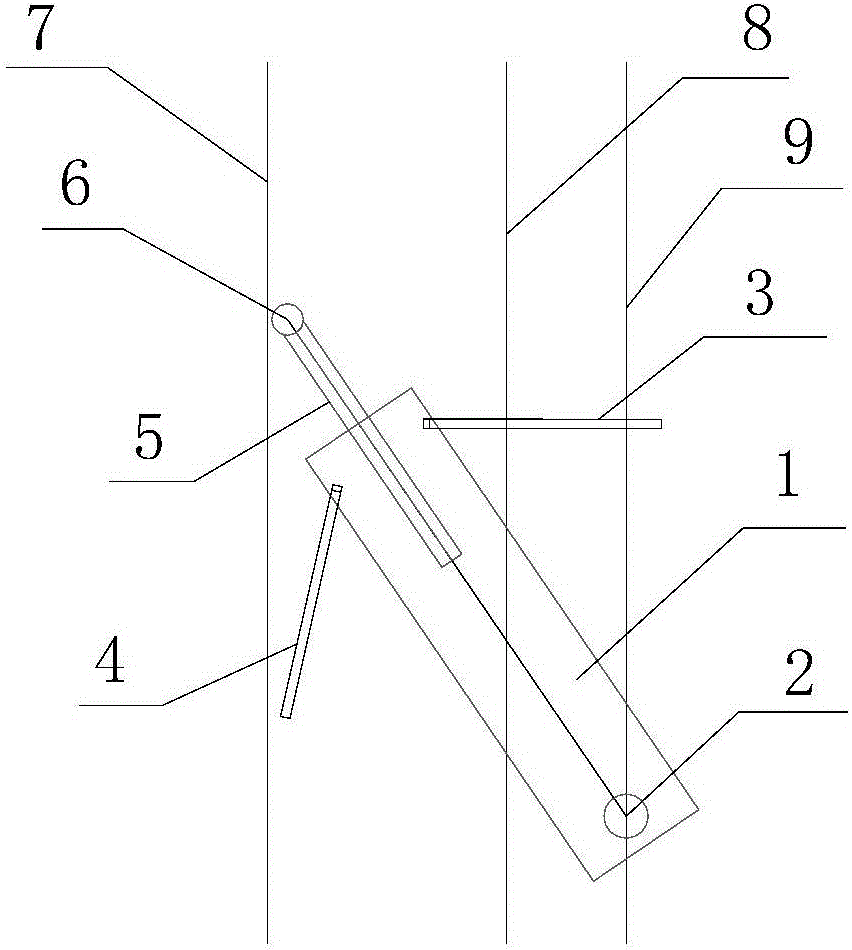

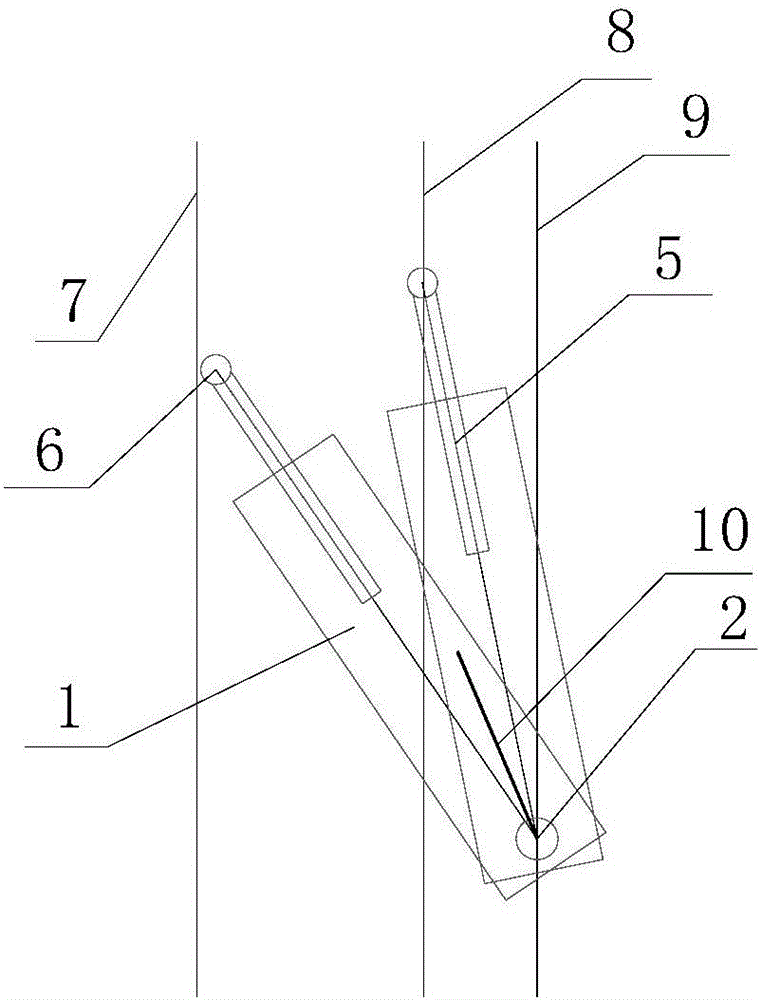

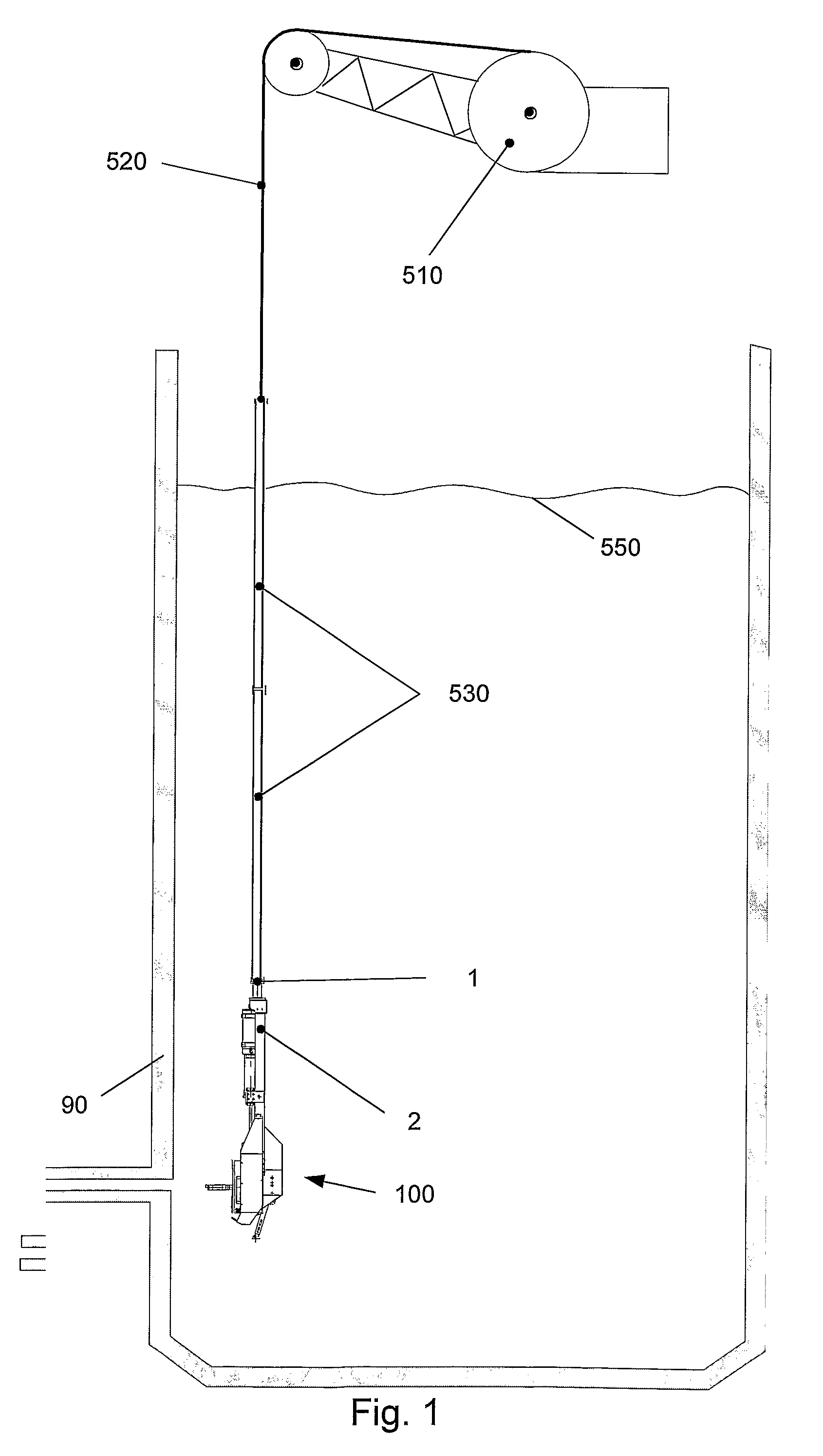

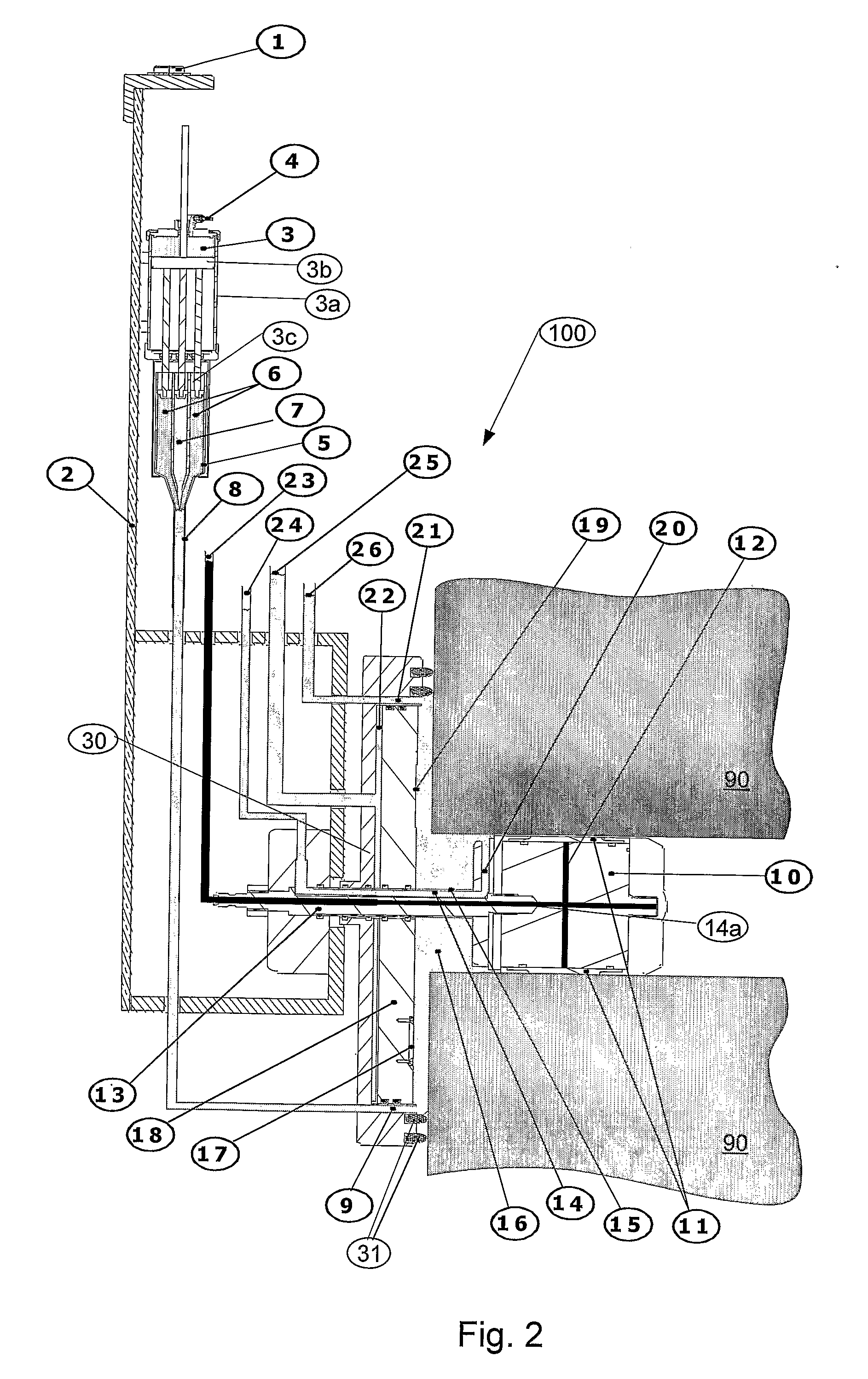

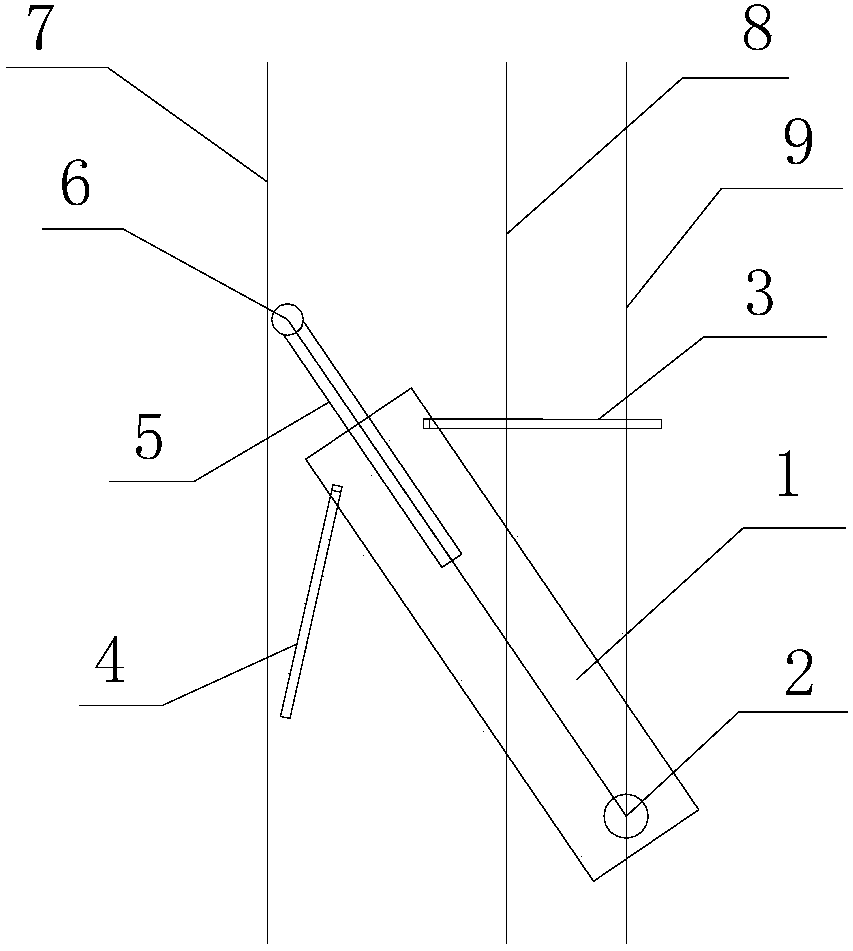

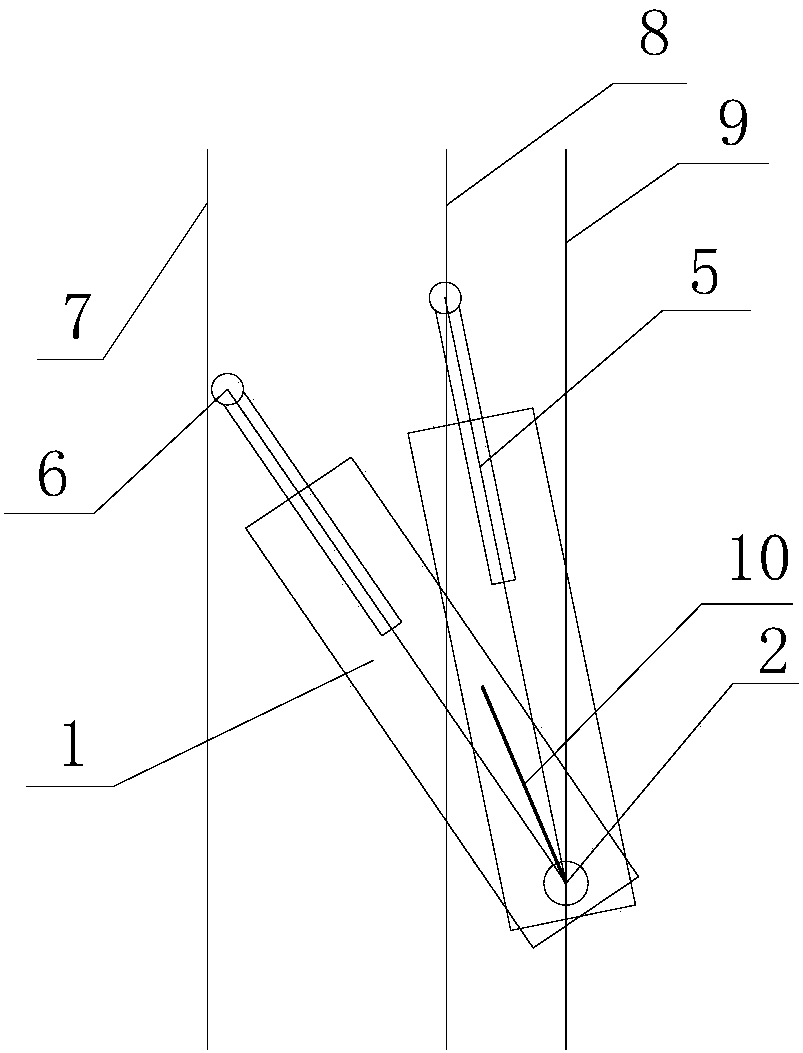

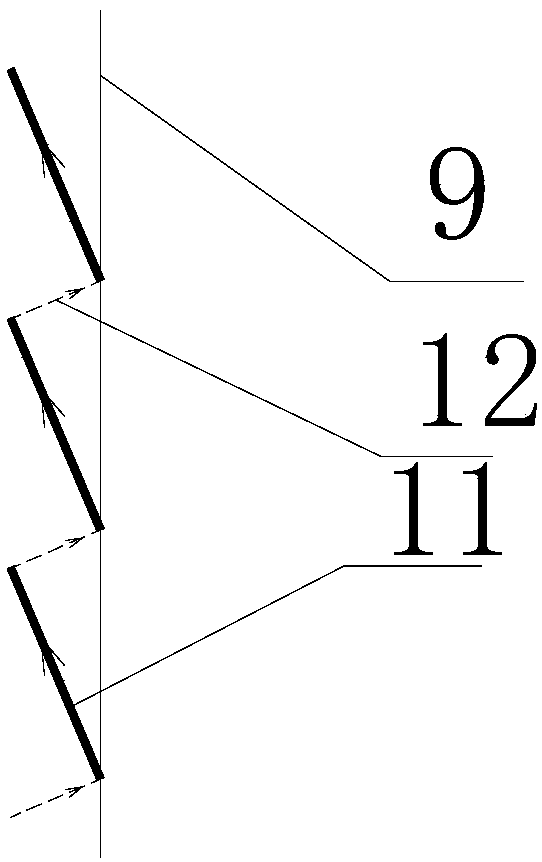

Ultra-short distance dredging construction method for cutter suction dredger dock apron

ActiveCN106193161AReduce security risksIncrease productivityMechanical machines/dredgersProduction rateShortest distance

The invention relates to an ultra-short distance dredging construction method for a cutter suction dredger dock apron. The ultra-short distance dredging construction method comprises the following steps: step 1, moving in and distributing a cutter suction dredger; after the cutter suction dredger moves in, dropping a steel pile onto a parallel steel pile reset line of the dock apron, and dropping a left lateral moving anchor and a right lateral moving anchor in a back anchoring form; step 2, carrying out cutter suction dredge excavation construction; taking the dock apron as a starting point during construction, dropping a reamer to a designed depth, carrying out fixed-point suction on the dock apron, and enabling the cutter suction dredge to reversely excavate rightwards; when the reamer rightwards swings to an excavation boundary line, lifting a bridge to enable the reamer to leave a mud surface and rightwards swing to a center line of the steel pile idly, wherein a certain included angle is formed between the center line of the steel pile and the dock apron; and advancing a trolley; and step 3, after the cutter suction dredger advances certain distance along the center line of the steel pile, limiting dredging width and lateral moving cable margin, pushing a stem by utilizing an anchor boat for enabling the steel pile to be on the steel pile reset line, and starting construction on next oblique area. The construction method can solve the universal technical problems such as a low production rate, high safety risks and poor quality of such construction.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

Method of inspecting the profile of a connection zone between a cylindrical portion and a taper of a turbomachine part

InactiveUS20070089495A1Mitigate such drawbackSimple processMachine bearings testingShaftsEngineeringSurface contour

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

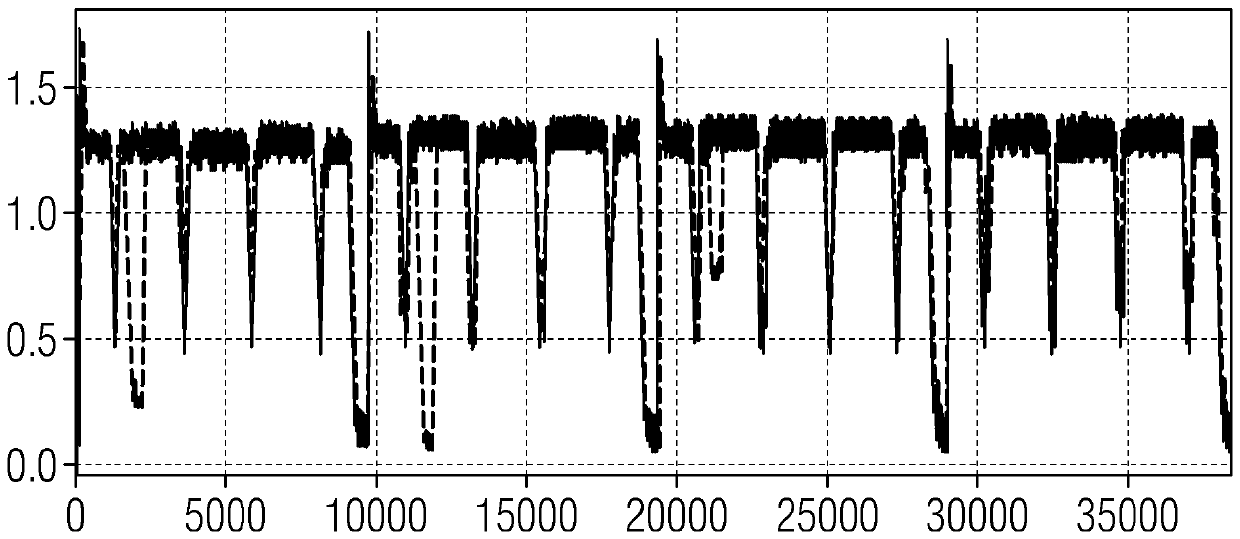

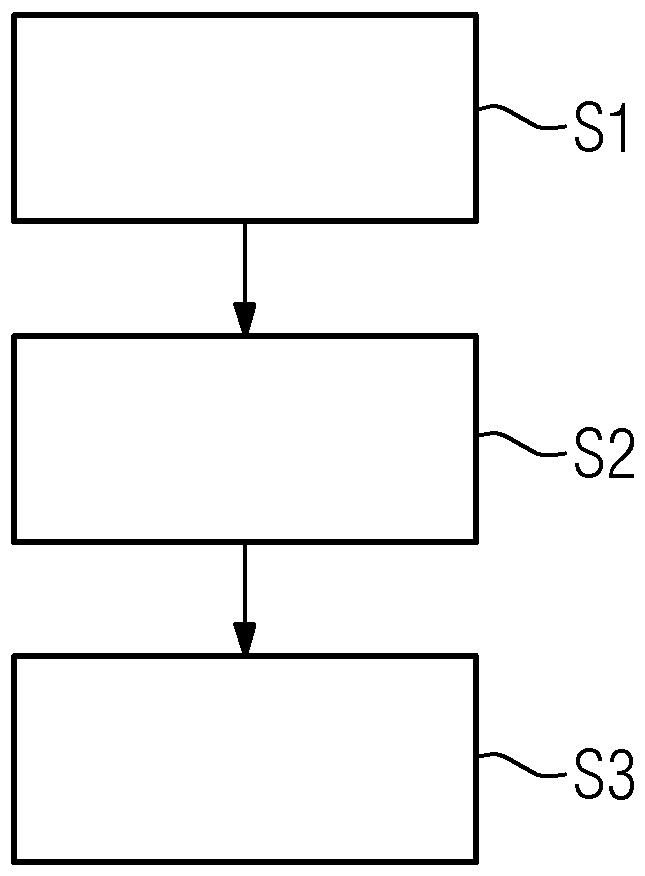

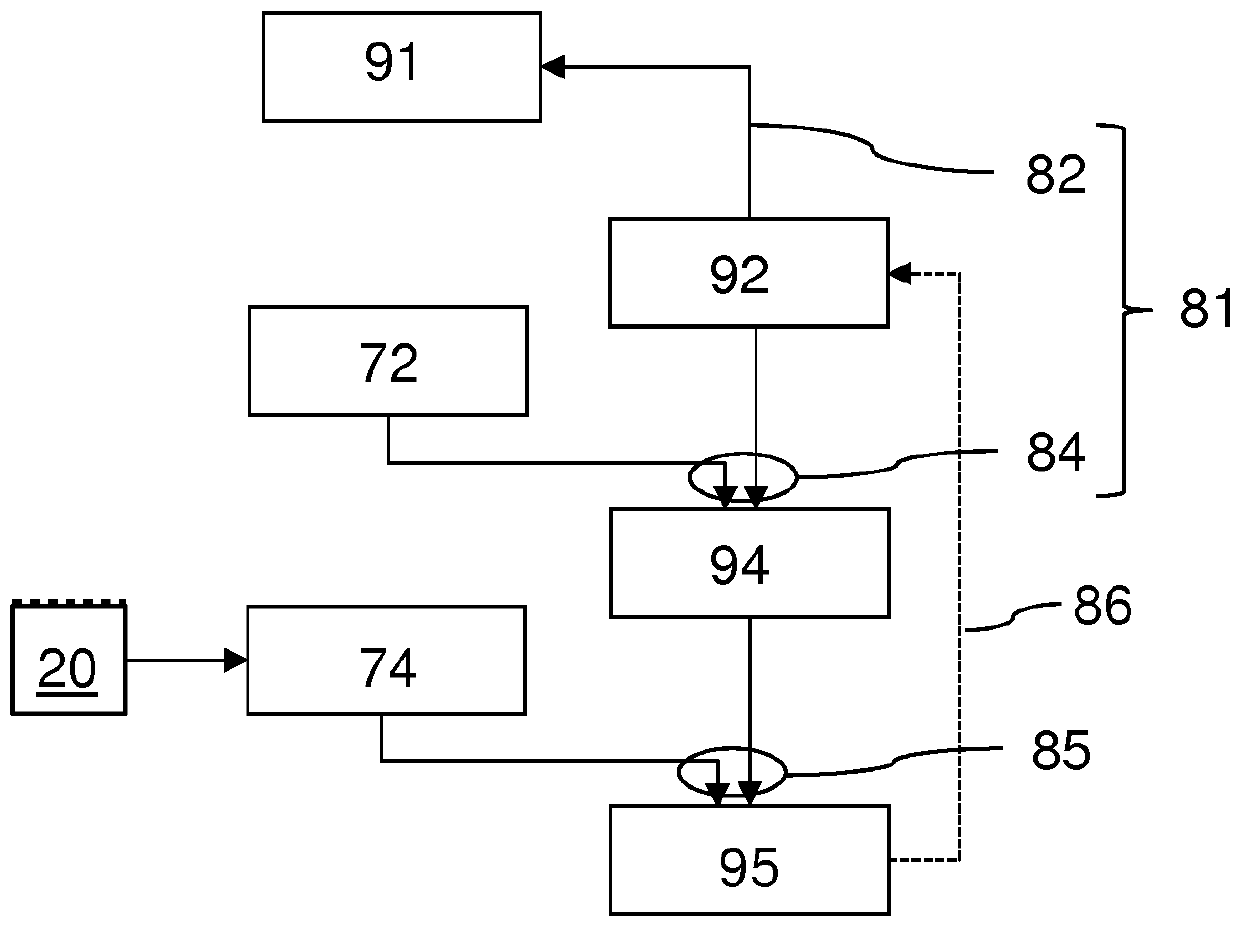

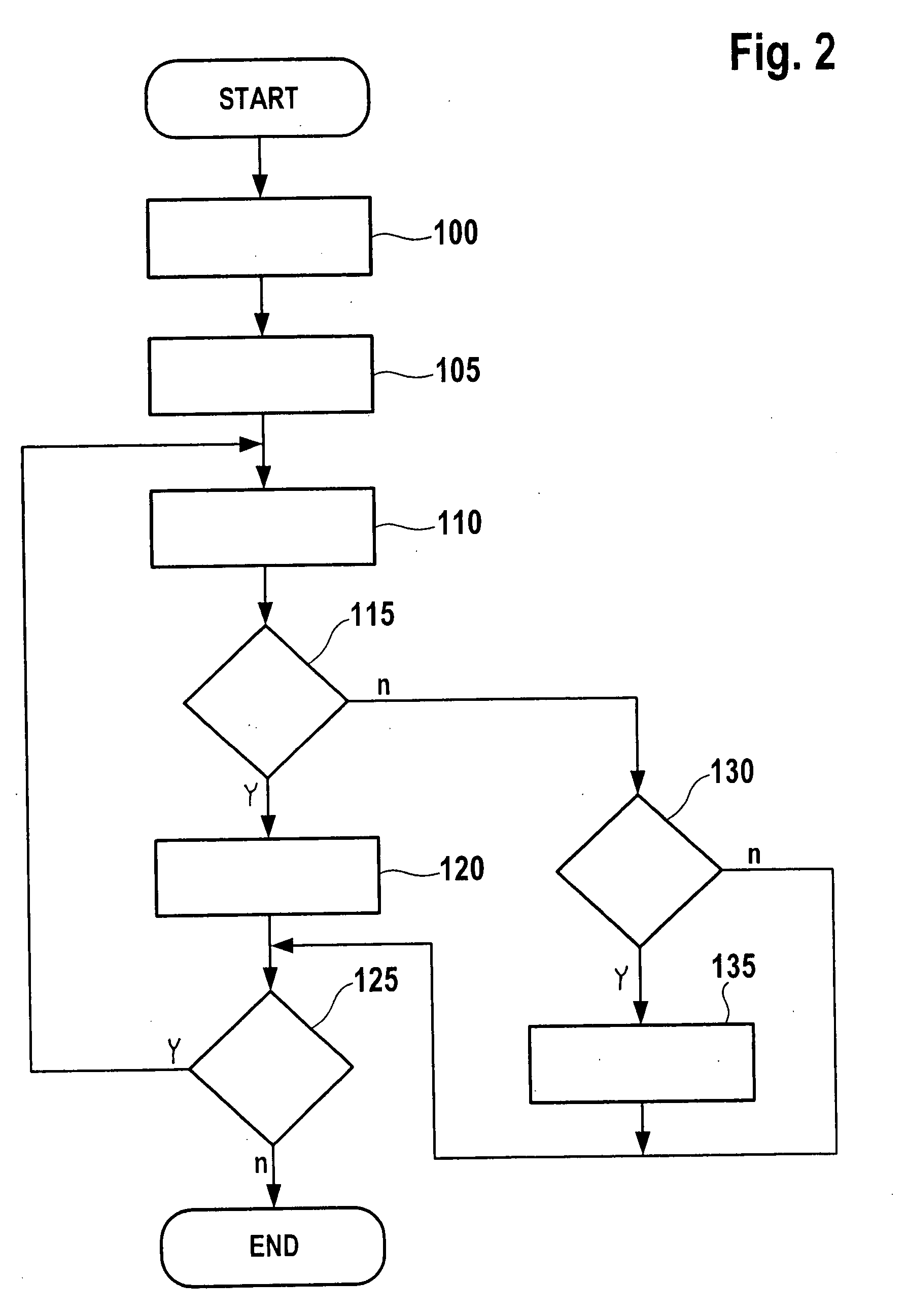

A data driven method for automated detection of anomalous work pieces during a production process

ActiveCN109947072AReliable quality controlProgramme controlElectric testing/monitoringPath lengthControl signal

The method and system for detection of anomalous work pieces during a production process, comprising computing for each production process step of the production process at least one deviation data signal for a target data signal of a target work piece with respect to reference data signals recorded for a corresponding production process step of a set of reference work pieces, wherein the deviation data signal comprises a number of deviation data samples for different production time steps, t, or path length steps, 1, of the respective production process step; performing a stepwise anomaly detection by data processing of the at least one computed deviation data signal and a process type indicator indicating a type of the production process step using a trained anomaly detection data modelto calculate for each time step, t, or path length step, 1, of the production process step an anomaly probability, p, that the respective time step, t, or path length step, 1, is anomalous; and classifying (S3) the target work piece and / or the production process step as being anomalous or not anomalous on the basis of the calculated anomaly probabilities, p, of the time steps, t, or path length steps, 1, of the production process step, wherein if the target work piece and / or the production process step is classified as anomalous, a warning signal for a user and / or a control signal for a production machine can be generated automatically.

Owner:SIEMENS AG

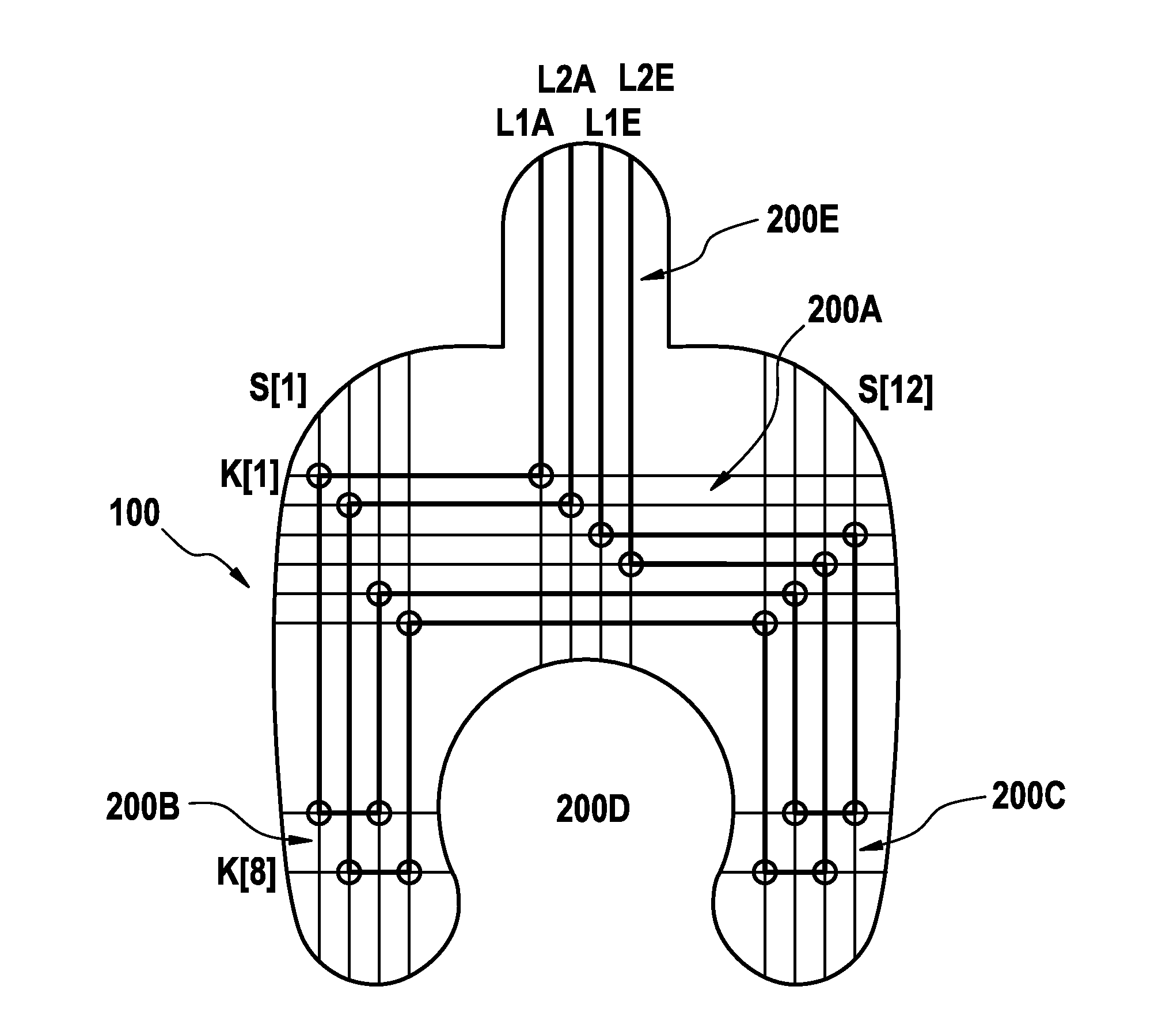

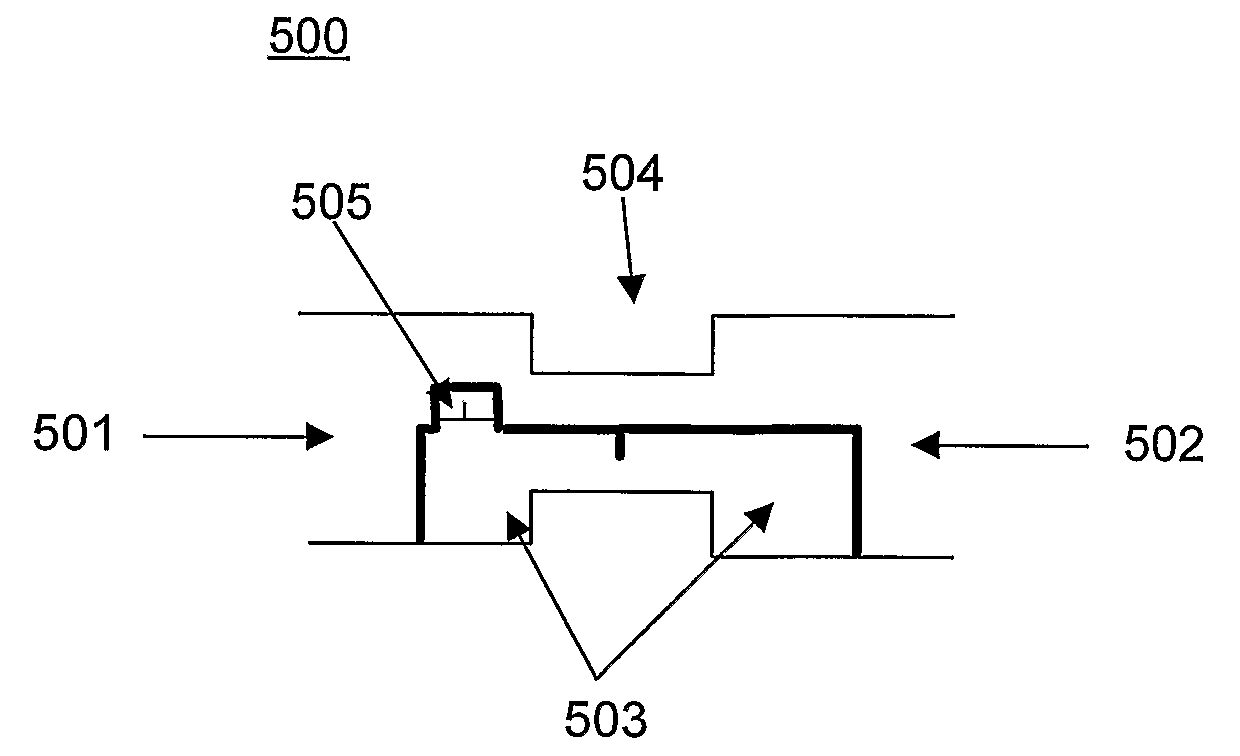

Moulding device

InactiveUS20090102096A1Promote escapeEasy to insertSamplingCeramic shaping apparatusShell moldingProduct gas

This invention is related to a method and a moulding device (100) for making a cast of a surface. The moulding device comprises a first moulding chamber part (30), which is adapted to be placed adjacent the surface and to form a moulding chamber (16) together with the surface. Moulding material can be introduced into the moulding chamber via an inlet (9), and one or more outlets (20, 21) serves to drain the moulding chamber from any entrapped liquid or gas. Further, at least one test piece (17) with surface defects, having well-known characteristics is provided in the moulding device for making at least one imprint on said cast surface. Hereby, a quality test of said cast can be performed.

Owner:FORCE TECH

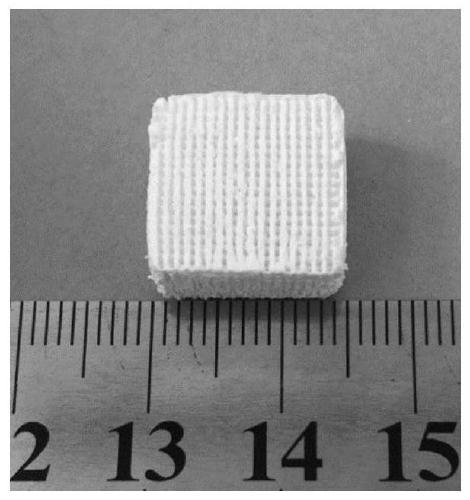

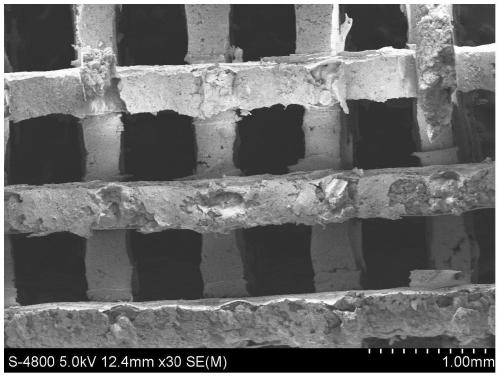

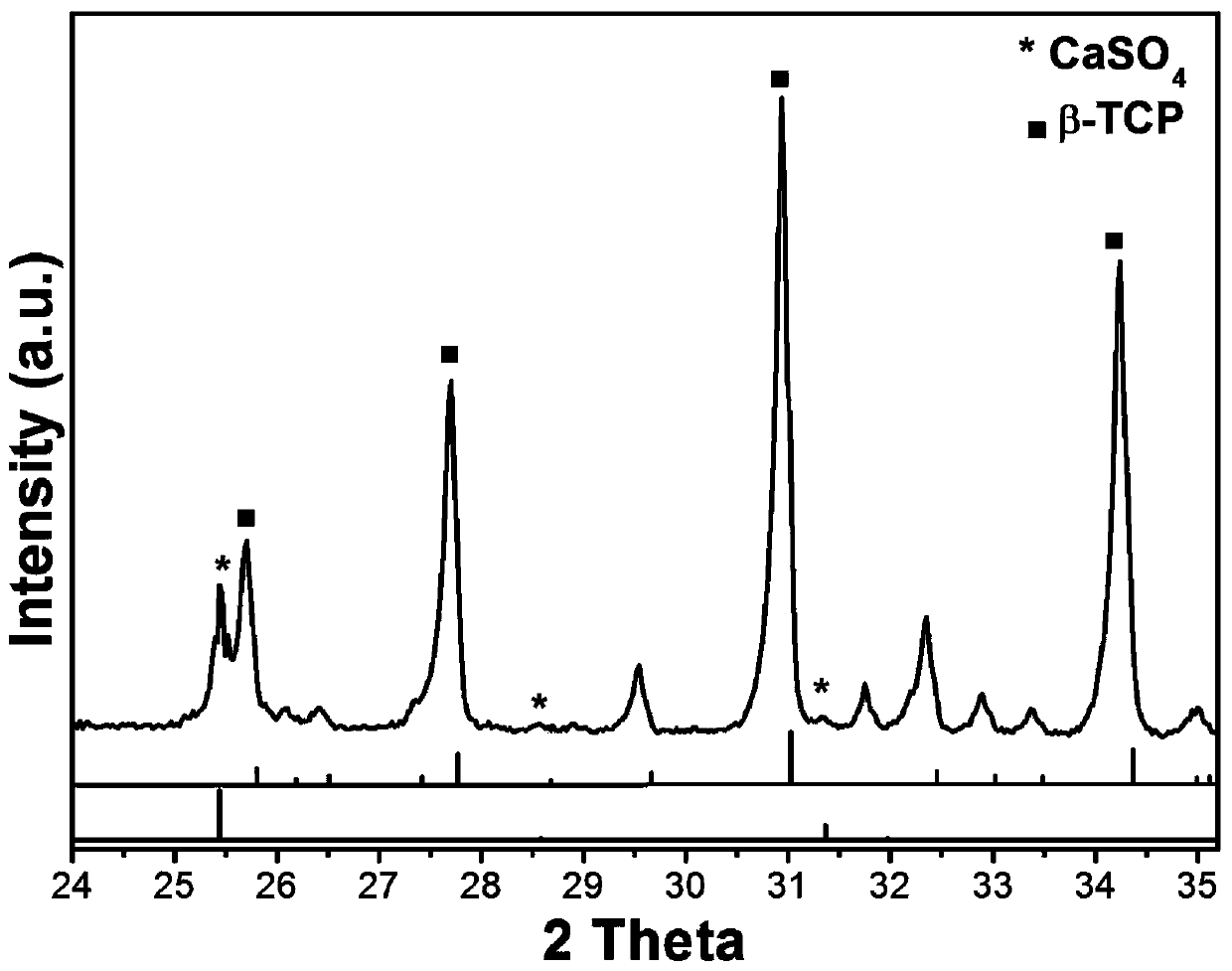

Porous composite ceramic capable of guiding bone regeneration and preparation method of porous composite ceramic

PendingCN110251723APromote ingrowthHigh strengthTissue regenerationCeramicwareSpatial directionS system

The invention discloses porous composite ceramic capable of guiding bone regeneration. The porous composite ceramic is formed by the combination of calcium sulfate and calcium phosphate in any other way except the coating to form a porous structure of an arbitrary shape, the pore pattern of pores with at least one dimensional direction in the three-dimensional spatial direction of the porous structure is regular, the distance from the center of each pore to the edge is 50-2000 microns, and all the pores are mutually communicated. The invention further provides a preparation method of the porous composite ceramic. The functional defect of a single composite is well overcome, cells and blood vessels are facilitated to grow into the ceramic to regenerate new bone, and new bone tissue is beneficial to the formation of dense bone with Huffler's system structure; meanwhile, the porous composite ceramic has the advantages that the pore shape rules are controllable, which is beneficial to unify the quality standard of the product and also facilitates the detection and quality control of the product; therefore, the porous composite ceramic is quite suitable for commercial and mass production applications.

Owner:陶合体科技(苏州)有限责任公司

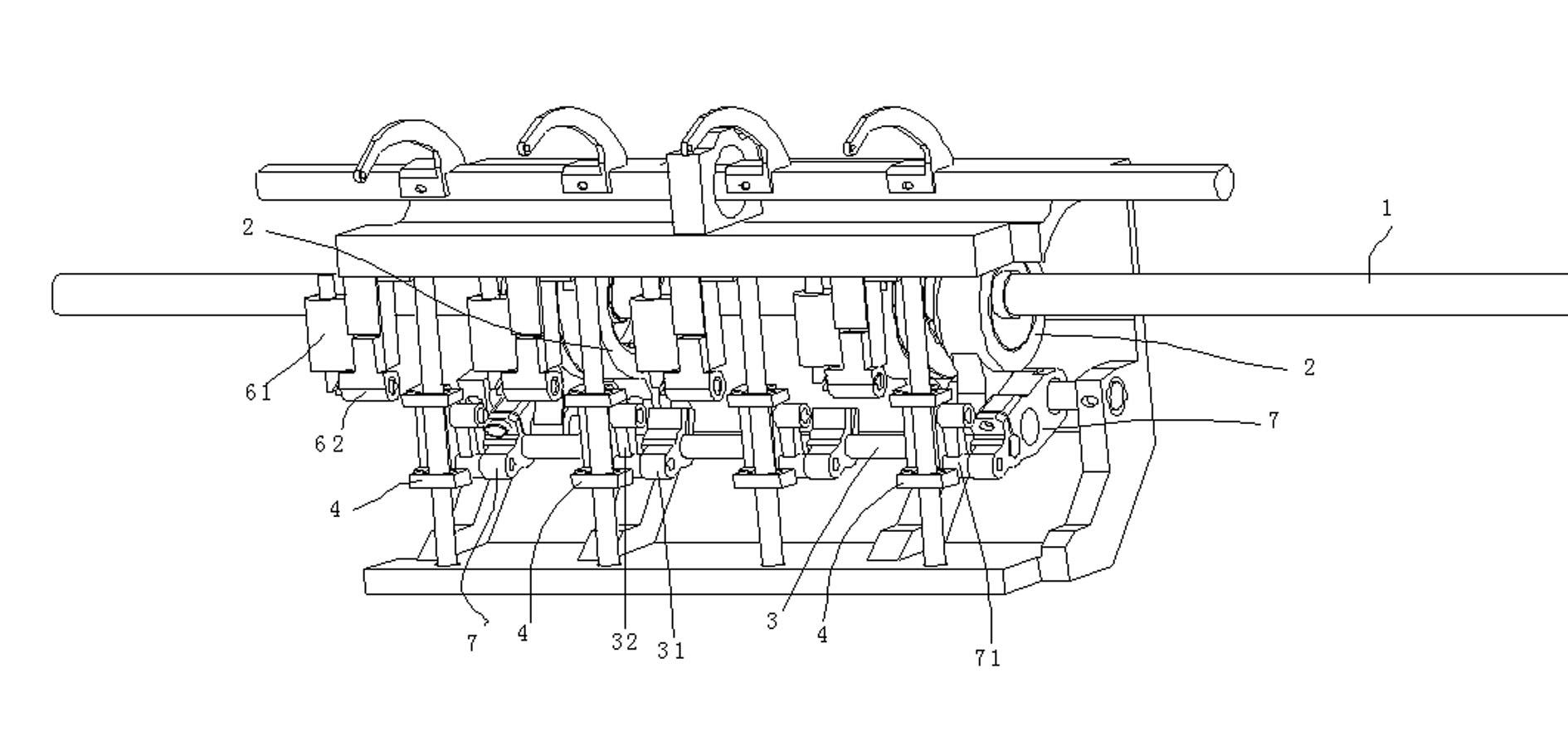

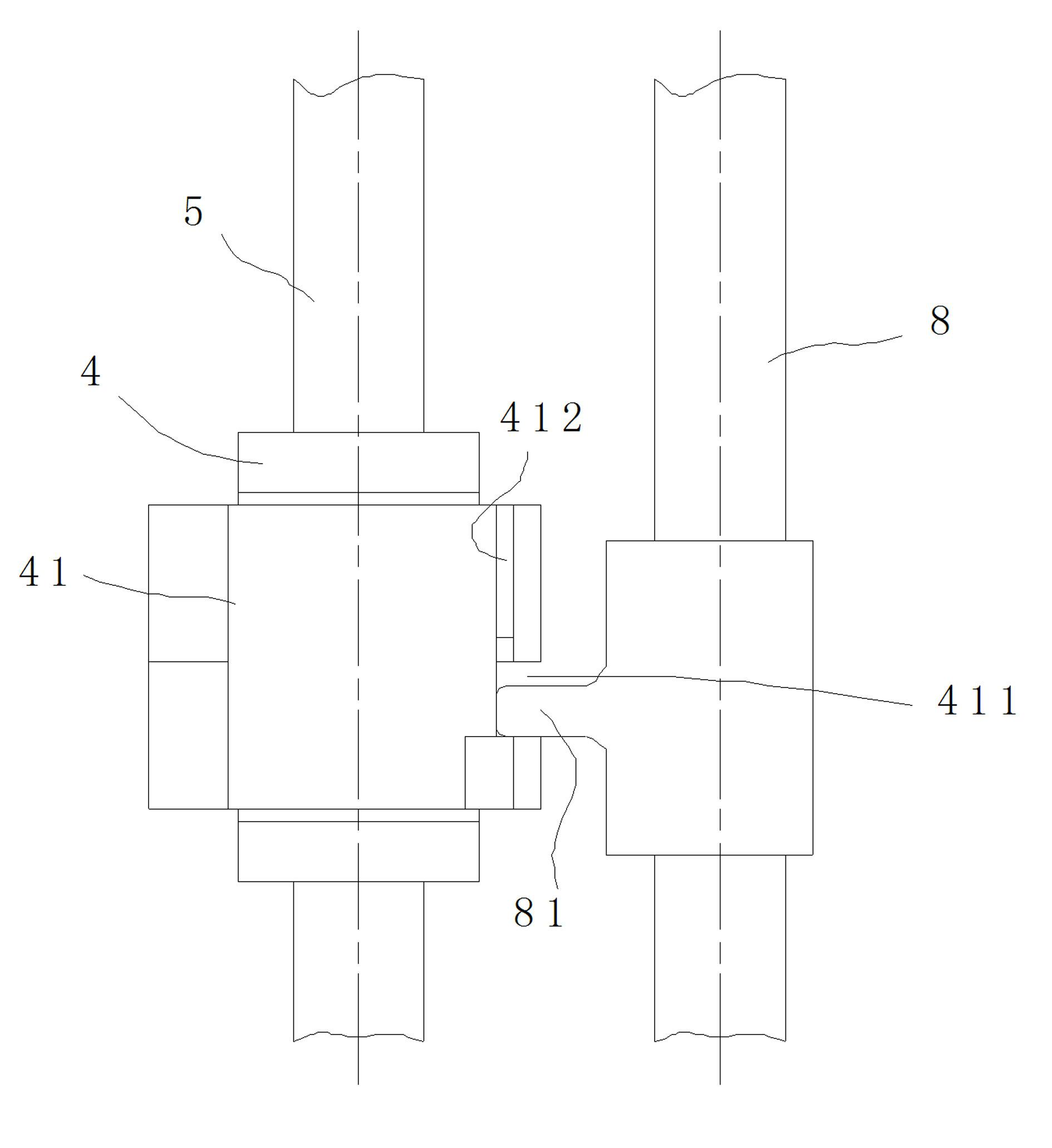

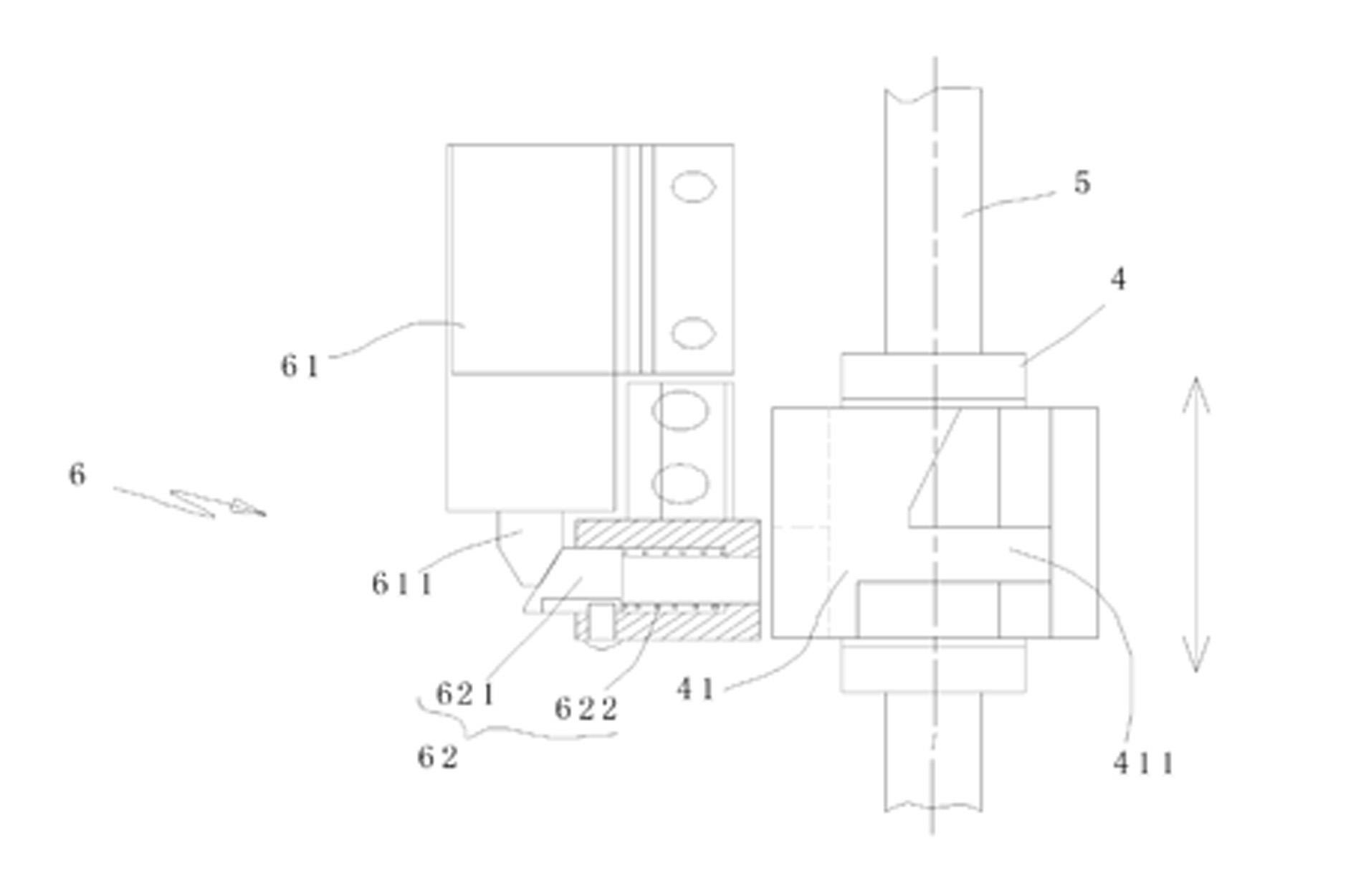

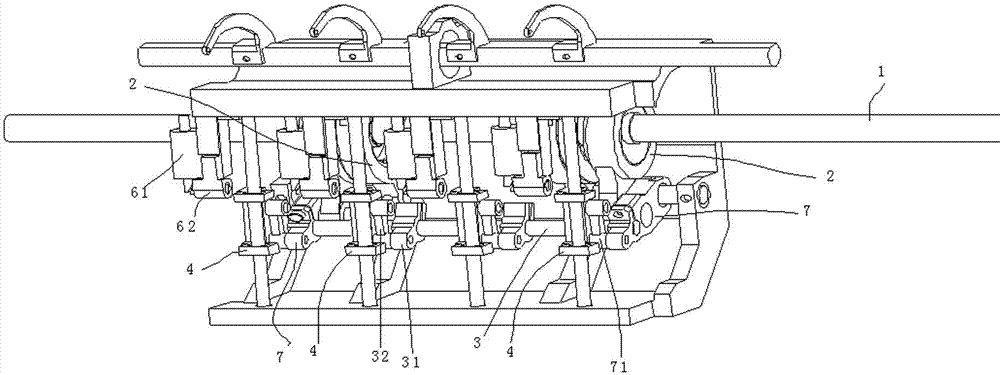

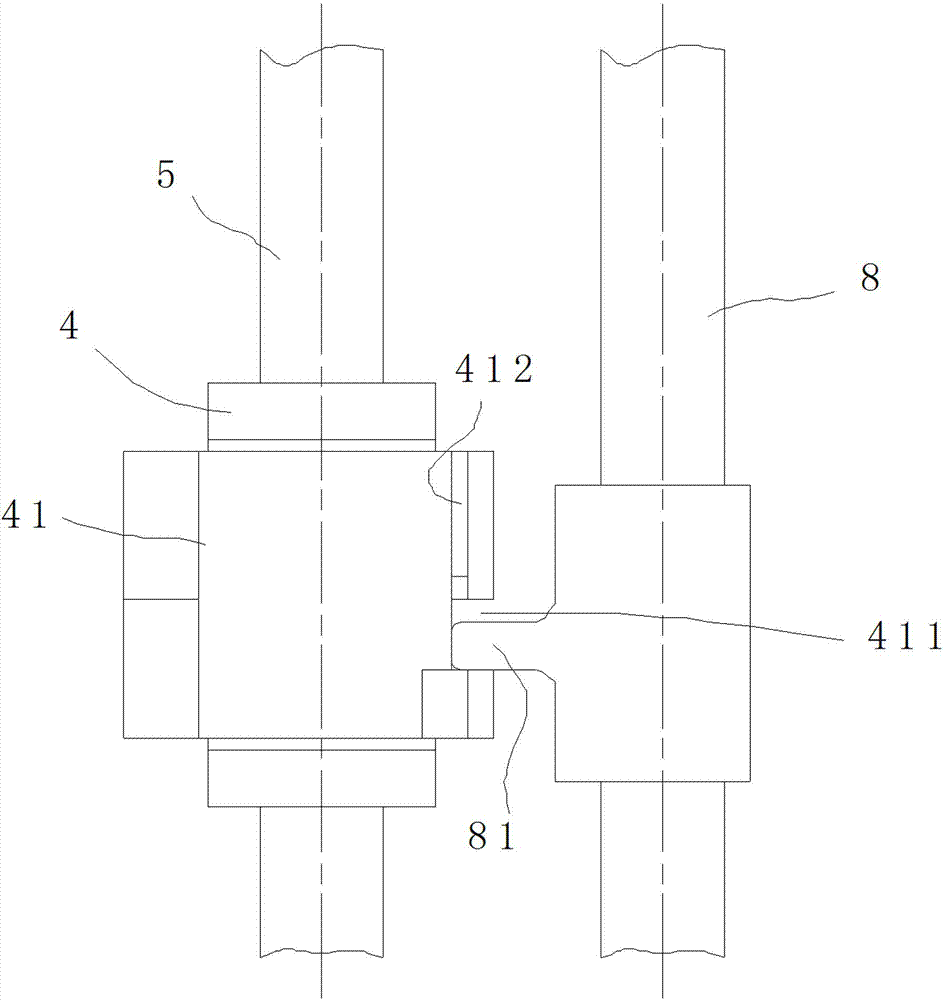

Needle bar driving mechanism of rotary shuttle loom for quilting and embroidering

ActiveCN102108607ACater to development needsOptimize and adjust the structureEmbroidering machines apparatusNeedle barsDrive shaftCam

The invention relates to the technical field of production machinery for quilting and embroidering, in particular to a rotary shuttle loom for quilting and embroidering. A needle bar driving mechanism of the rotary shuttle loom comprises a driving shaft, wherein the driving shaft drives a connecting shaft via cams; the connecting shaft is linked with two or more drivers which can move up and down; the drivers are installed on an upright bar; each driver corresponds to a needle bar; the drivers are provided with moving blocks which can move eccentrically; and the moving blocks are provided with clamp slots which can clamp the adaptation parts of the needle bars and drive the needle bars to move up and down. The needle bar driving mechanism also comprises an unlocking mechanism which can drive the clamp slots to be separated from the needle bars, wherein the unlocking mechanism comprises an electromagnet locking head device which is installed uprightly and a transverse propelling device. The needle bar driving mechanism has the following advantages: after the cams are output, the drivers are synchronously driven by the connecting shaft and three-hole connecting bars to move up and down, so the structure is optimized and adjusted and the spatial body is small; the unlocking mechanism has one-to-one relationship with the drivers, so the single needle locking function can be realized in the small needle gauge embroidering process and the production requirement is met; and the needle bar driving mechanism has simple, scientific and reasonable structure.

Owner:江西艺博达机械有限公司

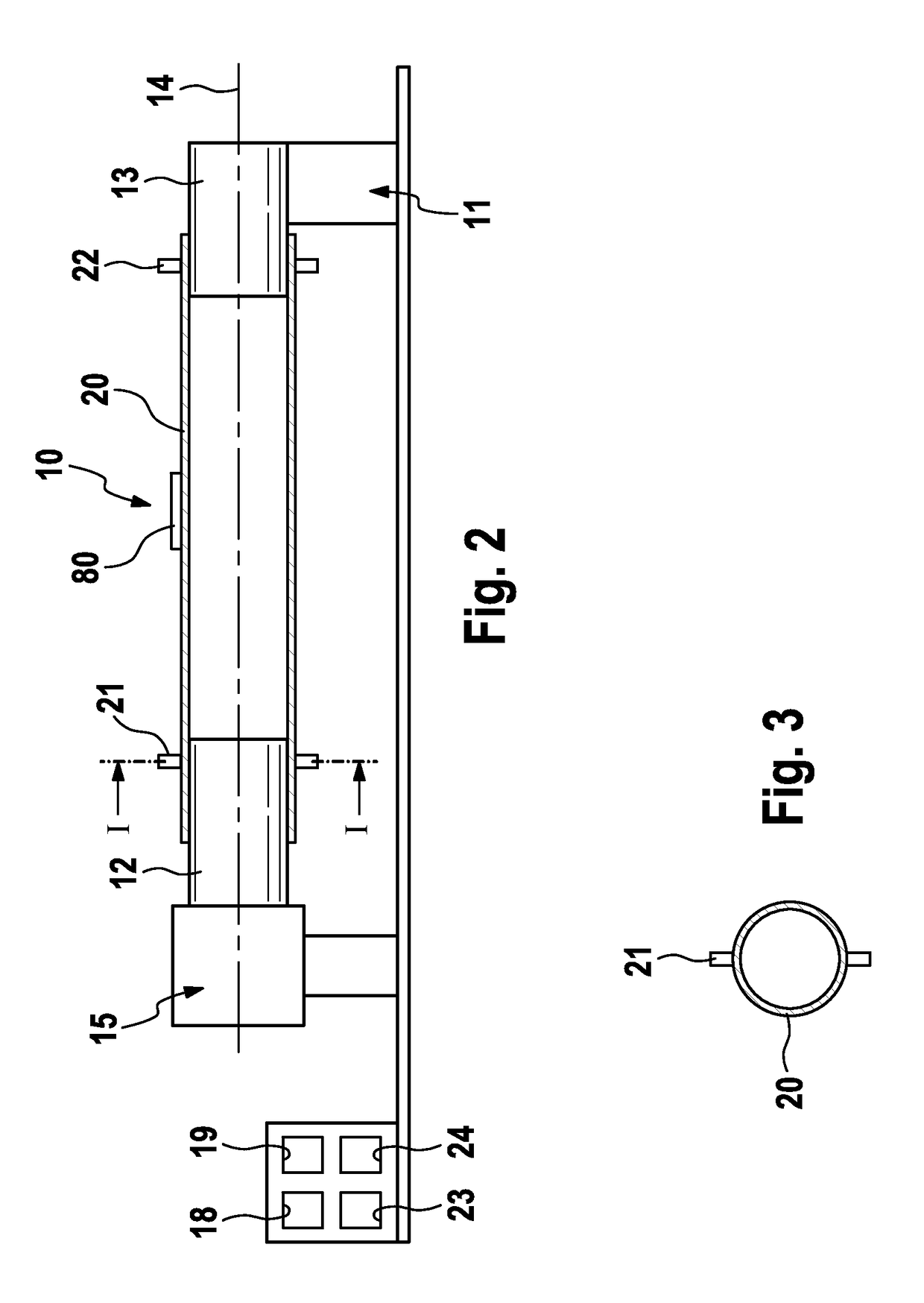

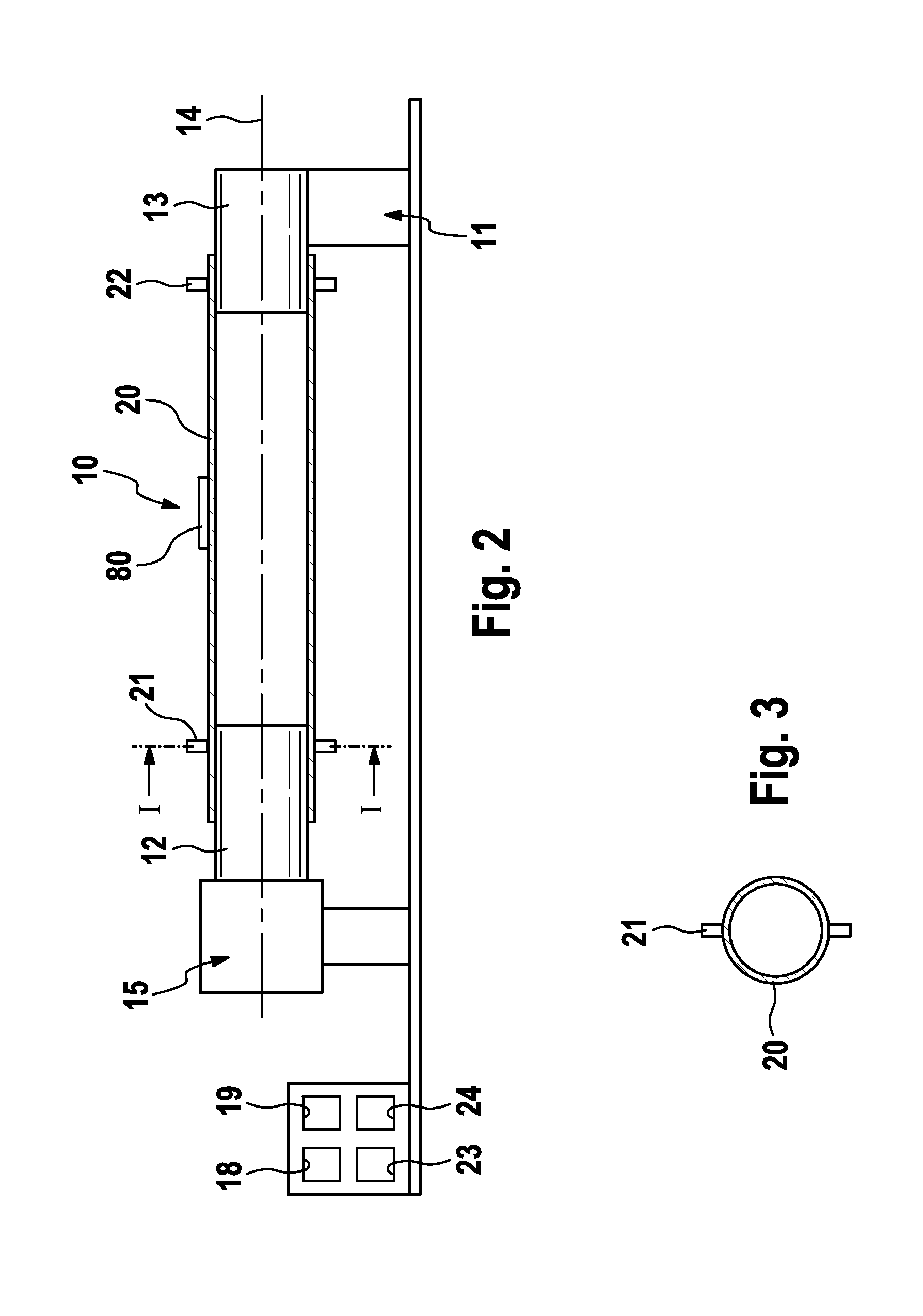

Method and apparatus for detecting a pulsed thz beam with time of flight correction

ActiveCN111201432AReliable measurementAccurate and Reliable CharacterizationMaterial analysis by optical meansMaterial testing goodsSoftware engineeringThz radiation

A method and an apparatus for detecting a pulsed THz beam comprise: emitting, by THz emitter (10), pulsed THz radiation (60) of outgoing pulse shape for interacting with target body; detecting, by THzdetector (20), incoming THz radiation comprising THz pulses, and outputting, by THz detector (20), a raw detector data of pulse shapes of incoming THz pulses; and determining, by pulse shape reconstruction module (36), a reconstructed incoming pulse shape based on the raw detector data, measuring, by sensor (80), a time-of-flight quantity (d) affecting the time of flight of the THz radiation (60); and adjusting operation of at least one of THz emitter (10), THz detector (20) and pulse shape reconstruction module (36) using the time-of-flight quantity (d), for correcting for variations in timeof flight of the THz radiation (60).

Owner:ABB (SCHWEIZ) AG

Method of inspecting the profile of the connection zone between the cylindrical portion and the taper of a roller for a turbomachine roller bearing

ActiveUS7359829B2Reliable quality controlDistance minimizationFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansEngineeringSurface contour

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

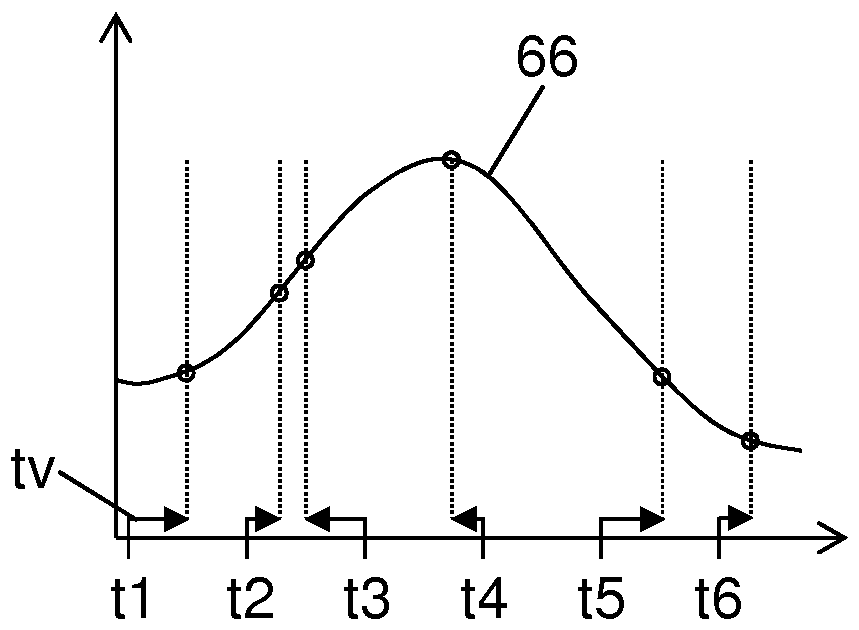

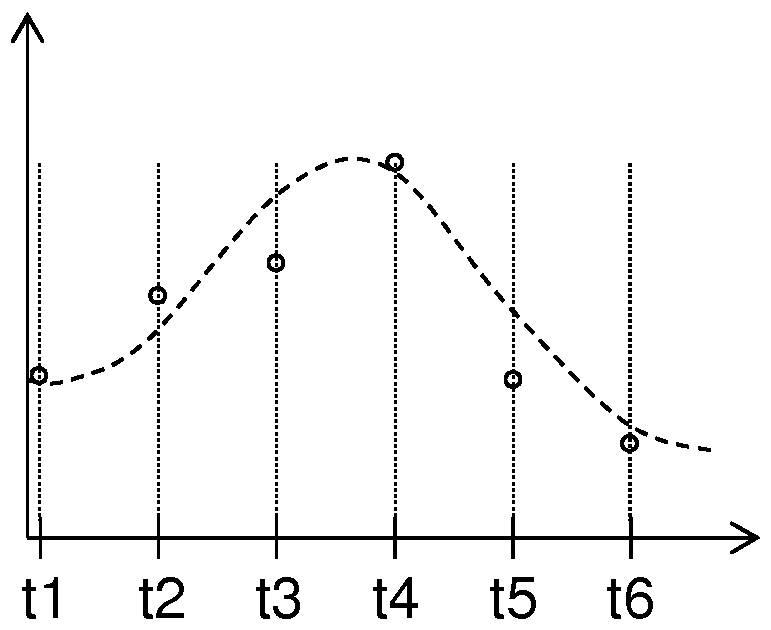

Method and device for operating a drive unit, and test device for testing a drive unit

InactiveUS20070239323A1Reliable quality controlReliable error diagnosisAnalogue computers for vehiclesCommutation monitoringStorage cellEngineering

In a method for operating a drive unit, for at least one operating quantity of the drive unit, a deviation from an initial value is represented by an adaptation value, which adaptation value is determined at various times. In an extreme value storage unit, a first adaptation value, determined at a first point in time, is stored. A second adaptation value, determined at a second point in time after the first point in time, is compared with the first adaptation value stored in the extreme value storage unit to determine whether the second adaptation value exceeds the first adaptation value in a prespecified direction. In this case, the extreme value storage unit is overwritten by the second adaptation value.

Owner:ROBERT BOSCH GMBH

A super-short-distance dredging construction method at the front of cutter suction ship wharf

ActiveCN106193161BReduce security risksIncrease productivityMechanical machines/dredgersProduction rateShortest distance

The invention relates to an ultra-short distance dredging construction method for a cutter suction dredger dock apron. The ultra-short distance dredging construction method comprises the following steps: step 1, moving in and distributing a cutter suction dredger; after the cutter suction dredger moves in, dropping a steel pile onto a parallel steel pile reset line of the dock apron, and dropping a left lateral moving anchor and a right lateral moving anchor in a back anchoring form; step 2, carrying out cutter suction dredge excavation construction; taking the dock apron as a starting point during construction, dropping a reamer to a designed depth, carrying out fixed-point suction on the dock apron, and enabling the cutter suction dredge to reversely excavate rightwards; when the reamer rightwards swings to an excavation boundary line, lifting a bridge to enable the reamer to leave a mud surface and rightwards swing to a center line of the steel pile idly, wherein a certain included angle is formed between the center line of the steel pile and the dock apron; and advancing a trolley; and step 3, after the cutter suction dredger advances certain distance along the center line of the steel pile, limiting dredging width and lateral moving cable margin, pushing a stem by utilizing an anchor boat for enabling the steel pile to be on the steel pile reset line, and starting construction on next oblique area. The construction method can solve the universal technical problems such as a low production rate, high safety risks and poor quality of such construction.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

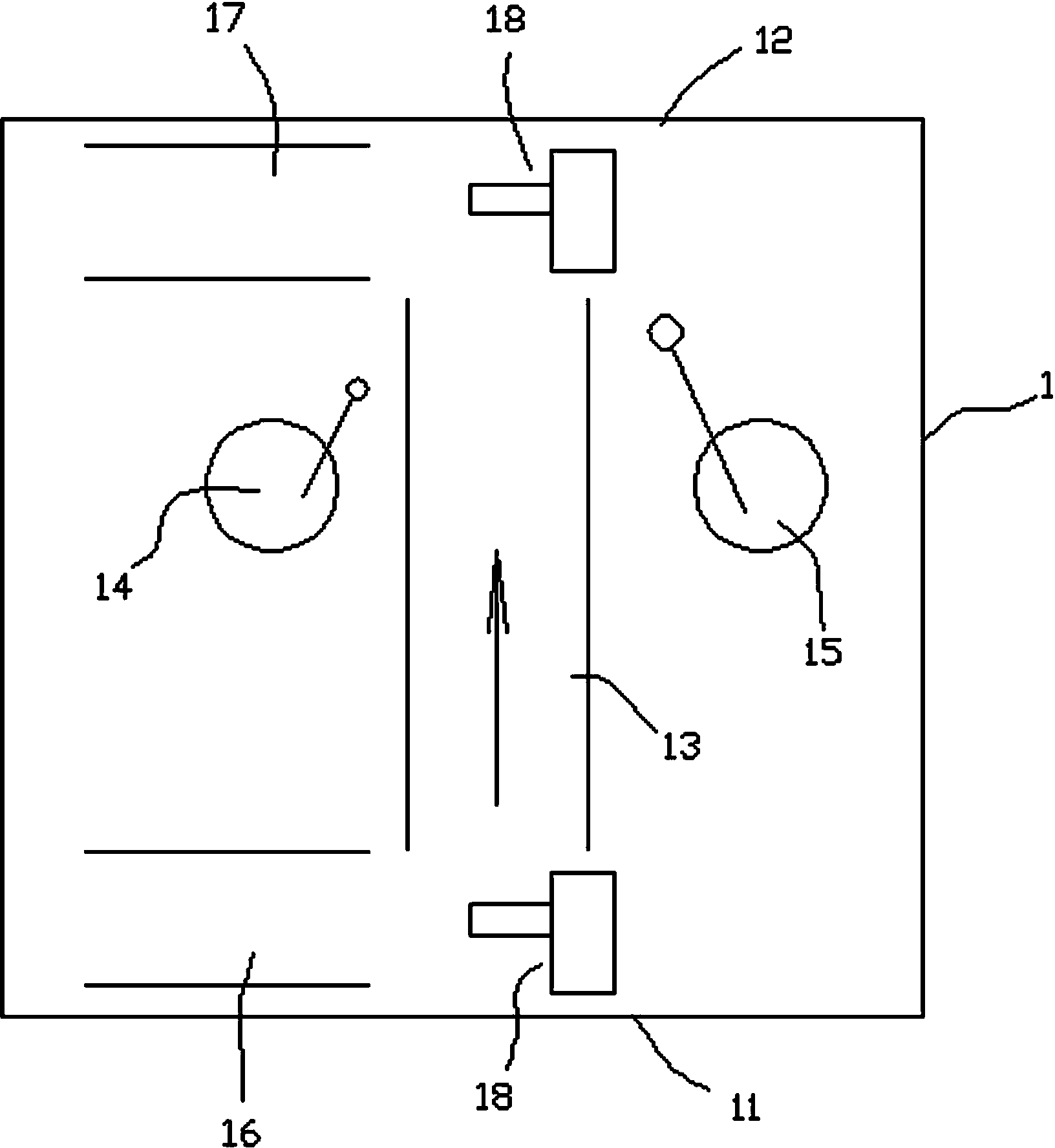

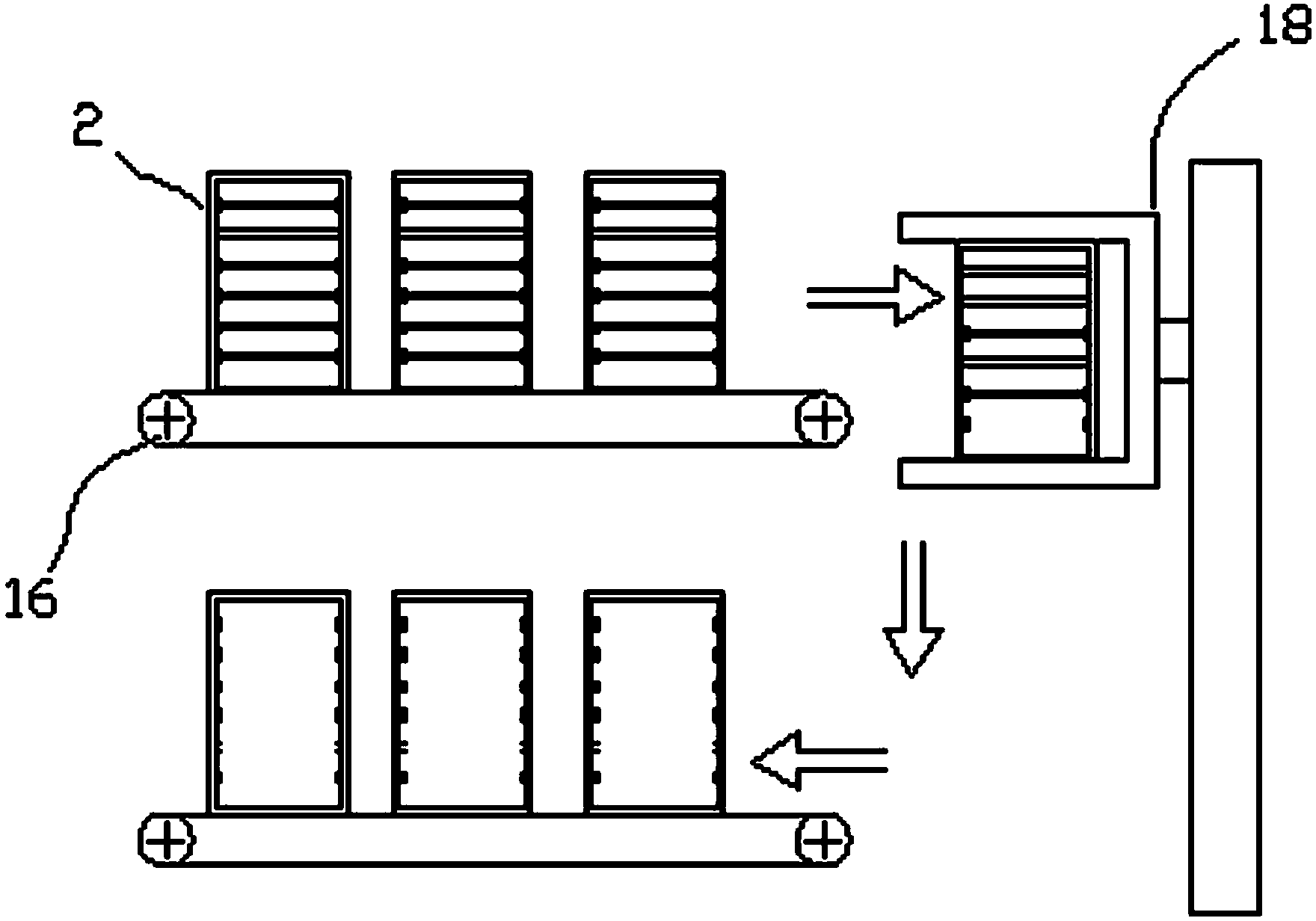

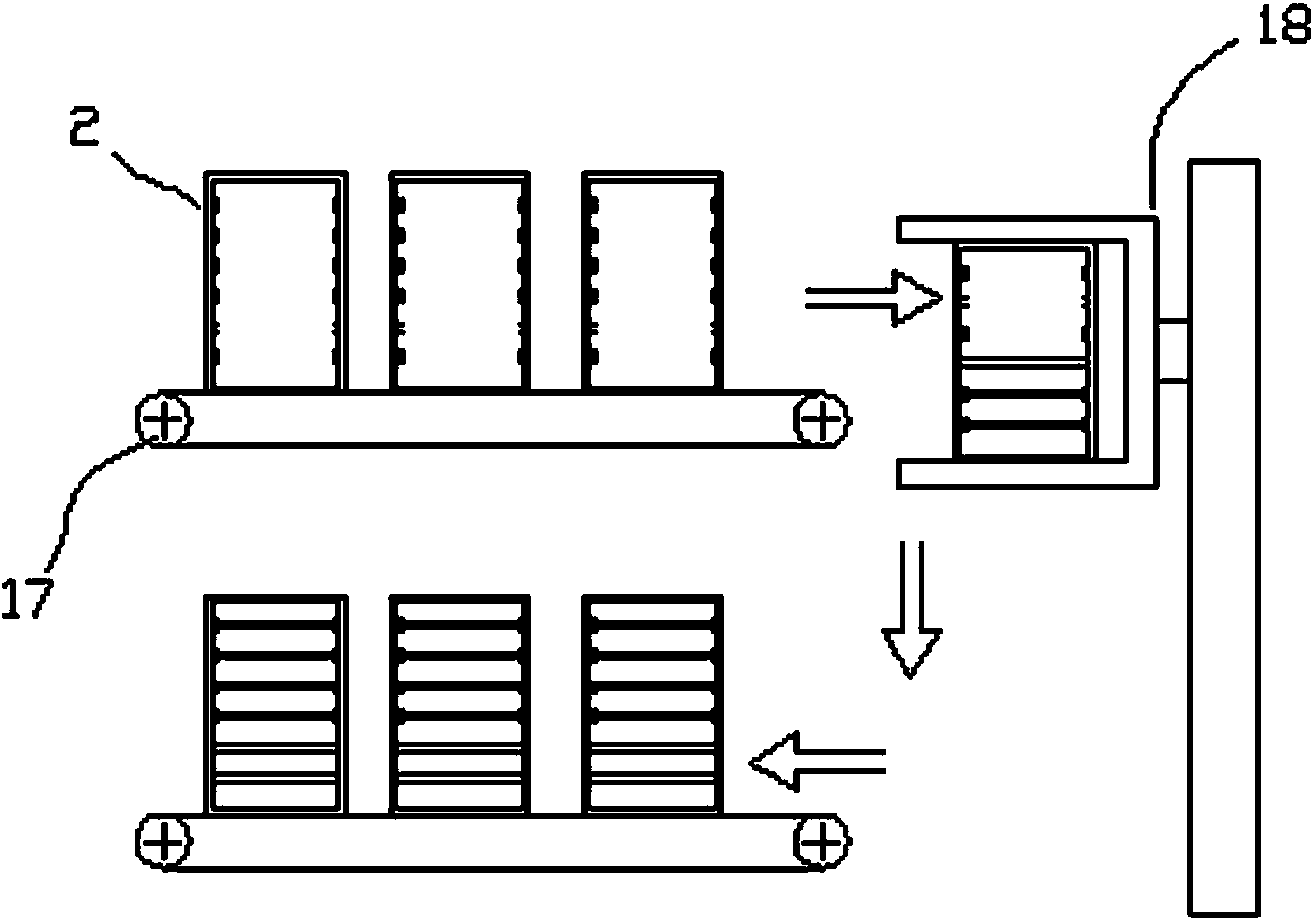

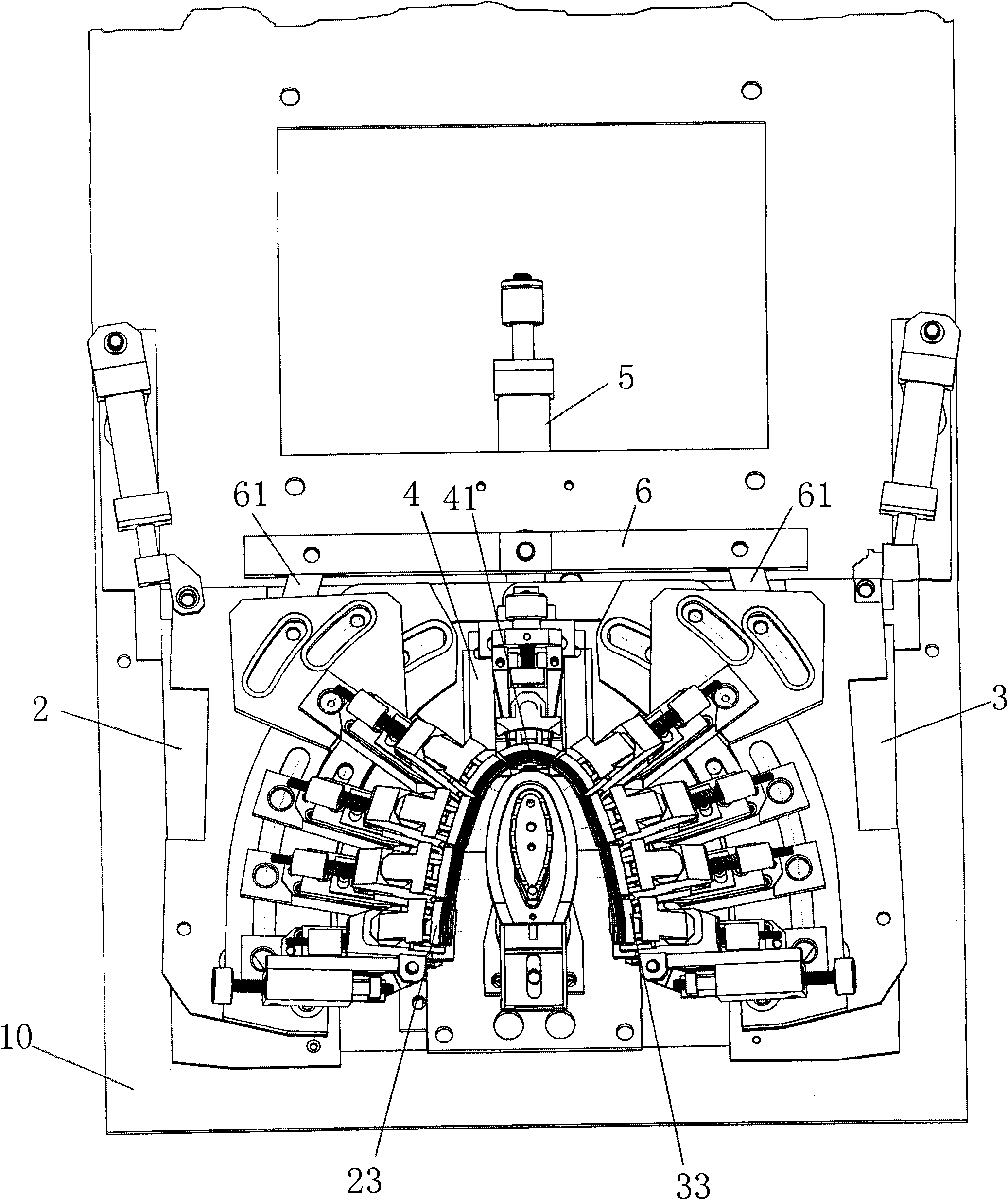

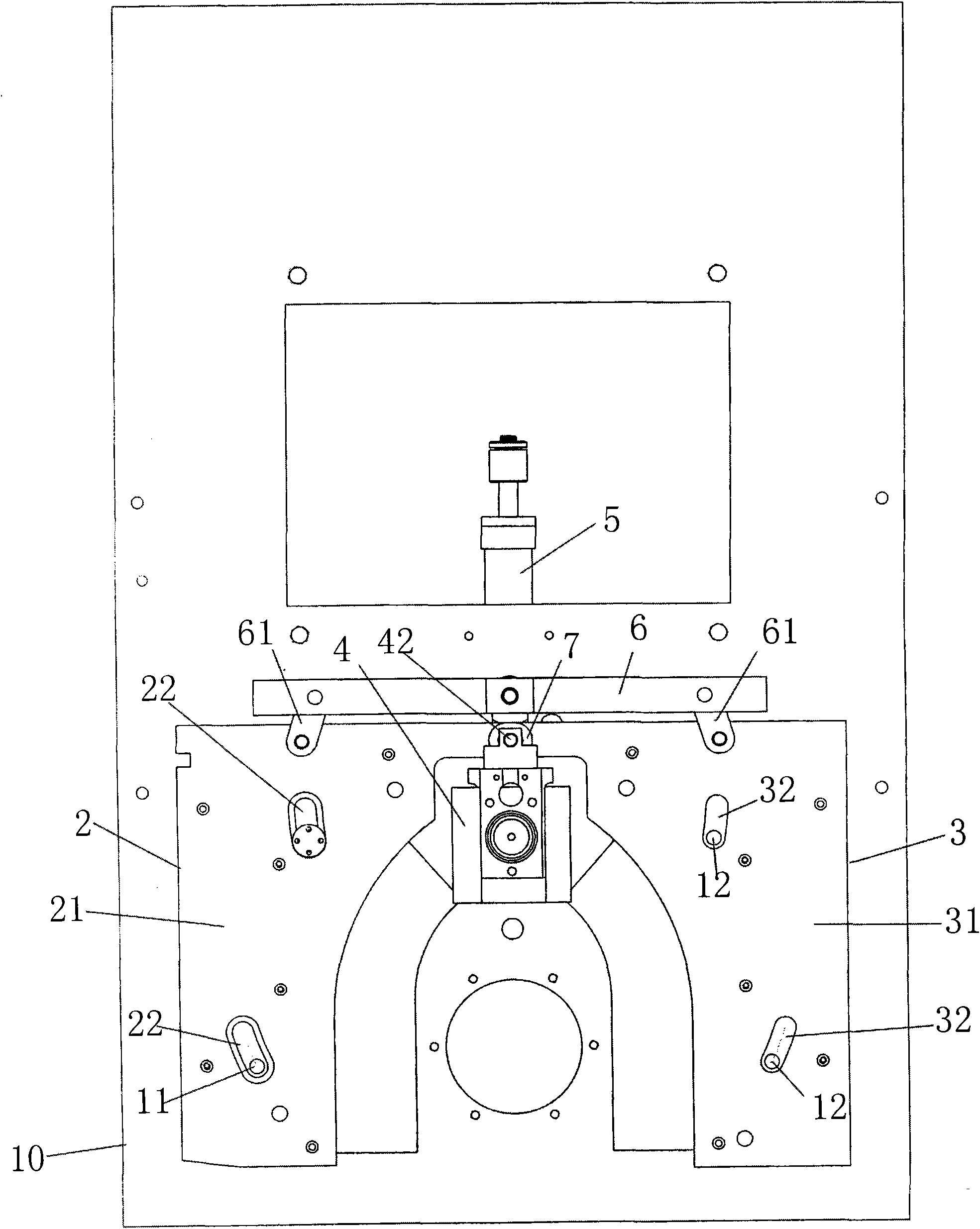

Fully-automatic patch-type LED die bonder with new operation flows

The invention discloses a fully-automatic patch-type LED die bonder with new operation flows. The invention relates to the technical field of LED manufacturing equipment, in particular to a fully-automatic patch-type LED die bonder, which comprises a base, wherein the base is provided with a front end facing to an operator and a back end back to the front end; a dispensing device and a chip picking and placing device are arranged on the base; and feed materials on the base are conveyed to a region between the dispensing device and the chip picking and placing device from the front end and / or back end of the base in a unidirectional or bidirectional way. The fully-automatic patch-type LED die bonder breaks through the operation mode and the layout structure of the traditional die bonder; a working mode of front-in and back-out or front-in and front-out as well as back-in and back-out is adopted and a region at the back end of the base is fully utilized, so that the structure layout is easier, the structure combination is optimized, and feed materials and discharged materials flow more smoothly, therefore the production efficiency is improved, the operation rate and the operability of equipment are greatly improved, unnecessary interference during die bonding is reduced, and the production progress and the die bonding quality are ensured; and the operation of the front ends and the back ends of different die bonders can be mastered by one person, therefore human resources are saved and the production cost is reduced.

Owner:GKG PRECISION MACHINE

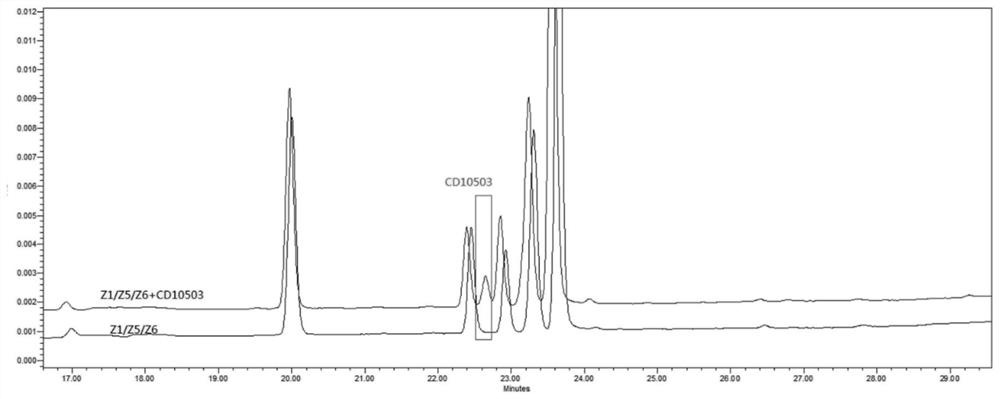

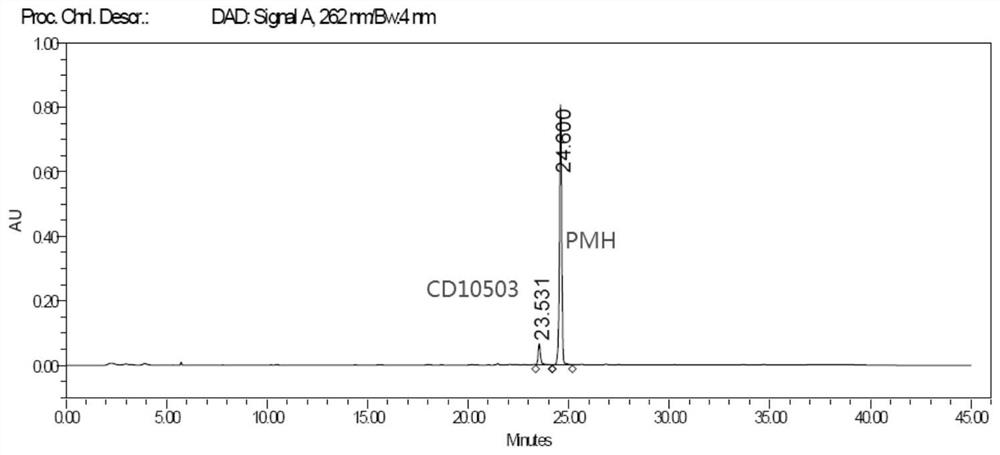

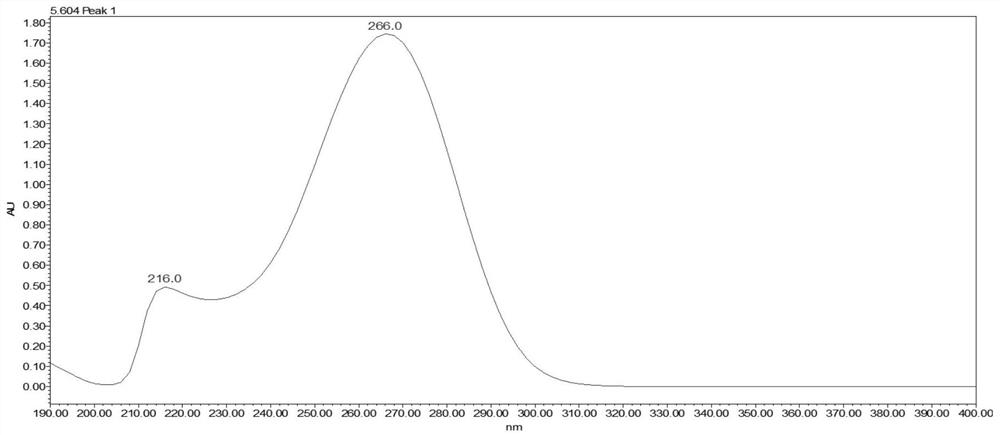

Method for detecting related substances of pramipexole dihydrochloride sustained-release tablets

ActiveCN112858527AImprove quality controlRealize accurate quantitative detectionComponent separationProlonged-release tabletPramipexole Dihydrochloride

The invention discloses a method for detecting related substances of pramipexole dihydrochloride sustained-release tablets, which adopts an organic diluent and a normal-phase chromatographic system, so that an impurity CD10503 can be stable and not decomposed in the detection process, the accurate quantitative detection of the impurity CD10503 can be achieved, and the quality of the pramipexole dihydrochloride sustained-release tablet can be better controlled.

Owner:CHENGDU BRILLIANT PHARMA CO LTD

Needle bar driving mechanism of rotary shuttle loom for quilting and embroidering

ActiveCN102108607BCater to development needsOptimize and adjust the structureEmbroidering machines apparatusNeedle barsDrive shaftCam

The invention relates to the technical field of production machinery for quilting and embroidering, in particular to a rotary shuttle loom for quilting and embroidering. A needle bar driving mechanism of the rotary shuttle loom comprises a driving shaft, wherein the driving shaft drives a connecting shaft via cams; the connecting shaft is linked with two or more drivers which can move up and down; the drivers are installed on an upright bar; each driver corresponds to a needle bar; the drivers are provided with moving blocks which can move eccentrically; and the moving blocks are provided with clamp slots which can clamp the adaptation parts of the needle bars and drive the needle bars to move up and down. The needle bar driving mechanism also comprises an unlocking mechanism which can drive the clamp slots to be separated from the needle bars, wherein the unlocking mechanism comprises an electromagnet locking head device which is installed uprightly and a transverse propelling device. The needle bar driving mechanism has the following advantages: after the cams are output, the drivers are synchronously driven by the connecting shaft and three-hole connecting bars to move up and down, so the structure is optimized and adjusted and the spatial body is small; the unlocking mechanism has one-to-one relationship with the drivers, so the single needle locking function can be realized in the small needle gauge embroidering process and the production requirement is met; and the needle bar driving mechanism has simple, scientific and reasonable structure.

Owner:江西艺博达机械有限公司

Production technology of double-point coating composite sponge for automotive fabrics and automotive composite fabrics

ActiveCN106393926BIncreasing the thicknessEasy dischargeSynthetic resin layered productsLaminationManufacturing cost reductionNonwoven fabric

The invention especially relates to a production process for a double-dot coating composite sponge used for an automobile fabric and an automobile composite fabric, belonging to the technical field of fabrics. The production process overcomes the problems of proneness to generation of pits, environment unfriendliness and the like in the prior art. The production process for the double-dot coating composite sponge comprises the following steps: A, gluing; and B, compounding. The automobile composite fabric is prepared by using the production process. The invention has the advantages that manufacturing cost is reduced; pits are prevented; peeling strength is improved; and environmental protection is better realized.

Owner:CPL NEW MATERIAL TECH CO LTD

A kind of multifunctional pull bolt and its application

ActiveCN103061505BHigh precisionIncrease stiffnessAuxillary members of forms/shuttering/falseworksBuilding reinforcementsSheet steelArchitectural engineering

The invention discloses a multifunctional split bolt and application thereof. Steel plates are penetratingly mounted at two ends of a bolt bar. The bolt bar is fixedly connected one steel plate by means of welding. A pair of positioning clamps for fixing rebar positions is welded on the bolt bar between the two steel plates. Fastening nuts are fitted at two ends of the bolt bar. When the split bolt is used in a composite structure with building prior to pouring, construction speed is increased, construction efficiency is improved, bonding degree and tightness of interfaces of different materials are enhanced, overall performance of a structure is improved, usability of the structure is more reliable, maintenance is reduced, service life of a project is prolonged, accuracy and reliability of rebar protective layer control are higher, soakage resistance and erosion resistance of concrete is guaranteed to be more reliable, formwork mounting and strengthening are more convenient and faster, influence of building verticality and evenness can be eliminated, construction accuracy is higher, common signal side formwork lateral supports can be reduced, construction difficulty can be lowered, cost is saved, and the split bolt is suitable for double-side formwork construction and embedded part positioning mounting of walls and board components.

Owner:河北省第四建筑工程有限公司

Vacuum ion plating process

InactiveCN102021520BHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingManganeseCobalt

The invention relates to the technical field of electroplating, in particular to a vacuum ion plating process. The vacuum ion plating process is characterized in that cobalt-chromium alloy is selected as a target material and the plating process is completed in a vacuum environment, wherein the vacuum degree of the vacuum environment is required to be 0.2-0.9Pa, the temperature is 0-300 DEG C, the target current is 0-100A, the pulse bias voltage is 0-200V, and a reactant gas is argon; and the cobalt-chromium alloy target material is composed of the following components by weight percent: 40-85% of cobalt, 10-55% of chromium and the balance of trace element, wherein the trace element is one or more of molybdenum, nickel, iron, carbon, manganese, silicon, nitrogen, titanium, copper, aluminum and vanadium. The vacuum ion plating process is simple, scientific and reasonable, and is easy and convenient to operate, thus greatly improving the operation ratio and the maneuverability of the vacuum ion plating, catering to production of novel materials, and ensuring that the product surfaces are of bright platinum; and in addition, the investment cost is low, the coating film is even in color and luster, high in surface hardness, good in wearing resistance, and excellent in inoxidizability.

Owner:许正诚

Claw chuck inner displacement structure for toe lasting machine

Owner:DONGGUAN QIFENG HYDRAULIC TECH

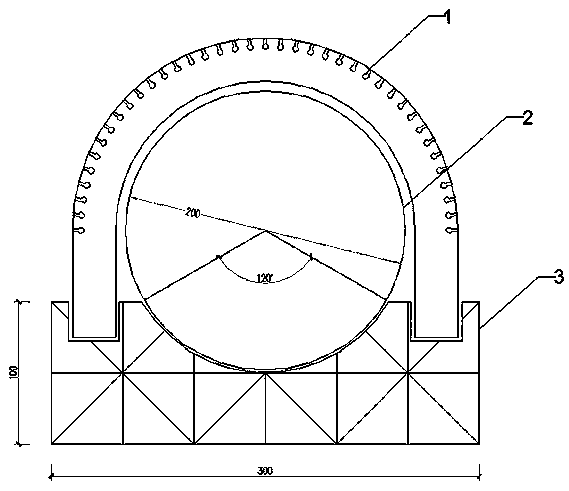

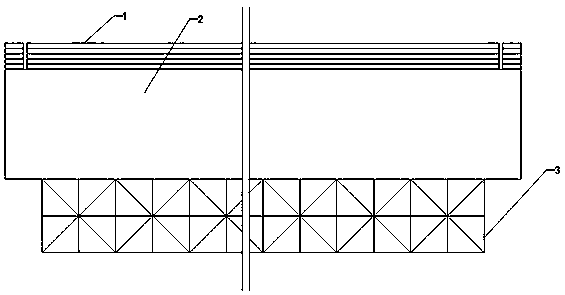

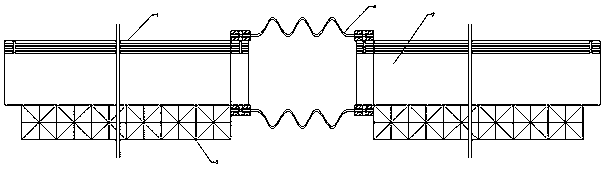

Active type underground efficient water suction and drainage blind tube system

The invention discloses an active type underground efficient water suction and drainage blind tube system. The active type underground efficient water suction and drainage blind tube system comprisesa water collecting inspection well, active type efficient water suction and drainage tube assemblies and a flexible joint, wherein the two sides of the water collecting inspection well are connected with the active type efficient water suction and drainage tube assemblies; the third surface of the water collecting inspection well is connected with an outlet tube; the flexible joint is used for connecting the two sections of the active type efficient water suction and drainage tube assemblies; each active type efficient water suction and drainage tube assembly consists of a base, a water drainage base, and an active type water suction plate, wherein the base, the water drainage tube and the active type water suction plate are connected through a heat-melting way, the base, the water drainage tube and the active type water suction plate are made of a high-strength engineering PVC material, so that anti-pressure ability and plastic mechanical properties are very good; and the flexible joint can be suitable for uneven local settling of various foundations, and can realize small-angle rotation in any direction. Active type water suction plates delicately improve single passive water seepage to active water drainage, so that water drainage efficiency is greatly improved.

Owner:刘亚丁

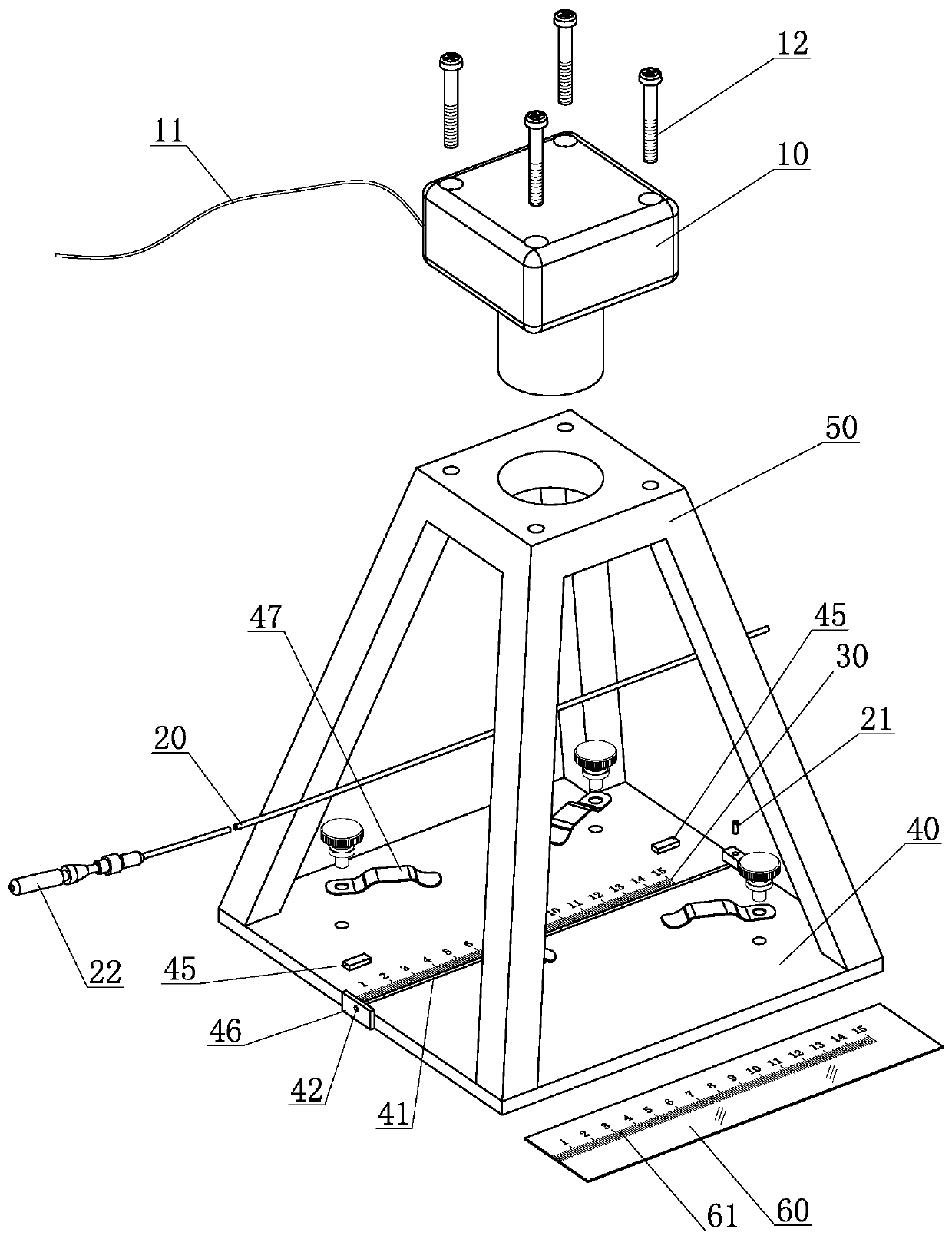

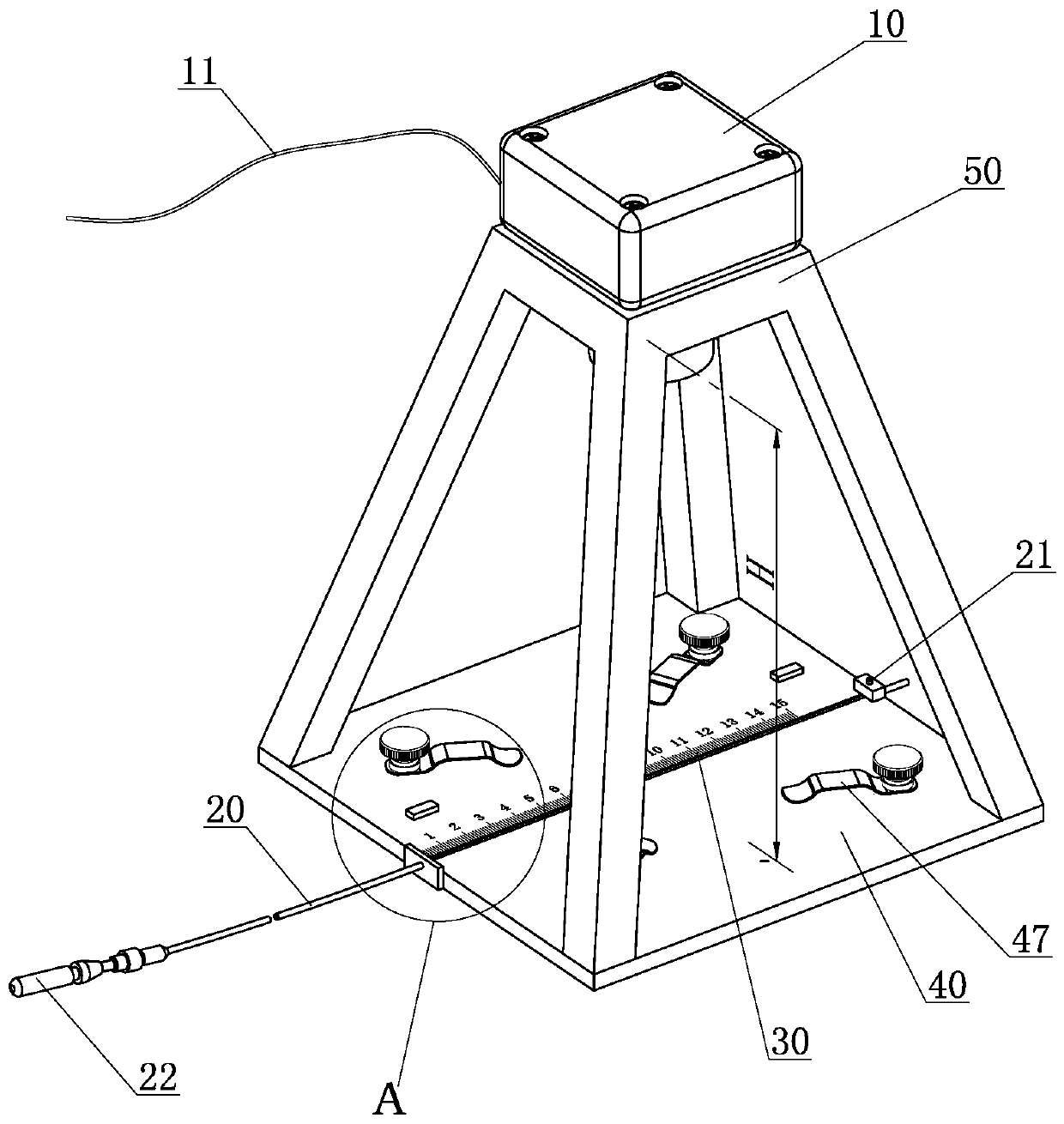

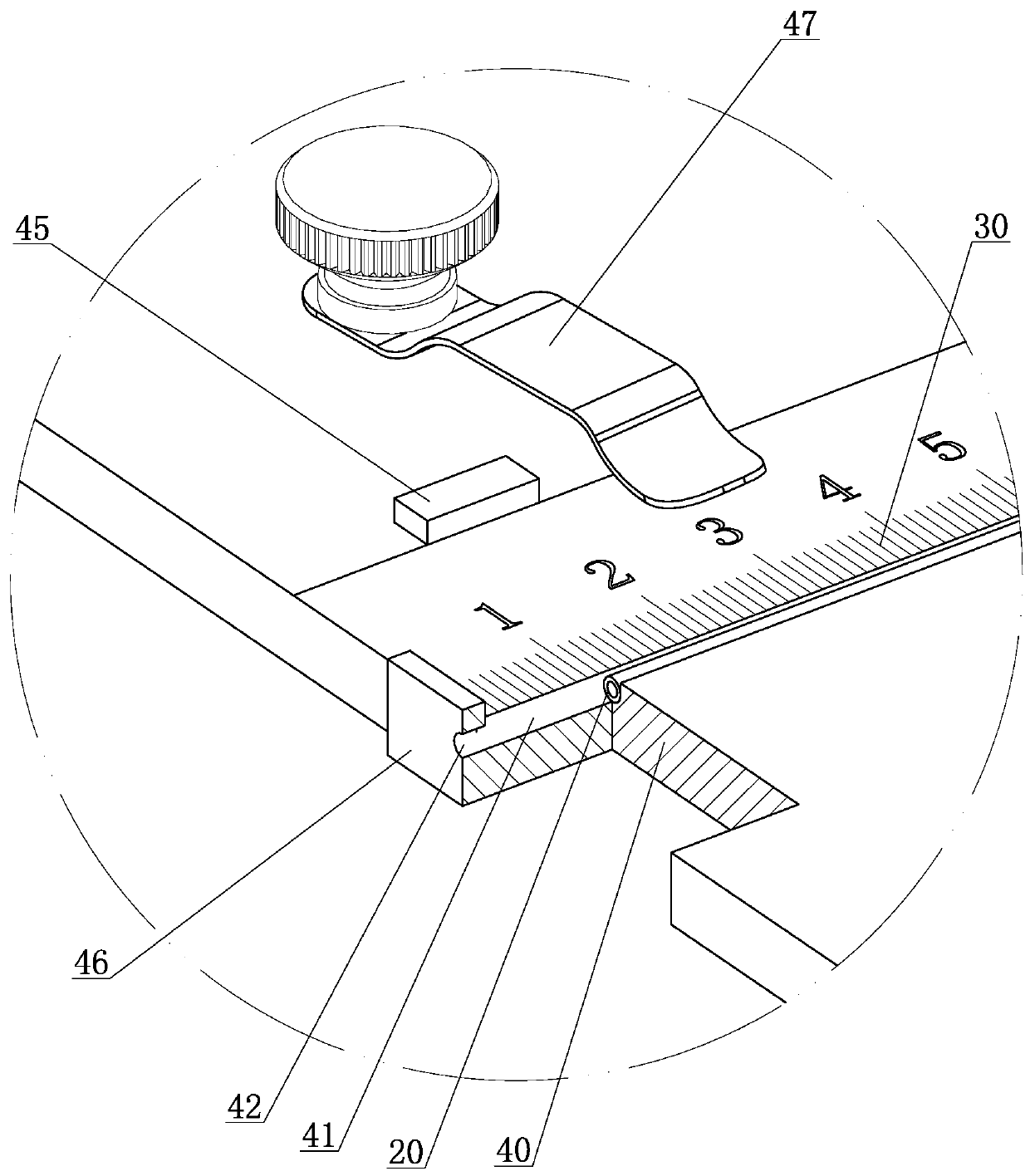

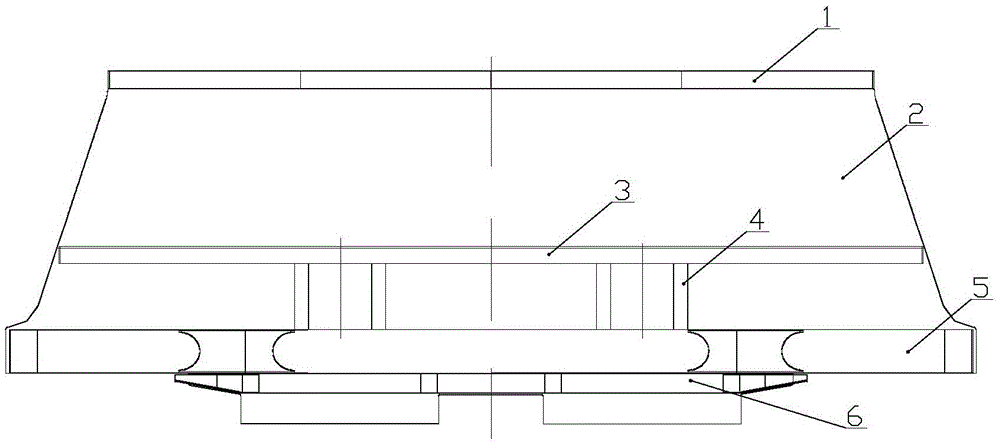

A quality control device installed after radiotherapy

ActiveCN108478937BImprove quality control management levelThe test result is accurateX-ray/gamma-ray/particle-irradiation therapyQuality controlCatheter

The invention relates to a quality control device for a radiation afterloading unit. The device detects the positional accuracy of a radiation source extending from the radiation afterloading unit ata dwell point and the timing accuracy of the radiation source at the dwell point. The quality control device for the radiation afterloading unit comprises a camera, a detection catheter and a detection scale. The detection catheter is a transparent catheter. The radiation source enters the detection catheter and reaches the dwell position. The detection scale measures the position of the radiationsource in the detection catheter. The camera acquires the image of the position of the radiation source in the detection catheter. The quality control device for the radiation afterloading unit has the advantages that the camera is used to acquire the image of the radiation source at the dwell point; a detecting person and the detected radiation source can be isolated; the radiation source whichis actually applied is detected and calibrated; a detection result is true, and the quality control effect is reliable; the detection result can be accurately judged and analyzed through the image; the timing precision of the afterloading unit is analyzed through video interception; and the quality control management level of the radiation afterloading unit is improved.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

A manufacturing process for the composition of the arc side wall of the railway freight car

ActiveCN104002828BSimple manufacturing processShorten the lengthAxle-box lubricationRailway bodiesMaterial consumptionUltimate tensile strength

The invention relates to a wagon arc side wall assembly production process. The wagon arc side wall assembly comprises a first side wall plate, a second side wall plate and a third side wall plate which are cambered and welded successively from the top to the bottom. An upper side beam assembly is welded and fixed on a top end plate wall of the first side wall plate. A side wall stiffening beam assembly is welded and fixed longitudinally at the first side wall plate and second side wall plate side wall welding position. A lower side beam assembly is welded and fixed longitudinally at the second side wall plate and third side wall plate welding position. A lower side beam reinforcing beam assembly is welded and fixed longitudinally below the lower side beam assembly. According to the production process, by the side wall plate longitudinal splicing design mode and different-thickness design, spliced welded joints are hidden, the spliced welded joint length is reduced effectively, the joint groove machining amount and the welding material consumption are reduced, the production efficiency is improved, and costs are saved; the side wall flatness is controlled effectively, and the appearance is attractive; the process is simplified, the production difficulty and the labor intensity are reduced, the tooling equipment investment is simple, and the efficiency is improved effectively.

Owner:CRRC ZHUZHOU ROLLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com