Broad-spectrum wax-proof pour point depressant for crude oil

A technology of wax-preventing pour point depressant and pour point depressant, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of small quantity of crude oil pour point depressant and limited application range, etc., and achieve good economic benefits, reduce Good coagulation effect, suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: prepare broad-spectrum crude oil anti-wax pour point depressant 5000mg

[0027] The consumption of each raw material is as follows:

[0028] Octadecyl Acrylate 400mg

[0029] Behenyl Methacrylate 1150mg

[0030] Fatty alcohol polyoxyethylene ether 250mg

[0031] Styrene 650mg

[0032] Maleic anhydride 450mg

[0033] 3-Ethyltoluene 2100mg

[0034] The production process is as follows:

[0035] (1) Add the stearyl acrylate, behenyl methacrylate, maleic anhydride and styrene in the above weight ratio into the reaction kettle and heat it to 120°C while stirring, keep the temperature for 4-4.5 hours and leave the kettle , as agent A and put into a special tank for storage;

[0036] (2) Add the fatty alcohol polyoxyethylene ether and 3-ethyltoluene in the above weight ratio into another reaction kettle, heat it to 60-65°C and stir for 1.5-2 hours, and take it out of the kettle as B agent and put it into a special tank middle;

[0037] (3) Pour all the p...

Embodiment 2

[0038] Embodiment 2: Preparation of broad-spectrum crude oil wax control and pour point depressant 5000mg

[0039] The consumption of each raw material is as follows:

[0040] Octadecyl Acrylate 500mg

[0041] Behenyl Methacrylate 900mg

[0042] Fatty alcohol polyoxyethylene ether 400mg

[0043] Styrene 500mg

[0044] Maleic anhydride 500mg

[0045] 3-Ethyltoluene 2200mg

[0046] The production process is as follows:

[0047] (1) Add stearyl acrylate, behenyl methacrylate, maleic anhydride and styrene in the above weight ratio into the reaction kettle and stir evenly, heat to 125°C and keep the temperature for 4 hours, then leave the kettle, as A The agent is stored in a special tank;

[0048] (2) Add the fatty alcohol polyoxyethylene ether and 3-ethyltoluene in the above weight ratio into another reaction kettle, heat it to 60°C and stir for 2 hours, and take it out of the kettle as agent B and pour it into a special tank;

[0049] (3) Pour all the prepared agents A a...

Embodiment 3

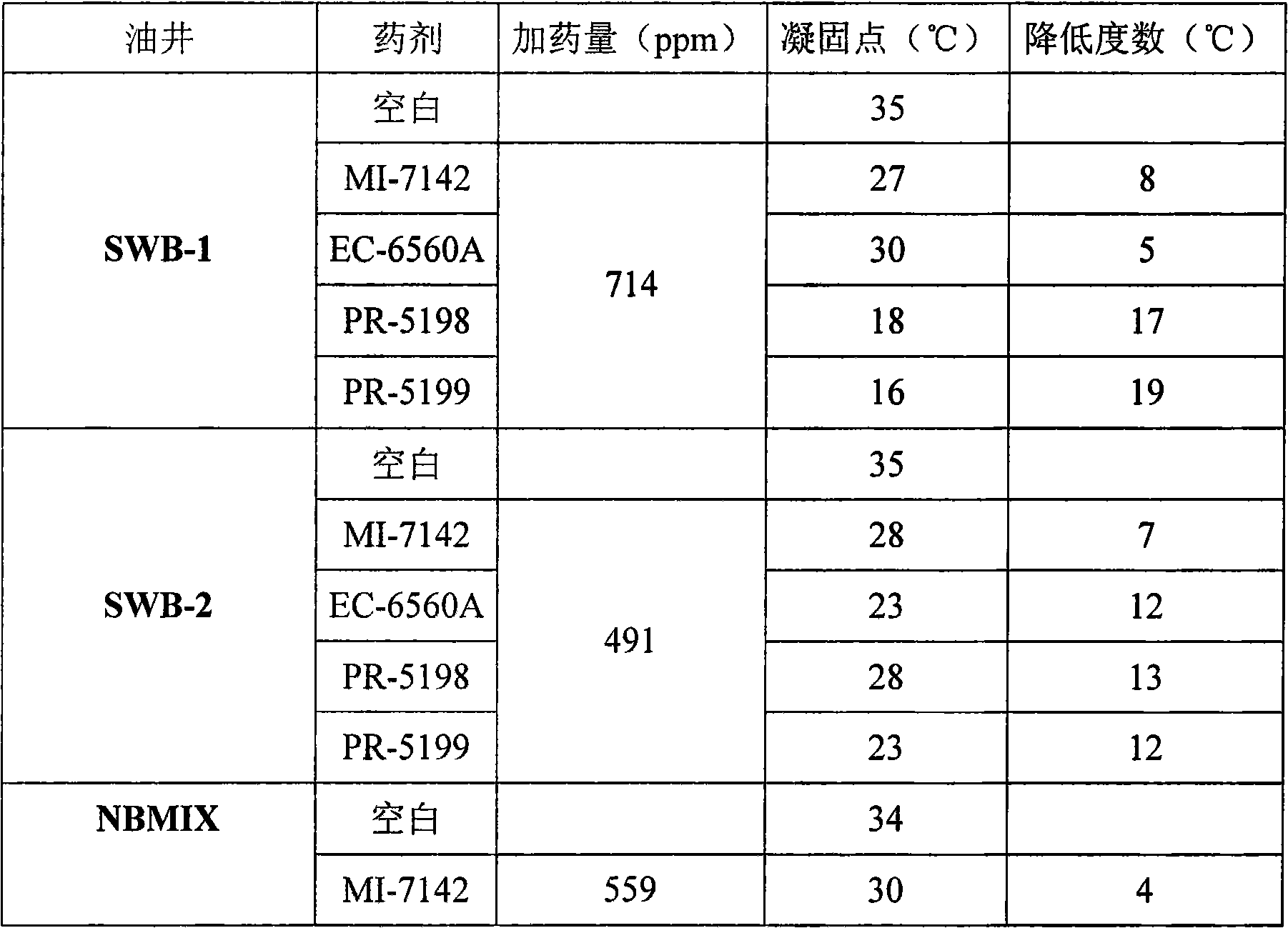

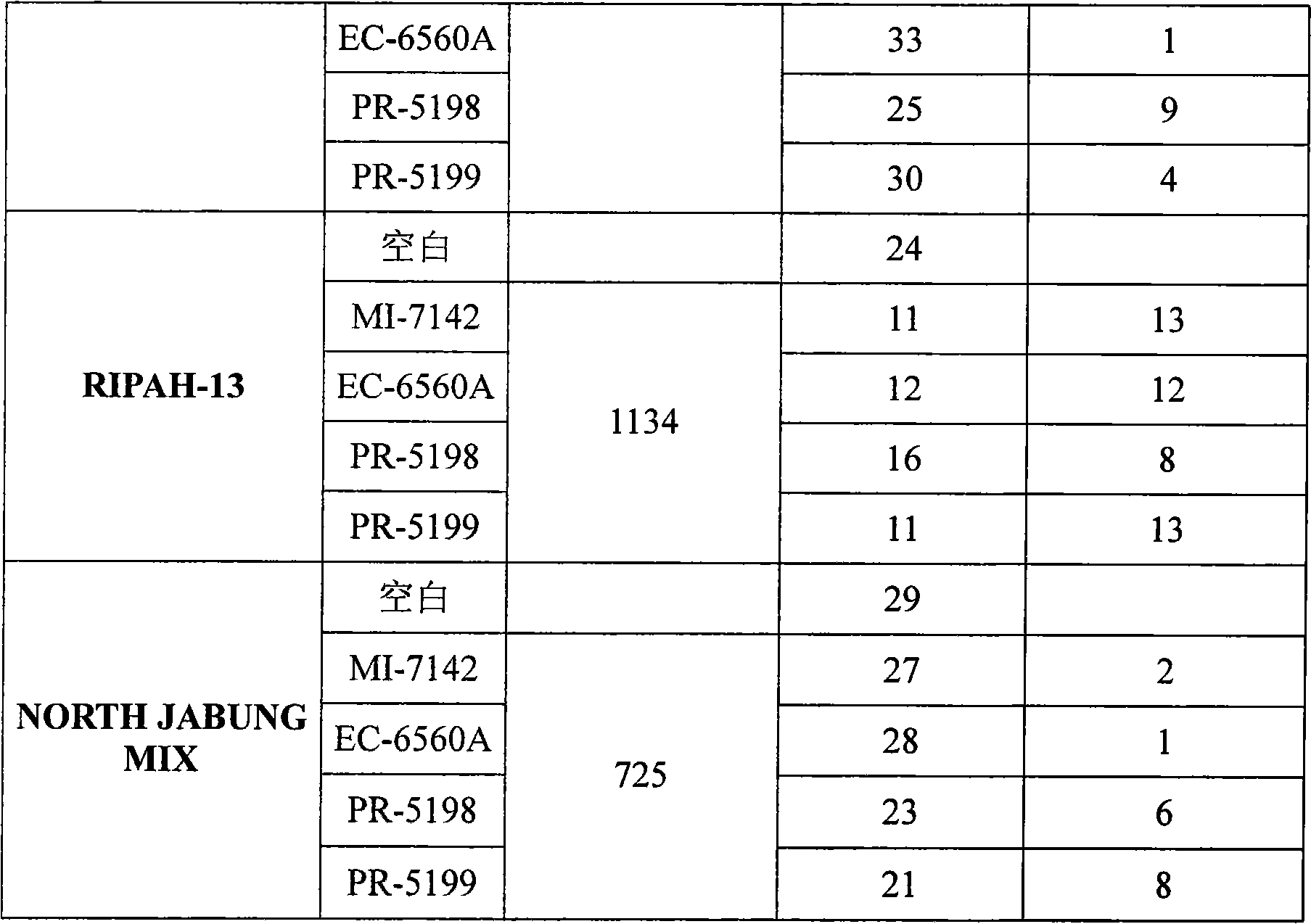

[0050] Example 3 Oil field evaluation test of pour point depressant of the present invention

[0051] As shown in Table 1, the crude oil pour point depressant of the present invention is tested in the Jabung Oilfield in Indonesia, and its application range is wide, and its performance in different oil well tests is better than that of foreign similar products or equivalent to foreign similar products.

[0052] Table 1. Evaluation tests of various crude oil pour point depressants in Jabung Oilfield, Indonesia

[0053]

[0054]

[0055] Note: PR-5198 and PR-5199 are crude oil pour point depressants prepared according to Examples 1 and 2, respectively, and MI-7142 and EC-6560A are control reagents, both of which are crude oil pour point depressants produced abroad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com