A data driven method for automated detection of anomalous work pieces during a production process

一种生产过程、测量数据的技术,应用在程序控制、全面工厂控制、计算机零部件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

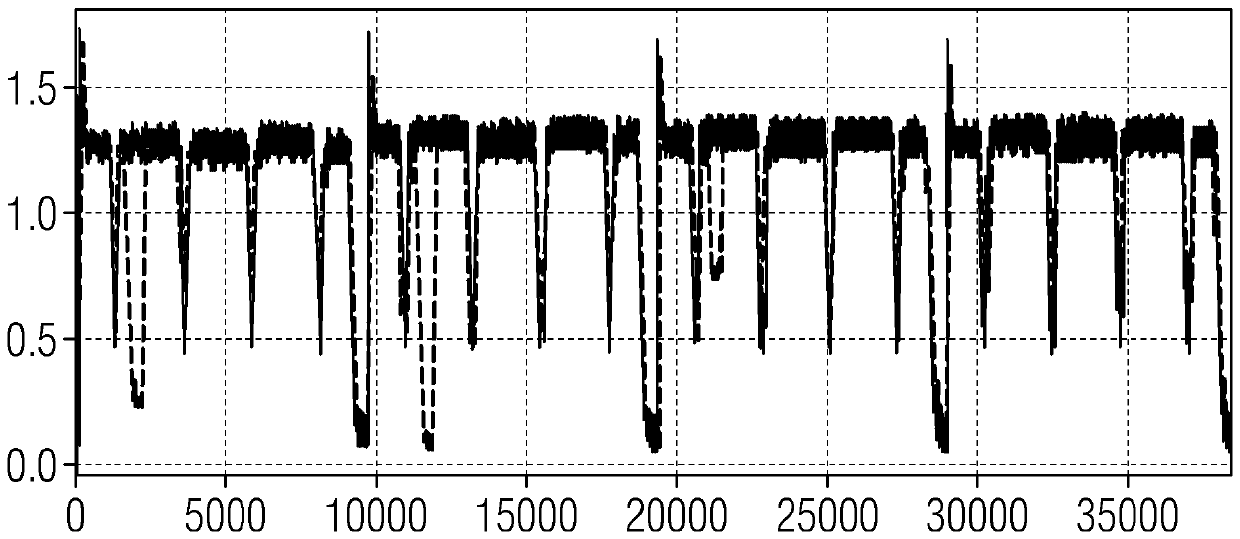

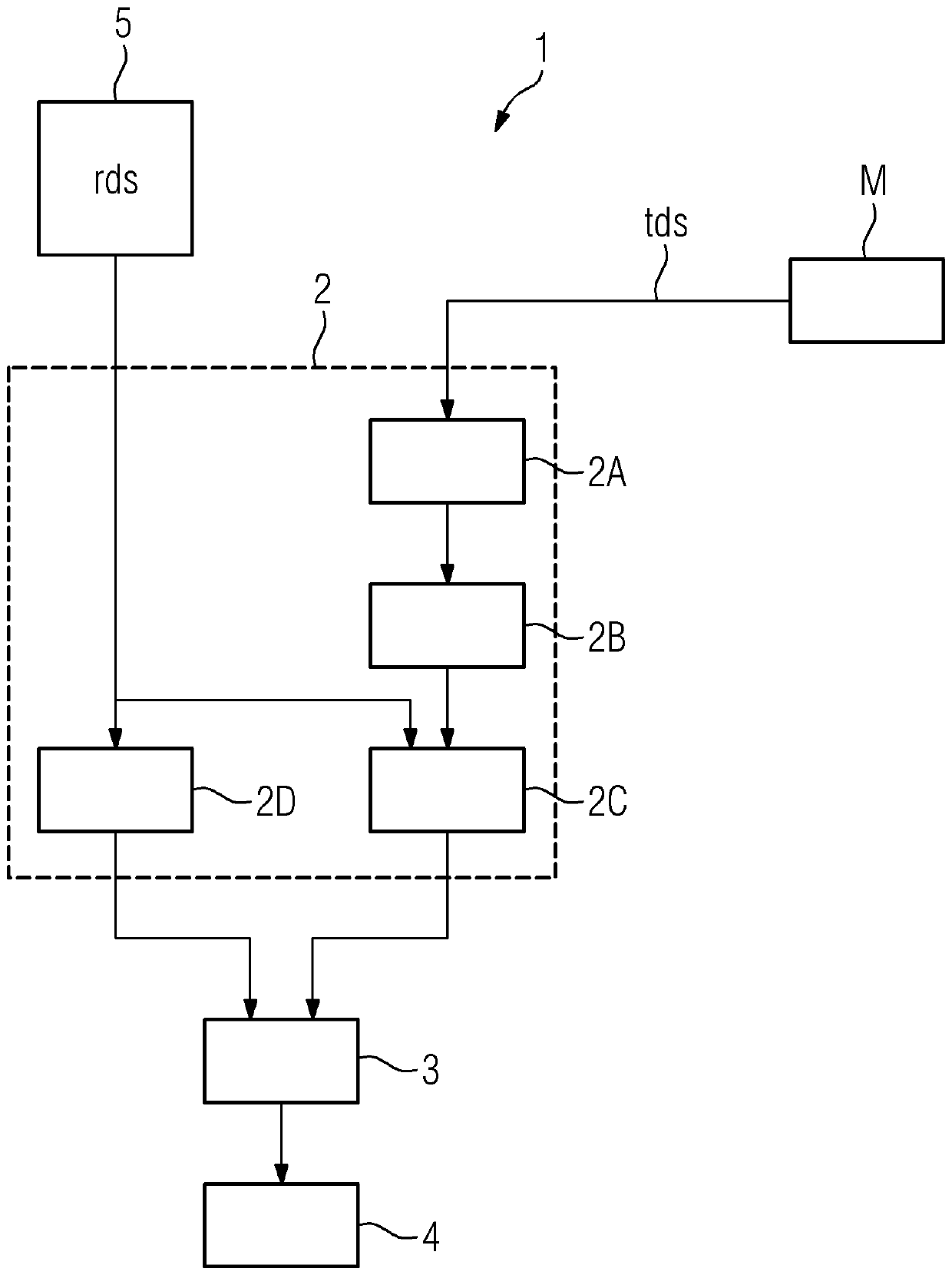

[0037] as in figure 1 As can be seen in , the quality control system 1 according to one aspect of the present invention comprises in the exemplary embodiment shown a data preprocessing unit 2 having an input interface for receiving a target data signal. The input interface can eg be connected to a controller of a production machine M adapted to process workpieces in a production process comprising several production process steps. The production or manufacturing machine M can be connected to the input interface of the data preprocessing unit 2 via a signal line or a signal bus. A production machine M may process one or more workpieces in a current production process step which forms part of a production process carried out by the respective production machine M. For example, workpieces can be processed by milling and boring machines. The manufacturing machine M may carry out a manufacturing or production process comprising a sequence of process steps such as roughing or fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com