Fully-automatic patch-type LED die bonder with new operation flows

A kind of operation process and chip-type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that affect the automatic mass production of equipment, affect the production process and the quality of die bonding, and unfavorable the layout of the transmission mechanism, etc., to meet the needs of large Batch continuous work, improve operating rate and operability, easy to observe the effect of feeding and eliminating operational obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

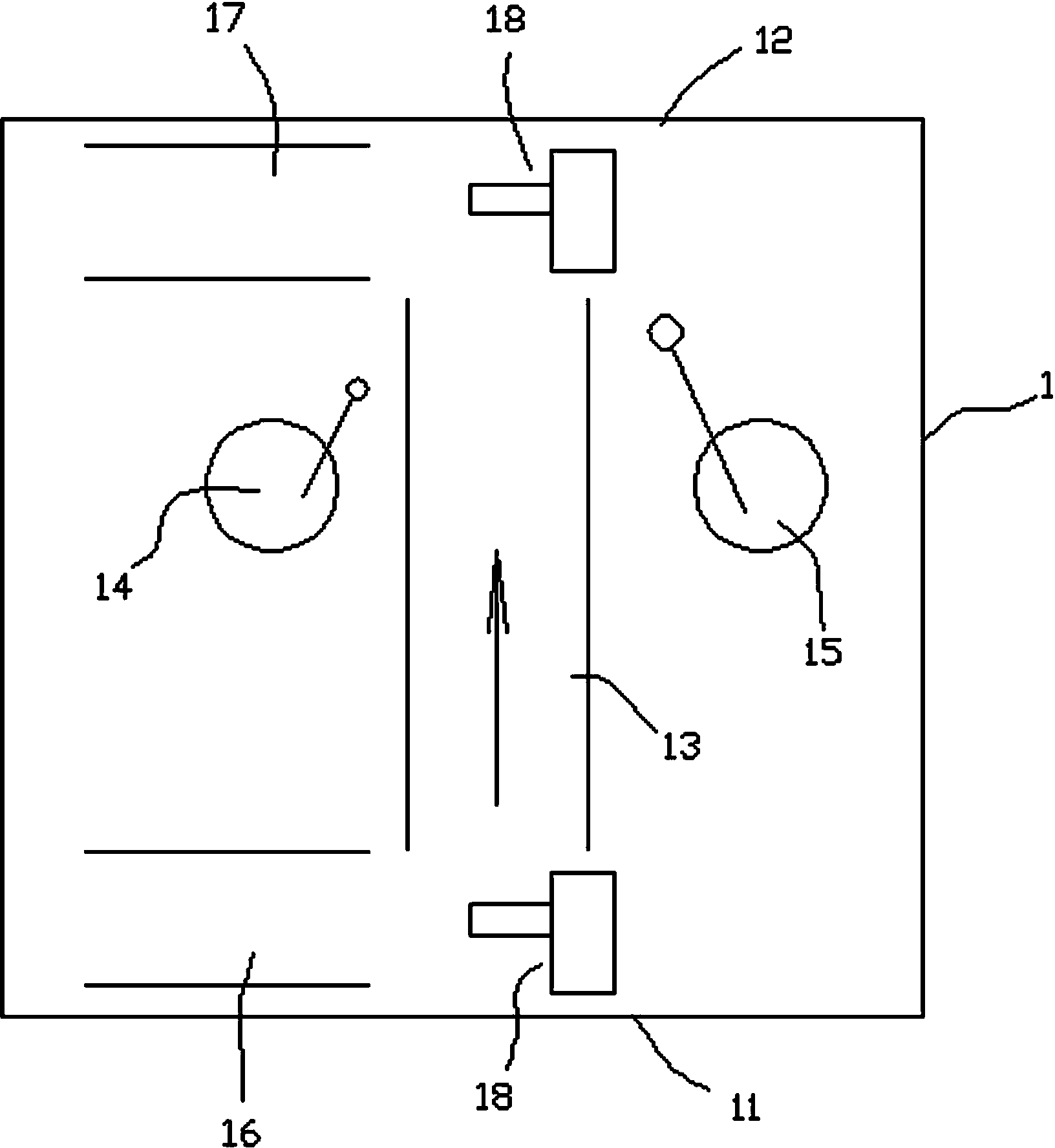

[0028] refer to figure 1 As shown, the fully automatic die-bonding machine of the SMD LED of the new operation process provided by the present invention is mainly used for processing the SMD LED, and it includes an organic base 1, which is provided with a feeding channel 13, a point Glue device 14 and chip pick-and-place device 15, etc., of course, also have a control unit and corresponding transmission mechanism (omitted in the figure) to meet the automatic die-bonding work. The frame 1 has a front end 11 facing the operator and a rear end 12 opposite to the front end 11; The area in between is transported and output from the rear end 12 of the machine base. The feeding channel 13 on the machine base 1 is arranged in a straight line toward the area between the glue dispensing device 14 and the chip pick-and-place device 15, so as to realize the feeding mode of forwarding and then out. In this embodiment, the feeding channel 13 is arranged in a straight line, and the glue d...

Embodiment 2

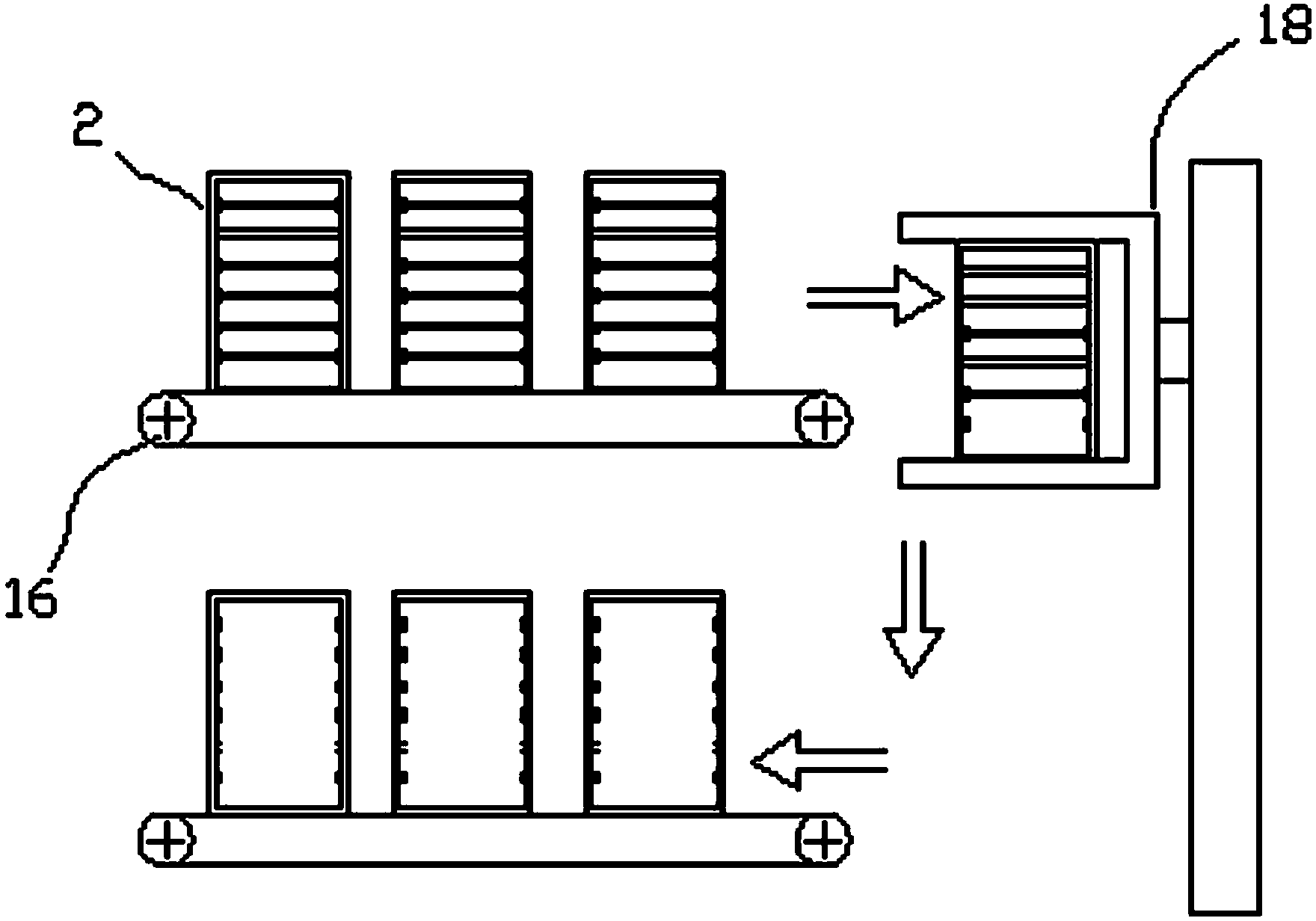

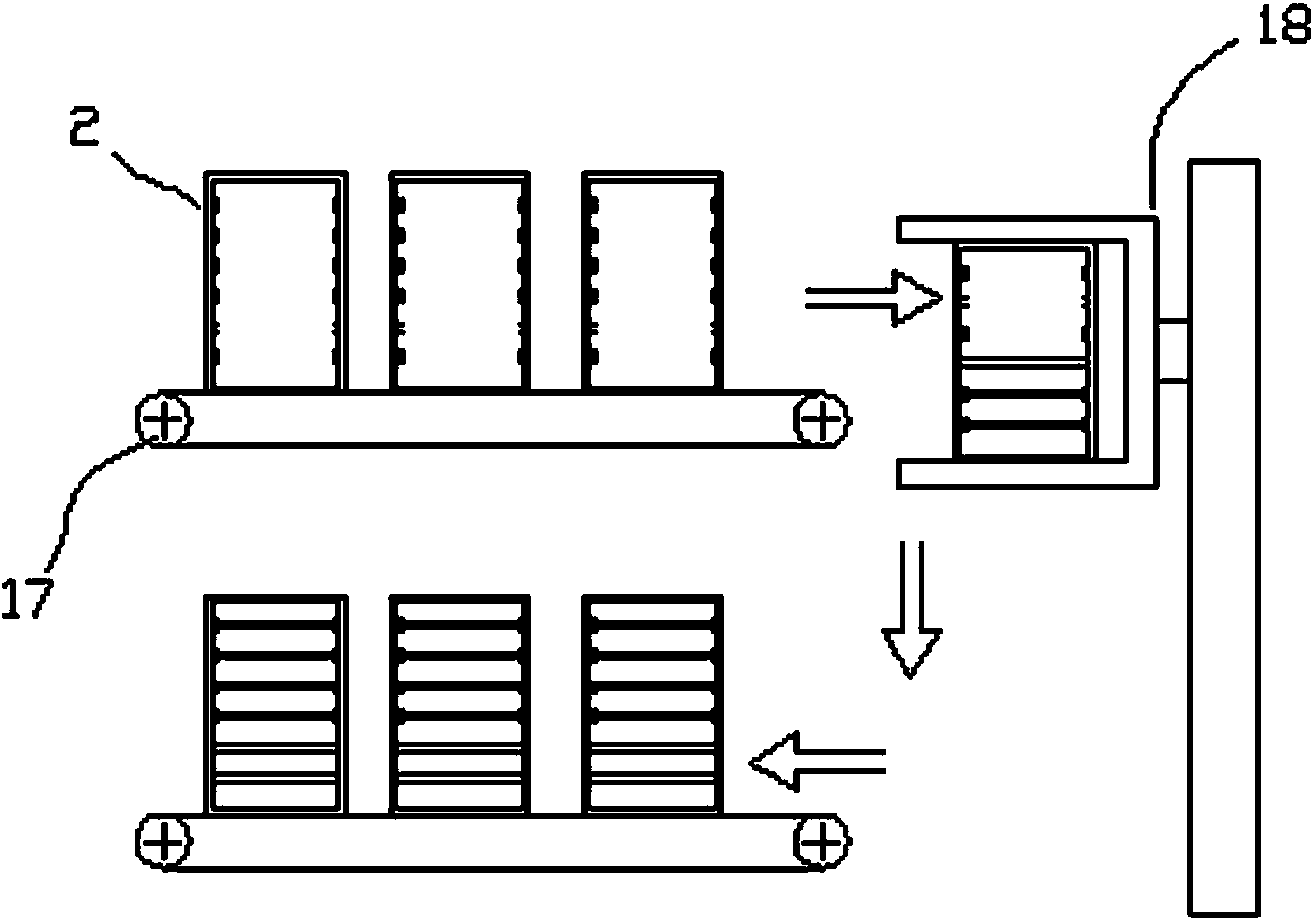

[0032] refer to Figure 4As shown, the fully automatic die-bonding machine of the SMD LED of the new operation process provided by the present invention is mainly used for processing the SMD LED, and it includes an organic base 1, which is provided with a feeding channel 13, a point Glue device 14 and chip pick-and-place device 15, etc., of course, also have a control unit and corresponding transmission mechanism (omitted in the figure) to meet the automatic die-bonding work. The base 1 has a front end 11 facing the operator and a rear end 12 opposite to the front end 11; the feed on the base 1 is taken and placed from the front end 11 and the rear end 12 of the base alternately towards the dispensing device 14 and chips Area delivery between devices 15. The feeding table of the front end 11 on the machine base and the feeding table of the rear end 12 are connected as a whole and move synchronously. The working mode is forward, front out and back in, back out, that is, two-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com