Needle bar driving mechanism of rotary shuttle loom for quilting and embroidering

A driving mechanism and a technology of a rotary hook machine, which are used in the rotary hook machine of quilting and embroidery, and the field of quilting, can solve the problems of inability to flexibly configure the spacing of quilting needles, difficult to meet the needs of the market, and inability to lock a single needle, so as to improve the operation. efficiency and operability, stable and reliable quality control, and the effect of structural optimization and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with accompanying drawing:

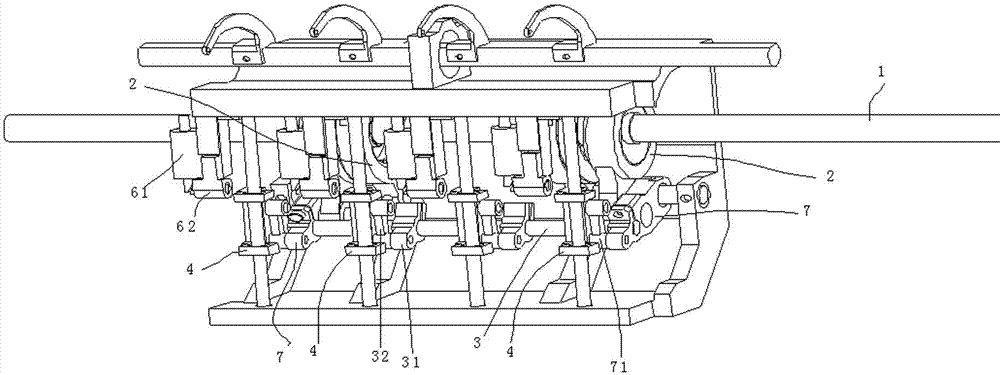

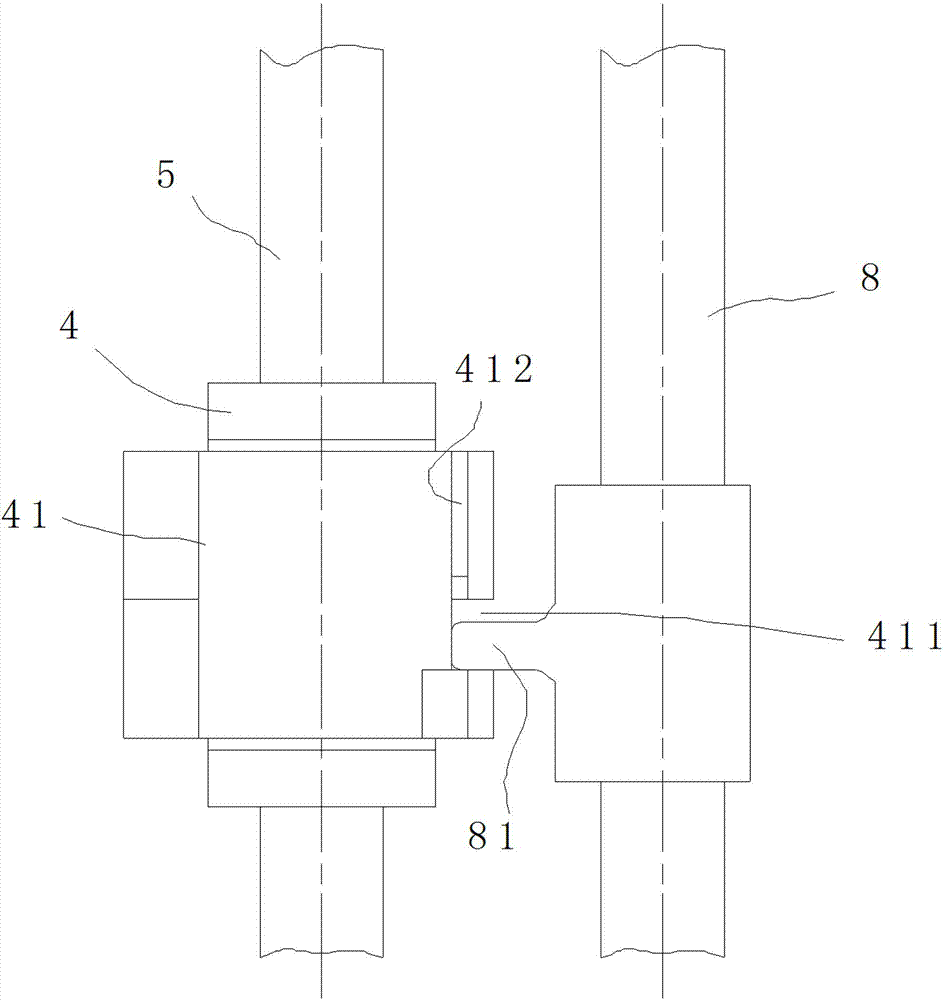

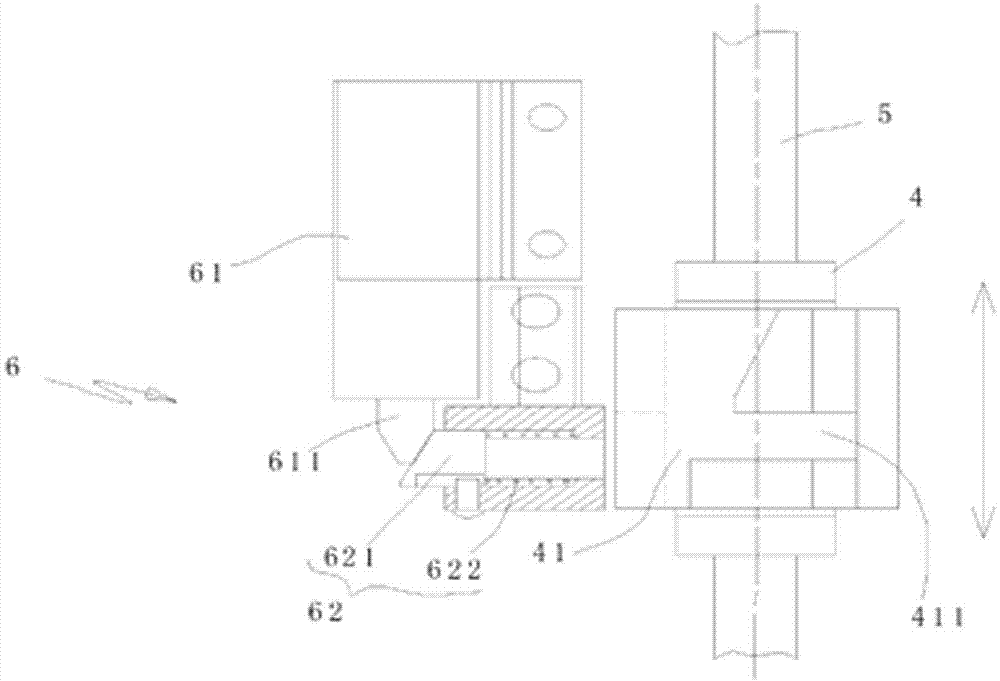

[0018] refer to Figure 1~4 As shown, it is a schematic diagram of a preferred embodiment of the present invention. The present invention relates to a needle bar driving mechanism of a rotary hook machine used for quilting and quilting embroidery, including a driving shaft 1, which is driven and connected by a cam 2. Axis 3 and connecting shaft 3 are linked with two or more drivers 4 that can move up and down. The drivers 4 are installed on a vertical rod 5, and each driver 4 corresponds to a needle bar; the driver 4 is provided with movable Block 41, the movable block 41 is provided with a card slot 411 that can lock the adapter part of the needle bar and drive the needle bar to move up and down; it also includes an unlocking mechanism 6 that can drive the card slot 411 to separate from the needle bar. Unlocking mechanism 6 comprises the electromagnet end lock device 61 of ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com