Production technology of double-point coating composite sponge for automotive fabrics and automotive composite fabrics

A two-point coating and production process technology, applied in the field of fabrics, can solve the problems of large residues of organic volatile gases and other harmful substances, high requirements for combustion nozzles and airflow control, and the inability to be used in the field of automotive fabric compounding, etc., to save sponges Thickness, reduced inventory value, improved effect of harmful exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

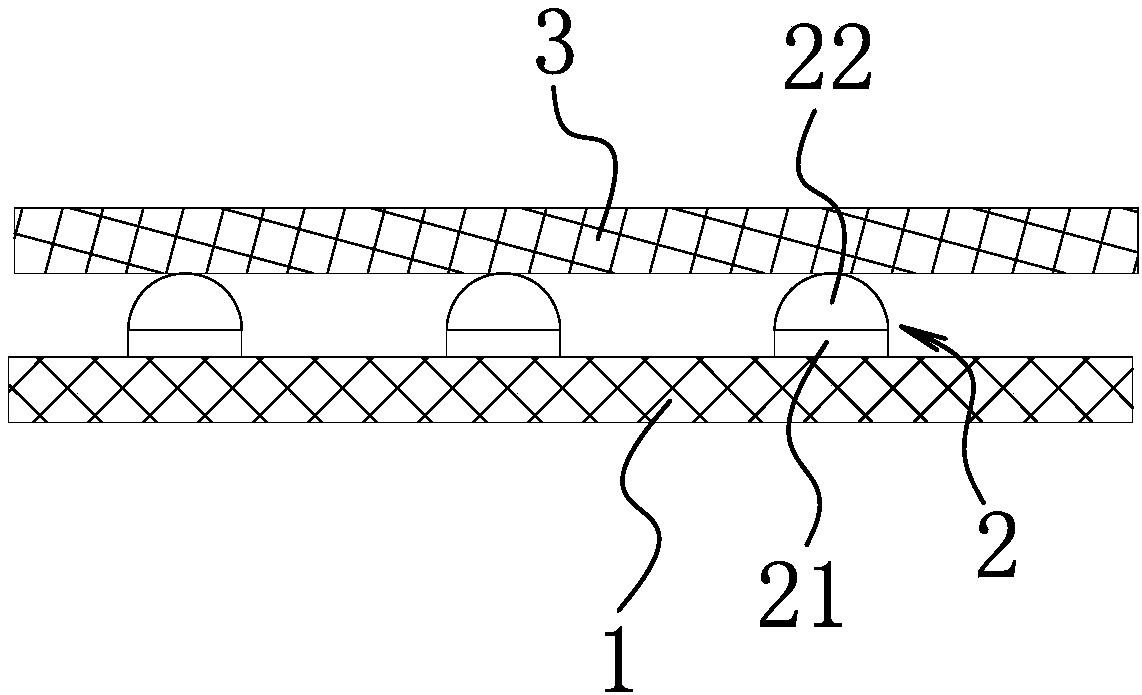

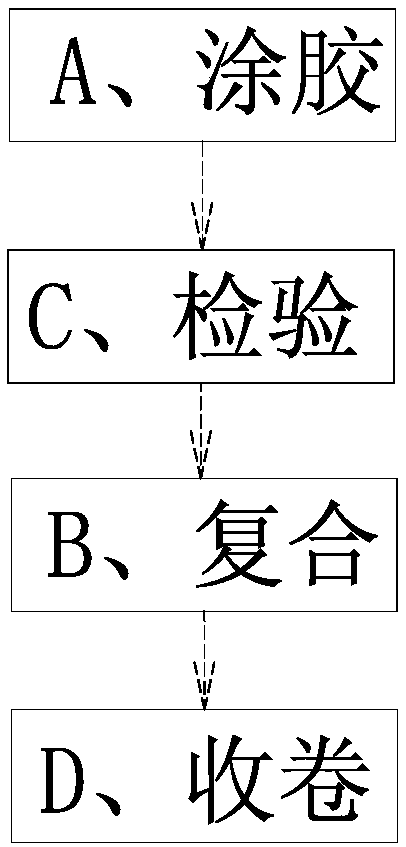

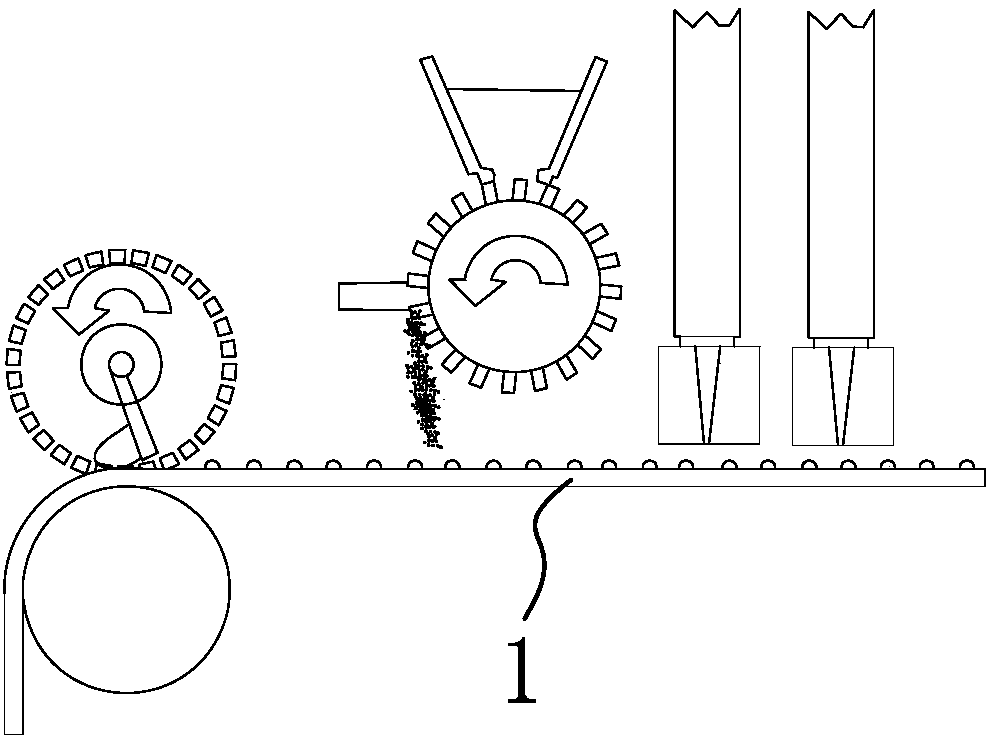

[0051] Such as Figure 1-4 Shown, the production technology of this automobile fabric two-point coating composite sponge comprises the steps:

[0052] A. Gluing: Put the water-repellent treated automotive fabric 1 on the unwinding frame of the double-point coating machine after the coating surface is judged, and put on the cloth, and process it on the coating surface through the double-point coating process. Double-point coating 2 and the coating amount of double-point coating 2 on the coating surface of automobile fabric 1 is 14-20 grams per square meter, that is, the automobile fabric with coating on one side is made; Wherein, the double-point coating Coating 2 is formed by the following steps:

[0053] a1. Choose a 30-40-mesh computer-designed double-point coated circular screen with a hole density of 150-200 holes / cm² and a hole diameter between 0.2-0.3 mm, and the wall thickness of the rotary screen is between 0.15-0.22 mm. ; Such dots are small and dense, the amount of...

Embodiment 2

[0077] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0078] In above-mentioned A step, described automobile fabric 1 is the warp-knitted automobile fabric of water-repellent treatment, and the warp-knitted automobile fabric with a door width of 156 centimeters and a specification of 170 grams per square meter is placed on the double Put the cloth on the unwinding rack of the dot coating machine, set the speed of the double dot coating machine at 22 m / min, and raise the temperature of the drying room to 180-185°C; choose 180 holes / square centimeter arranged randomly by computer , a round screen with a wall thickness of 0.18 mm and an aperture of 0.22 mm; select polyacrylate primer and adjust the machine parameters according to the solid content of polyacrylate of 4.0-4.5 grams per square meter of primer, and apply the polyacrylate base through the round screen The slur...

Embodiment 3

[0085] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0086] In the above-mentioned step A, the automobile fabric 1 is a water-repellent black and white interwoven and dyed warp knitted automobile fabric, and the warp knitted automobile fabric with a door width of 156 cm and a specification of 150 grams per square meter is judged to be good for painting. Put it on the unwinding frame of the double-point coating machine after layering and put on the cloth. The speed of the double-point coating machine is set at 22 m / min, and the temperature of the drying room is raised to 180-185°C; the computer random point arrangement is used 180 holes / square centimeter, wall thickness 0.18 mm and hole diameter 0.22 mm; choose polyacrylate primer and adjust the machine parameters according to the solid content of polyacrylate of 3.5-4 grams per square meter of primer, through the circl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com