Active type underground efficient water suction and drainage blind tube system

An active, suction and drainage technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of difficult to guarantee drainage efficiency, reduced seepage and drainage efficiency, and difficult to control quality, and is conducive to construction quality control, reducing Construction cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

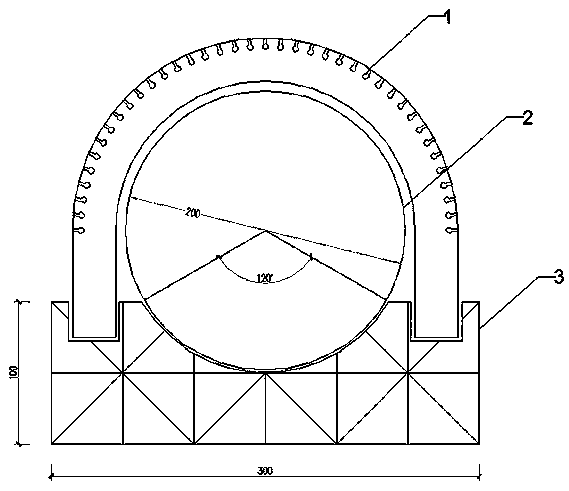

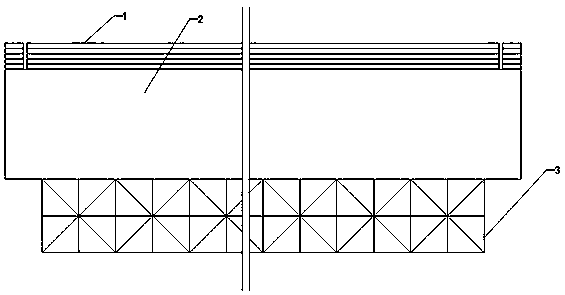

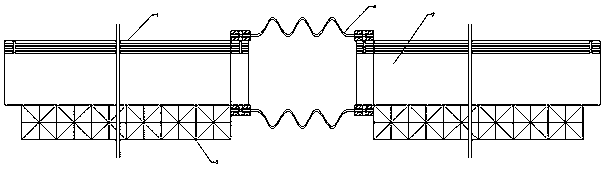

[0039] When the active underground high-efficiency integral suction and drainage blind pipe is used, it is installed on both sides of the lower part of the railway (highway) roadbed. After the excavation of the roadbed is completed, a 100mm thick coarse sand leveling layer is laid longitudinally at the designed blind ditch position on both sides of the bottom of the roadbed foundation. , and then placed in the active underground high-efficiency integral suction and drainage blind pipe system, and the two sections are connected by flexible joints. When the active underground high-efficiency integral suction and drainage blind pipe system is installed, an integral water collection inspection well is installed every 200 meters . The active underground high-efficiency integral suction and drainage blind pipes on both sides of the water collection inspection well are sloped 0.5% in the direction of the water collection inspection well, and ordinary PVC pipes are installed at the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com