Ultra-short distance dredging construction method for cutter suction dredger dock apron

A technology of wharf frontier and construction method, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as high safety risks, poor quality, and low productivity, and achieve quality control Reliable, safety hazards are reduced, and production efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

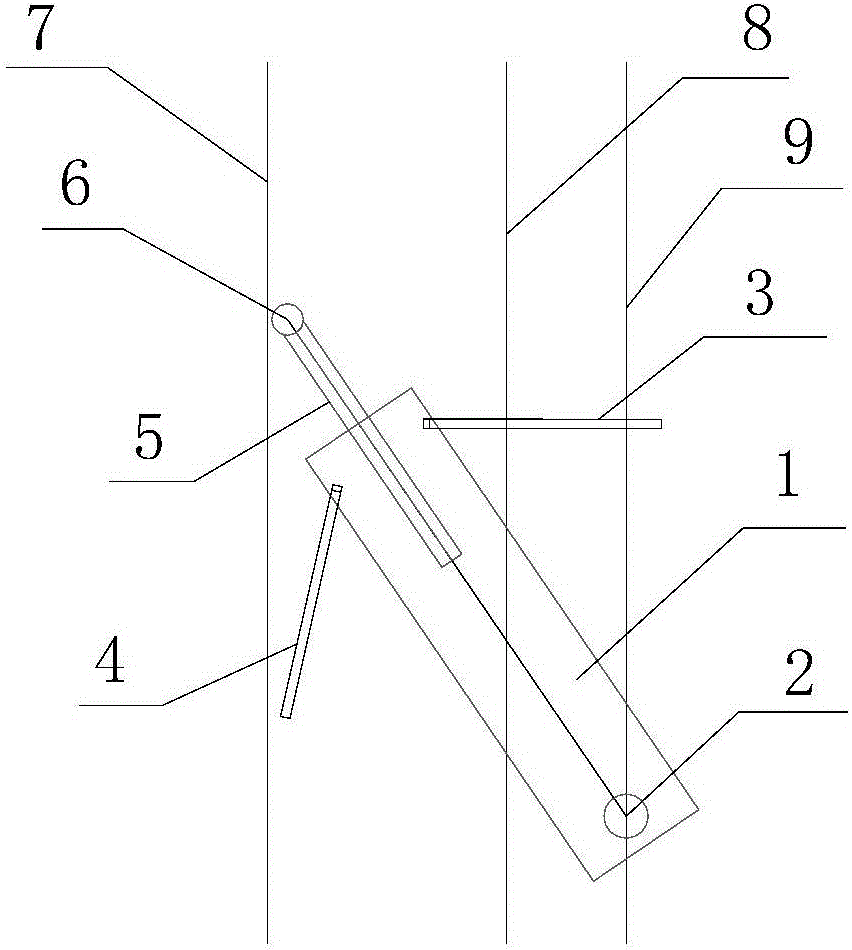

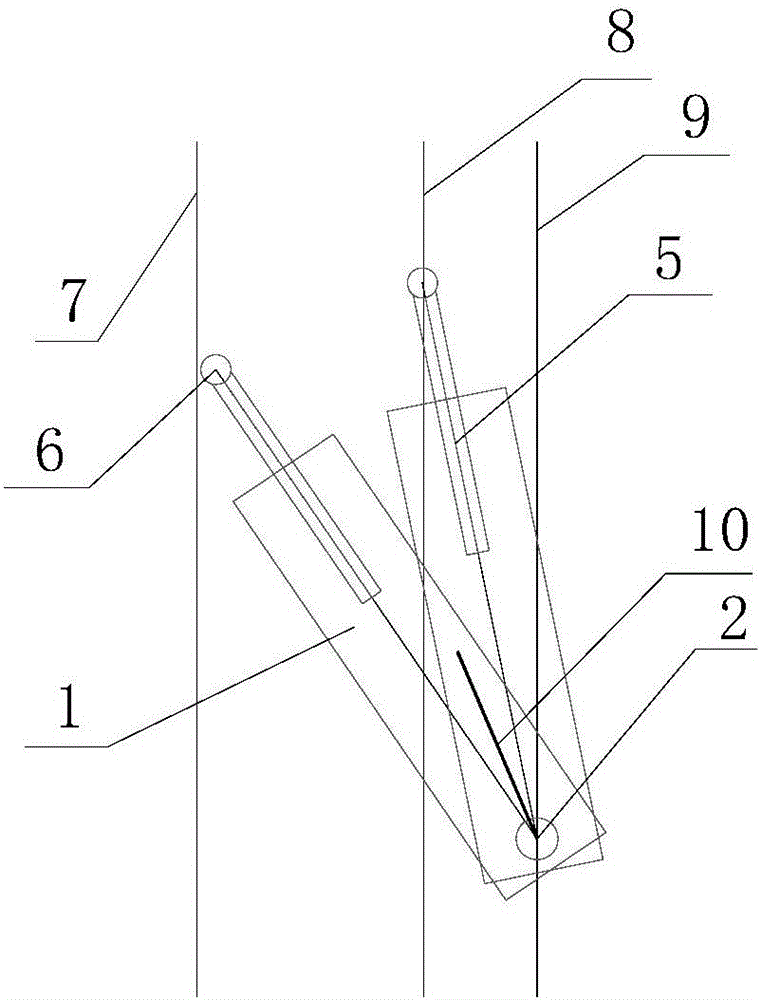

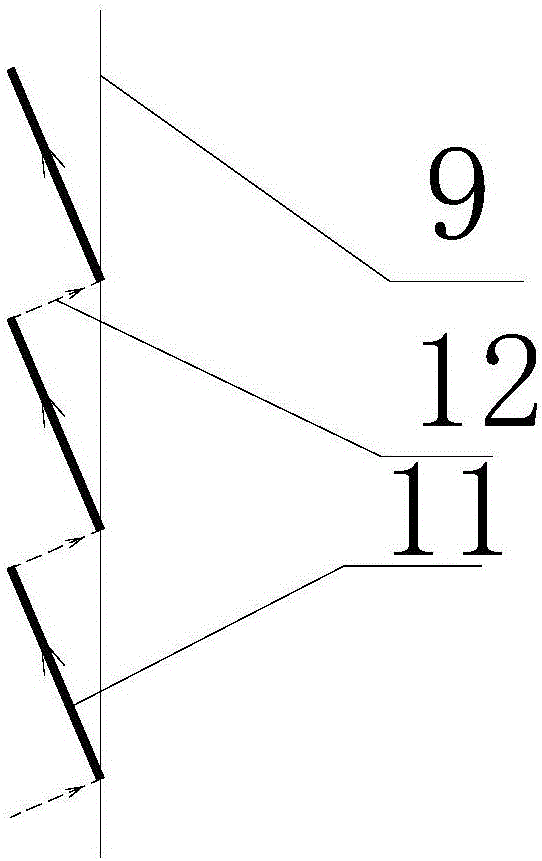

[0016] see figure 1 , figure 2 and image 3 , a construction method for ultra-short-distance dredging at the front of a cutter suction ship wharf, specifically comprising the following steps:

[0017] Step 1, the ship is stationed in the spread; after the cutter suction ship 1 enters the site, the steel pile 2 is lowered to the steel pile reset line 9 parallel to the front edge of the wharf 7, and the reamer 6 fixes the hull at 8 points at the excavation boundary; then use The form of "back anchor" throws the right lateral anchor 3, and in the same way, after the bridge 5 is lifted, the anchor boat is used to rotate the position of the reamer 6 to the left with the steel pile 2 as the center to the front line 7 of the wharf, and the reamer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com