Claw chuck inner displacement structure for toe lasting machine

A technology of front upper machine and front claw plate, which is applied in the direction of shoe uppers, clothing, footwear, etc., can solve the problem that the edge of the upper can not be completely attached to the edge of the last, so as to improve the operation rate and operability, and the upper Smooth, maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

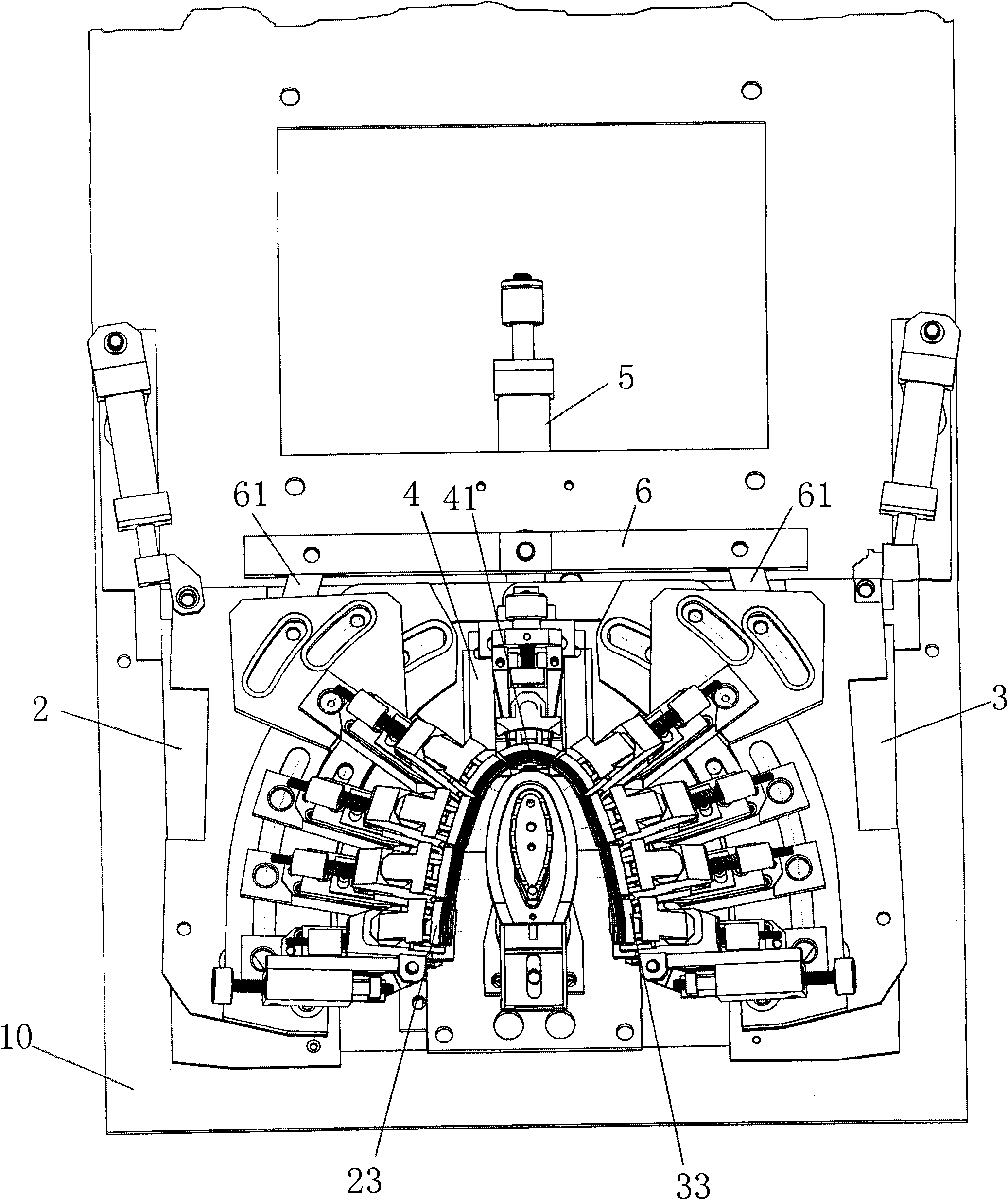

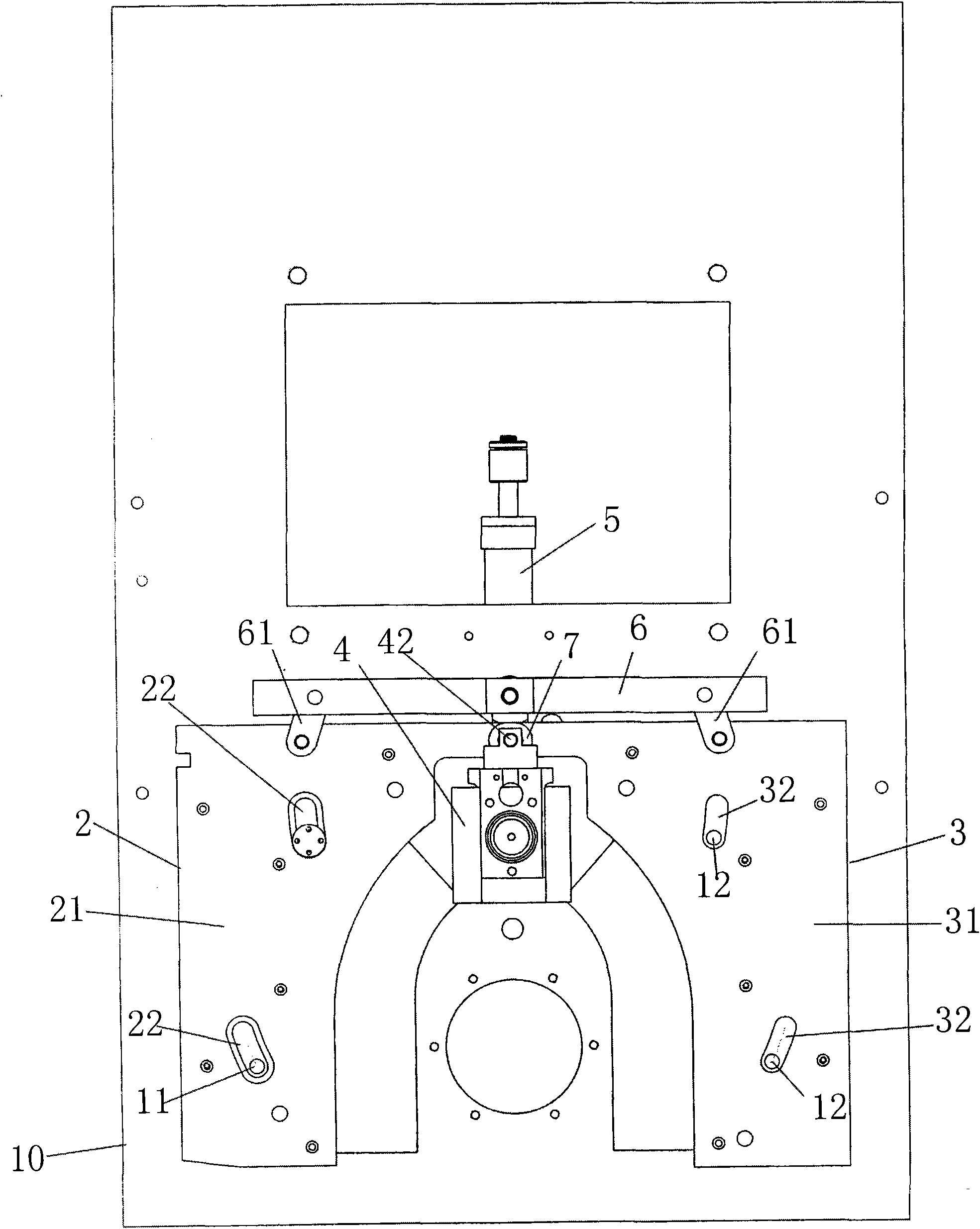

[0018] refer to figure 1 , 2 As shown, it is a structural schematic diagram of the present invention, and the structure of the claw plate moving inward of the front lasting machine according to the present invention includes:

[0019] A left claw plate 2 is movably installed on the large plate 10 of the machine. The left claw plate 2 has an upward first mounting surface 21 and a first moving guide groove 22. The first moving guide groove 22 cooperates with the first moving guide groove on the large plate. A restricting part 11 is installed, and a number of left claws 23 are installed on the first installation surface 21 . The first moving guide groove 22 is a waist-shaped arc groove, and the first restricting part 11 is a convex pin fixed on a large plate. When the left claw plate 2 moves, the first restricting part 11 gives guidance and positioning, so that the left claw plate 2 moves according to the arc direction of the first moving guide groove 22, and ensures that the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com